How to Conduct V6 Engine Wear Analysis Accurately

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Wear Analysis Background and Objectives

Engine wear analysis has evolved significantly over the past decades, transitioning from basic visual inspections to sophisticated analytical methodologies. The V6 engine, a compact and efficient powerplant widely used in modern vehicles, presents unique wear characteristics due to its specific configuration and operational dynamics. Understanding these wear patterns is crucial for enhancing engine longevity, optimizing maintenance schedules, and improving future engine designs.

The historical development of engine wear analysis techniques began with rudimentary methods in the early automotive era, progressing through mechanical measurements in the mid-20th century, to today's advanced spectroscopic and computational approaches. This evolution has been driven by increasing demands for engine efficiency, durability, and environmental compliance, particularly as V6 engines have become more prevalent in both passenger and commercial vehicle applications.

Current technological trends in V6 engine wear analysis include the integration of real-time monitoring systems, machine learning algorithms for predictive maintenance, and non-destructive testing methodologies. These advancements allow for more precise identification of wear mechanisms, including cylinder wall scoring, bearing degradation, valve train wear, and timing chain elongation—all critical areas in V6 engine performance.

The primary objective of accurate V6 engine wear analysis is to establish reliable methodologies for quantifying wear rates under various operating conditions. This includes developing standardized protocols for data collection, establishing meaningful wear indicators, and creating reference databases for comparative analysis. Such standardization is essential for meaningful cross-platform comparisons and industry-wide improvements.

Secondary objectives include correlating wear patterns with specific operational parameters, identifying early indicators of potential catastrophic failures, and developing cost-effective monitoring solutions suitable for implementation across diverse vehicle fleets. These goals support both immediate maintenance optimization and long-term engine design enhancements.

The technical challenges in this field encompass the need for non-invasive measurement techniques, accurate differentiation between normal and abnormal wear, and the development of wear models that account for the complex interactions between engine components. Additionally, there is growing interest in understanding how modern fuels, lubricants, and emission control systems impact traditional wear mechanisms in V6 configurations.

As environmental regulations become increasingly stringent, another emerging objective is to understand how wear analysis can contribute to reduced emissions and improved fuel efficiency through optimized engine operation and maintenance. This represents a significant shift from traditional reliability-focused approaches to a more holistic view of engine performance and environmental impact.

The historical development of engine wear analysis techniques began with rudimentary methods in the early automotive era, progressing through mechanical measurements in the mid-20th century, to today's advanced spectroscopic and computational approaches. This evolution has been driven by increasing demands for engine efficiency, durability, and environmental compliance, particularly as V6 engines have become more prevalent in both passenger and commercial vehicle applications.

Current technological trends in V6 engine wear analysis include the integration of real-time monitoring systems, machine learning algorithms for predictive maintenance, and non-destructive testing methodologies. These advancements allow for more precise identification of wear mechanisms, including cylinder wall scoring, bearing degradation, valve train wear, and timing chain elongation—all critical areas in V6 engine performance.

The primary objective of accurate V6 engine wear analysis is to establish reliable methodologies for quantifying wear rates under various operating conditions. This includes developing standardized protocols for data collection, establishing meaningful wear indicators, and creating reference databases for comparative analysis. Such standardization is essential for meaningful cross-platform comparisons and industry-wide improvements.

Secondary objectives include correlating wear patterns with specific operational parameters, identifying early indicators of potential catastrophic failures, and developing cost-effective monitoring solutions suitable for implementation across diverse vehicle fleets. These goals support both immediate maintenance optimization and long-term engine design enhancements.

The technical challenges in this field encompass the need for non-invasive measurement techniques, accurate differentiation between normal and abnormal wear, and the development of wear models that account for the complex interactions between engine components. Additionally, there is growing interest in understanding how modern fuels, lubricants, and emission control systems impact traditional wear mechanisms in V6 configurations.

As environmental regulations become increasingly stringent, another emerging objective is to understand how wear analysis can contribute to reduced emissions and improved fuel efficiency through optimized engine operation and maintenance. This represents a significant shift from traditional reliability-focused approaches to a more holistic view of engine performance and environmental impact.

Market Demand for Precision Engine Diagnostics

The global market for precision engine diagnostics has witnessed substantial growth over the past decade, driven primarily by increasing complexity in engine designs and stricter emission regulations. The V6 engine segment, in particular, represents a significant portion of this market due to its widespread adoption in mid-size to luxury vehicles across multiple automotive manufacturers. Industry reports indicate that the engine diagnostics market is expected to grow at a compound annual growth rate of 5.7% through 2028, with wear analysis tools and technologies constituting approximately one-third of this expanding sector.

Vehicle manufacturers and fleet operators are increasingly demanding more accurate wear analysis solutions for V6 engines to extend engine life, optimize maintenance schedules, and reduce warranty costs. This demand stems from the high replacement costs associated with V6 engines, which can range from $3,000 to $10,000 depending on the vehicle model and manufacturer. Precision diagnostics that can accurately predict wear patterns before catastrophic failure occurs represent significant cost-saving opportunities for both manufacturers and end-users.

The aftermarket service sector has emerged as a particularly strong driver for advanced V6 engine wear analysis tools. Independent repair facilities and service chains are seeking diagnostic technologies that can provide competitive advantages through more precise maintenance recommendations. This trend is reinforced by consumer expectations for transparency in vehicle maintenance and repair processes, with customers increasingly requesting evidence-based service recommendations rather than time-based maintenance schedules.

Environmental regulations worldwide have created additional market pressure for precision diagnostics. As emission standards become more stringent, the ability to detect subtle changes in engine performance that might affect emissions becomes increasingly valuable. Early detection of wear patterns that could lead to increased emissions helps manufacturers maintain compliance and avoid potential regulatory penalties.

The commercial vehicle segment presents another substantial market opportunity for V6 engine wear analysis technologies. Fleet operators managing medium-duty trucks, delivery vehicles, and service fleets equipped with V6 engines are increasingly adopting predictive maintenance approaches to maximize vehicle uptime and optimize total cost of ownership. These operators typically calculate that a 10% improvement in maintenance efficiency translates to operational savings of thousands of dollars per vehicle annually.

Insurance companies have also begun influencing market demand by offering premium reductions for fleet operators who implement advanced diagnostic protocols. This emerging trend creates additional financial incentives for the adoption of precision wear analysis technologies beyond the direct operational benefits they provide.

Vehicle manufacturers and fleet operators are increasingly demanding more accurate wear analysis solutions for V6 engines to extend engine life, optimize maintenance schedules, and reduce warranty costs. This demand stems from the high replacement costs associated with V6 engines, which can range from $3,000 to $10,000 depending on the vehicle model and manufacturer. Precision diagnostics that can accurately predict wear patterns before catastrophic failure occurs represent significant cost-saving opportunities for both manufacturers and end-users.

The aftermarket service sector has emerged as a particularly strong driver for advanced V6 engine wear analysis tools. Independent repair facilities and service chains are seeking diagnostic technologies that can provide competitive advantages through more precise maintenance recommendations. This trend is reinforced by consumer expectations for transparency in vehicle maintenance and repair processes, with customers increasingly requesting evidence-based service recommendations rather than time-based maintenance schedules.

Environmental regulations worldwide have created additional market pressure for precision diagnostics. As emission standards become more stringent, the ability to detect subtle changes in engine performance that might affect emissions becomes increasingly valuable. Early detection of wear patterns that could lead to increased emissions helps manufacturers maintain compliance and avoid potential regulatory penalties.

The commercial vehicle segment presents another substantial market opportunity for V6 engine wear analysis technologies. Fleet operators managing medium-duty trucks, delivery vehicles, and service fleets equipped with V6 engines are increasingly adopting predictive maintenance approaches to maximize vehicle uptime and optimize total cost of ownership. These operators typically calculate that a 10% improvement in maintenance efficiency translates to operational savings of thousands of dollars per vehicle annually.

Insurance companies have also begun influencing market demand by offering premium reductions for fleet operators who implement advanced diagnostic protocols. This emerging trend creates additional financial incentives for the adoption of precision wear analysis technologies beyond the direct operational benefits they provide.

Current Challenges in V6 Engine Wear Detection

Despite significant advancements in engine diagnostics, V6 engine wear detection continues to present substantial technical challenges that impede accurate analysis. Traditional methods often rely on simplistic indicators such as oil analysis and vibration monitoring, which fail to capture the complex wear patterns unique to V6 configurations. The angular arrangement of cylinders in V6 engines creates asymmetrical forces that conventional wear detection systems struggle to properly interpret, leading to potential misdiagnosis or missed early warning signs.

One critical challenge is the differentiation between normal operational wear and abnormal degradation patterns. V6 engines experience varying thermal gradients across their cylinder banks, resulting in uneven expansion and contraction cycles that complicate wear signature identification. Current sensor technologies lack sufficient resolution to distinguish these subtle variations, particularly at the microscopic level where initial wear indicators first manifest.

Data integration presents another significant obstacle. Modern V6 engines generate vast amounts of operational data from multiple subsystems, but existing analytical frameworks struggle to correlate this information meaningfully. The interdependencies between combustion efficiency, lubrication performance, and mechanical wear create complex causal relationships that current algorithms cannot fully model, resulting in fragmented analysis and potentially misleading conclusions.

The time-dependent nature of wear progression further complicates detection efforts. V6 engines exhibit non-linear wear patterns that evolve differently based on driving conditions, maintenance history, and manufacturing variations. Current diagnostic approaches typically employ static thresholds that fail to account for this dynamic progression, leading to either premature maintenance interventions or delayed response to critical wear conditions.

Material science limitations also hinder accurate wear detection. The interaction between modern alloys, advanced coatings, and contemporary lubricants creates wear mechanisms that traditional detection methods were not designed to identify. Microscopic surface changes that precede catastrophic failure often remain undetected until significant damage has occurred, particularly at critical interfaces such as valve seats, camshaft lobes, and bearing surfaces.

Calibration inconsistencies across different engine variants further complicate standardized wear analysis. Manufacturing tolerances, assembly variations, and aftermarket modifications create a diverse population of V6 engines that respond differently to identical operating conditions. Current diagnostic systems lack the adaptability to normalize these variations, resulting in unreliable comparative analysis between similar engine models.

One critical challenge is the differentiation between normal operational wear and abnormal degradation patterns. V6 engines experience varying thermal gradients across their cylinder banks, resulting in uneven expansion and contraction cycles that complicate wear signature identification. Current sensor technologies lack sufficient resolution to distinguish these subtle variations, particularly at the microscopic level where initial wear indicators first manifest.

Data integration presents another significant obstacle. Modern V6 engines generate vast amounts of operational data from multiple subsystems, but existing analytical frameworks struggle to correlate this information meaningfully. The interdependencies between combustion efficiency, lubrication performance, and mechanical wear create complex causal relationships that current algorithms cannot fully model, resulting in fragmented analysis and potentially misleading conclusions.

The time-dependent nature of wear progression further complicates detection efforts. V6 engines exhibit non-linear wear patterns that evolve differently based on driving conditions, maintenance history, and manufacturing variations. Current diagnostic approaches typically employ static thresholds that fail to account for this dynamic progression, leading to either premature maintenance interventions or delayed response to critical wear conditions.

Material science limitations also hinder accurate wear detection. The interaction between modern alloys, advanced coatings, and contemporary lubricants creates wear mechanisms that traditional detection methods were not designed to identify. Microscopic surface changes that precede catastrophic failure often remain undetected until significant damage has occurred, particularly at critical interfaces such as valve seats, camshaft lobes, and bearing surfaces.

Calibration inconsistencies across different engine variants further complicate standardized wear analysis. Manufacturing tolerances, assembly variations, and aftermarket modifications create a diverse population of V6 engines that respond differently to identical operating conditions. Current diagnostic systems lack the adaptability to normalize these variations, resulting in unreliable comparative analysis between similar engine models.

Contemporary V6 Engine Wear Analysis Solutions

01 Lubrication systems for V6 engines

Specialized lubrication systems designed specifically for V6 engines can significantly reduce wear. These systems ensure proper oil distribution to critical engine components, particularly at high temperatures and under heavy loads. Advanced oil circulation methods and optimized oil passages help maintain adequate lubrication to cylinder walls, bearings, and valve trains, extending engine life and reducing friction-related wear.- Lubrication systems for V6 engines: Specialized lubrication systems designed specifically for V6 engines can significantly reduce wear. These systems ensure proper oil distribution to critical engine components, particularly at high temperatures and under heavy loads. Advanced oil circulation methods and strategic placement of oil channels help maintain adequate lubrication to cylinder walls, pistons, and valve trains, thereby extending engine life and reducing friction-related wear.

- Wear-resistant coatings and materials: The application of wear-resistant coatings and materials on V6 engine components can significantly reduce wear rates. These include ceramic coatings, diamond-like carbon films, and specialized metal alloys that provide superior hardness and reduced friction. Such coatings are particularly effective for high-stress components like cylinder liners, piston rings, and valve train components, resulting in extended service life and improved engine performance.

- Monitoring and diagnostic systems: Advanced monitoring and diagnostic systems can detect early signs of V6 engine wear before catastrophic failure occurs. These systems utilize sensors to monitor oil quality, temperature, pressure, and particulate content, providing real-time data on engine condition. Early detection of abnormal wear patterns allows for timely maintenance interventions, preventing accelerated component degradation and extending overall engine lifespan.

- Improved V6 engine design and component geometry: Optimized design and geometry of V6 engine components can significantly reduce wear. This includes refined piston ring designs that minimize blow-by and oil consumption, improved bearing surfaces that distribute loads more evenly, and enhanced cylinder head configurations that optimize combustion and reduce thermal stress. These design improvements address inherent wear points in V6 engines, particularly at the interface between moving components.

- Specialized additives and lubricant formulations: Specialized additives and lubricant formulations developed specifically for V6 engines can significantly reduce wear. These formulations contain anti-wear agents, friction modifiers, detergents, and dispersants tailored to the operating conditions of V6 engines. The additives form protective films on metal surfaces, neutralize acidic combustion byproducts, and keep contaminants in suspension, preventing abrasive wear and corrosion of engine components.

02 Wear-resistant coatings and materials

The application of wear-resistant coatings and materials on V6 engine components can significantly reduce wear rates. These include specialized surface treatments, ceramic coatings, and advanced metal alloys that provide superior hardness and reduced friction. Such materials are particularly effective for high-stress components like cylinder liners, piston rings, and valve train components, resulting in extended service life and improved engine performance.Expand Specific Solutions03 Monitoring and diagnostic systems

Advanced monitoring and diagnostic systems can detect early signs of V6 engine wear before catastrophic failure occurs. These systems utilize sensors to monitor oil quality, temperature, pressure, and particulate content, providing real-time data on engine condition. Early detection of abnormal wear patterns allows for timely maintenance interventions, preventing accelerated component degradation and extending overall engine lifespan.Expand Specific Solutions04 Structural improvements to reduce wear

Structural design improvements in V6 engines can significantly reduce wear by optimizing load distribution and minimizing stress concentrations. These include redesigned cylinder blocks, improved bearing supports, reinforced crankshafts, and optimized cooling passages. Such structural enhancements address inherent wear points in V6 configurations, particularly at the interface between moving components, resulting in more durable engines with extended service intervals.Expand Specific Solutions05 Specialized additives and lubricants

Specialized additives and lubricants formulated specifically for V6 engines can significantly reduce wear rates. These formulations contain friction modifiers, anti-wear compounds, detergents, and dispersants tailored to the operating conditions of V6 engines. Advanced synthetic oils with improved thermal stability and film strength provide superior protection at high temperatures and under heavy loads, extending component life and maintaining engine performance over time.Expand Specific Solutions

Leading Players in Engine Diagnostics Technology

V6 engine wear analysis is currently in a mature development phase within the automotive and industrial sectors, with a growing market estimated at $2.5 billion annually. The competitive landscape features established players like Robert Bosch GmbH, Caterpillar, and Weichai Power leading with comprehensive diagnostic solutions, while automotive manufacturers such as Mercedes-Benz, BMW, and Volkswagen contribute significant R&D. Technology maturity varies across competitors, with Bosch, Honeywell, and Schaeffler demonstrating advanced wear prediction algorithms, while companies like Donaldson and Castrol focus on specialized filtration and lubrication analysis. Emerging players including Vitesco Technologies are introducing AI-enhanced monitoring systems, creating a dynamic ecosystem balancing traditional expertise with innovative approaches.

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive V6 engine wear analysis system that combines advanced sensor technology with real-time monitoring capabilities. Their approach utilizes high-precision oil condition sensors that continuously monitor oil quality parameters including viscosity changes, particle contamination levels, and chemical composition alterations. The system incorporates ultrasonic measurement technology to detect microscopic wear patterns without engine disassembly, allowing for non-invasive diagnostics. Bosch's solution also features integrated thermal imaging capabilities that identify abnormal heat distribution patterns indicative of component wear. Their proprietary algorithms analyze sensor data against extensive baseline performance metrics collected from thousands of engine tests, enabling predictive maintenance recommendations before catastrophic failure occurs. The system connects to Bosch's cloud-based analytics platform, providing comparative wear analysis against similar engine profiles and operational conditions.

Strengths: Exceptional integration with vehicle electronic systems, comprehensive sensor network coverage, and extensive historical data for comparative analysis. The system provides early detection capabilities for wear issues before they become critical failures. Weaknesses: Higher implementation cost compared to traditional methods, requires specialized training for maintenance personnel, and depends on consistent connectivity for optimal cloud-based analytics functionality.

Weichai Power

Technical Solution: Weichai Power has pioneered an innovative V6 engine wear analysis methodology combining traditional tribology with advanced digital technologies. Their system employs embedded micro-sensors strategically positioned at critical wear points throughout the engine, continuously monitoring friction coefficients, temperature variations, and material displacement at the microscopic level. These sensors transmit data to Weichai's proprietary Engine Lifecycle Management System (ELMS), which utilizes machine learning algorithms to establish wear patterns specific to different operational conditions. The company has developed specialized spectrographic oil analysis techniques that can detect metal particles down to 5 microns, providing early indication of component degradation. Weichai's approach also incorporates acoustic emission analysis to detect and characterize the sound signatures of various wear mechanisms, allowing for differentiation between normal and abnormal wear patterns. Their comprehensive database contains wear profiles from over 10,000 engine tests across diverse operating environments, enabling highly accurate predictive maintenance scheduling.

Strengths: Exceptional sensitivity to early-stage wear detection, comprehensive data collection across multiple parameters, and strong integration with predictive maintenance systems. Their solution is particularly effective in heavy-duty applications with variable load conditions. Weaknesses: Requires specialized equipment for data interpretation, higher initial implementation costs, and system calibration needs periodic updates based on specific engine applications.

Critical Technologies in Engine Surface Metrology

Engine wear characterizing and quantifying method

PatentWO2008100766A1

Innovation

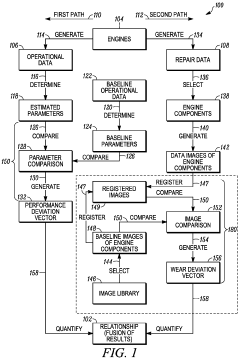

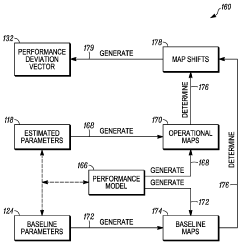

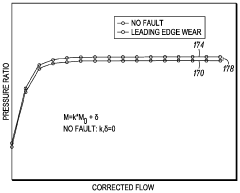

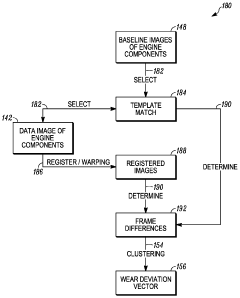

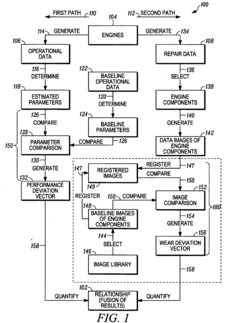

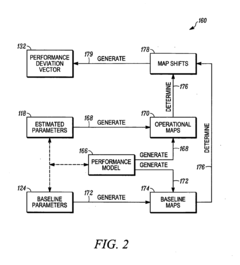

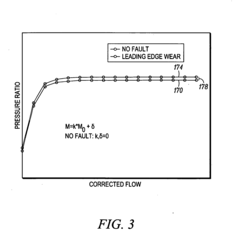

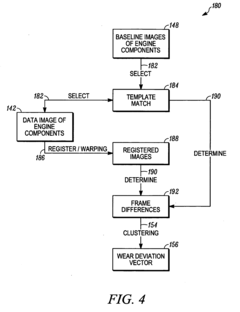

- A method involving the generation of operational data and image data comparison to create deviation vectors, which are then correlated to quantify engine wear and performance characteristics, allowing for the determination of wear based on operational data and image analysis.

Engine wear characterizing and quantifying method

PatentInactiveEP2111607B1

Innovation

- A method that generates operational and image data comparisons to create deviation vectors, quantifying the relationship between engine performance and wear, allowing for the determination of wear and performance characteristics using baseline data and statistical techniques.

Material Science Advancements for Engine Durability

Recent advancements in material science have revolutionized engine durability analysis, particularly for V6 engines. The development of nano-engineered coatings has significantly improved wear resistance in critical engine components. These coatings, typically composed of ceramic-metallic composites (cermets), create surfaces with unprecedented hardness-to-weight ratios while maintaining thermal stability under extreme operating conditions.

High-entropy alloys (HEAs) represent another breakthrough, offering superior mechanical properties compared to traditional engine materials. These multi-principal element alloys demonstrate exceptional resistance to wear, corrosion, and fatigue at elevated temperatures—characteristics particularly valuable for V6 engine components subjected to continuous thermal cycling and mechanical stress.

Advanced polymer composites reinforced with carbon nanotubes have emerged as viable alternatives for specific engine components. These materials provide substantial weight reduction while maintaining structural integrity, contributing to overall engine efficiency. Their self-lubricating properties further enhance wear resistance in boundary lubrication conditions frequently encountered during cold starts.

Surface texturing technologies have evolved to optimize tribological interfaces within V6 engines. Laser surface texturing (LST) creates precisely controlled micropores that serve as lubricant reservoirs and trap wear debris, significantly extending component lifespan. When combined with diamond-like carbon (DLC) coatings, these textured surfaces demonstrate up to 45% reduction in friction coefficients under boundary lubrication conditions.

Computational materials science has accelerated durability improvements through predictive modeling of material behavior under complex operating conditions. Machine learning algorithms now accurately forecast wear progression based on material composition and microstructure, enabling engineers to optimize material selection for specific engine applications before physical prototyping.

Self-healing materials represent the cutting edge of engine durability enhancement. These innovative materials contain microcapsules filled with healing agents that automatically release when microcracks form, effectively "repairing" damage before it propagates to critical failure. While still in developmental stages for high-temperature engine applications, preliminary results show promising potential for extending component lifespan by up to 30%.

The integration of these material science advancements into V6 engine design has collectively contributed to significant improvements in durability metrics, with modern engines demonstrating wear rates approximately 60% lower than those manufactured a decade ago, while simultaneously meeting increasingly stringent emissions and performance requirements.

High-entropy alloys (HEAs) represent another breakthrough, offering superior mechanical properties compared to traditional engine materials. These multi-principal element alloys demonstrate exceptional resistance to wear, corrosion, and fatigue at elevated temperatures—characteristics particularly valuable for V6 engine components subjected to continuous thermal cycling and mechanical stress.

Advanced polymer composites reinforced with carbon nanotubes have emerged as viable alternatives for specific engine components. These materials provide substantial weight reduction while maintaining structural integrity, contributing to overall engine efficiency. Their self-lubricating properties further enhance wear resistance in boundary lubrication conditions frequently encountered during cold starts.

Surface texturing technologies have evolved to optimize tribological interfaces within V6 engines. Laser surface texturing (LST) creates precisely controlled micropores that serve as lubricant reservoirs and trap wear debris, significantly extending component lifespan. When combined with diamond-like carbon (DLC) coatings, these textured surfaces demonstrate up to 45% reduction in friction coefficients under boundary lubrication conditions.

Computational materials science has accelerated durability improvements through predictive modeling of material behavior under complex operating conditions. Machine learning algorithms now accurately forecast wear progression based on material composition and microstructure, enabling engineers to optimize material selection for specific engine applications before physical prototyping.

Self-healing materials represent the cutting edge of engine durability enhancement. These innovative materials contain microcapsules filled with healing agents that automatically release when microcracks form, effectively "repairing" damage before it propagates to critical failure. While still in developmental stages for high-temperature engine applications, preliminary results show promising potential for extending component lifespan by up to 30%.

The integration of these material science advancements into V6 engine design has collectively contributed to significant improvements in durability metrics, with modern engines demonstrating wear rates approximately 60% lower than those manufactured a decade ago, while simultaneously meeting increasingly stringent emissions and performance requirements.

Environmental Impact of Engine Wear Monitoring Systems

The environmental implications of engine wear monitoring systems extend far beyond their primary function of ensuring engine performance. As V6 engines continue to be widely used in various transportation sectors, the environmental footprint of their wear analysis technologies deserves critical examination.

Advanced wear monitoring systems significantly reduce unnecessary maintenance interventions, directly decreasing waste generation from premature part replacements. Traditional maintenance schedules often result in components being discarded before reaching their actual end-of-life, creating substantial material waste. Real-time monitoring technologies enable precise service timing, potentially reducing parts consumption by 15-30% across fleet operations.

These systems also contribute to emissions reduction through optimized engine performance. Undetected wear patterns can lead to increased fuel consumption and higher emissions of nitrogen oxides, carbon monoxide, and particulate matter. Studies indicate that engines operating with undiagnosed wear issues may produce up to 25% more emissions than those maintained at optimal conditions. By enabling timely interventions, monitoring systems help maintain emission control systems at peak efficiency.

The manufacturing of sensor technologies themselves presents environmental considerations. Modern wear analysis systems incorporate various materials including rare earth elements and precious metals. The extraction and processing of these materials carry significant environmental impacts, including habitat disruption, water pollution, and energy-intensive processing. However, lifecycle assessments suggest that these impacts are typically offset by the environmental benefits gained through extended engine life and improved performance.

Energy consumption during operation represents another environmental factor. While earlier monitoring systems imposed notable parasitic loads on engines, contemporary technologies have dramatically reduced power requirements. Current sensor networks typically consume less than 0.1% of engine output, minimizing their operational carbon footprint.

End-of-life management for monitoring components presents recycling challenges due to their complex material composition. However, emerging circular economy initiatives are developing specialized recycling processes for electronic monitoring components, potentially recovering up to 85% of critical materials.

Looking forward, integration of biodegradable sensor components and energy harvesting technologies may further reduce environmental impacts. Research into self-powered sensors utilizing engine vibration energy shows promise for creating truly sustainable monitoring solutions that align with broader environmental goals while maintaining accurate V6 engine wear analysis capabilities.

Advanced wear monitoring systems significantly reduce unnecessary maintenance interventions, directly decreasing waste generation from premature part replacements. Traditional maintenance schedules often result in components being discarded before reaching their actual end-of-life, creating substantial material waste. Real-time monitoring technologies enable precise service timing, potentially reducing parts consumption by 15-30% across fleet operations.

These systems also contribute to emissions reduction through optimized engine performance. Undetected wear patterns can lead to increased fuel consumption and higher emissions of nitrogen oxides, carbon monoxide, and particulate matter. Studies indicate that engines operating with undiagnosed wear issues may produce up to 25% more emissions than those maintained at optimal conditions. By enabling timely interventions, monitoring systems help maintain emission control systems at peak efficiency.

The manufacturing of sensor technologies themselves presents environmental considerations. Modern wear analysis systems incorporate various materials including rare earth elements and precious metals. The extraction and processing of these materials carry significant environmental impacts, including habitat disruption, water pollution, and energy-intensive processing. However, lifecycle assessments suggest that these impacts are typically offset by the environmental benefits gained through extended engine life and improved performance.

Energy consumption during operation represents another environmental factor. While earlier monitoring systems imposed notable parasitic loads on engines, contemporary technologies have dramatically reduced power requirements. Current sensor networks typically consume less than 0.1% of engine output, minimizing their operational carbon footprint.

End-of-life management for monitoring components presents recycling challenges due to their complex material composition. However, emerging circular economy initiatives are developing specialized recycling processes for electronic monitoring components, potentially recovering up to 85% of critical materials.

Looking forward, integration of biodegradable sensor components and energy harvesting technologies may further reduce environmental impacts. Research into self-powered sensors utilizing engine vibration energy shows promise for creating truly sustainable monitoring solutions that align with broader environmental goals while maintaining accurate V6 engine wear analysis capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!