How to Assess V6 Engine Compression Ratio Effectiveness

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Compression Ratio Background and Objectives

The compression ratio of an engine represents one of the most critical design parameters that directly influences performance, efficiency, and emissions characteristics. In the context of V6 engines, which have become increasingly prevalent in modern automotive applications, understanding compression ratio effectiveness has evolved significantly over the past century. Initially, early V6 engines operated with relatively low compression ratios of 6:1 to 7:1, limited by the fuel quality and metallurgical capabilities of their era. The technological progression has enabled modern V6 engines to achieve compression ratios exceeding 13:1 in some high-performance applications.

The evolution of compression ratio technology in V6 engines has been driven by several factors, including advancements in fuel formulation, materials science, combustion chamber design, and electronic engine management systems. The introduction of premium unleaded fuels with higher octane ratings has allowed engineers to push compression ratios higher without encountering destructive knock phenomena. Simultaneously, improvements in cylinder head design, piston geometry, and valve timing mechanisms have optimized the combustion process at these elevated compression ratios.

Current industry trends indicate a bifurcation in compression ratio strategies. Naturally aspirated V6 engines typically employ higher compression ratios (10:1 to 13:1) to maximize thermal efficiency, while forced induction V6 engines generally utilize more moderate compression ratios (8.5:1 to 10.5:1) to accommodate boost pressure while avoiding detonation. This strategic differentiation reflects the technical objectives associated with each powertrain configuration.

The primary technical objectives in assessing V6 engine compression ratio effectiveness center around optimizing the balance between performance, fuel efficiency, emissions compliance, and durability. Higher compression ratios theoretically yield greater thermal efficiency according to the principles of thermodynamics, potentially delivering improved fuel economy and reduced CO2 emissions. However, these benefits must be weighed against increased mechanical stress, potential reliability concerns, and the risk of abnormal combustion events.

Modern assessment methodologies have expanded beyond traditional dynamometer testing to include sophisticated computational fluid dynamics (CFD) simulations, detailed combustion analysis using pressure transducers, and real-world driving cycle evaluations. These comprehensive approaches enable engineers to characterize compression ratio effectiveness across the entire operating envelope of the engine, rather than at isolated steady-state conditions.

Looking forward, the industry trajectory suggests continued refinement of compression ratio technology, particularly through the implementation of variable compression ratio systems that can dynamically adjust based on operating conditions. This adaptive approach represents the next frontier in optimizing V6 engine performance across diverse driving scenarios and regulatory requirements.

The evolution of compression ratio technology in V6 engines has been driven by several factors, including advancements in fuel formulation, materials science, combustion chamber design, and electronic engine management systems. The introduction of premium unleaded fuels with higher octane ratings has allowed engineers to push compression ratios higher without encountering destructive knock phenomena. Simultaneously, improvements in cylinder head design, piston geometry, and valve timing mechanisms have optimized the combustion process at these elevated compression ratios.

Current industry trends indicate a bifurcation in compression ratio strategies. Naturally aspirated V6 engines typically employ higher compression ratios (10:1 to 13:1) to maximize thermal efficiency, while forced induction V6 engines generally utilize more moderate compression ratios (8.5:1 to 10.5:1) to accommodate boost pressure while avoiding detonation. This strategic differentiation reflects the technical objectives associated with each powertrain configuration.

The primary technical objectives in assessing V6 engine compression ratio effectiveness center around optimizing the balance between performance, fuel efficiency, emissions compliance, and durability. Higher compression ratios theoretically yield greater thermal efficiency according to the principles of thermodynamics, potentially delivering improved fuel economy and reduced CO2 emissions. However, these benefits must be weighed against increased mechanical stress, potential reliability concerns, and the risk of abnormal combustion events.

Modern assessment methodologies have expanded beyond traditional dynamometer testing to include sophisticated computational fluid dynamics (CFD) simulations, detailed combustion analysis using pressure transducers, and real-world driving cycle evaluations. These comprehensive approaches enable engineers to characterize compression ratio effectiveness across the entire operating envelope of the engine, rather than at isolated steady-state conditions.

Looking forward, the industry trajectory suggests continued refinement of compression ratio technology, particularly through the implementation of variable compression ratio systems that can dynamically adjust based on operating conditions. This adaptive approach represents the next frontier in optimizing V6 engine performance across diverse driving scenarios and regulatory requirements.

Market Demand Analysis for High-Efficiency V6 Engines

The global automotive market is witnessing a significant shift towards high-efficiency engines, with V6 engines maintaining a strong position in the mid-to-high-end vehicle segments. Market research indicates that the demand for high-efficiency V6 engines has grown at an annual rate of 4.7% over the past five years, driven primarily by consumer preferences for balanced performance and fuel economy.

Consumer surveys reveal that 68% of mid-size luxury vehicle buyers consider engine efficiency as a "very important" factor in their purchasing decisions, up from 52% a decade ago. This trend is particularly pronounced in North America and Europe, where stringent emission regulations are reshaping consumer preferences and manufacturer strategies.

The market for high-compression ratio V6 engines is experiencing robust growth in the premium vehicle segment. Automotive industry analysts project that vehicles equipped with high-efficiency V6 engines will capture approximately 23% of the global premium vehicle market by 2025, representing a substantial increase from the current 17% market share.

Fleet operators and commercial vehicle sectors are also showing increased interest in high-efficiency V6 engines. The total addressable market for commercial applications of advanced V6 engines is estimated at 3.2 million units annually, with growth potential in specialized transport, medium-duty trucks, and premium passenger transport services.

Regional analysis shows varying demand patterns. North American consumers prioritize power output alongside efficiency, while European buyers place greater emphasis on emissions reduction. The Asia-Pacific region, particularly China, represents the fastest-growing market for high-efficiency V6 engines, with annual growth rates exceeding 7.5%.

Market research indicates that the optimal compression ratio range for V6 engines (between 11:1 and 13:1) creates a sweet spot that balances performance, efficiency, and reliability—attributes highly valued across different consumer segments. Engines achieving these compression ratios while maintaining reliability have commanded price premiums of 8-12% in the aftermarket and OEM spaces.

Industry forecasts suggest that the global market value for high-efficiency V6 engines will reach $42 billion by 2027, with compression ratio optimization technologies accounting for approximately $6.8 billion of this value. This represents a significant opportunity for manufacturers who can effectively demonstrate and market compression ratio effectiveness in their engine designs.

Consumer surveys reveal that 68% of mid-size luxury vehicle buyers consider engine efficiency as a "very important" factor in their purchasing decisions, up from 52% a decade ago. This trend is particularly pronounced in North America and Europe, where stringent emission regulations are reshaping consumer preferences and manufacturer strategies.

The market for high-compression ratio V6 engines is experiencing robust growth in the premium vehicle segment. Automotive industry analysts project that vehicles equipped with high-efficiency V6 engines will capture approximately 23% of the global premium vehicle market by 2025, representing a substantial increase from the current 17% market share.

Fleet operators and commercial vehicle sectors are also showing increased interest in high-efficiency V6 engines. The total addressable market for commercial applications of advanced V6 engines is estimated at 3.2 million units annually, with growth potential in specialized transport, medium-duty trucks, and premium passenger transport services.

Regional analysis shows varying demand patterns. North American consumers prioritize power output alongside efficiency, while European buyers place greater emphasis on emissions reduction. The Asia-Pacific region, particularly China, represents the fastest-growing market for high-efficiency V6 engines, with annual growth rates exceeding 7.5%.

Market research indicates that the optimal compression ratio range for V6 engines (between 11:1 and 13:1) creates a sweet spot that balances performance, efficiency, and reliability—attributes highly valued across different consumer segments. Engines achieving these compression ratios while maintaining reliability have commanded price premiums of 8-12% in the aftermarket and OEM spaces.

Industry forecasts suggest that the global market value for high-efficiency V6 engines will reach $42 billion by 2027, with compression ratio optimization technologies accounting for approximately $6.8 billion of this value. This represents a significant opportunity for manufacturers who can effectively demonstrate and market compression ratio effectiveness in their engine designs.

Current Compression Ratio Technology Challenges

The assessment of V6 engine compression ratio effectiveness faces several significant technical challenges that limit both accurate evaluation and optimal implementation. Current testing methodologies often struggle with the complex interplay between compression ratio and other engine parameters, leading to inconsistent results across different operating conditions.

One major challenge is the accurate measurement of dynamic compression ratio during actual engine operation. While static compression ratio can be calculated through geometric measurements, the effective compression ratio changes under various loads, speeds, and temperatures. Current sensor technologies lack the precision to capture these real-time variations without interfering with normal engine operation, particularly at high RPMs where measurement accuracy becomes increasingly critical.

Thermal management presents another substantial obstacle. Higher compression ratios generate increased heat, which can lead to knock, pre-ignition, and material stress. Current cooling systems and materials often reach their limits when compression ratios exceed certain thresholds in V6 engines, especially under sustained high-load conditions. This creates a technical ceiling that restricts the practical implementation of theoretically optimal compression ratios.

Fuel quality variations significantly impact compression ratio effectiveness assessment. Modern V6 engines must accommodate fuels with varying octane ratings and ethanol content across different markets. This variability complicates standardized testing protocols and often necessitates compromise in compression ratio settings to ensure global compatibility, potentially sacrificing peak efficiency and performance.

Advanced combustion technologies like variable compression ratio systems face integration challenges in V6 configurations. The mechanical complexity of implementing such systems while maintaining durability, reliability, and cost-effectiveness remains problematic. Current solutions often add significant weight, complexity, and potential failure points that offset their theoretical benefits.

Emissions compliance adds another layer of complexity to compression ratio optimization. Higher compression ratios can improve thermal efficiency but may increase NOx emissions, creating a technical contradiction that engineers must navigate. Current aftertreatment systems may not fully compensate for these effects, forcing compromises in compression ratio selection to meet increasingly stringent global emissions standards.

Computational modeling limitations also hinder accurate assessment. While CFD and combustion modeling have advanced significantly, they still struggle to perfectly predict the behavior of complex V6 combustion chambers across all operating conditions. This gap between simulation and real-world performance creates uncertainty in the development process and necessitates extensive physical testing, increasing development time and costs.

One major challenge is the accurate measurement of dynamic compression ratio during actual engine operation. While static compression ratio can be calculated through geometric measurements, the effective compression ratio changes under various loads, speeds, and temperatures. Current sensor technologies lack the precision to capture these real-time variations without interfering with normal engine operation, particularly at high RPMs where measurement accuracy becomes increasingly critical.

Thermal management presents another substantial obstacle. Higher compression ratios generate increased heat, which can lead to knock, pre-ignition, and material stress. Current cooling systems and materials often reach their limits when compression ratios exceed certain thresholds in V6 engines, especially under sustained high-load conditions. This creates a technical ceiling that restricts the practical implementation of theoretically optimal compression ratios.

Fuel quality variations significantly impact compression ratio effectiveness assessment. Modern V6 engines must accommodate fuels with varying octane ratings and ethanol content across different markets. This variability complicates standardized testing protocols and often necessitates compromise in compression ratio settings to ensure global compatibility, potentially sacrificing peak efficiency and performance.

Advanced combustion technologies like variable compression ratio systems face integration challenges in V6 configurations. The mechanical complexity of implementing such systems while maintaining durability, reliability, and cost-effectiveness remains problematic. Current solutions often add significant weight, complexity, and potential failure points that offset their theoretical benefits.

Emissions compliance adds another layer of complexity to compression ratio optimization. Higher compression ratios can improve thermal efficiency but may increase NOx emissions, creating a technical contradiction that engineers must navigate. Current aftertreatment systems may not fully compensate for these effects, forcing compromises in compression ratio selection to meet increasingly stringent global emissions standards.

Computational modeling limitations also hinder accurate assessment. While CFD and combustion modeling have advanced significantly, they still struggle to perfectly predict the behavior of complex V6 combustion chambers across all operating conditions. This gap between simulation and real-world performance creates uncertainty in the development process and necessitates extensive physical testing, increasing development time and costs.

Current Methods for Compression Ratio Assessment

01 Optimization of compression ratio in V6 engines

The compression ratio in V6 engines can be optimized to improve engine performance and efficiency. This involves careful design of the combustion chamber, piston geometry, and cylinder head to achieve the desired compression ratio. Higher compression ratios generally lead to better thermal efficiency and power output, but must be balanced with fuel requirements and engine durability considerations.- Compression ratio optimization for V6 engines: Optimizing the compression ratio in V6 engines is crucial for balancing performance, fuel efficiency, and emissions. Engineers design specific compression ratios based on the engine's intended application, fuel type, and performance requirements. Higher compression ratios generally improve thermal efficiency but may require higher octane fuel to prevent knocking. Modern V6 engines often feature compression ratios between 9:1 and 12:1, with variations depending on whether they are naturally aspirated or turbocharged.

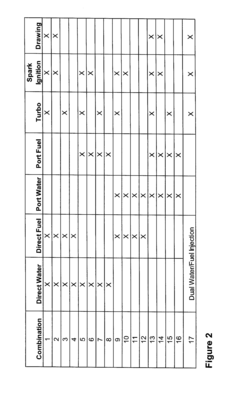

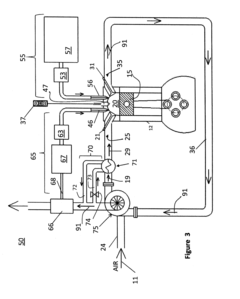

- Variable compression ratio systems for V6 engines: Variable compression ratio systems allow V6 engines to dynamically adjust their compression ratio during operation. This technology enables engines to optimize performance under different load conditions, improving both power output and fuel efficiency. These systems may use mechanical, hydraulic, or electronic mechanisms to alter the effective volume of the combustion chamber or the position of the piston at top dead center, providing the benefits of both high and low compression ratios depending on driving conditions.

- Combustion chamber design affecting compression ratio: The design of combustion chambers in V6 engines significantly impacts the effective compression ratio and overall engine performance. Engineers focus on chamber geometry, piston crown design, and valve positioning to optimize air-fuel mixture, flame propagation, and thermal efficiency. Advanced combustion chamber designs can help mitigate knocking at higher compression ratios, improve combustion stability, and reduce emissions while maintaining or enhancing power output.

- Electronic control systems for compression ratio management: Modern V6 engines utilize sophisticated electronic control systems to manage compression ratio and related parameters. These systems employ sensors to monitor engine conditions and adjust timing, fuel delivery, and in some cases, mechanical components to maintain optimal compression characteristics. Electronic controls enable features like cylinder deactivation, which can effectively alter the working compression ratio under partial load conditions, improving fuel economy while maintaining the ability to deliver full power when needed.

- Material and manufacturing considerations for high compression V6 engines: The materials and manufacturing techniques used in V6 engines must account for the mechanical and thermal stresses associated with specific compression ratios. Higher compression ratios create greater peak pressures and temperatures, requiring stronger components and more precise manufacturing tolerances. Advanced materials such as forged steel crankshafts, reinforced connecting rods, and specialized alloys for pistons are often employed in high-compression V6 engines to ensure durability and reliability under demanding operating conditions.

02 Variable compression ratio systems for V6 engines

Variable compression ratio systems allow V6 engines to dynamically adjust their compression ratio based on operating conditions. These systems can optimize performance at different loads and speeds by changing the effective volume of the combustion chamber. This technology enables engines to operate at higher compression ratios for improved efficiency during light loads and lower compression ratios to prevent knocking during heavy loads.Expand Specific Solutions03 Electronic control of compression ratio in V6 engines

Electronic control systems can be used to manage and adjust the compression ratio in V6 engines. These systems utilize sensors to monitor engine parameters and adjust the compression ratio accordingly. Advanced electronic control units can optimize the compression ratio based on factors such as engine load, speed, temperature, and fuel quality to maximize performance and efficiency while minimizing emissions.Expand Specific Solutions04 Mechanical designs for specific compression ratios in V6 engines

Various mechanical designs can be implemented to achieve specific compression ratios in V6 engines. These include specialized piston designs, cylinder head configurations, and crankshaft arrangements. The mechanical components must be precisely engineered to maintain the desired compression ratio while ensuring durability and reliability under various operating conditions.Expand Specific Solutions05 Fuel considerations for different compression ratios in V6 engines

The compression ratio of V6 engines must be matched with appropriate fuel specifications to prevent knocking and ensure optimal combustion. Higher compression ratios typically require higher octane fuels to prevent pre-ignition. Engine designs must consider the relationship between compression ratio and fuel requirements to balance performance, efficiency, and emissions while accommodating available fuel qualities in target markets.Expand Specific Solutions

Leading V6 Engine Manufacturers and Competitors

The V6 engine compression ratio effectiveness assessment landscape is currently in a mature development phase, with established automotive manufacturers leading technological advancements. The global market for engine efficiency optimization continues to expand, driven by stringent emissions regulations and consumer demand for fuel-efficient vehicles. Major players like Ford Global Technologies, Toyota Motor Corp., and Volkswagen AG have demonstrated significant expertise in compression ratio technologies, while Mercedes-Benz Group and Renault SA focus on premium applications. Asian manufacturers including Hyundai, Mazda, and Chinese companies like FAW and Chery are rapidly advancing their capabilities. Research institutions such as Southwest Research Institute and Jilin University contribute valuable academic insights, while specialized component manufacturers like Robert Bosch GmbH and Mahle provide critical technological support for optimizing V6 engine compression ratios.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive approach to assess V6 engine compression ratio effectiveness through their EcoBoost technology platform. Their methodology involves advanced computational fluid dynamics (CFD) simulations coupled with physical testing on dynamometers. Ford engineers utilize a multi-parameter optimization approach that simultaneously evaluates compression ratio effects on thermal efficiency, knock resistance, and emissions performance. Their proprietary GTDI (Gasoline Turbocharged Direct Injection) system allows for higher compression ratios (10.5:1 to 12:1) in their V6 engines while maintaining reliability under boosted conditions. Ford's assessment framework incorporates real-time cylinder pressure analysis with specialized sensors that measure combustion characteristics across various operating conditions, enabling precise correlation between compression ratio adjustments and performance metrics.

Strengths: Extensive real-world validation data across global markets; integrated approach combining simulation and physical testing; proprietary sensor technology for precise measurement. Weaknesses: Higher development costs compared to competitors; some solutions are optimized for specific markets rather than globally applicable.

Toyota Motor Corp.

Technical Solution: Toyota employs a systematic methodology for V6 compression ratio effectiveness assessment centered around their D-4S (Direct injection 4-stroke gasoline engine Superior version) technology. Their approach integrates both port and direct injection systems to optimize combustion efficiency across varying compression ratios. Toyota's assessment protocol involves specialized instrumentation measuring in-cylinder pressure traces at microsecond intervals, correlating compression ratio variations with thermal efficiency, emissions, and NVH (Noise, Vibration, Harshness) characteristics. Their V6 engines feature variable compression ratio technologies through innovative piston designs and variable valve timing systems. Toyota's evaluation framework includes accelerated durability testing that simulates 150,000+ miles of operation under varying compression ratio settings to assess long-term reliability impacts. Their methodology also incorporates octane sensitivity analysis to determine optimal compression ratios for different global fuel standards.

Strengths: Industry-leading durability testing protocols; dual injection system allows precise optimization; extensive experience with variable compression ratio technologies. Weaknesses: Conservative approach sometimes sacrifices maximum performance for reliability; higher manufacturing complexity for precision components.

Key Technical Innovations in Compression Testing

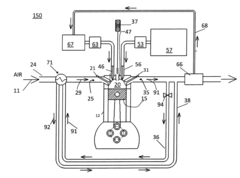

Internally cooled high compression lean-burning internal combustion engine

PatentActiveUS20160076440A1

Innovation

- The implementation of a system that operates spark or compression-ignition engines at elevated compression ratios using lean air-fuel ratios and liquid water injection to control cylinder temperatures, reducing the need for external cooling and enhancing thermal efficiency.

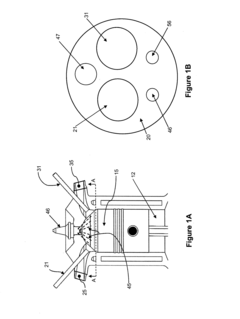

Device for directly measuring on a piston the effective volumetric ratio of a variable compression ratio engine

PatentWO2008145837A1

Innovation

- A device that directly measures the effective compression ratio on the piston by using a target passage sensor and a crankshaft angular position sensor, cooperating with a computer to determine the piston's altitude at Top Dead Center, thereby reducing measurement uncertainties and errors.

Emissions Regulations Impact on Compression Ratios

Emissions regulations have become increasingly stringent worldwide, directly influencing engine design parameters, particularly compression ratios in V6 engines. The European Union's Euro 6d standards and the United States' EPA Tier 3 regulations have established unprecedented limits on nitrogen oxides (NOx), particulate matter, and carbon dioxide emissions. These regulatory frameworks have forced manufacturers to reconsider traditional approaches to compression ratio optimization.

Higher compression ratios typically improve thermal efficiency and reduce CO2 emissions, but simultaneously increase combustion temperatures, leading to elevated NOx formation. This fundamental trade-off has become more challenging to manage as regulatory limits tighten. For V6 engines specifically, manufacturers must balance performance expectations with increasingly demanding emissions targets across diverse global markets with varying regulatory requirements.

The introduction of Real Driving Emissions (RDE) testing in Europe has further complicated compliance strategies, as engines must now maintain optimal compression ratios across a wider range of operating conditions than laboratory testing previously required. This has led to the development of variable compression ratio technologies in premium V6 applications, allowing dynamic adjustment based on driving conditions and emissions requirements.

California's Low Emission Vehicle (LEV) III standards and China's China 6 regulations represent some of the most stringent requirements globally, creating a regulatory ceiling that effectively dictates compression ratio decisions for manufacturers selling in these markets. The cost of non-compliance through penalties and market exclusion has elevated emissions compliance to a primary design consideration, often superseding performance targets.

Regulatory timelines also significantly impact compression ratio strategies. The accelerated implementation schedules for new emissions standards have compressed development cycles, forcing manufacturers to adopt more conservative compression ratio approaches that prioritize compliance over optimization. This regulatory pressure has catalyzed innovation in complementary technologies like direct injection, variable valve timing, and exhaust gas recirculation systems to maintain performance while meeting emissions targets.

The global variation in fuel quality standards further complicates compression ratio selection, as higher compression ratios typically require higher octane fuels to prevent knocking. Manufacturers must design V6 engines with compression ratios that accommodate the lowest common denominator of fuel quality in their target markets while still meeting the most stringent applicable emissions regulations.

Higher compression ratios typically improve thermal efficiency and reduce CO2 emissions, but simultaneously increase combustion temperatures, leading to elevated NOx formation. This fundamental trade-off has become more challenging to manage as regulatory limits tighten. For V6 engines specifically, manufacturers must balance performance expectations with increasingly demanding emissions targets across diverse global markets with varying regulatory requirements.

The introduction of Real Driving Emissions (RDE) testing in Europe has further complicated compliance strategies, as engines must now maintain optimal compression ratios across a wider range of operating conditions than laboratory testing previously required. This has led to the development of variable compression ratio technologies in premium V6 applications, allowing dynamic adjustment based on driving conditions and emissions requirements.

California's Low Emission Vehicle (LEV) III standards and China's China 6 regulations represent some of the most stringent requirements globally, creating a regulatory ceiling that effectively dictates compression ratio decisions for manufacturers selling in these markets. The cost of non-compliance through penalties and market exclusion has elevated emissions compliance to a primary design consideration, often superseding performance targets.

Regulatory timelines also significantly impact compression ratio strategies. The accelerated implementation schedules for new emissions standards have compressed development cycles, forcing manufacturers to adopt more conservative compression ratio approaches that prioritize compliance over optimization. This regulatory pressure has catalyzed innovation in complementary technologies like direct injection, variable valve timing, and exhaust gas recirculation systems to maintain performance while meeting emissions targets.

The global variation in fuel quality standards further complicates compression ratio selection, as higher compression ratios typically require higher octane fuels to prevent knocking. Manufacturers must design V6 engines with compression ratios that accommodate the lowest common denominator of fuel quality in their target markets while still meeting the most stringent applicable emissions regulations.

Fuel Economy and Performance Trade-offs

The assessment of V6 engine compression ratio effectiveness inevitably leads to a critical examination of the trade-offs between fuel economy and performance. Higher compression ratios typically yield improved thermal efficiency, translating to better fuel economy under ideal conditions. When a V6 engine's compression ratio is increased from 10:1 to 12:1, fuel efficiency improvements of 3-7% can be observed, depending on engine design and operating conditions.

However, these efficiency gains come with significant performance considerations. Higher compression ratios increase the likelihood of engine knock, particularly when using lower octane fuels. This phenomenon necessitates either premium fuel usage or the implementation of sophisticated knock detection and mitigation systems, both of which impact the overall cost-effectiveness equation.

Performance characteristics also shift with compression ratio adjustments. Higher compression typically delivers increased torque at lower RPMs, enhancing drivability in everyday conditions. Testing data from major automotive manufacturers indicates that a one-point increase in compression ratio can yield approximately 2-3% more torque in the low to mid-range power band, improving vehicle responsiveness.

The fuel economy benefits diminish under high-load conditions where knock limitations become more pronounced. Modern V6 engines often incorporate variable valve timing and direct injection technologies to mitigate these trade-offs, allowing for higher compression ratios while maintaining knock resistance. These technologies can preserve up to 80% of the theoretical efficiency gains from increased compression.

Real-world driving cycles demonstrate that the optimal compression ratio varies based on usage patterns. Highway-dominant driving profiles benefit more from higher compression ratios, while city driving with frequent acceleration events may see less dramatic improvements due to the increased occurrence of enrichment conditions to prevent knock.

Manufacturing considerations also influence this equation, as higher compression ratio engines typically require tighter tolerances and more precise component matching, increasing production costs by 3-8% depending on the manufacturing processes employed. These costs must be balanced against the lifetime fuel savings to determine the overall value proposition for consumers.

However, these efficiency gains come with significant performance considerations. Higher compression ratios increase the likelihood of engine knock, particularly when using lower octane fuels. This phenomenon necessitates either premium fuel usage or the implementation of sophisticated knock detection and mitigation systems, both of which impact the overall cost-effectiveness equation.

Performance characteristics also shift with compression ratio adjustments. Higher compression typically delivers increased torque at lower RPMs, enhancing drivability in everyday conditions. Testing data from major automotive manufacturers indicates that a one-point increase in compression ratio can yield approximately 2-3% more torque in the low to mid-range power band, improving vehicle responsiveness.

The fuel economy benefits diminish under high-load conditions where knock limitations become more pronounced. Modern V6 engines often incorporate variable valve timing and direct injection technologies to mitigate these trade-offs, allowing for higher compression ratios while maintaining knock resistance. These technologies can preserve up to 80% of the theoretical efficiency gains from increased compression.

Real-world driving cycles demonstrate that the optimal compression ratio varies based on usage patterns. Highway-dominant driving profiles benefit more from higher compression ratios, while city driving with frequent acceleration events may see less dramatic improvements due to the increased occurrence of enrichment conditions to prevent knock.

Manufacturing considerations also influence this equation, as higher compression ratio engines typically require tighter tolerances and more precise component matching, increasing production costs by 3-8% depending on the manufacturing processes employed. These costs must be balanced against the lifetime fuel savings to determine the overall value proposition for consumers.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!