How to Evaluate Noise Emissions in V6 Engines

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Noise Evaluation Background and Objectives

Noise evaluation in V6 engines has evolved significantly over the past decades, driven by increasingly stringent regulatory requirements and consumer expectations for quieter, more refined vehicles. The historical development of noise analysis techniques began with simple sound pressure level measurements in the 1960s and has progressed to sophisticated computational models and advanced signal processing methodologies today. This evolution reflects the automotive industry's growing understanding of the complex acoustic phenomena associated with internal combustion engines.

V6 engines present unique noise characteristics due to their specific firing order, crankshaft arrangement, and inherent balance properties. Unlike inline-four or V8 configurations, V6 engines often exhibit distinctive harmonic patterns that require specialized evaluation approaches. The primary noise sources in V6 engines include combustion processes, mechanical components interaction, intake/exhaust systems, and auxiliary systems operation, each contributing to the overall noise signature in different frequency ranges.

Current technological trends in engine noise evaluation are moving toward more holistic approaches that combine traditional experimental methods with advanced simulation techniques. The integration of artificial intelligence and machine learning algorithms has enabled more accurate prediction of noise characteristics during the design phase, reducing the need for costly physical prototypes. Additionally, the industry is witnessing increased focus on psychoacoustic metrics that better correlate with human perception of sound quality rather than mere noise levels.

The objectives of V6 engine noise evaluation are multifaceted. From a regulatory compliance perspective, manufacturers must ensure their engines meet increasingly strict noise emission standards across global markets. From a product differentiation standpoint, creating a distinctive and pleasant sound signature has become a critical competitive advantage, particularly in premium vehicle segments where engine sound contributes significantly to brand identity and perceived quality.

Technical objectives include the identification and mitigation of specific noise sources, optimization of engine design parameters to minimize unwanted noise while preserving desirable acoustic feedback, and development of effective noise control strategies that do not compromise performance, fuel efficiency, or manufacturing costs. Additionally, there is growing emphasis on evaluating noise characteristics across the entire operating range, including transient conditions that better represent real-world driving scenarios.

The emergence of electrification and hybrid powertrains has further complicated noise evaluation objectives, as V6 engines in these applications must function harmoniously with electric motors, creating new challenges in noise, vibration, and harshness (NVH) engineering. This technological shift necessitates innovative approaches to noise evaluation that account for the complex interaction between conventional and electric propulsion systems.

V6 engines present unique noise characteristics due to their specific firing order, crankshaft arrangement, and inherent balance properties. Unlike inline-four or V8 configurations, V6 engines often exhibit distinctive harmonic patterns that require specialized evaluation approaches. The primary noise sources in V6 engines include combustion processes, mechanical components interaction, intake/exhaust systems, and auxiliary systems operation, each contributing to the overall noise signature in different frequency ranges.

Current technological trends in engine noise evaluation are moving toward more holistic approaches that combine traditional experimental methods with advanced simulation techniques. The integration of artificial intelligence and machine learning algorithms has enabled more accurate prediction of noise characteristics during the design phase, reducing the need for costly physical prototypes. Additionally, the industry is witnessing increased focus on psychoacoustic metrics that better correlate with human perception of sound quality rather than mere noise levels.

The objectives of V6 engine noise evaluation are multifaceted. From a regulatory compliance perspective, manufacturers must ensure their engines meet increasingly strict noise emission standards across global markets. From a product differentiation standpoint, creating a distinctive and pleasant sound signature has become a critical competitive advantage, particularly in premium vehicle segments where engine sound contributes significantly to brand identity and perceived quality.

Technical objectives include the identification and mitigation of specific noise sources, optimization of engine design parameters to minimize unwanted noise while preserving desirable acoustic feedback, and development of effective noise control strategies that do not compromise performance, fuel efficiency, or manufacturing costs. Additionally, there is growing emphasis on evaluating noise characteristics across the entire operating range, including transient conditions that better represent real-world driving scenarios.

The emergence of electrification and hybrid powertrains has further complicated noise evaluation objectives, as V6 engines in these applications must function harmoniously with electric motors, creating new challenges in noise, vibration, and harshness (NVH) engineering. This technological shift necessitates innovative approaches to noise evaluation that account for the complex interaction between conventional and electric propulsion systems.

Market Requirements for Engine Noise Control

The automotive market has witnessed a significant shift in consumer preferences regarding engine noise over the past decade. Luxury vehicle buyers increasingly demand a refined driving experience where engine noise is carefully controlled yet maintains a distinctive character that reinforces brand identity. Market research indicates that V6 engine noise perception directly influences purchase decisions, with up to 65% of premium segment customers citing sound quality as a "very important" factor in their vehicle selection process.

Environmental regulations have simultaneously become more stringent worldwide, with the European Union's vehicle noise emission standards reducing permissible limits by 3 decibels in the latest phase implementation. Similarly, regulations in North America and Asia have established increasingly restrictive thresholds for vehicle exterior noise, compelling manufacturers to prioritize noise control technologies in their development processes.

Consumer expectations vary significantly across market segments. In the sports and performance vehicle category, customers seek a powerful, emotionally engaging engine sound profile that communicates performance capabilities. Conversely, in the luxury sedan market, buyers prioritize minimal noise intrusion with selective sound enhancement that conveys refinement and engineering sophistication. The growing electric vehicle market has further complicated requirements, as manufacturers seek to differentiate hybrid V6 powertrains through distinctive sound signatures that contrast with the near-silence of fully electric alternatives.

Market analysis reveals regional variations in noise preference profiles. European consumers typically favor more subdued engine notes with emphasis on refinement, while North American buyers often respond positively to more pronounced sound characteristics that communicate power. Asian markets show increasing preference for technological sophistication in sound management, with particular emphasis on customizable sound profiles.

The aftermarket sector presents additional requirements, with a substantial segment of V6 engine owners seeking enhancement rather than reduction of engine sound. This has created a parallel market for sound enhancement technologies that modify the acoustic character of production engines while remaining within regulatory compliance.

Industry benchmarking studies demonstrate that perceived quality of engine sound correlates strongly with overall brand perception and customer satisfaction metrics. Manufacturers achieving excellence in V6 engine acoustics typically command price premiums of 5-8% compared to competitors with less refined sound management. This translates to significant revenue potential, making strategic investment in noise evaluation and control technologies a competitive necessity rather than a luxury in contemporary automotive development.

Environmental regulations have simultaneously become more stringent worldwide, with the European Union's vehicle noise emission standards reducing permissible limits by 3 decibels in the latest phase implementation. Similarly, regulations in North America and Asia have established increasingly restrictive thresholds for vehicle exterior noise, compelling manufacturers to prioritize noise control technologies in their development processes.

Consumer expectations vary significantly across market segments. In the sports and performance vehicle category, customers seek a powerful, emotionally engaging engine sound profile that communicates performance capabilities. Conversely, in the luxury sedan market, buyers prioritize minimal noise intrusion with selective sound enhancement that conveys refinement and engineering sophistication. The growing electric vehicle market has further complicated requirements, as manufacturers seek to differentiate hybrid V6 powertrains through distinctive sound signatures that contrast with the near-silence of fully electric alternatives.

Market analysis reveals regional variations in noise preference profiles. European consumers typically favor more subdued engine notes with emphasis on refinement, while North American buyers often respond positively to more pronounced sound characteristics that communicate power. Asian markets show increasing preference for technological sophistication in sound management, with particular emphasis on customizable sound profiles.

The aftermarket sector presents additional requirements, with a substantial segment of V6 engine owners seeking enhancement rather than reduction of engine sound. This has created a parallel market for sound enhancement technologies that modify the acoustic character of production engines while remaining within regulatory compliance.

Industry benchmarking studies demonstrate that perceived quality of engine sound correlates strongly with overall brand perception and customer satisfaction metrics. Manufacturers achieving excellence in V6 engine acoustics typically command price premiums of 5-8% compared to competitors with less refined sound management. This translates to significant revenue potential, making strategic investment in noise evaluation and control technologies a competitive necessity rather than a luxury in contemporary automotive development.

Current Noise Measurement Technologies and Challenges

The evaluation of noise emissions in V6 engines currently employs a diverse array of measurement technologies, each with specific applications and limitations. Sound pressure level (SPL) measurements using precision microphones remain the industry standard, typically conducted in semi-anechoic chambers to minimize environmental interference. These measurements capture the overall acoustic signature but may not fully isolate specific noise sources within complex engine architectures.

Advanced acoustic holography and beamforming technologies have emerged as powerful tools for noise source identification. These systems utilize microphone arrays to create spatial maps of sound radiation, enabling engineers to pinpoint specific components contributing to undesirable noise. However, the computational requirements and complex setup procedures limit their application in high-volume production testing environments.

Vibration analysis using accelerometers provides complementary data to acoustic measurements, as many engine noises originate from mechanical vibrations. Modern systems employ triaxial accelerometers at multiple mounting points to capture comprehensive vibration profiles across different operational conditions. The challenge lies in correlating vibration data with perceived acoustic quality, as the relationship is often non-linear and frequency-dependent.

Near-field acoustic measurements have gained prominence for component-level analysis, allowing engineers to evaluate noise contributions from specific engine subsystems such as intake manifolds, fuel injectors, and valve trains. These targeted measurements help in developing focused mitigation strategies but require careful experimental design to account for the complex acoustic environment within an operating engine.

Real-time spectrum analyzers have revolutionized noise measurement by providing instantaneous frequency analysis across the audible spectrum. This capability is particularly valuable for identifying transient noise phenomena that occur during specific operational phases of V6 engines, such as cold starts or rapid acceleration. The challenge remains in establishing meaningful metrics that correlate with subjective human perception of noise quality.

A significant limitation across all measurement technologies is the difficulty in replicating real-world operating conditions in controlled testing environments. Laboratory measurements may not fully capture the acoustic behavior of engines under variable load conditions, thermal cycles, or after extended operation. Additionally, the integration of noise data from multiple measurement systems presents challenges in data fusion and interpretation.

Emerging technologies such as acoustic cameras and artificial intelligence-based noise analysis systems show promise for more comprehensive evaluation but face challenges in standardization and validation against established methods. The industry continues to seek more efficient, accurate, and repeatable measurement protocols that can keep pace with increasingly stringent noise regulations and consumer expectations.

Advanced acoustic holography and beamforming technologies have emerged as powerful tools for noise source identification. These systems utilize microphone arrays to create spatial maps of sound radiation, enabling engineers to pinpoint specific components contributing to undesirable noise. However, the computational requirements and complex setup procedures limit their application in high-volume production testing environments.

Vibration analysis using accelerometers provides complementary data to acoustic measurements, as many engine noises originate from mechanical vibrations. Modern systems employ triaxial accelerometers at multiple mounting points to capture comprehensive vibration profiles across different operational conditions. The challenge lies in correlating vibration data with perceived acoustic quality, as the relationship is often non-linear and frequency-dependent.

Near-field acoustic measurements have gained prominence for component-level analysis, allowing engineers to evaluate noise contributions from specific engine subsystems such as intake manifolds, fuel injectors, and valve trains. These targeted measurements help in developing focused mitigation strategies but require careful experimental design to account for the complex acoustic environment within an operating engine.

Real-time spectrum analyzers have revolutionized noise measurement by providing instantaneous frequency analysis across the audible spectrum. This capability is particularly valuable for identifying transient noise phenomena that occur during specific operational phases of V6 engines, such as cold starts or rapid acceleration. The challenge remains in establishing meaningful metrics that correlate with subjective human perception of noise quality.

A significant limitation across all measurement technologies is the difficulty in replicating real-world operating conditions in controlled testing environments. Laboratory measurements may not fully capture the acoustic behavior of engines under variable load conditions, thermal cycles, or after extended operation. Additionally, the integration of noise data from multiple measurement systems presents challenges in data fusion and interpretation.

Emerging technologies such as acoustic cameras and artificial intelligence-based noise analysis systems show promise for more comprehensive evaluation but face challenges in standardization and validation against established methods. The industry continues to seek more efficient, accurate, and repeatable measurement protocols that can keep pace with increasingly stringent noise regulations and consumer expectations.

Contemporary V6 Engine Noise Assessment Techniques

01 Exhaust system modifications for noise reduction

Various modifications to the exhaust system can significantly reduce noise emissions in V6 engines. These include specialized mufflers, resonators, and acoustic chambers that are designed to cancel or dampen sound waves generated during combustion. The exhaust path can be engineered with specific geometries and materials to absorb vibrations and reduce noise transmission. These modifications help meet increasingly stringent noise emission regulations while maintaining engine performance.- Exhaust system modifications for noise reduction: Various modifications to the exhaust system can significantly reduce noise emissions from V6 engines. These include specialized mufflers, resonators, and catalytic converters designed to dampen sound waves generated during combustion. Advanced exhaust system designs incorporate acoustic chambers and flow-optimized pathways that help attenuate noise while maintaining engine performance and efficiency.

- Engine block and component design for noise attenuation: The structural design of V6 engine blocks and internal components plays a crucial role in noise reduction. This includes optimized cylinder arrangements, reinforced engine blocks with sound-dampening materials, and precision-engineered moving parts that minimize mechanical vibration. Special attention to bearing design, piston clearances, and balancing mechanisms helps reduce operational noise at its source.

- Active noise control systems: Modern V6 engines employ active noise control technologies to counteract unwanted sound emissions. These systems use microphones to detect engine noise patterns and generate anti-phase sound waves through speakers to cancel out specific frequencies. Some advanced systems integrate with the vehicle's audio system and can be tuned to either eliminate undesirable noise or enhance desirable engine sounds for driver feedback.

- Intake system design for noise reduction: The intake system design significantly impacts V6 engine noise emissions. Innovations include resonator chambers, variable geometry intake manifolds, and acoustic filters that reduce induction noise. Advanced air intake designs incorporate sound-absorbing materials and flow-optimized pathways to minimize turbulence and associated noise while maintaining optimal airflow for engine performance.

- Vibration isolation and damping technologies: Vibration isolation systems are critical for reducing noise transmission from V6 engines to the vehicle structure. These include advanced engine mounts with variable stiffness properties, hydraulic damping elements, and active control systems that adjust damping characteristics based on engine operating conditions. Strategic placement of sound-absorbing materials and isolation barriers prevents vibration-induced noise from propagating through the vehicle body.

02 Engine block and component design for noise reduction

The design of the engine block and internal components plays a crucial role in reducing noise emissions from V6 engines. This includes optimizing the stiffness of the engine block, using sound-dampening materials, and implementing vibration isolation techniques. Specific design features such as reinforced cylinder walls, modified crankshaft configurations, and balanced rotating assemblies help minimize vibrations that contribute to noise. Advanced manufacturing techniques and materials can also be employed to reduce structural resonance.Expand Specific Solutions03 Electronic control systems for noise management

Electronic control systems can be implemented to actively manage and reduce noise emissions from V6 engines. These systems include active noise cancellation, variable valve timing adjustments, and precise fuel injection control to optimize combustion patterns. Sensors monitor engine operation in real-time, allowing the control system to make adjustments that minimize noise-producing conditions. Some systems can also modify the engine's operating parameters based on driving conditions to maintain an optimal balance between performance and noise reduction.Expand Specific Solutions04 Intake system design for noise attenuation

The intake system design significantly impacts noise emissions from V6 engines. Specialized air intake geometries, resonators, and acoustic chambers can be incorporated to reduce intake noise. Airflow management techniques, including optimized runner lengths and plenum designs, help minimize turbulence and associated noise. Advanced filtration systems can also be designed to reduce noise while maintaining adequate airflow for engine performance. These intake modifications work in conjunction with other noise reduction strategies to create a comprehensive approach to engine acoustics.Expand Specific Solutions05 Vibration isolation and damping technologies

Vibration isolation and damping technologies are essential for reducing noise emissions from V6 engines. These include specialized engine mounts that incorporate hydraulic or elastomeric elements to absorb vibrations before they can be transmitted to the vehicle structure. Additional damping materials can be strategically placed throughout the engine compartment to absorb sound waves. Advanced composite materials with superior vibration-damping properties can be used for engine covers and shields. These technologies collectively minimize the transmission of engine-generated vibrations that would otherwise manifest as noise.Expand Specific Solutions

Leading Companies in Engine Acoustics Engineering

The V6 engine noise emissions evaluation landscape is currently in a mature phase, with established methodologies and technologies developed by major automotive manufacturers. The market for noise reduction solutions is expanding due to increasing consumer demand for quieter vehicles and stricter regulatory requirements. Ford, Toyota, and Hyundai lead technological innovation in this space, with significant contributions from AVL List and Robert Bosch in testing equipment. Mercedes-Benz and GM Global Technology have made notable advancements in computational modeling for noise prediction. Chinese manufacturers like Changan and Great Wall Motor are rapidly closing the technology gap through strategic partnerships and increased R&D investment, while specialized companies such as MANN+HUMMEL focus on component-level solutions for noise attenuation.

Ford Motor Co.

Technical Solution: Ford has developed a comprehensive V6 Engine Noise Evaluation Protocol (VENEP) that combines traditional testing methods with advanced digital technologies. Their approach utilizes a multi-faceted methodology incorporating both objective measurements and subjective assessments. Ford's system employs an array of precision microphones positioned at standardized locations around the engine to capture the acoustic signature from multiple angles. These measurements are supplemented with accelerometers mounted directly on the engine block and components to correlate vibration patterns with noise emissions. Ford has pioneered the use of binaural recording technology that simulates human hearing, allowing engineers to evaluate noise as it would be perceived by vehicle occupants. Their methodology includes specialized testing procedures for different operating conditions, including cold start, idle, acceleration, and high-speed operation - conditions where V6 engines exhibit distinctive noise characteristics. Ford has also developed proprietary software tools that can identify specific noise sources within the V6 architecture, such as timing chain noise, bearing noise, and combustion irregularities. Their approach integrates noise evaluation into the broader NVH development process, with feedback loops that inform design modifications to address noise issues at their source.

Strengths: Comprehensive testing methodology covering all operating conditions; integration of objective measurements with subjective human perception; strong connection between testing results and design modifications. Weaknesses: System requires extensive testing facilities and equipment; methodology has evolved primarily for Ford's specific V6 designs and may require adaptation for other configurations.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered an innovative approach to V6 engine noise evaluation through their Advanced Engine Noise Analysis System (AENAS). This technology combines physical testing with computational modeling to create a comprehensive noise profile of their V6 engines. Toyota's methodology involves strategic placement of accelerometers and microphones at critical points on the engine block, intake, and exhaust systems to capture vibration and acoustic data across the full operating range. Their system incorporates real-time spectral analysis to identify frequency components that contribute most significantly to perceived noise. Toyota has developed proprietary algorithms that can separate and quantify different noise sources including combustion noise, mechanical noise, and intake/exhaust noise. A key innovation in their approach is the use of psychoacoustic metrics that correlate measured noise with human perception, allowing engineers to focus on the most objectionable noise characteristics. Toyota also employs a transfer path analysis technique to understand how engine noise propagates through vehicle structures to reach occupants, enabling targeted countermeasures for noise reduction.

Strengths: Holistic approach that considers both objective measurements and subjective human perception; extensive experience with various V6 configurations; strong integration with overall vehicle development process. Weaknesses: Some proprietary technologies not available to other manufacturers; approach heavily tailored to Toyota's specific engine designs and may not be universally applicable.

Key Patents and Research in Engine Noise Reduction

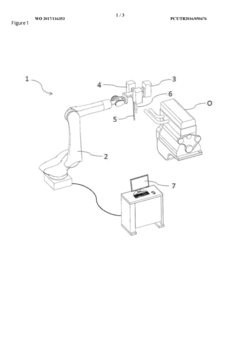

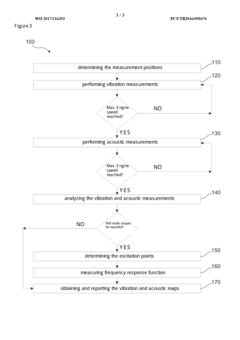

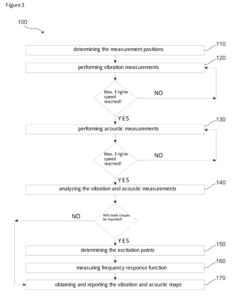

Vibration and noise mapping system and method

PatentWO2017116353A1

Innovation

- A vibration and noise mapping system utilizing a mobile robotic arm with vibration and acoustic measurement units, contactless acoustic excitation, and geometric scanning to perform automatic tri-directional measurements, generate vectorial maps, and determine optimal excitation points for improved performance.

Vibration and noise mapping system and method

PatentActiveUS20190025159A1

Innovation

- A vibration and noise mapping system utilizing a mobile robotic arm with vibration and acoustic measurement units, contactless acoustic excitation, and geometric scanning to perform automatic, tri-directional measurements, generating maps with vectorial orientations and enabling quick identification of areas for improvement.

Regulatory Standards for Vehicle Noise Emissions

The regulatory landscape for vehicle noise emissions has evolved significantly over the past decades, with increasingly stringent standards being implemented worldwide. For V6 engines specifically, these regulations play a crucial role in design, manufacturing, and testing processes. The European Union's Regulation No. 540/2014 represents one of the most comprehensive frameworks, establishing progressive noise limits that have been phased in since 2016. This regulation mandates that passenger vehicles must not exceed 72 dB(A) during standardized pass-by noise tests, with further reductions planned in coming years.

In the United States, the Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) jointly regulate vehicle noise emissions under the Noise Control Act. Current standards limit passenger vehicles to 80 dB(A) at speeds above 35 mph. California maintains even stricter requirements through the California Vehicle Code Section 27200, which particularly impacts V6 engine designs for vehicles sold in this significant market.

International Organization for Standardization (ISO) standards provide the methodological foundation for noise emission testing. ISO 362 specifies the measurement procedures for vehicle pass-by noise, while ISO 5130 details stationary noise measurement protocols. These standards ensure consistency in testing methodologies across different regulatory jurisdictions, facilitating global compliance for V6 engine manufacturers.

Japan and China have also implemented rigorous noise emission standards through their respective regulatory bodies. Japan's Ministry of Land, Infrastructure, Transport and Tourism enforces standards comparable to European regulations, while China's GB 1495-2002 standard has been progressively tightened with the latest update requiring passenger vehicles to meet a 72 dB(A) limit.

Testing protocols for regulatory compliance typically involve controlled acceleration tests on specified surfaces, with microphones positioned at standardized distances. For V6 engines specifically, the unique firing order and exhaust configuration require particular attention during these tests. Manufacturers must document test conditions including ambient temperature, wind speed, and background noise levels to ensure valid measurements.

Penalties for non-compliance vary by jurisdiction but can include substantial fines, sales restrictions, and mandatory recalls. The European Union can impose penalties up to €30,000 per non-compliant vehicle, while the US system allows for civil penalties reaching $37,500 per violation. These financial implications make regulatory compliance a critical consideration in V6 engine development and validation processes.

In the United States, the Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) jointly regulate vehicle noise emissions under the Noise Control Act. Current standards limit passenger vehicles to 80 dB(A) at speeds above 35 mph. California maintains even stricter requirements through the California Vehicle Code Section 27200, which particularly impacts V6 engine designs for vehicles sold in this significant market.

International Organization for Standardization (ISO) standards provide the methodological foundation for noise emission testing. ISO 362 specifies the measurement procedures for vehicle pass-by noise, while ISO 5130 details stationary noise measurement protocols. These standards ensure consistency in testing methodologies across different regulatory jurisdictions, facilitating global compliance for V6 engine manufacturers.

Japan and China have also implemented rigorous noise emission standards through their respective regulatory bodies. Japan's Ministry of Land, Infrastructure, Transport and Tourism enforces standards comparable to European regulations, while China's GB 1495-2002 standard has been progressively tightened with the latest update requiring passenger vehicles to meet a 72 dB(A) limit.

Testing protocols for regulatory compliance typically involve controlled acceleration tests on specified surfaces, with microphones positioned at standardized distances. For V6 engines specifically, the unique firing order and exhaust configuration require particular attention during these tests. Manufacturers must document test conditions including ambient temperature, wind speed, and background noise levels to ensure valid measurements.

Penalties for non-compliance vary by jurisdiction but can include substantial fines, sales restrictions, and mandatory recalls. The European Union can impose penalties up to €30,000 per non-compliant vehicle, while the US system allows for civil penalties reaching $37,500 per violation. These financial implications make regulatory compliance a critical consideration in V6 engine development and validation processes.

NVH Benchmarking Methodologies

NVH Benchmarking Methodologies for evaluating noise emissions in V6 engines require systematic approaches that combine both objective measurements and subjective assessments. The industry has established several standardized protocols that ensure consistency and comparability across different engine designs and manufacturers.

The primary methodology involves controlled environment testing, where V6 engines are mounted on specialized test benches equipped with precision microphones positioned at strategic locations. These setups typically follow ISO 3745 standards for anechoic and semi-anechoic chambers, ensuring that measurements are not contaminated by external noise sources. Multiple microphone arrays are deployed to capture the three-dimensional sound field, with particular attention to driver position equivalents.

Frequency domain analysis forms the cornerstone of objective evaluation, with Fast Fourier Transform (FFT) techniques converting time-domain signals into frequency spectra. This allows engineers to identify specific frequency components that contribute to overall noise emissions. For V6 engines specifically, attention is paid to the characteristic firing order frequencies and their harmonics, which typically occur at multiples of one-third engine rotational frequency due to the V6 configuration.

Statistical energy analysis (SEA) has emerged as a valuable benchmarking tool, particularly for high-frequency noise paths that are difficult to model using finite element methods. This approach divides the engine and surrounding structures into subsystems and analyzes energy flow between them, helping identify critical noise transmission paths specific to V6 architecture.

Operational deflection shape (ODS) analysis complements these methods by visualizing how engine components vibrate during operation. Using laser vibrometry or accelerometer arrays, engineers can map surface vibrations at different RPM ranges, correlating structural behavior with acoustic emissions. This proves particularly valuable for identifying issues related to the inherent balance characteristics of V6 engines.

Psychoacoustic metrics have gained prominence in benchmarking methodologies, recognizing that human perception of noise differs from pure sound pressure level measurements. Metrics such as loudness, sharpness, roughness, and tonality provide insights into how engine noise is subjectively experienced. For V6 engines, the evaluation of sound quality often focuses on the distinctive "character" that results from their firing sequence and inherent second-order forces.

Comparative benchmarking against competitor engines represents the final critical methodology, establishing relative performance within the market. This involves back-to-back testing under identical conditions, with both objective measurements and jury evaluations by trained listeners who assess subjective qualities like refinement, sportiness, and overall impression.

The primary methodology involves controlled environment testing, where V6 engines are mounted on specialized test benches equipped with precision microphones positioned at strategic locations. These setups typically follow ISO 3745 standards for anechoic and semi-anechoic chambers, ensuring that measurements are not contaminated by external noise sources. Multiple microphone arrays are deployed to capture the three-dimensional sound field, with particular attention to driver position equivalents.

Frequency domain analysis forms the cornerstone of objective evaluation, with Fast Fourier Transform (FFT) techniques converting time-domain signals into frequency spectra. This allows engineers to identify specific frequency components that contribute to overall noise emissions. For V6 engines specifically, attention is paid to the characteristic firing order frequencies and their harmonics, which typically occur at multiples of one-third engine rotational frequency due to the V6 configuration.

Statistical energy analysis (SEA) has emerged as a valuable benchmarking tool, particularly for high-frequency noise paths that are difficult to model using finite element methods. This approach divides the engine and surrounding structures into subsystems and analyzes energy flow between them, helping identify critical noise transmission paths specific to V6 architecture.

Operational deflection shape (ODS) analysis complements these methods by visualizing how engine components vibrate during operation. Using laser vibrometry or accelerometer arrays, engineers can map surface vibrations at different RPM ranges, correlating structural behavior with acoustic emissions. This proves particularly valuable for identifying issues related to the inherent balance characteristics of V6 engines.

Psychoacoustic metrics have gained prominence in benchmarking methodologies, recognizing that human perception of noise differs from pure sound pressure level measurements. Metrics such as loudness, sharpness, roughness, and tonality provide insights into how engine noise is subjectively experienced. For V6 engines, the evaluation of sound quality often focuses on the distinctive "character" that results from their firing sequence and inherent second-order forces.

Comparative benchmarking against competitor engines represents the final critical methodology, establishing relative performance within the market. This involves back-to-back testing under identical conditions, with both objective measurements and jury evaluations by trained listeners who assess subjective qualities like refinement, sportiness, and overall impression.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!