How to Adapt V6 Engine to Alternative Fuels

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Alternative Fuel Adaptation Background & Objectives

The V6 engine has been a cornerstone of automotive propulsion since its commercial introduction in the 1950s, offering an optimal balance between performance, fuel efficiency, and packaging compared to inline or V8 configurations. As global environmental concerns intensify and fossil fuel resources diminish, the automotive industry faces mounting pressure to reduce carbon emissions while maintaining performance standards that consumers expect. This technological evolution necessitates adapting conventional internal combustion engines, including the widely-used V6 platform, to operate efficiently with alternative fuels.

Alternative fuels encompass a diverse range of non-petroleum-based energy sources including ethanol, methanol, compressed natural gas (CNG), liquefied petroleum gas (LPG), hydrogen, biodiesel, and synthetic fuels. Each presents unique chemical properties that require specific adaptations to traditional engine architecture. The historical trajectory of alternative fuel development has accelerated significantly since the 1970s oil crisis, with subsequent environmental legislation further catalyzing research and implementation efforts.

The primary objective of V6 engine adaptation to alternative fuels is to achieve comparable or superior performance metrics while significantly reducing greenhouse gas emissions and dependence on fossil fuels. This adaptation must address several critical parameters: combustion efficiency, material compatibility, fuel delivery systems, emission control, and long-term durability. Additionally, adaptations must be economically viable for both manufacturers and consumers to ensure widespread adoption.

Current technological objectives focus on developing flexible-fuel V6 engines capable of operating on multiple fuel types without compromising reliability or requiring frequent maintenance interventions. This includes creating adaptive engine management systems that can optimize combustion parameters in real-time based on fuel composition detection. Another key goal is minimizing the modification requirements to existing V6 architectures, thereby reducing implementation costs and manufacturing disruption.

The evolution of V6 engine adaptation technologies has progressed through several distinct phases: initial compatibility modifications, dedicated alternative fuel variants, and the current development of truly flexible multi-fuel systems. Each phase has built upon previous innovations while addressing emerging challenges in fuel storage, delivery, ignition timing, and emissions control.

Looking forward, the industry aims to achieve seamless integration of alternative fuels within conventional V6 platforms, potentially extending engine lifespan while meeting increasingly stringent emissions regulations. This technological transition represents not merely an engineering challenge but a fundamental reimagining of internal combustion technology for a sustainable transportation future.

Alternative fuels encompass a diverse range of non-petroleum-based energy sources including ethanol, methanol, compressed natural gas (CNG), liquefied petroleum gas (LPG), hydrogen, biodiesel, and synthetic fuels. Each presents unique chemical properties that require specific adaptations to traditional engine architecture. The historical trajectory of alternative fuel development has accelerated significantly since the 1970s oil crisis, with subsequent environmental legislation further catalyzing research and implementation efforts.

The primary objective of V6 engine adaptation to alternative fuels is to achieve comparable or superior performance metrics while significantly reducing greenhouse gas emissions and dependence on fossil fuels. This adaptation must address several critical parameters: combustion efficiency, material compatibility, fuel delivery systems, emission control, and long-term durability. Additionally, adaptations must be economically viable for both manufacturers and consumers to ensure widespread adoption.

Current technological objectives focus on developing flexible-fuel V6 engines capable of operating on multiple fuel types without compromising reliability or requiring frequent maintenance interventions. This includes creating adaptive engine management systems that can optimize combustion parameters in real-time based on fuel composition detection. Another key goal is minimizing the modification requirements to existing V6 architectures, thereby reducing implementation costs and manufacturing disruption.

The evolution of V6 engine adaptation technologies has progressed through several distinct phases: initial compatibility modifications, dedicated alternative fuel variants, and the current development of truly flexible multi-fuel systems. Each phase has built upon previous innovations while addressing emerging challenges in fuel storage, delivery, ignition timing, and emissions control.

Looking forward, the industry aims to achieve seamless integration of alternative fuels within conventional V6 platforms, potentially extending engine lifespan while meeting increasingly stringent emissions regulations. This technological transition represents not merely an engineering challenge but a fundamental reimagining of internal combustion technology for a sustainable transportation future.

Market Demand Analysis for Alternative Fuel V6 Engines

The global market for alternative fuel vehicles has been experiencing significant growth, driven by increasing environmental concerns, stringent emission regulations, and the volatility of fossil fuel prices. Within this expanding market, the adaptation of V6 engines to alternative fuels represents a particularly promising segment with substantial growth potential.

Recent market research indicates that the alternative fuel vehicle market is projected to grow at a compound annual growth rate (CAGR) of 22.5% from 2023 to 2030. The V6 engine segment within this market is expected to maintain a steady growth trajectory, especially in regions where consumers prioritize performance alongside environmental considerations.

Consumer demand for alternative fuel V6 engines is primarily driven by the desire to maintain vehicle performance characteristics while reducing environmental impact. This is particularly evident in the mid-size SUV, luxury sedan, and light commercial vehicle segments, where V6 engines have traditionally dominated due to their balance of power and efficiency.

Regional analysis reveals varying market dynamics. North America shows strong demand for alternative fuel V6 engines in the pickup truck and SUV segments, while European markets demonstrate greater interest in hydrogen and synthetic fuel adaptations for premium vehicles. The Asia-Pacific region, particularly China and Japan, is witnessing rapid growth in demand for hybrid V6 systems.

Fleet operators represent another significant market segment, with logistics companies, ride-sharing services, and government agencies increasingly seeking to convert their V6-powered fleets to alternative fuels to meet corporate sustainability goals and comply with urban emission regulations.

By fuel type, the market can be segmented into ethanol/methanol blends, compressed natural gas (CNG), liquefied petroleum gas (LPG), hydrogen, and synthetic fuels. Among these, CNG and LPG adaptations currently hold the largest market share due to their established infrastructure and relatively straightforward engine conversion requirements.

Market forecasts suggest that hydrogen fuel adaptations for V6 engines will experience the fastest growth rate over the next decade, albeit from a smaller base, as hydrogen infrastructure expands and fuel cell technology advances. Synthetic fuels are also gaining traction, particularly in markets with strong automotive manufacturing bases seeking to preserve internal combustion expertise.

Price sensitivity analysis indicates that consumers are willing to pay a premium of approximately 15-20% for alternative fuel V6 engines compared to conventional counterparts, provided that operational costs are competitive over the vehicle's lifetime. This price tolerance varies significantly by region and vehicle segment.

Recent market research indicates that the alternative fuel vehicle market is projected to grow at a compound annual growth rate (CAGR) of 22.5% from 2023 to 2030. The V6 engine segment within this market is expected to maintain a steady growth trajectory, especially in regions where consumers prioritize performance alongside environmental considerations.

Consumer demand for alternative fuel V6 engines is primarily driven by the desire to maintain vehicle performance characteristics while reducing environmental impact. This is particularly evident in the mid-size SUV, luxury sedan, and light commercial vehicle segments, where V6 engines have traditionally dominated due to their balance of power and efficiency.

Regional analysis reveals varying market dynamics. North America shows strong demand for alternative fuel V6 engines in the pickup truck and SUV segments, while European markets demonstrate greater interest in hydrogen and synthetic fuel adaptations for premium vehicles. The Asia-Pacific region, particularly China and Japan, is witnessing rapid growth in demand for hybrid V6 systems.

Fleet operators represent another significant market segment, with logistics companies, ride-sharing services, and government agencies increasingly seeking to convert their V6-powered fleets to alternative fuels to meet corporate sustainability goals and comply with urban emission regulations.

By fuel type, the market can be segmented into ethanol/methanol blends, compressed natural gas (CNG), liquefied petroleum gas (LPG), hydrogen, and synthetic fuels. Among these, CNG and LPG adaptations currently hold the largest market share due to their established infrastructure and relatively straightforward engine conversion requirements.

Market forecasts suggest that hydrogen fuel adaptations for V6 engines will experience the fastest growth rate over the next decade, albeit from a smaller base, as hydrogen infrastructure expands and fuel cell technology advances. Synthetic fuels are also gaining traction, particularly in markets with strong automotive manufacturing bases seeking to preserve internal combustion expertise.

Price sensitivity analysis indicates that consumers are willing to pay a premium of approximately 15-20% for alternative fuel V6 engines compared to conventional counterparts, provided that operational costs are competitive over the vehicle's lifetime. This price tolerance varies significantly by region and vehicle segment.

Technical Challenges in V6 Engine Fuel Conversion

Converting V6 engines to operate on alternative fuels presents numerous technical challenges that must be addressed systematically. The fundamental issue stems from the different combustion characteristics of alternative fuels compared to conventional gasoline or diesel. Ethanol, biodiesel, natural gas, hydrogen, and synthetic fuels each possess unique chemical properties requiring specific engine modifications.

Fuel delivery systems represent a primary challenge area. Alternative fuels often have different energy densities, requiring recalibration of fuel injectors and fuel pressure regulators. For gaseous fuels like hydrogen or CNG, entirely new injection systems may be necessary, as traditional liquid fuel injectors cannot accommodate gaseous state delivery. Additionally, some alternative fuels possess corrosive properties that can degrade standard fuel system components, necessitating materials upgrades.

Combustion chamber modifications present another significant hurdle. The compression ratio of V6 engines typically requires adjustment when converting to alternative fuels. For instance, ethanol blends benefit from higher compression ratios to maximize efficiency, while some gaseous fuels may require lower compression to prevent pre-ignition. Piston design, valve timing, and ignition timing all require recalibration to accommodate the different flame propagation speeds and combustion characteristics.

Thermal management challenges also emerge during conversion. Many alternative fuels burn at different temperatures than conventional fuels, potentially creating hot spots or uneven thermal loading across the engine block. This can lead to increased thermal stress, accelerated wear, and potential failure points if not properly addressed through cooling system modifications and materials selection.

Emissions control systems require substantial reconfiguration. Catalytic converters and oxygen sensors designed for gasoline or diesel may not function optimally with alternative fuels. The different combustion byproducts necessitate recalibration of the engine control unit (ECU) and potentially new catalyst formulations to effectively treat exhaust gases and meet increasingly stringent emissions regulations.

Electronic control systems present perhaps the most complex challenge. The ECU must be reprogrammed extensively to manage fuel delivery, ignition timing, and emissions control for the alternative fuel. This often requires sophisticated mapping procedures and extensive testing across various operating conditions. Many older V6 engines lack the electronic flexibility to accommodate such extensive reprogramming without hardware upgrades.

Durability and longevity concerns also arise with fuel conversion. Alternative fuels may affect valve seat wear, piston ring lubrication, and overall engine durability differently than conventional fuels. Comprehensive testing is required to ensure that converted engines maintain reliability and service life comparable to their conventional counterparts.

Fuel delivery systems represent a primary challenge area. Alternative fuels often have different energy densities, requiring recalibration of fuel injectors and fuel pressure regulators. For gaseous fuels like hydrogen or CNG, entirely new injection systems may be necessary, as traditional liquid fuel injectors cannot accommodate gaseous state delivery. Additionally, some alternative fuels possess corrosive properties that can degrade standard fuel system components, necessitating materials upgrades.

Combustion chamber modifications present another significant hurdle. The compression ratio of V6 engines typically requires adjustment when converting to alternative fuels. For instance, ethanol blends benefit from higher compression ratios to maximize efficiency, while some gaseous fuels may require lower compression to prevent pre-ignition. Piston design, valve timing, and ignition timing all require recalibration to accommodate the different flame propagation speeds and combustion characteristics.

Thermal management challenges also emerge during conversion. Many alternative fuels burn at different temperatures than conventional fuels, potentially creating hot spots or uneven thermal loading across the engine block. This can lead to increased thermal stress, accelerated wear, and potential failure points if not properly addressed through cooling system modifications and materials selection.

Emissions control systems require substantial reconfiguration. Catalytic converters and oxygen sensors designed for gasoline or diesel may not function optimally with alternative fuels. The different combustion byproducts necessitate recalibration of the engine control unit (ECU) and potentially new catalyst formulations to effectively treat exhaust gases and meet increasingly stringent emissions regulations.

Electronic control systems present perhaps the most complex challenge. The ECU must be reprogrammed extensively to manage fuel delivery, ignition timing, and emissions control for the alternative fuel. This often requires sophisticated mapping procedures and extensive testing across various operating conditions. Many older V6 engines lack the electronic flexibility to accommodate such extensive reprogramming without hardware upgrades.

Durability and longevity concerns also arise with fuel conversion. Alternative fuels may affect valve seat wear, piston ring lubrication, and overall engine durability differently than conventional fuels. Comprehensive testing is required to ensure that converted engines maintain reliability and service life comparable to their conventional counterparts.

Current V6 Engine Modification Solutions

01 V6 Engine Design and Configuration

V6 engines feature a V-shaped configuration with two banks of three cylinders arranged at an angle. This design offers a good balance between power output and compact size, making it suitable for various vehicle applications. The V6 configuration provides better balance and smoother operation compared to inline engines while maintaining a relatively compact form factor.- V6 Engine Design and Configuration: V6 engines feature a specific configuration where cylinders are arranged in two banks of three cylinders each, forming a V-shape. This design offers a balance between power output and compact size, making it suitable for various vehicle applications. The V-angle between cylinder banks affects engine balance, vibration characteristics, and overall performance. Modern V6 designs incorporate advanced features to optimize power delivery while maintaining fuel efficiency.

- Cooling and Thermal Management Systems: Specialized cooling systems are essential for V6 engines to maintain optimal operating temperatures. These systems include water jackets, coolant circulation pathways, and thermal management components designed specifically for the V6 configuration. Advanced cooling solutions address the unique thermal challenges of the V-shaped cylinder arrangement, preventing hotspots and ensuring consistent performance across all cylinders while extending engine lifespan.

- Intake and Exhaust Innovations: Innovative intake and exhaust systems for V6 engines optimize airflow and combustion efficiency. These include variable intake manifolds, advanced exhaust headers designed for the V-configuration, and integrated catalytic converters. Such systems are engineered to enhance power output, reduce emissions, and improve fuel economy by maximizing the volumetric efficiency of the engine while meeting increasingly stringent environmental regulations.

- Lubrication Systems for V6 Engines: Specialized lubrication systems are developed for V6 engines to ensure proper oil distribution across all moving components. These systems feature optimized oil passages, pressure regulation mechanisms, and oil pump designs tailored to the V6 configuration. Advanced lubrication solutions address the unique challenges of lubricating components in the V-arrangement, reducing friction and wear while extending engine durability under various operating conditions.

- V6 Engine Performance Enhancements: Various technologies are employed to enhance V6 engine performance, including turbocharging, direct injection, variable valve timing, and cylinder deactivation systems. These advancements allow V6 engines to deliver power comparable to larger displacement engines while maintaining better fuel efficiency. Performance enhancements also include electronic control systems that optimize combustion parameters in real-time based on driving conditions and demands.

02 Cooling and Thermal Management Systems

Advanced cooling systems for V6 engines incorporate innovative thermal management solutions to maintain optimal operating temperatures. These systems include specialized coolant circulation paths, temperature-controlled valves, and efficient heat exchangers. Proper thermal management improves engine efficiency, reduces emissions, and extends engine life by preventing overheating during high-performance operation.Expand Specific Solutions03 Intake and Exhaust Optimization

Optimized intake and exhaust systems for V6 engines enhance airflow dynamics to improve combustion efficiency and power output. These innovations include variable geometry intake manifolds, advanced exhaust gas recirculation systems, and precision-engineered exhaust headers. Such optimizations contribute to increased horsepower, improved torque characteristics, and reduced emissions.Expand Specific Solutions04 Fuel Efficiency and Emission Control

Modern V6 engines incorporate technologies focused on improving fuel efficiency and reducing emissions. These include direct fuel injection systems, variable valve timing, cylinder deactivation, and advanced combustion chamber designs. Such innovations help meet stringent emission standards while maintaining performance characteristics expected from V6 engines.Expand Specific Solutions05 Integration with Hybrid and Electric Systems

V6 engines are increasingly being integrated with hybrid and electric propulsion systems to create more efficient powertrains. These hybrid V6 configurations combine internal combustion with electric motors to provide improved fuel economy and reduced emissions while maintaining performance capabilities. The integration includes sophisticated control systems that optimize power distribution between conventional and electric power sources.Expand Specific Solutions

Key Industry Players in Engine Conversion Technology

The alternative fuel adaptation for V6 engines market is currently in a growth phase, with increasing regulatory pressure and sustainability goals driving innovation. The market size is expanding rapidly, projected to reach significant scale as automotive manufacturers transition from traditional fuels. In terms of technical maturity, established players like Ford Global Technologies, GM Global Technology Operations, and Caterpillar have made substantial advancements in flex-fuel and bi-fuel systems. European manufacturers including BMW, Bosch, and FEV Europe are focusing on hydrogen compatibility, while Chinese companies such as Chery Automobile, China FAW, and Weichai Power are investing heavily in alternative fuel adaptation technologies. Specialized firms like ICOM North America have developed proprietary solutions specifically for propane autogas conversion of conventional V6 engines, indicating a diversifying technological landscape.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive V6 engine adaptation system for alternative fuels, particularly focusing on flex-fuel technology that allows engines to run on ethanol blends up to E85. Their system incorporates advanced fuel injection mapping and variable valve timing specifically calibrated for alternative fuels. Ford's EcoBoost V6 platform has been modified with corrosion-resistant fuel system components and specialized fuel sensors that can detect ethanol content and adjust combustion parameters accordingly. The company has implemented dual-fuel injection systems in some V6 models, combining port and direct injection to optimize performance across different fuel types. Ford's adaptive technology includes modified engine control units (ECUs) with sophisticated algorithms that continuously adjust ignition timing, air-fuel ratios, and turbocharger boost pressure based on the detected fuel composition, ensuring optimal performance regardless of the fuel being used.

Strengths: Ford's system offers excellent fuel flexibility without compromising performance, with seamless switching between conventional and alternative fuels. Their extensive dealer network provides strong support for alternative fuel vehicles. Weaknesses: The technology adds complexity and cost to the engine system, and high ethanol blends still result in some fuel economy reduction compared to gasoline.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered a multi-fuel adaptation system for their V6 engines that enables operation on various alternative fuels including ethanol, compressed natural gas (CNG), and propane. Their technology centers around a flexible fuel management system with specialized fuel injectors capable of handling different fuel properties and energy densities. GM's V6 engines feature hardened valve seats and specialized piston rings designed to withstand the unique combustion characteristics of alternative fuels. The company has developed an integrated fuel recognition system that automatically identifies the fuel type and blend ratio, then dynamically adjusts combustion parameters for optimal performance and emissions control. GM's approach includes cylinder deactivation technology that works in conjunction with alternative fuels to maximize efficiency, particularly important when using lower energy density fuels like ethanol. Their V6 engines incorporate dual-path intake systems that optimize air-fuel mixing for different fuel types, ensuring consistent performance across various alternative fuels.

Strengths: GM's system offers true multi-fuel capability beyond just ethanol, with robust components designed specifically for alternative fuel use. Their cylinder deactivation technology helps mitigate efficiency losses when using alternative fuels. Weaknesses: The complex fuel detection and management systems add cost and potential maintenance issues, and CNG/propane conversions require additional onboard storage systems that reduce cargo space.

Critical Patents in Alternative Fuel Engine Adaptation

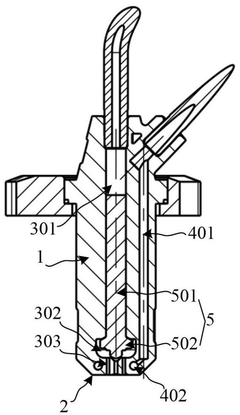

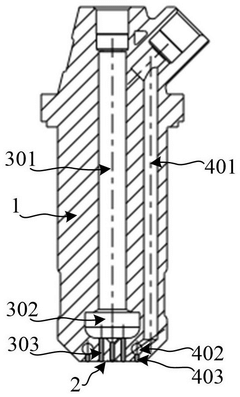

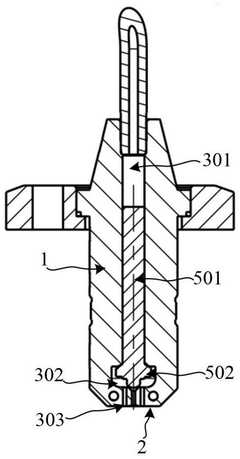

Air-assisted alternative fuel injection device, multi-point injection engine and operation method

PatentPendingCN120402271A

Innovation

- The gas-assisted alternative fuel injection device is adopted, and the high-temperature gas channel and alternative fuel channel are designed to break the droplets through high-temperature gas auxiliary injection and heat and vaporize, forming multi-point injection to improve mixing uniformity.

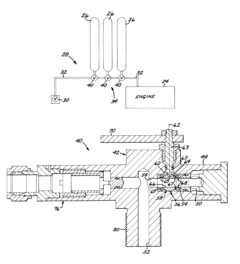

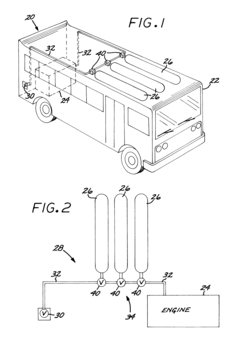

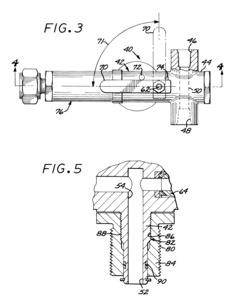

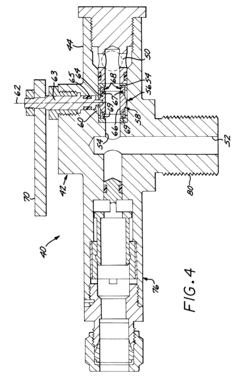

Alternative fuels vehicle and fuel-system valve used therein

PatentInactiveUS6439334B1

Innovation

- A ball valve design with a rotatable handle allowing 1/4 turn operation between open and closed positions, featuring a large-diameter diametral passage for high flow rates, visual indication of valve status, and an optional rotatable coupling for convenient orientation within confined spaces, ensuring safety and ease of use by untrained operators.

Environmental Impact Assessment

The adaptation of V6 engines to alternative fuels presents significant environmental implications that must be thoroughly assessed. Traditional V6 engines running on fossil fuels contribute substantially to greenhouse gas emissions, particularly carbon dioxide, nitrogen oxides, and particulate matter. By transitioning to alternative fuels such as ethanol, biodiesel, hydrogen, or compressed natural gas (CNG), these environmental impacts can be considerably reduced.

Ethanol-adapted V6 engines demonstrate a 20-30% reduction in carbon dioxide emissions compared to their gasoline counterparts, though nitrogen oxide emissions may increase slightly without proper calibration. Biodiesel adaptations show promising results with up to 78% reduction in lifecycle carbon emissions and significantly lower sulfur emissions, addressing critical air quality concerns in urban environments.

Hydrogen fuel adaptations represent the most dramatic environmental improvement, producing only water vapor as exhaust, effectively eliminating carbon emissions at the point of use. However, the environmental footprint of hydrogen production must be considered in lifecycle assessments, as current production methods often rely on natural gas reforming with significant carbon implications.

CNG adaptations offer immediate environmental benefits with 20-30% lower carbon dioxide emissions and substantially reduced particulate matter compared to gasoline. These adaptations also minimize soil and water contamination risks associated with fuel spills, as natural gas dissipates rather than contaminating groundwater.

The environmental assessment must also consider manufacturing impacts of adaptation components. Specialized fuel injectors, modified intake systems, and corrosion-resistant materials required for alternative fuel compatibility may initially increase the carbon footprint of engine production, though these impacts are typically offset by operational emission reductions within 1-3 years of vehicle operation.

Noise pollution represents another environmental consideration, with ethanol and biodiesel adaptations maintaining similar acoustic profiles to conventional fuels, while hydrogen and CNG adaptations often demonstrate measurable reductions in engine noise due to more complete combustion characteristics and different combustion pressures.

Long-term environmental sustainability must account for resource availability and land use impacts, particularly for biofuels that may compete with food production or contribute to deforestation if not properly managed. A comprehensive environmental impact assessment therefore requires full lifecycle analysis from fuel production through engine operation to eventual recycling of adaptation components.

Ethanol-adapted V6 engines demonstrate a 20-30% reduction in carbon dioxide emissions compared to their gasoline counterparts, though nitrogen oxide emissions may increase slightly without proper calibration. Biodiesel adaptations show promising results with up to 78% reduction in lifecycle carbon emissions and significantly lower sulfur emissions, addressing critical air quality concerns in urban environments.

Hydrogen fuel adaptations represent the most dramatic environmental improvement, producing only water vapor as exhaust, effectively eliminating carbon emissions at the point of use. However, the environmental footprint of hydrogen production must be considered in lifecycle assessments, as current production methods often rely on natural gas reforming with significant carbon implications.

CNG adaptations offer immediate environmental benefits with 20-30% lower carbon dioxide emissions and substantially reduced particulate matter compared to gasoline. These adaptations also minimize soil and water contamination risks associated with fuel spills, as natural gas dissipates rather than contaminating groundwater.

The environmental assessment must also consider manufacturing impacts of adaptation components. Specialized fuel injectors, modified intake systems, and corrosion-resistant materials required for alternative fuel compatibility may initially increase the carbon footprint of engine production, though these impacts are typically offset by operational emission reductions within 1-3 years of vehicle operation.

Noise pollution represents another environmental consideration, with ethanol and biodiesel adaptations maintaining similar acoustic profiles to conventional fuels, while hydrogen and CNG adaptations often demonstrate measurable reductions in engine noise due to more complete combustion characteristics and different combustion pressures.

Long-term environmental sustainability must account for resource availability and land use impacts, particularly for biofuels that may compete with food production or contribute to deforestation if not properly managed. A comprehensive environmental impact assessment therefore requires full lifecycle analysis from fuel production through engine operation to eventual recycling of adaptation components.

Supply Chain Considerations

The adaptation of V6 engines to alternative fuels necessitates a comprehensive evaluation of supply chain implications. Traditional petroleum-based fuel supply chains have been optimized over decades, while alternative fuel supply networks remain in various stages of development. This disparity creates significant challenges for manufacturers considering engine modifications.

Raw material sourcing represents a primary concern when transitioning to alternative fuels. Biofuels require agricultural feedstocks that compete with food production, potentially causing price volatility and supply uncertainties. Hydrogen fuel systems demand rare metals for fuel cells and storage solutions, creating potential bottlenecks in scaling production. Synthetic fuels require specialized production facilities that currently exist in limited numbers globally.

Distribution infrastructure presents another critical consideration. While petroleum products benefit from extensive global distribution networks, alternative fuels often lack comparable infrastructure. Hydrogen requires specialized high-pressure transportation and storage systems, while certain biofuels may be incompatible with existing pipelines due to corrosive properties or water absorption tendencies. These limitations necessitate significant investment in new distribution channels.

Manufacturing adaptations also impact supply chains substantially. Engine components designed for traditional fuels may require different materials or manufacturing processes when exposed to alternative fuels. For instance, ethanol's corrosive properties necessitate different sealing materials and fuel system components. This requires retraining of workforce, retooling of production lines, and development of new supplier relationships.

Regional availability variations further complicate supply chain planning. Alternative fuel production often depends on local resources and policies, creating geographic disparities in availability. Engine manufacturers must consider these regional differences when designing adaptable V6 engines, potentially requiring multiple fuel system configurations to accommodate market-specific fuel availability.

Cost structures throughout the supply chain differ significantly between traditional and alternative fuels. While petroleum benefits from economies of scale and established infrastructure, alternative fuels often face higher production costs and distribution expenses. These cost differentials impact pricing strategies and may necessitate government incentives or subsidies to achieve market competitiveness during transition periods.

Regulatory compliance adds another layer of complexity to supply chain considerations. Different regions maintain varying standards for alternative fuel quality, blending requirements, and emissions regulations. Engine manufacturers must navigate this regulatory landscape while ensuring consistent performance across markets, often requiring sophisticated supply chain tracking and verification systems.

Raw material sourcing represents a primary concern when transitioning to alternative fuels. Biofuels require agricultural feedstocks that compete with food production, potentially causing price volatility and supply uncertainties. Hydrogen fuel systems demand rare metals for fuel cells and storage solutions, creating potential bottlenecks in scaling production. Synthetic fuels require specialized production facilities that currently exist in limited numbers globally.

Distribution infrastructure presents another critical consideration. While petroleum products benefit from extensive global distribution networks, alternative fuels often lack comparable infrastructure. Hydrogen requires specialized high-pressure transportation and storage systems, while certain biofuels may be incompatible with existing pipelines due to corrosive properties or water absorption tendencies. These limitations necessitate significant investment in new distribution channels.

Manufacturing adaptations also impact supply chains substantially. Engine components designed for traditional fuels may require different materials or manufacturing processes when exposed to alternative fuels. For instance, ethanol's corrosive properties necessitate different sealing materials and fuel system components. This requires retraining of workforce, retooling of production lines, and development of new supplier relationships.

Regional availability variations further complicate supply chain planning. Alternative fuel production often depends on local resources and policies, creating geographic disparities in availability. Engine manufacturers must consider these regional differences when designing adaptable V6 engines, potentially requiring multiple fuel system configurations to accommodate market-specific fuel availability.

Cost structures throughout the supply chain differ significantly between traditional and alternative fuels. While petroleum benefits from economies of scale and established infrastructure, alternative fuels often face higher production costs and distribution expenses. These cost differentials impact pricing strategies and may necessitate government incentives or subsidies to achieve market competitiveness during transition periods.

Regulatory compliance adds another layer of complexity to supply chain considerations. Different regions maintain varying standards for alternative fuel quality, blending requirements, and emissions regulations. Engine manufacturers must navigate this regulatory landscape while ensuring consistent performance across markets, often requiring sophisticated supply chain tracking and verification systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!