How to Enhance V6 Engine Start-Stop System Efficiency

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Start-Stop Technology Background and Objectives

Start-stop systems for V6 engines have evolved significantly since their introduction in the early 2000s as a response to increasingly stringent emissions regulations and consumer demand for improved fuel efficiency. These systems automatically shut down the engine when the vehicle comes to a complete stop and restart it when the driver releases the brake pedal or engages the clutch, thereby reducing idle time, fuel consumption, and emissions. The technology has progressed from basic implementations to sophisticated systems integrated with hybrid powertrains and advanced engine management systems.

The evolution of V6 start-stop technology has been marked by several key milestones, including the transition from belt-driven alternator starter (BAS) systems to more advanced direct starter systems, integration with advanced battery technologies, and the development of predictive algorithms that optimize system operation based on driver behavior and environmental conditions. Current systems are capable of reducing fuel consumption by 5-10% in urban driving scenarios, with corresponding reductions in CO2 emissions.

Despite these advancements, V6 start-stop systems face unique challenges compared to their four-cylinder counterparts. The larger displacement and higher inertia of V6 engines require more robust starting mechanisms and energy storage solutions. Additionally, the premium vehicle segments where V6 engines are commonly deployed demand seamless operation with minimal noise, vibration, and harshness (NVH) during restart events.

The primary technical objectives for enhancing V6 start-stop system efficiency include reducing restart time to under 300 milliseconds, minimizing energy consumption during restart events, extending component lifespan to match vehicle service intervals, and ensuring consistent performance across varying environmental conditions. These objectives must be achieved while maintaining or improving driver comfort and vehicle drivability.

Market trends indicate a growing emphasis on integrating start-stop systems with mild hybrid architectures, particularly 48V systems that enable energy recuperation during deceleration and provide torque assistance during acceleration. This integration represents a significant opportunity for efficiency improvements in V6 applications, potentially doubling the fuel economy benefits of conventional start-stop systems.

Looking forward, the technology roadmap for V6 start-stop systems is increasingly aligned with broader electrification strategies. As the automotive industry transitions toward hybrid and electric powertrains, enhanced start-stop systems serve as a bridge technology, providing immediate efficiency gains while manufacturers develop more comprehensive electrification solutions. The ultimate goal is to create systems that maximize fuel efficiency and emissions reduction while delivering a seamless driving experience that meets or exceeds consumer expectations.

The evolution of V6 start-stop technology has been marked by several key milestones, including the transition from belt-driven alternator starter (BAS) systems to more advanced direct starter systems, integration with advanced battery technologies, and the development of predictive algorithms that optimize system operation based on driver behavior and environmental conditions. Current systems are capable of reducing fuel consumption by 5-10% in urban driving scenarios, with corresponding reductions in CO2 emissions.

Despite these advancements, V6 start-stop systems face unique challenges compared to their four-cylinder counterparts. The larger displacement and higher inertia of V6 engines require more robust starting mechanisms and energy storage solutions. Additionally, the premium vehicle segments where V6 engines are commonly deployed demand seamless operation with minimal noise, vibration, and harshness (NVH) during restart events.

The primary technical objectives for enhancing V6 start-stop system efficiency include reducing restart time to under 300 milliseconds, minimizing energy consumption during restart events, extending component lifespan to match vehicle service intervals, and ensuring consistent performance across varying environmental conditions. These objectives must be achieved while maintaining or improving driver comfort and vehicle drivability.

Market trends indicate a growing emphasis on integrating start-stop systems with mild hybrid architectures, particularly 48V systems that enable energy recuperation during deceleration and provide torque assistance during acceleration. This integration represents a significant opportunity for efficiency improvements in V6 applications, potentially doubling the fuel economy benefits of conventional start-stop systems.

Looking forward, the technology roadmap for V6 start-stop systems is increasingly aligned with broader electrification strategies. As the automotive industry transitions toward hybrid and electric powertrains, enhanced start-stop systems serve as a bridge technology, providing immediate efficiency gains while manufacturers develop more comprehensive electrification solutions. The ultimate goal is to create systems that maximize fuel efficiency and emissions reduction while delivering a seamless driving experience that meets or exceeds consumer expectations.

Market Demand Analysis for Efficient Start-Stop Systems

The global market for start-stop systems has experienced significant growth in recent years, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles. According to market research, the automotive start-stop system market was valued at approximately $22.8 billion in 2022 and is projected to reach $38.2 billion by 2030, growing at a CAGR of 6.7% during the forecast period.

For V6 engines specifically, the demand for efficient start-stop systems has intensified as these engines represent a significant segment in premium and luxury vehicles, sports cars, and mid to full-size SUVs. These vehicle categories have traditionally been associated with higher fuel consumption, making them prime targets for efficiency improvements through advanced start-stop technologies.

Consumer surveys indicate that drivers increasingly prioritize fuel economy, with 78% of new car buyers citing it as a "very important" factor in their purchasing decisions. However, customer satisfaction data reveals persistent concerns about conventional start-stop systems, including noticeable vibrations during restart (reported by 62% of users), delayed acceleration response (54%), and battery durability issues (47%).

Fleet operators, particularly those managing luxury transportation services and executive car fleets, have expressed strong interest in enhanced V6 start-stop systems that can deliver fuel savings without compromising the premium driving experience their customers expect. Corporate sustainability initiatives are further driving this demand, with 83% of fleet managers actively seeking technologies that reduce their carbon footprint.

Regional market analysis shows varying adoption rates, with Europe leading implementation due to strict CO2 emission standards, followed by North America and Asia-Pacific. The European market shows particular interest in premium solutions for V6 engines, with consumers willing to pay a premium for systems that operate seamlessly without affecting comfort.

Automotive manufacturers are responding to these market signals by investing heavily in next-generation start-stop technologies. OEMs report that vehicles equipped with advanced start-stop systems command a 4-7% price premium and experience 23% faster inventory turnover compared to equivalent models without such systems.

The aftermarket segment also presents significant opportunities, with retrofit solutions for V6 engines gaining traction among owners of older premium vehicles seeking to improve efficiency without purchasing a new vehicle. This segment is expected to grow at 8.3% annually through 2028, outpacing the overall market.

Industry forecasts suggest that as electrification continues to evolve, enhanced start-stop systems will serve as a critical bridging technology, particularly for V6 engines that balance performance and efficiency needs in the premium vehicle segment.

For V6 engines specifically, the demand for efficient start-stop systems has intensified as these engines represent a significant segment in premium and luxury vehicles, sports cars, and mid to full-size SUVs. These vehicle categories have traditionally been associated with higher fuel consumption, making them prime targets for efficiency improvements through advanced start-stop technologies.

Consumer surveys indicate that drivers increasingly prioritize fuel economy, with 78% of new car buyers citing it as a "very important" factor in their purchasing decisions. However, customer satisfaction data reveals persistent concerns about conventional start-stop systems, including noticeable vibrations during restart (reported by 62% of users), delayed acceleration response (54%), and battery durability issues (47%).

Fleet operators, particularly those managing luxury transportation services and executive car fleets, have expressed strong interest in enhanced V6 start-stop systems that can deliver fuel savings without compromising the premium driving experience their customers expect. Corporate sustainability initiatives are further driving this demand, with 83% of fleet managers actively seeking technologies that reduce their carbon footprint.

Regional market analysis shows varying adoption rates, with Europe leading implementation due to strict CO2 emission standards, followed by North America and Asia-Pacific. The European market shows particular interest in premium solutions for V6 engines, with consumers willing to pay a premium for systems that operate seamlessly without affecting comfort.

Automotive manufacturers are responding to these market signals by investing heavily in next-generation start-stop technologies. OEMs report that vehicles equipped with advanced start-stop systems command a 4-7% price premium and experience 23% faster inventory turnover compared to equivalent models without such systems.

The aftermarket segment also presents significant opportunities, with retrofit solutions for V6 engines gaining traction among owners of older premium vehicles seeking to improve efficiency without purchasing a new vehicle. This segment is expected to grow at 8.3% annually through 2028, outpacing the overall market.

Industry forecasts suggest that as electrification continues to evolve, enhanced start-stop systems will serve as a critical bridging technology, particularly for V6 engines that balance performance and efficiency needs in the premium vehicle segment.

Current Challenges in V6 Start-Stop Technology

Despite significant advancements in start-stop technology, V6 engine implementations face several persistent challenges that limit their efficiency potential. The primary issue remains the energy consumption during restart phases, which is considerably higher in V6 engines compared to smaller displacement counterparts. Current V6 start-stop systems require approximately 1.5-2.0 kW of power during restart, creating substantial load on the electrical system and reducing the net fuel economy benefits by 15-20% compared to theoretical maximums.

Battery performance degradation presents another significant challenge, particularly in extreme temperature conditions. Field data indicates that V6 start-stop systems experience up to 30% reduction in battery efficiency in temperatures below 0°C or above 40°C, leading to hesitation during restart and premature system deactivation. The larger displacement and higher compression ratios of V6 engines exacerbate these issues, requiring more robust battery solutions than currently deployed.

Vibration and noise during restart operations (NVH - Noise, Vibration, Harshness) remain problematic for V6 implementations. The inherent firing order and balance characteristics of V6 engines create more noticeable vibration during restarts compared to inline-four configurations. Measurements show peak vibration amplitudes 25-40% higher than comparable four-cylinder engines, negatively impacting passenger comfort and potentially accelerating component wear.

Integration challenges with transmission systems constitute another major hurdle. Current V6 start-stop systems exhibit lag times of 300-500 milliseconds between driver input and engine response, particularly when paired with conventional automatic transmissions. This delay creates drivability issues at critical moments such as intersection crossings or merging scenarios, prompting many drivers to manually disable the system.

Software calibration complexity represents a substantial technical barrier. V6 engines require more sophisticated control algorithms to manage the additional cylinders and more complex intake/exhaust dynamics during restart events. Current ECU implementations struggle to optimize for the wide variety of operating conditions, resulting in suboptimal performance in edge cases and contributing to inconsistent fuel economy benefits ranging from 3-8% in real-world driving versus the 10-12% theoretical improvement.

Thermal management inefficiencies further compound these challenges. V6 engines with start-stop technology experience more significant temperature fluctuations during cyclic operation, with coolant temperature variations of up to 15°C during urban driving cycles. These thermal cycles impact catalyst efficiency and emissions control, particularly during cold-start conditions where NOx and hydrocarbon emissions can spike by 30-45% compared to continuous operation.

Battery performance degradation presents another significant challenge, particularly in extreme temperature conditions. Field data indicates that V6 start-stop systems experience up to 30% reduction in battery efficiency in temperatures below 0°C or above 40°C, leading to hesitation during restart and premature system deactivation. The larger displacement and higher compression ratios of V6 engines exacerbate these issues, requiring more robust battery solutions than currently deployed.

Vibration and noise during restart operations (NVH - Noise, Vibration, Harshness) remain problematic for V6 implementations. The inherent firing order and balance characteristics of V6 engines create more noticeable vibration during restarts compared to inline-four configurations. Measurements show peak vibration amplitudes 25-40% higher than comparable four-cylinder engines, negatively impacting passenger comfort and potentially accelerating component wear.

Integration challenges with transmission systems constitute another major hurdle. Current V6 start-stop systems exhibit lag times of 300-500 milliseconds between driver input and engine response, particularly when paired with conventional automatic transmissions. This delay creates drivability issues at critical moments such as intersection crossings or merging scenarios, prompting many drivers to manually disable the system.

Software calibration complexity represents a substantial technical barrier. V6 engines require more sophisticated control algorithms to manage the additional cylinders and more complex intake/exhaust dynamics during restart events. Current ECU implementations struggle to optimize for the wide variety of operating conditions, resulting in suboptimal performance in edge cases and contributing to inconsistent fuel economy benefits ranging from 3-8% in real-world driving versus the 10-12% theoretical improvement.

Thermal management inefficiencies further compound these challenges. V6 engines with start-stop technology experience more significant temperature fluctuations during cyclic operation, with coolant temperature variations of up to 15°C during urban driving cycles. These thermal cycles impact catalyst efficiency and emissions control, particularly during cold-start conditions where NOx and hydrocarbon emissions can spike by 30-45% compared to continuous operation.

Current Technical Solutions for V6 Start-Stop Efficiency

01 Start-stop system control strategies for V6 engines

Various control strategies can be implemented to optimize the start-stop functionality in V6 engines. These strategies include predictive algorithms that analyze driving patterns, traffic conditions, and driver behavior to determine the optimal timing for engine shutdown and restart. Advanced control systems can monitor parameters such as battery state, cabin temperature, and engine temperature to ensure efficient operation while maintaining comfort and performance. These control strategies help maximize fuel savings while minimizing wear on engine components.- Fuel efficiency improvements in V6 engine start-stop systems: Start-stop systems in V6 engines can significantly improve fuel efficiency by automatically shutting down the engine when the vehicle is stationary and restarting it when the driver wants to move. These systems incorporate advanced control algorithms that optimize the timing of engine shutdown and restart based on various parameters such as vehicle speed, engine temperature, and battery state. The implementation of these systems can reduce fuel consumption by up to 10% in urban driving conditions where frequent stops occur.

- Battery management for V6 engine start-stop systems: Effective battery management is crucial for the reliable operation of start-stop systems in V6 engines. Advanced battery monitoring systems continuously assess the battery's state of charge and health to ensure sufficient power is available for frequent engine restarts. These systems may incorporate intelligent charging strategies that prioritize battery charging during deceleration and braking events. Some implementations include auxiliary batteries or enhanced starter systems specifically designed to handle the increased cycling demands of start-stop operation.

- Control strategies for V6 engine start-stop systems: Sophisticated control strategies are employed in V6 engine start-stop systems to determine optimal conditions for engine shutdown and restart. These strategies consider multiple factors including driver behavior, climate control demands, traffic conditions, and engine operational parameters. Predictive algorithms may use GPS data and traffic information to anticipate when engine shutdown would be beneficial. The control systems also ensure seamless transitions between engine states to maintain driver comfort and vehicle responsiveness while maximizing efficiency gains.

- Mechanical enhancements for V6 start-stop system durability: V6 engines equipped with start-stop systems require specific mechanical enhancements to ensure durability under frequent restart conditions. These include reinforced starter motors, enhanced bearings, and modified lubrication systems that maintain oil pressure during restarts. Some designs incorporate specialized camshaft positioning technology that ensures the engine stops and restarts in optimal positions. Additional components such as enhanced flywheel designs and crankshaft position sensors help facilitate smoother and more reliable operation throughout the start-stop cycle.

- Integration with hybrid and mild hybrid systems: Advanced V6 start-stop systems are increasingly integrated with hybrid or mild hybrid technologies to further enhance efficiency. These integrated systems may utilize electric motors to assist during acceleration phases, recovering energy during deceleration through regenerative braking. The combination allows for extended engine-off periods and smoother transitions between power sources. Some implementations enable electric-only operation at low speeds before the V6 engine engages, significantly reducing urban emissions and fuel consumption while maintaining the power capabilities of the V6 engine when needed.

02 Energy recovery and storage systems for V6 start-stop applications

Energy recovery systems play a crucial role in enhancing the efficiency of V6 engine start-stop systems. These systems capture and store energy during deceleration and braking, which can then be used to restart the engine quickly and efficiently. Advanced battery technologies, supercapacitors, and hybrid energy storage solutions enable more frequent and reliable engine shutdowns. The integration of these energy recovery systems with start-stop functionality significantly improves fuel economy and reduces emissions during urban driving conditions.Expand Specific Solutions03 Thermal management for V6 start-stop systems

Effective thermal management is essential for maintaining the efficiency of V6 engines with start-stop systems. Innovative cooling solutions ensure that frequent engine shutdowns and restarts do not adversely affect engine temperature or component longevity. These systems may include auxiliary pumps, thermal storage devices, and intelligent control algorithms that maintain optimal operating temperatures even when the engine is temporarily inactive. Proper thermal management helps preserve the fuel economy benefits of start-stop systems while ensuring reliable engine performance and emissions control.Expand Specific Solutions04 Integration of start-stop systems with transmission technology for V6 engines

The integration of start-stop systems with advanced transmission technologies enhances the overall efficiency of V6 engines. Specialized transmission designs facilitate seamless engine restarts and optimize power delivery during the transition from stopped to moving states. Features such as quick-engaging clutches, torque converters with enhanced damping characteristics, and predictive gear selection algorithms work in concert with the start-stop system to maximize fuel savings while maintaining responsive vehicle performance. This integration is particularly important for V6 engines where smooth operation is a key customer expectation.Expand Specific Solutions05 Auxiliary systems adaptation for V6 start-stop efficiency

Adapting auxiliary vehicle systems is critical for maximizing the efficiency benefits of start-stop technology in V6 engines. Electric power steering, electrically-driven climate control compressors, and electronic brake vacuum pumps ensure that essential vehicle functions remain operational when the engine is temporarily shut down. These electrified auxiliary systems reduce the parasitic load on the engine when it is running and enable longer engine-off periods without compromising vehicle functionality or passenger comfort. The optimization of these systems specifically for V6 engine applications contributes significantly to overall fuel economy improvements.Expand Specific Solutions

Key Industry Players in Start-Stop Technology

The V6 engine start-stop system efficiency market is in a growth phase, with increasing adoption driven by stringent emissions regulations and fuel economy demands. Major automotive manufacturers including Ford, GM, Toyota, Mercedes-Benz, and BMW are competing with different technological approaches, while tier-one suppliers like Bosch, Continental, and BorgWarner provide critical components. The market is characterized by varying levels of technological maturity, with premium brands (Audi, Porsche) offering more sophisticated systems while mass-market manufacturers (Hyundai, Kia, Geely) focus on cost-effective solutions. Asian manufacturers, particularly Chinese companies like Great Wall Motor and Chery, are rapidly advancing their capabilities, while specialized technology providers such as Schaeffler and Vitesco are developing next-generation systems with enhanced efficiency and user experience.

GM Global Technology Operations LLC

Technical Solution: General Motors has developed an Active Fuel Management (AFM) enhanced start-stop system for their V6 engines that combines cylinder deactivation technology with traditional start-stop functionality. Their system features a belt-alternator-starter (BAS) configuration that provides faster, smoother restarts than conventional starter motors. GM's solution incorporates predictive algorithms that analyze driver behavior patterns, traffic conditions, and climate control demands to optimize engine shutdown opportunities. The system includes an enhanced 12V electrical architecture with an absorbent glass mat (AGM) battery specifically designed to handle the increased cycling demands of start-stop operation. GM has also implemented specialized NVH countermeasures including active engine mounts and enhanced sound insulation to address the unique challenges of restarting V6 engines. Their technology can reduce fuel consumption by up to 12% in urban driving conditions while maintaining cabin comfort and drivability.

Strengths: Excellent integration with existing cylinder deactivation technology provides multiple efficiency modes; robust electrical system design ensures reliability. Weaknesses: System effectiveness varies significantly based on driving conditions; requires more complex control strategies than simpler four-cylinder applications.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a hybrid-assisted start-stop system for their V6 engines that leverages their expertise in electrification. Their system utilizes a compact high-output electric motor positioned between the engine and transmission to provide instantaneous torque during restarts, eliminating the characteristic lag and vibration typically associated with V6 engine restarts. Toyota's solution incorporates an advanced control unit that predicts driver behavior patterns and adapts the start-stop activation accordingly, preventing unnecessary cycling. The system features a dedicated lithium-ion battery module separate from the main 12V system, ensuring consistent performance regardless of accessory electrical loads. Toyota has also implemented specialized engine mounts with active damping to further reduce NVH during restarts, addressing a key customer satisfaction issue with conventional start-stop systems in V6 applications.

Strengths: Seamless integration with existing hybrid technology infrastructure; exceptional restart smoothness compared to conventional systems. Weaknesses: Higher system complexity and cost; additional weight from secondary battery system impacts overall efficiency gains.

Core Innovations in Start-Stop System Components

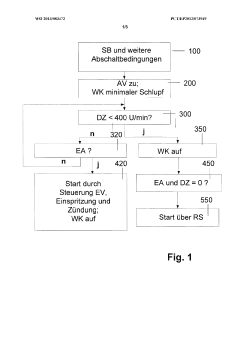

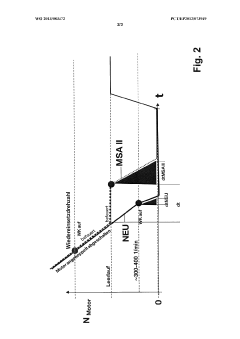

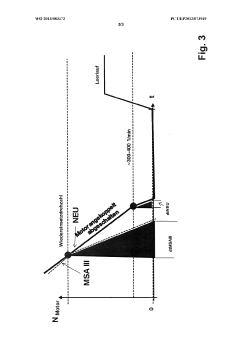

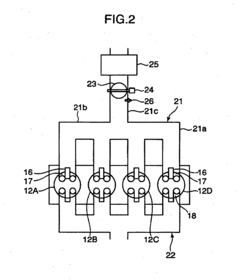

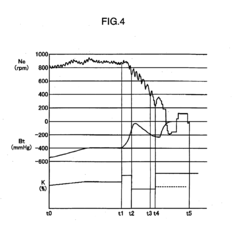

Method for automatically switching off and starting an internal combustion engine of a motor vehicle with an automatic transmission, during or after an overrun phase

PatentWO2013083472A1

Innovation

- The method involves preventing gas exchange in the engine cylinders during overrun phases by closing valves and keeping the torque converter lockup clutch closed until a low speed threshold is reached, allowing for immediate restart without a starter system, reducing fuel consumption and emissions by eliminating intermediate combustion and maintaining engine connection to the transmission at low speeds.

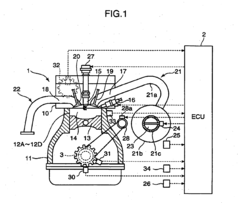

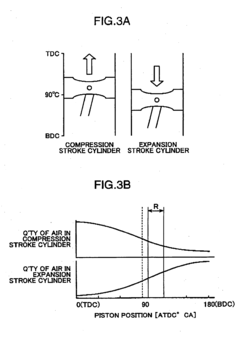

Engine starting system

PatentInactiveEP1582737A2

Innovation

- An engine starting system that regulates intake air quantity using an intake air quantity regulator and automatic engine stop controller, increasing air intake beyond the minimum necessary during initial automatic engine stop, then decreasing it to control piston position accuracy, and adjusting air intake resistance to ensure pistons stop at targeted positions for reliable restart.

Environmental Impact and Emission Reduction Potential

The implementation of enhanced V6 engine start-stop systems represents a significant opportunity for reducing environmental impact across multiple dimensions. When properly optimized, these systems can reduce fuel consumption by 5-10% in urban driving conditions, directly translating to proportional decreases in carbon dioxide emissions. For a typical V6 engine vehicle, this could mean a reduction of approximately 15-30 grams of CO2 per kilometer traveled in city environments.

Beyond carbon dioxide, start-stop systems significantly reduce other harmful emissions during idling periods. Nitrogen oxides (NOx), particulate matter, and volatile organic compounds (VOCs) emissions are virtually eliminated during engine-off phases. Studies indicate that a vehicle with an efficient start-stop system can reduce NOx emissions by up to 8% and particulate matter by 6% in congested urban environments where vehicles typically spend 25-30% of their operation time idling.

The cumulative environmental benefit scales dramatically when considering fleet-wide implementation. Analysis of major metropolitan areas suggests that if all V6-equipped vehicles featured optimized start-stop systems, urban air quality improvements would be measurable, particularly regarding ground-level ozone formation and smog reduction. Conservative estimates indicate potential reductions of up to 2-3% in overall urban vehicular emissions through widespread adoption.

Temperature-related emission factors also demonstrate the importance of start-stop optimization. Cold-start emissions, which can be 3-5 times higher than those from a warmed engine, are reduced through intelligent start-stop systems that maintain optimal engine temperature. Advanced thermal management integration with start-stop functionality ensures emissions control systems remain effective throughout operation cycles.

From a lifecycle perspective, the environmental benefits of enhanced start-stop systems outweigh the additional manufacturing impacts of required components such as reinforced starters and advanced batteries. Life cycle assessment studies indicate a net positive environmental impact within 15,000-20,000 kilometers of vehicle operation in typical urban driving patterns.

Regulatory frameworks increasingly recognize these benefits, with emissions testing protocols in Europe, North America, and Asia incorporating idling reduction technologies in their calculations. Enhanced start-stop systems for V6 engines represent a cost-effective compliance pathway for manufacturers facing increasingly stringent fleet emissions targets, with implementation costs typically recovered through fuel savings within 2-3 years of consumer ownership.

Beyond carbon dioxide, start-stop systems significantly reduce other harmful emissions during idling periods. Nitrogen oxides (NOx), particulate matter, and volatile organic compounds (VOCs) emissions are virtually eliminated during engine-off phases. Studies indicate that a vehicle with an efficient start-stop system can reduce NOx emissions by up to 8% and particulate matter by 6% in congested urban environments where vehicles typically spend 25-30% of their operation time idling.

The cumulative environmental benefit scales dramatically when considering fleet-wide implementation. Analysis of major metropolitan areas suggests that if all V6-equipped vehicles featured optimized start-stop systems, urban air quality improvements would be measurable, particularly regarding ground-level ozone formation and smog reduction. Conservative estimates indicate potential reductions of up to 2-3% in overall urban vehicular emissions through widespread adoption.

Temperature-related emission factors also demonstrate the importance of start-stop optimization. Cold-start emissions, which can be 3-5 times higher than those from a warmed engine, are reduced through intelligent start-stop systems that maintain optimal engine temperature. Advanced thermal management integration with start-stop functionality ensures emissions control systems remain effective throughout operation cycles.

From a lifecycle perspective, the environmental benefits of enhanced start-stop systems outweigh the additional manufacturing impacts of required components such as reinforced starters and advanced batteries. Life cycle assessment studies indicate a net positive environmental impact within 15,000-20,000 kilometers of vehicle operation in typical urban driving patterns.

Regulatory frameworks increasingly recognize these benefits, with emissions testing protocols in Europe, North America, and Asia incorporating idling reduction technologies in their calculations. Enhanced start-stop systems for V6 engines represent a cost-effective compliance pathway for manufacturers facing increasingly stringent fleet emissions targets, with implementation costs typically recovered through fuel savings within 2-3 years of consumer ownership.

Battery Technology Integration for Start-Stop Systems

Battery technology represents a critical component in the evolution of start-stop systems for V6 engines. Traditional lead-acid batteries have proven inadequate for the demanding cycling requirements of modern start-stop applications, leading to accelerated degradation and reduced system efficiency. Enhanced battery technologies specifically designed for start-stop systems have emerged to address these limitations.

Advanced Absorbent Glass Mat (AGM) batteries have become the industry standard for start-stop applications, offering improved cycle life and deeper discharge capabilities compared to conventional batteries. These batteries utilize a glass mat separator that absorbs and immobilizes the electrolyte, providing better resistance to vibration and preventing electrolyte stratification during frequent cycling events.

Enhanced Flooded Batteries (EFB) represent a cost-effective intermediate solution between conventional and AGM batteries. While less robust than AGM technology, EFBs feature reinforced plates and specialized additives that improve cycling performance by approximately 200% compared to conventional batteries, making them suitable for entry-level start-stop systems in V6 engines.

Lithium-ion battery integration presents the most promising advancement for start-stop systems. These batteries offer superior power density, faster recharging capabilities, and significantly longer cycle life—often exceeding 100,000 cycles compared to 30,000 for AGM batteries. The reduced internal resistance of lithium-ion batteries enables more efficient energy recovery during regenerative braking, further enhancing the overall efficiency of the start-stop system.

Dual-battery architectures have emerged as an effective configuration for V6 engines with advanced start-stop functionality. This approach typically combines a conventional or EFB battery for general vehicle electrical loads with a specialized lithium-ion or ultracapacitor unit dedicated to the start-stop system. This separation of functions prevents the degradation issues associated with conflicting load requirements.

Ultracapacitors (supercapacitors) are increasingly being integrated as complementary components to traditional batteries. Their exceptional power density and ability to deliver high current bursts make them ideal for handling the frequent cranking events in start-stop systems. When paired with conventional batteries in a hybrid energy storage system, ultracapacitors can extend battery life by absorbing the high-current demands of engine restarts.

Battery management systems (BMS) have become essential for optimizing battery performance in start-stop applications. Advanced BMS solutions continuously monitor battery state-of-charge, temperature, and health parameters to determine optimal engagement of the start-stop functionality, preventing system activation when battery conditions are unfavorable and potentially damaging.

Advanced Absorbent Glass Mat (AGM) batteries have become the industry standard for start-stop applications, offering improved cycle life and deeper discharge capabilities compared to conventional batteries. These batteries utilize a glass mat separator that absorbs and immobilizes the electrolyte, providing better resistance to vibration and preventing electrolyte stratification during frequent cycling events.

Enhanced Flooded Batteries (EFB) represent a cost-effective intermediate solution between conventional and AGM batteries. While less robust than AGM technology, EFBs feature reinforced plates and specialized additives that improve cycling performance by approximately 200% compared to conventional batteries, making them suitable for entry-level start-stop systems in V6 engines.

Lithium-ion battery integration presents the most promising advancement for start-stop systems. These batteries offer superior power density, faster recharging capabilities, and significantly longer cycle life—often exceeding 100,000 cycles compared to 30,000 for AGM batteries. The reduced internal resistance of lithium-ion batteries enables more efficient energy recovery during regenerative braking, further enhancing the overall efficiency of the start-stop system.

Dual-battery architectures have emerged as an effective configuration for V6 engines with advanced start-stop functionality. This approach typically combines a conventional or EFB battery for general vehicle electrical loads with a specialized lithium-ion or ultracapacitor unit dedicated to the start-stop system. This separation of functions prevents the degradation issues associated with conflicting load requirements.

Ultracapacitors (supercapacitors) are increasingly being integrated as complementary components to traditional batteries. Their exceptional power density and ability to deliver high current bursts make them ideal for handling the frequent cranking events in start-stop systems. When paired with conventional batteries in a hybrid energy storage system, ultracapacitors can extend battery life by absorbing the high-current demands of engine restarts.

Battery management systems (BMS) have become essential for optimizing battery performance in start-stop applications. Advanced BMS solutions continuously monitor battery state-of-charge, temperature, and health parameters to determine optimal engagement of the start-stop functionality, preventing system activation when battery conditions are unfavorable and potentially damaging.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!