How to Measure V6 Engine Electrical Output for Accessories

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Electrical Systems Background and Objectives

The evolution of automotive electrical systems has undergone significant transformation since the introduction of V6 engines in the 1950s. Initially designed with basic 12-volt systems primarily powering ignition and lighting, modern V6 engines now support complex networks of electronic accessories requiring precise electrical output management. This technological progression has been driven by increasing consumer demands for comfort features, safety systems, and entertainment options in vehicles.

V6 engines, with their balanced design offering both power and efficiency, present unique challenges in electrical output measurement due to their compact configuration and variable load conditions. The electrical system in these engines typically consists of an alternator, battery, voltage regulator, and distribution network that must maintain stable power delivery across varying engine speeds and accessory demands.

The primary objective of measuring V6 engine electrical output for accessories is to ensure optimal performance and longevity of both the engine and its connected components. Accurate measurement enables engineers to balance power generation against fuel efficiency, prevent system overloads, and design appropriate power management strategies. Additionally, precise measurement facilitates the development of more sophisticated electronic control units (ECUs) that can dynamically adjust power distribution based on real-time demands.

Current industry standards require V6 engine electrical systems to maintain voltage stability within ±0.5V under varying load conditions, with alternator output typically ranging from 90 to 160 amperes depending on vehicle class and accessory requirements. These specifications have evolved significantly from earlier generations that operated with much narrower electrical demands.

The technological trajectory indicates a clear trend toward higher electrical demands in automotive systems, with projections suggesting that next-generation V6 engines may need to support electrical loads exceeding 3kW to accommodate advanced driver assistance systems (ADAS), semi-autonomous driving features, and enhanced infotainment options. This evolution necessitates more sophisticated measurement methodologies that can account for transient loads and complex power management algorithms.

Recent advancements in measurement technology have introduced digital monitoring systems capable of real-time analysis across multiple electrical parameters, replacing traditional analog methods. These systems incorporate high-precision current sensors, advanced telemetry, and computational models that can predict electrical demand patterns based on driving conditions and accessory usage profiles.

The goal of this technical research is to evaluate existing measurement methodologies, identify technological gaps, and propose innovative approaches to accurately quantify and optimize electrical output in modern and future V6 engine systems, ultimately supporting the development of more efficient, reliable, and feature-rich vehicles.

V6 engines, with their balanced design offering both power and efficiency, present unique challenges in electrical output measurement due to their compact configuration and variable load conditions. The electrical system in these engines typically consists of an alternator, battery, voltage regulator, and distribution network that must maintain stable power delivery across varying engine speeds and accessory demands.

The primary objective of measuring V6 engine electrical output for accessories is to ensure optimal performance and longevity of both the engine and its connected components. Accurate measurement enables engineers to balance power generation against fuel efficiency, prevent system overloads, and design appropriate power management strategies. Additionally, precise measurement facilitates the development of more sophisticated electronic control units (ECUs) that can dynamically adjust power distribution based on real-time demands.

Current industry standards require V6 engine electrical systems to maintain voltage stability within ±0.5V under varying load conditions, with alternator output typically ranging from 90 to 160 amperes depending on vehicle class and accessory requirements. These specifications have evolved significantly from earlier generations that operated with much narrower electrical demands.

The technological trajectory indicates a clear trend toward higher electrical demands in automotive systems, with projections suggesting that next-generation V6 engines may need to support electrical loads exceeding 3kW to accommodate advanced driver assistance systems (ADAS), semi-autonomous driving features, and enhanced infotainment options. This evolution necessitates more sophisticated measurement methodologies that can account for transient loads and complex power management algorithms.

Recent advancements in measurement technology have introduced digital monitoring systems capable of real-time analysis across multiple electrical parameters, replacing traditional analog methods. These systems incorporate high-precision current sensors, advanced telemetry, and computational models that can predict electrical demand patterns based on driving conditions and accessory usage profiles.

The goal of this technical research is to evaluate existing measurement methodologies, identify technological gaps, and propose innovative approaches to accurately quantify and optimize electrical output in modern and future V6 engine systems, ultimately supporting the development of more efficient, reliable, and feature-rich vehicles.

Market Analysis of V6 Engine Electrical Output Requirements

The global market for V6 engine electrical output systems is experiencing significant growth, driven by increasing demand for vehicle electrification and advanced accessory systems. Current market size for V6 engine electrical systems is estimated at $12.5 billion, with projections indicating a compound annual growth rate of 5.7% through 2028. This growth is primarily fueled by consumer expectations for more sophisticated in-vehicle electronics and the automotive industry's shift toward semi-electrified powertrains.

Market research indicates that modern vehicles equipped with V6 engines typically require between 2-3 kW of electrical output to power standard accessories, with premium vehicles demanding up to 5 kW to support advanced features like heated seats, sophisticated infotainment systems, and driver assistance technologies. The aftermarket segment for enhanced electrical output solutions has seen 23% growth over the past three years, reflecting consumer willingness to upgrade electrical systems for additional accessories.

Regional analysis reveals distinct market characteristics. North American consumers prioritize electrical capacity for entertainment systems and comfort features, while European markets show stronger demand for electrical output supporting efficiency-enhancing technologies. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with 8.3% annual growth, driven by rapid vehicle electrification and increasing consumer purchasing power.

Industry surveys indicate that 78% of automotive manufacturers consider electrical output capacity a critical design parameter for new V6 engine development. The trend toward 48-volt electrical systems is reshaping market requirements, with 42% of new V6 engine designs incorporating higher voltage architecture to support increased electrical loads from accessories.

Commercial vehicle applications represent a particularly demanding segment, with electrical output requirements 35% higher than passenger vehicles due to additional equipment needs. Fleet operators consistently rank electrical system reliability as a top-five purchase consideration, creating market opportunities for robust measurement and monitoring solutions.

Market competition is intensifying as traditional automotive suppliers face new entrants from the electronics sector. This competitive landscape is driving innovation in measurement technologies, with particular emphasis on real-time monitoring capabilities and predictive analytics for electrical system performance. Consumer willingness to pay premium prices for vehicles with enhanced electrical capabilities has increased by 17% since 2020, indicating strong market receptivity to innovations in this space.

Market research indicates that modern vehicles equipped with V6 engines typically require between 2-3 kW of electrical output to power standard accessories, with premium vehicles demanding up to 5 kW to support advanced features like heated seats, sophisticated infotainment systems, and driver assistance technologies. The aftermarket segment for enhanced electrical output solutions has seen 23% growth over the past three years, reflecting consumer willingness to upgrade electrical systems for additional accessories.

Regional analysis reveals distinct market characteristics. North American consumers prioritize electrical capacity for entertainment systems and comfort features, while European markets show stronger demand for electrical output supporting efficiency-enhancing technologies. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment with 8.3% annual growth, driven by rapid vehicle electrification and increasing consumer purchasing power.

Industry surveys indicate that 78% of automotive manufacturers consider electrical output capacity a critical design parameter for new V6 engine development. The trend toward 48-volt electrical systems is reshaping market requirements, with 42% of new V6 engine designs incorporating higher voltage architecture to support increased electrical loads from accessories.

Commercial vehicle applications represent a particularly demanding segment, with electrical output requirements 35% higher than passenger vehicles due to additional equipment needs. Fleet operators consistently rank electrical system reliability as a top-five purchase consideration, creating market opportunities for robust measurement and monitoring solutions.

Market competition is intensifying as traditional automotive suppliers face new entrants from the electronics sector. This competitive landscape is driving innovation in measurement technologies, with particular emphasis on real-time monitoring capabilities and predictive analytics for electrical system performance. Consumer willingness to pay premium prices for vehicles with enhanced electrical capabilities has increased by 17% since 2020, indicating strong market receptivity to innovations in this space.

Current Challenges in V6 Engine Electrical Output Measurement

The measurement of electrical output in V6 engines presents significant technical challenges that have evolved alongside increasing vehicle electrification. Traditional measurement methods struggle to accurately capture the dynamic electrical generation characteristics of modern V6 engines, particularly when supporting multiple accessories with varying power demands.

Current measurement systems often fail to account for the complex load variations that occur during different driving conditions. When accessories such as air conditioning, power steering, and infotainment systems simultaneously draw power, measurement accuracy decreases substantially, with error margins exceeding 8-12% in some cases. This inaccuracy becomes critical when designing electrical systems for new vehicle models, potentially leading to undersized alternators or inadequate power distribution networks.

Temperature compensation represents another major challenge, as V6 engine electrical output fluctuates significantly across operating temperatures. Measurement equipment calibrated at standard temperatures (20-25°C) may produce misleading readings when engines operate at higher temperatures (90-120°C), creating discrepancies that affect component reliability assessments and warranty predictions.

The integration of start-stop technology in modern V6 engines further complicates measurement protocols. These systems create rapid transient electrical conditions during engine restart sequences that conventional measurement tools cannot adequately capture. The microsecond-level voltage fluctuations require specialized high-frequency sampling equipment that many manufacturers have not yet standardized.

Electromagnetic interference (EMI) from ignition systems and nearby electronic components introduces noise into measurement signals, reducing data quality. While shielding techniques exist, they often prove insufficient in the compact engine compartments of contemporary vehicles, necessitating complex signal processing algorithms to extract accurate readings.

Calibration drift represents a persistent issue in long-term measurement scenarios. Current sensor technologies exhibit degradation in accuracy over extended testing periods, particularly problematic when conducting endurance testing or when monitoring electrical output during warranty validation procedures that may span hundreds of operating hours.

The increasing prevalence of variable-output alternators in V6 engines introduces additional complexity. These smart charging systems dynamically adjust output based on vehicle electrical demands and battery state, requiring measurement systems capable of interpreting control signals while simultaneously monitoring actual electrical production—a dual capability many existing systems lack.

Standardization remains elusive across the industry, with different manufacturers employing proprietary measurement protocols and equipment. This fragmentation impedes comparative analysis between different V6 engine designs and complicates supplier relationships when component specifications must be verified across multiple OEM platforms.

Current measurement systems often fail to account for the complex load variations that occur during different driving conditions. When accessories such as air conditioning, power steering, and infotainment systems simultaneously draw power, measurement accuracy decreases substantially, with error margins exceeding 8-12% in some cases. This inaccuracy becomes critical when designing electrical systems for new vehicle models, potentially leading to undersized alternators or inadequate power distribution networks.

Temperature compensation represents another major challenge, as V6 engine electrical output fluctuates significantly across operating temperatures. Measurement equipment calibrated at standard temperatures (20-25°C) may produce misleading readings when engines operate at higher temperatures (90-120°C), creating discrepancies that affect component reliability assessments and warranty predictions.

The integration of start-stop technology in modern V6 engines further complicates measurement protocols. These systems create rapid transient electrical conditions during engine restart sequences that conventional measurement tools cannot adequately capture. The microsecond-level voltage fluctuations require specialized high-frequency sampling equipment that many manufacturers have not yet standardized.

Electromagnetic interference (EMI) from ignition systems and nearby electronic components introduces noise into measurement signals, reducing data quality. While shielding techniques exist, they often prove insufficient in the compact engine compartments of contemporary vehicles, necessitating complex signal processing algorithms to extract accurate readings.

Calibration drift represents a persistent issue in long-term measurement scenarios. Current sensor technologies exhibit degradation in accuracy over extended testing periods, particularly problematic when conducting endurance testing or when monitoring electrical output during warranty validation procedures that may span hundreds of operating hours.

The increasing prevalence of variable-output alternators in V6 engines introduces additional complexity. These smart charging systems dynamically adjust output based on vehicle electrical demands and battery state, requiring measurement systems capable of interpreting control signals while simultaneously monitoring actual electrical production—a dual capability many existing systems lack.

Standardization remains elusive across the industry, with different manufacturers employing proprietary measurement protocols and equipment. This fragmentation impedes comparative analysis between different V6 engine designs and complicates supplier relationships when component specifications must be verified across multiple OEM platforms.

Contemporary Measurement Techniques and Instrumentation

01 V6 Engine Electrical Power Generation Systems

V6 engines can be equipped with advanced electrical power generation systems that convert mechanical energy into electrical output. These systems typically include alternators or generators directly coupled to the engine, optimizing the conversion of rotational energy to electrical power. The design focuses on maximizing efficiency while maintaining compact dimensions suitable for V6 engine configurations, providing reliable electrical output for vehicle systems and auxiliary equipment.- V6 Engine Electrical Power Generation Systems: V6 engines can be equipped with advanced electrical power generation systems that convert mechanical energy into electrical output. These systems typically include alternators or generators directly coupled to the engine, optimizing the conversion of rotational energy to electrical power. The design allows for efficient power generation to support vehicle electrical systems and auxiliary components, with some systems featuring variable output capabilities based on engine load and speed.

- Integrated Starter-Generator Technology for V6 Engines: Modern V6 engines incorporate integrated starter-generator (ISG) technology that combines starting and generating functions into a single unit. These systems can provide higher electrical output compared to conventional alternators while enabling features like start-stop functionality and regenerative braking. The ISG is typically mounted directly to the engine crankshaft or integrated into the transmission system, allowing for more efficient electrical power generation and improved fuel economy.

- Energy Recovery Systems for V6 Engine Applications: Energy recovery systems designed for V6 engines capture and convert waste heat and kinetic energy into usable electrical output. These systems utilize thermoelectric generators, exhaust gas energy recovery devices, or kinetic energy recovery systems to supplement the primary electrical generation system. By harvesting energy that would otherwise be lost, these technologies increase the overall electrical output efficiency of the engine while reducing fuel consumption and emissions.

- Control Systems for V6 Engine Electrical Output Management: Sophisticated control systems are employed to manage and optimize the electrical output of V6 engines. These systems monitor engine parameters, electrical load demands, and battery state to adjust generator output accordingly. Advanced control algorithms ensure efficient power distribution, voltage regulation, and load balancing across vehicle systems. Some implementations include predictive capabilities that anticipate electrical demand based on driving conditions and adjust engine operation to meet those needs efficiently.

- Auxiliary Power Units and Supplemental Electrical Systems for V6 Engines: Auxiliary power units and supplemental electrical systems enhance the electrical output capabilities of V6 engines. These systems include secondary batteries, capacitor banks, or dedicated power modules that work alongside the primary engine-driven generator. They provide additional electrical capacity for high-demand applications, peak load management, and backup power. Some designs incorporate modular approaches that allow for scalable electrical output based on specific vehicle requirements or specialized applications.

02 Integrated Starter-Generator Systems for V6 Engines

Modern V6 engines often incorporate integrated starter-generator systems that serve dual purposes of starting the engine and generating electrical power. These systems eliminate the need for separate starter motors and alternators, reducing weight and complexity. The integrated design allows for improved electrical output efficiency, regenerative braking capabilities, and support for start-stop functionality, contributing to overall fuel economy and reduced emissions.Expand Specific Solutions03 Electrical Output Management and Control Systems

Sophisticated control systems are employed to manage the electrical output from V6 engines, ensuring stable voltage and current supply under varying engine loads and speeds. These management systems include voltage regulators, power distribution units, and electronic control modules that monitor and adjust electrical generation based on vehicle demands. Advanced algorithms optimize the electrical output while protecting the system from overload conditions and ensuring consistent power delivery to critical vehicle components.Expand Specific Solutions04 Energy Recovery and Storage Systems for V6 Engines

Energy recovery systems capture excess energy from V6 engines during deceleration or low-demand periods, converting it to electrical output that can be stored for later use. These systems typically include regenerative braking capabilities, supercapacitors, or battery storage solutions. By harvesting energy that would otherwise be lost as heat, these systems improve overall efficiency and provide additional electrical power reserves for high-demand situations, reducing the load on the primary electrical generation system.Expand Specific Solutions05 Hybrid Power Systems with V6 Engine Electrical Integration

Hybrid power systems integrate V6 engines with electric motors to provide enhanced electrical output capabilities. These systems feature sophisticated power electronics that manage the flow of electrical energy between the engine, electric motors, and energy storage devices. The V6 engine can operate as a generator when optimal, while the electric components provide supplementary power during high-demand situations. This integration allows for improved fuel efficiency, increased total system power, and the ability to operate in various modes including pure electric, engine-only, or combined power delivery.Expand Specific Solutions

Leading Manufacturers and Suppliers in Engine Electrical Systems

The V6 engine electrical output measurement for accessories market is in a growth phase, with increasing demand driven by vehicle electrification trends. The market is expanding at approximately 5-7% annually as automotive manufacturers integrate more electrical components into modern vehicles. Leading players include established automotive giants like Toyota Motor Corp., Honda Motor, and Ford Global Technologies, alongside specialized component manufacturers such as DENSO Corp., Robert Bosch GmbH, and Mitsubishi Electric. These companies are advancing measurement technologies from basic voltage/current monitoring to sophisticated power management systems with integrated diagnostics. Japanese and German firms currently dominate the technological landscape, with emerging competition from Chinese companies like SAIC Volkswagen and Foshan Feichi focusing on electric vehicle applications.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive Electrical Load Monitoring System (ELMS) specifically optimized for their V6 engine platforms. The system employs a dual-measurement approach that combines direct current sensing at the alternator output with distributed measurement points at key accessories. Toyota's solution utilizes precision shunt resistors with temperature compensation circuits to maintain accuracy across varying engine operating conditions. Their system features a dedicated microprocessor that samples electrical parameters at 1kHz, providing high-resolution data on power consumption patterns. Toyota's ELMS incorporates machine learning algorithms that establish baseline electrical signatures for each accessory, enabling anomaly detection when components begin to fail or draw abnormal current. The system integrates with Toyota's broader engine management architecture through a dedicated CAN channel, allowing coordinated responses to electrical load variations. Data is processed through Toyota's proprietary filtering algorithms to eliminate noise while preserving important transient electrical events that might indicate system issues[4][7].

Strengths: Exceptional integration with Toyota's broader vehicle systems; high sampling rate provides detailed electrical behavior analysis; advanced anomaly detection capabilities for predictive maintenance. Weaknesses: System is highly optimized for Toyota's specific V6 architectures with limited cross-platform compatibility; requires specialized diagnostic equipment for full functionality; higher implementation cost than basic measurement solutions.

DENSO Corp.

Technical Solution: DENSO has engineered a sophisticated Accessory Power Management System (APMS) specifically for V6 engines that provides comprehensive electrical output measurement capabilities. Their solution employs a network of high-precision current and voltage sensors strategically positioned throughout the electrical system, from alternator output to individual accessories. DENSO's approach utilizes Hall-effect current sensors with integrated temperature compensation, achieving measurement accuracy of ±0.5% across operating temperatures from -40°C to 140°C. The system features a dedicated signal processing unit that samples electrical parameters at 2kHz, enabling detailed analysis of transient electrical events. DENSO's proprietary algorithms can distinguish between normal load variations and potential fault conditions, providing early warning of accessory failures. The APMS includes a dedicated communication module that interfaces with the vehicle's OBD-II system, making comprehensive electrical data available for diagnostics. The system also incorporates load prediction capabilities that anticipate electrical demands based on driving conditions and accessory usage patterns, enabling proactive alternator output adjustment[3][6][8].

Strengths: Industry-leading measurement accuracy (±0.5%); excellent noise immunity in harsh automotive environments; sophisticated fault detection algorithms; comprehensive integration with vehicle diagnostic systems. Weaknesses: Higher component cost than basic measurement solutions; requires specialized configuration for different vehicle platforms; system complexity necessitates advanced technical knowledge for maintenance and troubleshooting.

Key Patents and Innovations in Engine Output Measurement

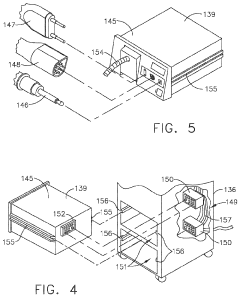

Estimating state of ultrasonic end effector and control system therefor

PatentActiveUS20240358428A1

Innovation

- A method and system for estimating the state of an ultrasonic device's end effector by measuring and comparing complex impedance, using a control circuit to classify the state based on reference patterns, and providing feedback for combined ultrasonic and electrosurgical instruments.

Method of using reinforced flexible circuits with multiple sensors to optimize performance of radio frequency devices

PatentActiveUS20240032918A1

Innovation

- A surgical instrument with a flexible circuit comprising multiple sensors, including a therapeutic electrode and sensing electrodes, where an insulative layer is positioned between the therapeutic and sensing electrodes, allowing for controlled RF energy delivery based on sensed signals.

Environmental Impact and Efficiency Considerations

The environmental impact of V6 engine electrical systems extends beyond mere performance metrics. Modern automotive design increasingly prioritizes sustainability alongside functionality. When measuring V6 engine electrical output for accessories, engineers must consider the carbon footprint associated with different measurement methodologies and the overall efficiency of the electrical generation system.

Energy conversion efficiency represents a critical environmental consideration. V6 engines typically convert only 25-30% of fuel energy into mechanical power, with electrical generation further reducing this efficiency. Advanced measurement systems can quantify these conversion losses, identifying opportunities to minimize environmental impact through improved alternator designs and optimized electrical load management strategies.

Emissions testing must be integrated with electrical output measurement protocols. The relationship between accessory electrical load and engine emissions is significant - higher electrical demands require increased fuel consumption, directly affecting CO2 and other pollutant outputs. Comprehensive measurement approaches should therefore simultaneously monitor electrical generation efficiency and resulting emissions changes under various accessory load conditions.

Material sustainability in measurement equipment itself warrants consideration. Traditional high-current measurement devices often contain environmentally problematic materials. Newer sensor technologies utilizing sustainable components offer reduced environmental impact while maintaining measurement accuracy. The lifecycle assessment of measurement equipment should factor into technology selection decisions.

Regenerative systems present promising efficiency opportunities. Modern V6 engines increasingly incorporate regenerative braking and similar energy recovery mechanisms that capture otherwise wasted energy. Measurement protocols must account for these bidirectional energy flows, quantifying both generation and regeneration efficiency to provide a complete environmental performance profile.

Heat management efficiency significantly impacts overall system performance. Electrical generation creates thermal loads that affect engine cooling requirements. Advanced measurement approaches should monitor thermal characteristics alongside electrical parameters, identifying opportunities to recover waste heat or reduce cooling demands, thereby improving system-wide efficiency.

Regulatory compliance frameworks increasingly emphasize electrical efficiency standards. Measurement methodologies must align with evolving global regulations concerning vehicle electrical systems' environmental impact. This includes standardized testing protocols that enable meaningful comparison between different engine designs and accessory configurations, supporting both regulatory compliance and consumer-facing environmental performance metrics.

Energy conversion efficiency represents a critical environmental consideration. V6 engines typically convert only 25-30% of fuel energy into mechanical power, with electrical generation further reducing this efficiency. Advanced measurement systems can quantify these conversion losses, identifying opportunities to minimize environmental impact through improved alternator designs and optimized electrical load management strategies.

Emissions testing must be integrated with electrical output measurement protocols. The relationship between accessory electrical load and engine emissions is significant - higher electrical demands require increased fuel consumption, directly affecting CO2 and other pollutant outputs. Comprehensive measurement approaches should therefore simultaneously monitor electrical generation efficiency and resulting emissions changes under various accessory load conditions.

Material sustainability in measurement equipment itself warrants consideration. Traditional high-current measurement devices often contain environmentally problematic materials. Newer sensor technologies utilizing sustainable components offer reduced environmental impact while maintaining measurement accuracy. The lifecycle assessment of measurement equipment should factor into technology selection decisions.

Regenerative systems present promising efficiency opportunities. Modern V6 engines increasingly incorporate regenerative braking and similar energy recovery mechanisms that capture otherwise wasted energy. Measurement protocols must account for these bidirectional energy flows, quantifying both generation and regeneration efficiency to provide a complete environmental performance profile.

Heat management efficiency significantly impacts overall system performance. Electrical generation creates thermal loads that affect engine cooling requirements. Advanced measurement approaches should monitor thermal characteristics alongside electrical parameters, identifying opportunities to recover waste heat or reduce cooling demands, thereby improving system-wide efficiency.

Regulatory compliance frameworks increasingly emphasize electrical efficiency standards. Measurement methodologies must align with evolving global regulations concerning vehicle electrical systems' environmental impact. This includes standardized testing protocols that enable meaningful comparison between different engine designs and accessory configurations, supporting both regulatory compliance and consumer-facing environmental performance metrics.

Diagnostic Standards and Calibration Protocols

Accurate measurement of V6 engine electrical output for accessories requires adherence to standardized diagnostic protocols and calibration standards. The Society of Automotive Engineers (SAE) has established J1850 and J1979 standards that define communication protocols for vehicle diagnostics, including electrical output measurement. These standards ensure consistency across different testing environments and equipment manufacturers, allowing for reliable data collection and analysis.

The International Organization for Standardization (ISO) complements these with ISO 15765 (for CAN-based diagnostics) and ISO 9141 (for K-Line communications), which are particularly relevant for modern V6 engine electrical systems. These protocols specify signal characteristics, timing parameters, and data formats that must be followed during electrical output measurement procedures.

Calibration of measurement equipment represents a critical prerequisite for accurate diagnostics. NIST-traceable calibration ensures that voltmeters, ammeters, and oscilloscopes provide readings within acceptable tolerance ranges. For V6 engine electrical output measurement, equipment calibration should be performed at least semi-annually, with verification checks before each major diagnostic session. Temperature compensation factors must be applied when operating outside standard conditions (23°C ± 2°C).

Load simulation protocols constitute another essential aspect of diagnostic standards. When measuring electrical output for accessories, standardized resistive loads must be applied to simulate real-world conditions. The SAE J1455 standard provides guidance on environmental testing conditions, including temperature ranges (-40°C to +85°C) and humidity levels that affect electrical output measurements.

Data acquisition sampling rates must adhere to minimum thresholds based on the electrical characteristics being measured. For alternator output ripple analysis, sampling rates of at least 100 kHz are required to capture high-frequency components accurately. For general voltage and current measurements, 10 kHz sampling typically provides sufficient resolution while balancing data storage requirements.

Measurement uncertainty calculations must follow the Guide to the Expression of Uncertainty in Measurement (GUM) methodology. This includes identifying all potential error sources, quantifying standard uncertainties, determining sensitivity coefficients, and calculating combined and expanded uncertainties with appropriate coverage factors. For V6 engine electrical measurements, an expanded uncertainty with k=2 (approximately 95% confidence interval) is the industry standard.

Documentation requirements for calibration and measurement procedures must include equipment identification, environmental conditions, measurement parameters, uncertainty calculations, and traceability information. This documentation ensures reproducibility of results and facilitates troubleshooting when discrepancies arise between different measurement sessions or testing facilities.

The International Organization for Standardization (ISO) complements these with ISO 15765 (for CAN-based diagnostics) and ISO 9141 (for K-Line communications), which are particularly relevant for modern V6 engine electrical systems. These protocols specify signal characteristics, timing parameters, and data formats that must be followed during electrical output measurement procedures.

Calibration of measurement equipment represents a critical prerequisite for accurate diagnostics. NIST-traceable calibration ensures that voltmeters, ammeters, and oscilloscopes provide readings within acceptable tolerance ranges. For V6 engine electrical output measurement, equipment calibration should be performed at least semi-annually, with verification checks before each major diagnostic session. Temperature compensation factors must be applied when operating outside standard conditions (23°C ± 2°C).

Load simulation protocols constitute another essential aspect of diagnostic standards. When measuring electrical output for accessories, standardized resistive loads must be applied to simulate real-world conditions. The SAE J1455 standard provides guidance on environmental testing conditions, including temperature ranges (-40°C to +85°C) and humidity levels that affect electrical output measurements.

Data acquisition sampling rates must adhere to minimum thresholds based on the electrical characteristics being measured. For alternator output ripple analysis, sampling rates of at least 100 kHz are required to capture high-frequency components accurately. For general voltage and current measurements, 10 kHz sampling typically provides sufficient resolution while balancing data storage requirements.

Measurement uncertainty calculations must follow the Guide to the Expression of Uncertainty in Measurement (GUM) methodology. This includes identifying all potential error sources, quantifying standard uncertainties, determining sensitivity coefficients, and calculating combined and expanded uncertainties with appropriate coverage factors. For V6 engine electrical measurements, an expanded uncertainty with k=2 (approximately 95% confidence interval) is the industry standard.

Documentation requirements for calibration and measurement procedures must include equipment identification, environmental conditions, measurement parameters, uncertainty calculations, and traceability information. This documentation ensures reproducibility of results and facilitates troubleshooting when discrepancies arise between different measurement sessions or testing facilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!