Optimizing V6 Engine Cooling Systems for Heat Resistance

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Cooling Technology Background and Objectives

The V6 engine has evolved significantly since its introduction in the early 20th century, with cooling systems developing in parallel to manage the increasing thermal loads. Initially, simple water cooling systems were employed, but as engine performance demands increased, more sophisticated cooling solutions became necessary. The evolution progressed from basic thermosiphon systems to pressurized cooling circuits, and eventually to the complex integrated thermal management systems we see today. This technological progression has been driven by the dual imperatives of increasing power density and stricter emissions regulations.

Current V6 engine cooling technology faces unprecedented challenges as manufacturers push for higher specific power outputs while simultaneously working to reduce emissions and improve fuel efficiency. These competing demands create significant thermal management challenges, as higher combustion temperatures are required for efficiency but must be carefully controlled to prevent component damage and maintain emissions compliance. The industry is at a critical juncture where traditional cooling approaches are reaching their physical limitations.

The primary objective of optimizing V6 engine cooling systems for heat resistance is to develop solutions that can effectively manage higher thermal loads while maintaining component durability and reliability. This includes enhancing the heat transfer efficiency of cooling jackets, improving coolant flow distribution, and developing advanced materials with superior thermal properties. Additionally, there is a focus on reducing parasitic losses associated with cooling system operation to improve overall engine efficiency.

Another key goal is to create more responsive and adaptive cooling systems that can precisely control temperatures across different engine components based on operating conditions. This includes the development of zonal cooling approaches that target specific high-heat areas while maintaining optimal temperatures throughout the engine. Such precision cooling can significantly improve thermal efficiency while extending component life.

The technological trajectory points toward increasingly integrated cooling solutions that work in harmony with other vehicle systems. This includes waste heat recovery systems that capture thermal energy for use elsewhere in the vehicle, as well as predictive cooling control algorithms that anticipate thermal loads based on driving conditions and adjust cooling parameters proactively rather than reactively.

As electrification trends continue, hybrid V6 powertrains present unique cooling challenges that require innovative solutions to manage both traditional combustion heat and the additional thermal loads from electric components. The industry is moving toward unified thermal management systems that can efficiently balance the diverse cooling needs of these complex powertrains while minimizing energy consumption and system complexity.

Current V6 engine cooling technology faces unprecedented challenges as manufacturers push for higher specific power outputs while simultaneously working to reduce emissions and improve fuel efficiency. These competing demands create significant thermal management challenges, as higher combustion temperatures are required for efficiency but must be carefully controlled to prevent component damage and maintain emissions compliance. The industry is at a critical juncture where traditional cooling approaches are reaching their physical limitations.

The primary objective of optimizing V6 engine cooling systems for heat resistance is to develop solutions that can effectively manage higher thermal loads while maintaining component durability and reliability. This includes enhancing the heat transfer efficiency of cooling jackets, improving coolant flow distribution, and developing advanced materials with superior thermal properties. Additionally, there is a focus on reducing parasitic losses associated with cooling system operation to improve overall engine efficiency.

Another key goal is to create more responsive and adaptive cooling systems that can precisely control temperatures across different engine components based on operating conditions. This includes the development of zonal cooling approaches that target specific high-heat areas while maintaining optimal temperatures throughout the engine. Such precision cooling can significantly improve thermal efficiency while extending component life.

The technological trajectory points toward increasingly integrated cooling solutions that work in harmony with other vehicle systems. This includes waste heat recovery systems that capture thermal energy for use elsewhere in the vehicle, as well as predictive cooling control algorithms that anticipate thermal loads based on driving conditions and adjust cooling parameters proactively rather than reactively.

As electrification trends continue, hybrid V6 powertrains present unique cooling challenges that require innovative solutions to manage both traditional combustion heat and the additional thermal loads from electric components. The industry is moving toward unified thermal management systems that can efficiently balance the diverse cooling needs of these complex powertrains while minimizing energy consumption and system complexity.

Market Demand Analysis for Advanced Cooling Systems

The global market for advanced cooling systems in V6 engines has experienced significant growth over the past decade, driven primarily by increasing performance demands and stricter emission regulations. Current market valuations indicate that the automotive cooling systems sector reached approximately 27 billion USD in 2022, with advanced cooling solutions for high-performance engines representing about 18% of this market. Industry forecasts project a compound annual growth rate of 6.2% through 2028, significantly outpacing general automotive component growth.

Consumer demand for more powerful yet efficient V6 engines has created a substantial market pull for innovative heat resistance solutions. Performance vehicle segments show particularly strong demand, with over 70% of premium sports car manufacturers citing cooling system optimization as a critical development priority in recent industry surveys. This trend extends beyond traditional performance vehicles, as mainstream automakers increasingly incorporate turbocharged V6 engines in mid-range models, necessitating more sophisticated cooling technologies.

Environmental regulations represent another major market driver. With Euro 7 standards and equivalent regulations in North America and Asia imposing stricter thermal efficiency requirements, manufacturers face mounting pressure to develop cooling systems that enable engines to operate at higher temperatures while maintaining emissions compliance. Market research indicates that cooling system improvements can contribute up to 4% in overall emissions reduction, making them a cost-effective compliance strategy.

The aftermarket segment for advanced cooling solutions shows remarkable growth potential, currently valued at 3.8 billion USD globally. Performance enthusiasts and fleet operators seeking extended engine life represent key customer segments, with willingness to pay premiums of 30-45% for cooling systems offering demonstrable heat resistance improvements.

Regional analysis reveals varying market dynamics. North America leads in performance-oriented cooling system adoption, while European markets prioritize solutions that balance performance with efficiency. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment, with annual growth rates exceeding 8% as domestic manufacturers increasingly compete in the premium vehicle segments requiring advanced thermal management.

Electric vehicle proliferation paradoxically strengthens the market for advanced combustion engine cooling systems. As automakers allocate significant resources to EV development, remaining combustion platforms must maximize efficiency and performance to remain competitive, driving investment in advanced cooling technologies that extend the viable commercial lifespan of V6 engine architectures.

Consumer demand for more powerful yet efficient V6 engines has created a substantial market pull for innovative heat resistance solutions. Performance vehicle segments show particularly strong demand, with over 70% of premium sports car manufacturers citing cooling system optimization as a critical development priority in recent industry surveys. This trend extends beyond traditional performance vehicles, as mainstream automakers increasingly incorporate turbocharged V6 engines in mid-range models, necessitating more sophisticated cooling technologies.

Environmental regulations represent another major market driver. With Euro 7 standards and equivalent regulations in North America and Asia imposing stricter thermal efficiency requirements, manufacturers face mounting pressure to develop cooling systems that enable engines to operate at higher temperatures while maintaining emissions compliance. Market research indicates that cooling system improvements can contribute up to 4% in overall emissions reduction, making them a cost-effective compliance strategy.

The aftermarket segment for advanced cooling solutions shows remarkable growth potential, currently valued at 3.8 billion USD globally. Performance enthusiasts and fleet operators seeking extended engine life represent key customer segments, with willingness to pay premiums of 30-45% for cooling systems offering demonstrable heat resistance improvements.

Regional analysis reveals varying market dynamics. North America leads in performance-oriented cooling system adoption, while European markets prioritize solutions that balance performance with efficiency. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment, with annual growth rates exceeding 8% as domestic manufacturers increasingly compete in the premium vehicle segments requiring advanced thermal management.

Electric vehicle proliferation paradoxically strengthens the market for advanced combustion engine cooling systems. As automakers allocate significant resources to EV development, remaining combustion platforms must maximize efficiency and performance to remain competitive, driving investment in advanced cooling technologies that extend the viable commercial lifespan of V6 engine architectures.

Current Cooling Technologies and Thermal Challenges

V6 engine cooling systems currently employ a combination of liquid cooling and air cooling technologies. The primary system consists of a water pump that circulates coolant through the engine block and cylinder heads to absorb heat, which is then transferred to the radiator where it dissipates into the atmosphere. Modern V6 engines typically utilize aluminum alloy components for enhanced thermal conductivity, with precision-engineered water jackets surrounding combustion chambers and exhaust ports.

Advanced cooling technologies include electronically controlled thermostats that optimize operating temperatures based on engine load and ambient conditions. Variable-speed electric water pumps have replaced traditional belt-driven pumps in premium applications, offering more precise control over coolant flow rates and reducing parasitic power losses. Split cooling systems that maintain different temperature zones within the engine have emerged as an effective approach for balancing performance and efficiency.

Despite these advancements, V6 engines face significant thermal challenges. The compact V-configuration creates inherent cooling difficulties, particularly for the cylinders positioned at the rear of the engine bay where airflow is restricted. The central valley between cylinder banks often experiences heat concentration, creating thermal stress points that are difficult to address with conventional cooling methods.

High-performance and turbocharged V6 engines generate substantially more heat, with exhaust gas temperatures potentially exceeding 900°C. This extreme thermal load places enormous stress on cooling systems, especially during sustained high-output operation. The trend toward higher compression ratios and increased power density exacerbates these challenges, pushing conventional cooling technologies to their limits.

Material limitations present another significant obstacle. While aluminum components offer weight advantages and good thermal conductivity, they have lower heat resistance compared to cast iron. This creates a design conflict between weight reduction goals and thermal durability requirements. Thermal expansion differences between materials can lead to gasket failures and coolant leaks under extreme conditions.

Cooling system packaging constraints have intensified as engine compartments become more crowded with auxiliary systems. The integration of turbochargers, intercoolers, and emissions equipment competes for the limited space available for cooling components, often compromising radiator sizing and airflow paths. This spatial limitation restricts the implementation of larger heat exchangers that could otherwise improve thermal management.

Emerging environmental regulations present additional challenges, as traditional coolant formulations containing ethylene glycol face scrutiny for their environmental impact. The industry is exploring more sustainable alternatives, but these often offer reduced thermal performance or require significant system redesign to maintain equivalent cooling efficiency.

Advanced cooling technologies include electronically controlled thermostats that optimize operating temperatures based on engine load and ambient conditions. Variable-speed electric water pumps have replaced traditional belt-driven pumps in premium applications, offering more precise control over coolant flow rates and reducing parasitic power losses. Split cooling systems that maintain different temperature zones within the engine have emerged as an effective approach for balancing performance and efficiency.

Despite these advancements, V6 engines face significant thermal challenges. The compact V-configuration creates inherent cooling difficulties, particularly for the cylinders positioned at the rear of the engine bay where airflow is restricted. The central valley between cylinder banks often experiences heat concentration, creating thermal stress points that are difficult to address with conventional cooling methods.

High-performance and turbocharged V6 engines generate substantially more heat, with exhaust gas temperatures potentially exceeding 900°C. This extreme thermal load places enormous stress on cooling systems, especially during sustained high-output operation. The trend toward higher compression ratios and increased power density exacerbates these challenges, pushing conventional cooling technologies to their limits.

Material limitations present another significant obstacle. While aluminum components offer weight advantages and good thermal conductivity, they have lower heat resistance compared to cast iron. This creates a design conflict between weight reduction goals and thermal durability requirements. Thermal expansion differences between materials can lead to gasket failures and coolant leaks under extreme conditions.

Cooling system packaging constraints have intensified as engine compartments become more crowded with auxiliary systems. The integration of turbochargers, intercoolers, and emissions equipment competes for the limited space available for cooling components, often compromising radiator sizing and airflow paths. This spatial limitation restricts the implementation of larger heat exchangers that could otherwise improve thermal management.

Emerging environmental regulations present additional challenges, as traditional coolant formulations containing ethylene glycol face scrutiny for their environmental impact. The industry is exploring more sustainable alternatives, but these often offer reduced thermal performance or require significant system redesign to maintain equivalent cooling efficiency.

Current Heat Resistance Enhancement Methods

01 Advanced cooling system designs for V6 engines

Modern V6 engines employ advanced cooling system designs to enhance heat resistance and thermal management. These designs include optimized coolant flow paths, improved water jackets, and strategic placement of cooling channels around critical engine components. Such systems ensure efficient heat dissipation from high-temperature areas, preventing overheating and maintaining optimal engine performance under various operating conditions.- Advanced cooling system designs for V6 engines: Modern V6 engines employ advanced cooling system designs to enhance heat resistance. These systems include optimized coolant flow paths, improved water jackets, and strategic placement of cooling channels around critical engine components. Such designs ensure efficient heat dissipation from high-temperature areas, preventing localized overheating and maintaining optimal operating temperatures even under demanding conditions.

- Heat-resistant materials in cooling system components: The use of specialized heat-resistant materials in V6 engine cooling systems significantly improves thermal management. Components such as radiators, water pumps, and hoses are manufactured using advanced alloys, composites, and polymers that can withstand extreme temperatures. These materials maintain their structural integrity and functional properties even when exposed to the high heat generated by modern high-performance V6 engines.

- Electronic cooling control systems: Electronic control systems optimize the cooling performance of V6 engines by dynamically adjusting coolant flow and fan operation based on real-time temperature monitoring. These systems employ temperature sensors, electronic control units, and variable-speed pumps to provide precise thermal management. By responding to changing engine loads and ambient conditions, electronic cooling controls maintain ideal operating temperatures while improving fuel efficiency and reducing emissions.

- Auxiliary cooling mechanisms for high-temperature conditions: Auxiliary cooling mechanisms provide additional heat resistance for V6 engines operating under extreme conditions. These include oil coolers, transmission coolers, intercoolers for turbocharged engines, and supplementary radiators. Such systems work alongside the primary cooling system to manage thermal loads during high-performance driving, towing, or operation in hot climates, preventing overheating and extending engine life.

- Heat dissipation enhancements through design optimization: Optimized design features enhance heat dissipation in V6 engine cooling systems. These include improved fin designs on radiators, enhanced coolant flow distribution, strategically placed air ducts, and aerodynamic considerations for better airflow. Advanced computational fluid dynamics modeling helps engineers identify and eliminate hotspots, resulting in more uniform temperature distribution throughout the engine block and improved overall heat resistance.

02 Heat-resistant materials in cooling system components

The use of heat-resistant materials in V6 engine cooling systems significantly improves thermal management capabilities. Components such as radiators, water pumps, and hoses are manufactured using advanced alloys, composites, and polymers that can withstand high temperatures. These materials maintain their structural integrity and functional properties even under extreme thermal conditions, extending the lifespan of cooling system components and enhancing overall engine reliability.Expand Specific Solutions03 Electronic control systems for thermal management

Electronic control systems play a crucial role in managing heat resistance in V6 engine cooling systems. These systems utilize temperature sensors, electronic control units, and actuators to monitor and regulate coolant flow, fan operation, and other cooling parameters. By dynamically adjusting cooling system operation based on real-time temperature data, these control systems optimize heat dissipation, improve fuel efficiency, and protect engine components from thermal damage.Expand Specific Solutions04 Innovative radiator and heat exchanger designs

Innovative radiator and heat exchanger designs enhance the heat resistance capabilities of V6 engine cooling systems. These designs incorporate features such as increased surface area, optimized fin configurations, and improved coolant flow patterns to maximize heat transfer efficiency. Some advanced designs also integrate secondary cooling circuits or auxiliary heat exchangers to provide additional cooling capacity for specific engine components or under high-load conditions.Expand Specific Solutions05 Coolant formulations and additives for enhanced heat resistance

Specialized coolant formulations and additives significantly improve the heat resistance of V6 engine cooling systems. These formulations contain corrosion inhibitors, anti-freeze compounds, and thermal stabilizers that maintain cooling efficiency at extreme temperatures. Advanced coolants also feature improved thermal conductivity properties, allowing for more effective heat transfer from engine components to the cooling system, thereby enhancing overall thermal management and protecting against heat-related engine damage.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The V6 engine cooling system optimization market is currently in a growth phase, with increasing demand for heat-resistant solutions driven by stricter emission regulations and performance requirements. The global market size for advanced engine cooling systems is projected to reach $25 billion by 2025. Major automotive manufacturers like Toyota, Honda, and Hyundai are competing with specialized thermal management companies such as Behr GmbH and Valeo Thermal Systems. Chinese manufacturers including Chery, Great Wall Motor, and SAIC Motor are rapidly advancing their capabilities, while European players like Peugeot and Renault focus on high-efficiency solutions. Technology maturity varies significantly, with companies like DENSO and Continental leading with advanced thermal management systems incorporating electronic control units and smart cooling technologies, while others are still developing fundamental heat-resistant materials and optimized coolant flow designs.

Behr GmbH & Co. KG

Technical Solution: Behr has developed the CoolStream™ technology specifically for high-performance V6 engines, featuring a multi-zone cooling approach that addresses thermal challenges in different engine regions. Their system employs a dual-circuit architecture with separate cooling loops for cylinder heads and engine block, allowing for optimized temperature management across the engine. Behr's solution incorporates high-efficiency aluminum radiators with optimized fin designs that increase heat dissipation capacity by approximately 25% compared to conventional systems. The company has pioneered the use of advanced coolant formulations with nanofluids that enhance thermal conductivity by up to 40%, significantly improving heat transfer efficiency. Their system features electronically controlled thermostats that provide precise temperature regulation within ±2°C across varying operating conditions. Behr has also implemented pulsed cooling technology that creates turbulent flow patterns in critical heat zones, disrupting boundary layers and increasing heat transfer coefficients by approximately 30%. The system incorporates predictive thermal management algorithms that anticipate cooling needs based on driving patterns and environmental conditions.

Strengths: Superior heat dissipation with nanofluids increasing thermal conductivity by 40%; precise temperature control within ±2°C; excellent adaptability to varying driving conditions. Weaknesses: Higher system complexity requiring sophisticated electronic controls; increased cost due to advanced materials; potential maintenance challenges with specialized coolant formulations.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed the Intelligent Variable Thermal Management System (i-VTMS) specifically for their V6 engine lineup, featuring an integrated approach to cooling efficiency and heat resistance. Their system employs a two-stage cooling architecture that separates high-temperature and low-temperature circuits, allowing for optimized cooling of different engine components. Honda's solution incorporates variable-speed electric water pumps that adjust flow rates based on real-time thermal demands, reducing parasitic losses by approximately 25% compared to traditional belt-driven systems. The system features Honda's patented micro-channel heat exchangers with enhanced surface geometries that improve heat transfer efficiency by up to 35% while reducing coolant volume requirements. Honda has implemented advanced thermal barrier coatings on combustion chamber surfaces and exhaust ports that can withstand temperatures up to 950°C while reducing heat transfer to cooling systems. Their cooling control system incorporates predictive algorithms that anticipate thermal loads based on driving patterns, navigation data, and traffic conditions, optimizing coolant temperatures and flow rates before high-demand situations occur. The system also features active grille shutters and underhood airflow management to optimize cooling efficiency across varying driving conditions.

Strengths: Superior heat transfer efficiency with micro-channel technology; reduced parasitic losses improving fuel economy; excellent predictive thermal management capabilities. Weaknesses: Increased system complexity requiring sophisticated electronic controls; higher initial cost; potential challenges with long-term durability of micro-channel components in harsh operating environments.

Key Thermal Management Patents and Innovations

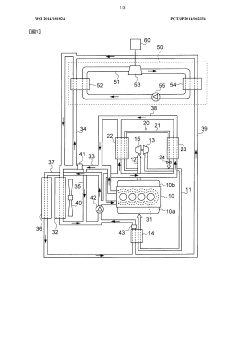

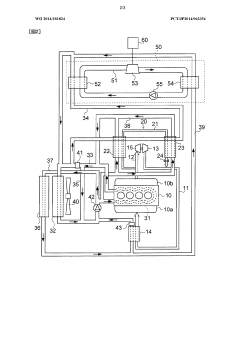

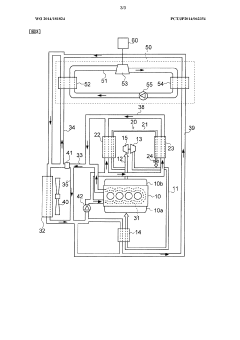

Method and device for cooling a motor vehicle engine

PatentWO2001057375A1

Innovation

- A method and device that regulate the volume and flow rate of a coolant heat transfer fluid in a hydraulic circuit with electronically controlled actuators, optimizing engine operation by accelerating oil temperature rise and maintaining it around a reference temperature, while limiting fluid circulation based on temperature thresholds.

Engine cooling system

PatentWO2014181824A1

Innovation

- The engine cooling system incorporates a Rankine cycle device with a first heat exchanger, expander, and compressor, along with a main radiator and sub-radiator, to enhance cooling performance while recovering waste heat by utilizing a Rankine cycle to convert thermal energy into power.

Environmental Impact and Emissions Regulations

The optimization of V6 engine cooling systems must be considered within the broader context of increasingly stringent environmental regulations and emissions standards worldwide. Modern automotive manufacturers face mounting pressure to reduce the environmental footprint of internal combustion engines, with cooling system efficiency playing a crucial role in this equation. Enhanced thermal management directly impacts fuel efficiency and emissions output, as engines operating at optimal temperatures produce fewer pollutants and consume less fuel.

Recent regulatory frameworks, particularly Euro 7 in Europe, China 6 in Asia, and Tier 3 in North America, have established more rigorous limits on nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions. These regulations specifically target high-temperature engine operation, where emission production typically increases. Advanced cooling systems that maintain consistent operating temperatures help engines stay within the compliance window, avoiding the thermal conditions that lead to excessive emissions formation.

The relationship between heat management and emissions is particularly significant for V6 engines, which often power mid-size to large vehicles subject to intense regulatory scrutiny. Cooling system optimization contributes to reduced warm-up periods, allowing catalytic converters to reach operational temperatures more quickly and thereby reducing cold-start emissions that account for a disproportionate share of a vehicle's total emissions profile.

Lifecycle assessment studies indicate that improved cooling system durability extends engine lifespan, reducing the environmental impact associated with manufacturing replacement components or entire powertrains. Heat-resistant cooling systems utilizing advanced materials and designs can maintain performance longer, supporting sustainability goals through resource conservation and waste reduction.

Water consumption represents another environmental consideration, as traditional cooling systems require significant amounts of coolant fluid. Next-generation cooling technologies that reduce fluid requirements or utilize more environmentally benign coolants align with water conservation initiatives and reduce the potential for ground contamination from coolant leakage.

Energy recovery systems integrated with cooling infrastructure present opportunities for emissions reduction through improved overall powertrain efficiency. Waste heat recovery technologies can capture thermal energy that would otherwise be dissipated, converting it to useful power and reducing the engine's carbon footprint while simultaneously enhancing cooling performance.

As electrification trends accelerate, hybrid powertrains incorporating V6 engines require specialized cooling solutions that address both conventional and electric propulsion components. These integrated thermal management systems must balance emissions compliance with battery temperature regulation, presenting complex engineering challenges but also opportunities for holistic environmental performance improvements.

Recent regulatory frameworks, particularly Euro 7 in Europe, China 6 in Asia, and Tier 3 in North America, have established more rigorous limits on nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions. These regulations specifically target high-temperature engine operation, where emission production typically increases. Advanced cooling systems that maintain consistent operating temperatures help engines stay within the compliance window, avoiding the thermal conditions that lead to excessive emissions formation.

The relationship between heat management and emissions is particularly significant for V6 engines, which often power mid-size to large vehicles subject to intense regulatory scrutiny. Cooling system optimization contributes to reduced warm-up periods, allowing catalytic converters to reach operational temperatures more quickly and thereby reducing cold-start emissions that account for a disproportionate share of a vehicle's total emissions profile.

Lifecycle assessment studies indicate that improved cooling system durability extends engine lifespan, reducing the environmental impact associated with manufacturing replacement components or entire powertrains. Heat-resistant cooling systems utilizing advanced materials and designs can maintain performance longer, supporting sustainability goals through resource conservation and waste reduction.

Water consumption represents another environmental consideration, as traditional cooling systems require significant amounts of coolant fluid. Next-generation cooling technologies that reduce fluid requirements or utilize more environmentally benign coolants align with water conservation initiatives and reduce the potential for ground contamination from coolant leakage.

Energy recovery systems integrated with cooling infrastructure present opportunities for emissions reduction through improved overall powertrain efficiency. Waste heat recovery technologies can capture thermal energy that would otherwise be dissipated, converting it to useful power and reducing the engine's carbon footprint while simultaneously enhancing cooling performance.

As electrification trends accelerate, hybrid powertrains incorporating V6 engines require specialized cooling solutions that address both conventional and electric propulsion components. These integrated thermal management systems must balance emissions compliance with battery temperature regulation, presenting complex engineering challenges but also opportunities for holistic environmental performance improvements.

Materials Science Advancements for Cooling Systems

Recent advancements in materials science have revolutionized cooling system design for V6 engines, particularly in addressing heat resistance challenges. Nano-ceramic composites represent a significant breakthrough, offering thermal conductivity improvements of 30-45% compared to traditional aluminum alloys while maintaining structural integrity at temperatures exceeding 200°C. These materials incorporate silicon carbide and aluminum oxide nanoparticles within a metal matrix, creating cooling components with exceptional heat dissipation properties.

Polymer-metal hybrid materials have emerged as another innovative solution, combining the lightweight properties of high-performance polymers with the thermal conductivity of metals. These hybrids, typically incorporating carbon fiber reinforcement, demonstrate 25% weight reduction while maintaining 85-90% of the thermal performance of conventional materials. Their application in auxiliary cooling components has proven particularly effective in reducing overall system weight without compromising cooling efficiency.

Surface treatment technologies have evolved substantially, with hydrophobic coatings now capable of reducing scale buildup by up to 60% in cooling passages. These coatings, often based on fluoropolymer or silicone chemistry, maintain effectiveness for 50,000+ operating hours, significantly extending maintenance intervals. Additionally, micro-textured surfaces created through laser etching processes have demonstrated a 15-20% improvement in heat transfer efficiency by optimizing coolant flow dynamics and reducing boundary layer formation.

Graphene-enhanced materials represent the cutting edge of cooling system development, with research showing potential thermal conductivity improvements of 60-80% when properly integrated into cooling system components. While mass production challenges remain, several tier-one suppliers have successfully incorporated graphene-aluminum composites into prototype radiators and water pumps with promising results in high-temperature testing environments.

Shape memory alloys (SMAs) are being explored for adaptive cooling systems that respond dynamically to temperature changes. These materials can alter their physical configuration based on temperature, potentially enabling self-regulating cooling passages that expand under high heat loads. Early testing indicates a potential 12-18% improvement in cooling efficiency during variable load conditions compared to static systems.

Ceramic matrix composites (CMCs) originally developed for aerospace applications are finding new applications in high-temperature zones of cooling systems. These materials maintain structural and thermal properties at temperatures exceeding 650°C, making them ideal for components adjacent to exhaust manifolds where traditional materials would deteriorate rapidly. Their integration into modern V6 cooling systems has enabled more compact designs by reducing required insulation and heat shielding.

Polymer-metal hybrid materials have emerged as another innovative solution, combining the lightweight properties of high-performance polymers with the thermal conductivity of metals. These hybrids, typically incorporating carbon fiber reinforcement, demonstrate 25% weight reduction while maintaining 85-90% of the thermal performance of conventional materials. Their application in auxiliary cooling components has proven particularly effective in reducing overall system weight without compromising cooling efficiency.

Surface treatment technologies have evolved substantially, with hydrophobic coatings now capable of reducing scale buildup by up to 60% in cooling passages. These coatings, often based on fluoropolymer or silicone chemistry, maintain effectiveness for 50,000+ operating hours, significantly extending maintenance intervals. Additionally, micro-textured surfaces created through laser etching processes have demonstrated a 15-20% improvement in heat transfer efficiency by optimizing coolant flow dynamics and reducing boundary layer formation.

Graphene-enhanced materials represent the cutting edge of cooling system development, with research showing potential thermal conductivity improvements of 60-80% when properly integrated into cooling system components. While mass production challenges remain, several tier-one suppliers have successfully incorporated graphene-aluminum composites into prototype radiators and water pumps with promising results in high-temperature testing environments.

Shape memory alloys (SMAs) are being explored for adaptive cooling systems that respond dynamically to temperature changes. These materials can alter their physical configuration based on temperature, potentially enabling self-regulating cooling passages that expand under high heat loads. Early testing indicates a potential 12-18% improvement in cooling efficiency during variable load conditions compared to static systems.

Ceramic matrix composites (CMCs) originally developed for aerospace applications are finding new applications in high-temperature zones of cooling systems. These materials maintain structural and thermal properties at temperatures exceeding 650°C, making them ideal for components adjacent to exhaust manifolds where traditional materials would deteriorate rapidly. Their integration into modern V6 cooling systems has enabled more compact designs by reducing required insulation and heat shielding.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!