How to Determine V6 Engine Knock Threshold Using Sensors

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Knock Detection Background and Objectives

Engine knock, also known as detonation, represents one of the most critical challenges in internal combustion engine design and operation. This abnormal combustion phenomenon occurs when portions of the air-fuel mixture ignite spontaneously before being reached by the normal flame front propagating from the spark plug. The history of engine knock detection dates back to the early 20th century when automotive engineers first recognized the metallic pinging sound as a symptom of potential engine damage.

The evolution of knock detection technology has progressed significantly from rudimentary mechanical listening devices to sophisticated electronic sensors and digital signal processing systems. Early detection methods relied primarily on human auditory perception, which proved inadequate for precise measurement and control. The introduction of piezoelectric sensors in the 1980s marked a significant advancement, enabling more accurate detection of the pressure waves associated with knock events.

For V6 engines specifically, knock detection presents unique challenges due to their particular firing order, cylinder arrangement, and vibration characteristics. The V-configuration creates asymmetric vibration patterns that can complicate the differentiation between normal combustion noise and actual knock events. This distinction becomes even more critical as manufacturers pursue higher compression ratios and turbocharging to improve fuel efficiency and performance.

The primary objective of establishing appropriate knock thresholds for V6 engines is to maximize engine performance while preventing damage to critical components. Setting thresholds too conservatively results in suboptimal performance and efficiency, while overly aggressive thresholds risk engine damage. This delicate balance necessitates sophisticated detection algorithms that can adapt to varying operating conditions, fuel qualities, and engine wear states.

Recent technological trends in knock detection include the integration of multiple sensor types, machine learning algorithms for pattern recognition, and real-time adaptive threshold adjustment. These advancements aim to overcome traditional limitations in knock detection accuracy across the full spectrum of engine operating conditions. The emergence of cylinder-specific knock control strategies represents a particularly promising direction for V6 engines, allowing for individualized combustion management.

The ultimate goal of modern knock threshold determination is to develop systems capable of distinguishing between harmful detonation and benign combustion variations with near-perfect accuracy. This requires not only advanced sensing hardware but also sophisticated signal processing techniques that can filter out background noise and identify the unique spectral signatures of knock events in V6 engines under diverse operating conditions.

The evolution of knock detection technology has progressed significantly from rudimentary mechanical listening devices to sophisticated electronic sensors and digital signal processing systems. Early detection methods relied primarily on human auditory perception, which proved inadequate for precise measurement and control. The introduction of piezoelectric sensors in the 1980s marked a significant advancement, enabling more accurate detection of the pressure waves associated with knock events.

For V6 engines specifically, knock detection presents unique challenges due to their particular firing order, cylinder arrangement, and vibration characteristics. The V-configuration creates asymmetric vibration patterns that can complicate the differentiation between normal combustion noise and actual knock events. This distinction becomes even more critical as manufacturers pursue higher compression ratios and turbocharging to improve fuel efficiency and performance.

The primary objective of establishing appropriate knock thresholds for V6 engines is to maximize engine performance while preventing damage to critical components. Setting thresholds too conservatively results in suboptimal performance and efficiency, while overly aggressive thresholds risk engine damage. This delicate balance necessitates sophisticated detection algorithms that can adapt to varying operating conditions, fuel qualities, and engine wear states.

Recent technological trends in knock detection include the integration of multiple sensor types, machine learning algorithms for pattern recognition, and real-time adaptive threshold adjustment. These advancements aim to overcome traditional limitations in knock detection accuracy across the full spectrum of engine operating conditions. The emergence of cylinder-specific knock control strategies represents a particularly promising direction for V6 engines, allowing for individualized combustion management.

The ultimate goal of modern knock threshold determination is to develop systems capable of distinguishing between harmful detonation and benign combustion variations with near-perfect accuracy. This requires not only advanced sensing hardware but also sophisticated signal processing techniques that can filter out background noise and identify the unique spectral signatures of knock events in V6 engines under diverse operating conditions.

Market Demand for Advanced Knock Detection Systems

The global market for advanced knock detection systems in automotive engines has witnessed substantial growth over the past decade, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles. According to recent industry analyses, the automotive engine management systems market, which includes knock detection technology, is projected to reach $95 billion by 2027, with knock sensors representing a significant segment of this market.

The demand for sophisticated knock detection systems is particularly pronounced in the premium and luxury vehicle segments, where V6 engines are commonly deployed. These market segments prioritize both performance and refinement, necessitating precise knock control systems that can operate effectively across various driving conditions and fuel qualities.

Automotive manufacturers are increasingly focusing on developing engines with higher compression ratios to improve fuel efficiency and power output. This technical evolution has intensified the need for more accurate and responsive knock detection systems, as higher compression engines are inherently more susceptible to knock phenomena. The market has responded with a clear shift toward sensor systems capable of real-time monitoring and adaptive threshold determination.

Regional market analysis reveals varying demand patterns. In North America and Europe, stringent emission standards and consumer preference for refined driving experiences are driving adoption of advanced knock detection technologies. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid automotive industry expansion and increasing consumer awareness regarding engine performance and longevity.

Fleet operators and commercial vehicle manufacturers have also emerged as significant market drivers, seeking technologies that can extend engine life and reduce maintenance costs. This segment values knock detection systems that can adapt to varying fuel qualities encountered across different geographical regions.

Market research indicates that OEMs are increasingly prioritizing integrated sensor solutions that combine knock detection with other engine monitoring functions. This trend toward system integration is reshaping supplier relationships and technology development pathways, with tier-one suppliers investing heavily in multi-functional sensor technologies.

Consumer awareness regarding engine health and performance optimization has created a growing aftermarket segment for advanced knock detection systems. This trend is particularly evident in markets with aging vehicle fleets, where retrofitting existing engines with improved knock detection capabilities represents a cost-effective alternative to vehicle replacement.

The market landscape is further influenced by emerging technologies such as cloud-connected engine management systems and predictive analytics, which promise to enhance knock detection accuracy through machine learning algorithms and historical performance data analysis.

The demand for sophisticated knock detection systems is particularly pronounced in the premium and luxury vehicle segments, where V6 engines are commonly deployed. These market segments prioritize both performance and refinement, necessitating precise knock control systems that can operate effectively across various driving conditions and fuel qualities.

Automotive manufacturers are increasingly focusing on developing engines with higher compression ratios to improve fuel efficiency and power output. This technical evolution has intensified the need for more accurate and responsive knock detection systems, as higher compression engines are inherently more susceptible to knock phenomena. The market has responded with a clear shift toward sensor systems capable of real-time monitoring and adaptive threshold determination.

Regional market analysis reveals varying demand patterns. In North America and Europe, stringent emission standards and consumer preference for refined driving experiences are driving adoption of advanced knock detection technologies. The Asia-Pacific region, particularly China and India, represents the fastest-growing market segment due to rapid automotive industry expansion and increasing consumer awareness regarding engine performance and longevity.

Fleet operators and commercial vehicle manufacturers have also emerged as significant market drivers, seeking technologies that can extend engine life and reduce maintenance costs. This segment values knock detection systems that can adapt to varying fuel qualities encountered across different geographical regions.

Market research indicates that OEMs are increasingly prioritizing integrated sensor solutions that combine knock detection with other engine monitoring functions. This trend toward system integration is reshaping supplier relationships and technology development pathways, with tier-one suppliers investing heavily in multi-functional sensor technologies.

Consumer awareness regarding engine health and performance optimization has created a growing aftermarket segment for advanced knock detection systems. This trend is particularly evident in markets with aging vehicle fleets, where retrofitting existing engines with improved knock detection capabilities represents a cost-effective alternative to vehicle replacement.

The market landscape is further influenced by emerging technologies such as cloud-connected engine management systems and predictive analytics, which promise to enhance knock detection accuracy through machine learning algorithms and historical performance data analysis.

Current Knock Sensor Technology Challenges

Despite significant advancements in knock detection technology, current knock sensor systems for V6 engines face several critical challenges that limit their effectiveness and reliability. The primary obstacle remains the accurate differentiation between actual engine knock and background noise. V6 engines generate complex vibration patterns due to their configuration, making it particularly difficult to isolate knock signals from normal combustion vibrations, mechanical noise, and external interference.

Signal-to-noise ratio (SNR) presents another substantial challenge. Traditional piezoelectric knock sensors often struggle to maintain adequate sensitivity across the entire engine operating range. At low engine speeds, knock signals may be too weak to detect reliably, while at high speeds, background noise can overwhelm the sensors, leading to false positives or missed detection events.

Temperature dependency significantly impacts sensor performance. Current knock sensors exhibit varying sensitivity levels across different temperature ranges, creating inconsistencies in detection thresholds. This is especially problematic during cold starts or when engines operate at extreme temperatures, potentially allowing damaging knock events to go undetected or triggering unnecessary interventions.

Sensor placement optimization remains problematic for V6 engines. The ideal location varies based on engine design, combustion characteristics, and operating conditions. Current approaches often rely on compromise positions that may not capture knock events from all cylinders equally, creating blind spots in detection capability.

Calibration complexity presents ongoing difficulties. Each engine design requires extensive calibration to establish appropriate knock thresholds, a process that is time-consuming, expensive, and often results in conservative settings that sacrifice performance for protection. The calibration must account for manufacturing variations, aging effects, and fuel quality differences, further complicating the process.

Real-time processing limitations affect response times. Current systems may experience delays between knock detection and corrective action implementation, potentially allowing damaging detonation to continue momentarily. This latency becomes more critical as engines evolve toward higher compression ratios and more aggressive timing strategies.

Aging and degradation of sensors over time lead to drift in sensitivity and response characteristics. This degradation is rarely accounted for in control algorithms, potentially leaving engines vulnerable to knock damage as vehicles age, or conversely, unnecessarily limiting performance due to false readings from deteriorated sensors.

Signal-to-noise ratio (SNR) presents another substantial challenge. Traditional piezoelectric knock sensors often struggle to maintain adequate sensitivity across the entire engine operating range. At low engine speeds, knock signals may be too weak to detect reliably, while at high speeds, background noise can overwhelm the sensors, leading to false positives or missed detection events.

Temperature dependency significantly impacts sensor performance. Current knock sensors exhibit varying sensitivity levels across different temperature ranges, creating inconsistencies in detection thresholds. This is especially problematic during cold starts or when engines operate at extreme temperatures, potentially allowing damaging knock events to go undetected or triggering unnecessary interventions.

Sensor placement optimization remains problematic for V6 engines. The ideal location varies based on engine design, combustion characteristics, and operating conditions. Current approaches often rely on compromise positions that may not capture knock events from all cylinders equally, creating blind spots in detection capability.

Calibration complexity presents ongoing difficulties. Each engine design requires extensive calibration to establish appropriate knock thresholds, a process that is time-consuming, expensive, and often results in conservative settings that sacrifice performance for protection. The calibration must account for manufacturing variations, aging effects, and fuel quality differences, further complicating the process.

Real-time processing limitations affect response times. Current systems may experience delays between knock detection and corrective action implementation, potentially allowing damaging detonation to continue momentarily. This latency becomes more critical as engines evolve toward higher compression ratios and more aggressive timing strategies.

Aging and degradation of sensors over time lead to drift in sensitivity and response characteristics. This degradation is rarely accounted for in control algorithms, potentially leaving engines vulnerable to knock damage as vehicles age, or conversely, unnecessarily limiting performance due to false readings from deteriorated sensors.

Current V6 Knock Threshold Determination Approaches

01 Knock detection methods using vibration sensors

Various methods for detecting engine knock in V6 engines involve the use of vibration sensors or accelerometers mounted on the engine block. These sensors measure the vibrations caused by abnormal combustion and compare them to predetermined threshold values to identify knock events. Advanced signal processing techniques are applied to filter out normal engine noise and isolate the characteristic frequencies associated with knock, enabling more accurate detection and threshold determination.- Knock detection methods for V6 engines: Various methods are employed to detect engine knock in V6 engines. These methods typically involve analyzing vibration patterns, acoustic signals, or pressure variations within the combustion chamber. Advanced signal processing techniques are used to filter out background noise and isolate the characteristic frequencies associated with knock events. These detection methods form the foundation for establishing knock thresholds and implementing appropriate control strategies.

- Adaptive knock threshold determination: Adaptive systems for determining knock thresholds adjust sensitivity based on engine operating conditions. These systems continuously monitor parameters such as engine speed, load, temperature, and fuel quality to dynamically adjust knock detection thresholds. By implementing adaptive threshold determination, false knock detection can be minimized while maintaining protection against damaging knock events. This approach allows for optimal engine performance across varying operating conditions.

- Cylinder-specific knock threshold calibration: Cylinder-specific calibration techniques address the unique knock characteristics of individual cylinders in V6 engines. These methods recognize that each cylinder may have different knock tendencies due to variations in cooling, fuel distribution, or manufacturing tolerances. By establishing individual knock thresholds for each cylinder, the engine management system can optimize ignition timing on a per-cylinder basis, improving overall engine efficiency while preventing knock-related damage.

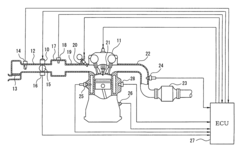

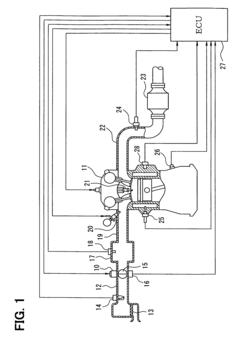

- Sensor-based knock detection systems: Various sensor technologies are employed in knock detection systems for V6 engines. These include accelerometers mounted on the engine block, in-cylinder pressure sensors, and specialized knock sensors designed to detect specific vibration frequencies. The placement and calibration of these sensors are critical for accurate knock detection. Advanced systems may use multiple sensors with different characteristics to improve detection reliability across the full range of engine operating conditions.

- Ignition timing control based on knock threshold: Engine management systems use established knock thresholds to control ignition timing in V6 engines. When knock is detected, the system typically retards ignition timing to reduce cylinder pressure and temperature, thereby eliminating knock. Advanced control algorithms may implement gradual timing adjustments, cylinder-specific corrections, or predictive models to optimize performance while maintaining operation below the knock threshold. These systems balance the trade-off between maximum power output and engine protection.

02 Adaptive knock threshold determination

Adaptive systems for determining knock thresholds in V6 engines adjust the threshold values based on operating conditions such as engine speed, load, temperature, and fuel quality. These systems continuously learn from engine operation patterns and update the threshold values to optimize performance while preventing engine damage. By dynamically adjusting knock thresholds, these systems can accommodate variations in engine conditions and environmental factors, improving both engine protection and performance.Expand Specific Solutions03 Cylinder-specific knock detection

Cylinder-specific knock detection systems for V6 engines monitor each cylinder individually to determine unique knock thresholds. These systems recognize that different cylinders may have varying propensities for knock due to their position in the engine block, cooling variations, or manufacturing tolerances. By establishing individual knock thresholds for each cylinder, these systems enable more precise engine management, optimizing the performance of each cylinder while preventing damaging knock conditions.Expand Specific Solutions04 Frequency-based knock analysis

Frequency-based knock analysis techniques for V6 engines involve examining the spectral characteristics of engine vibrations to identify knock events. These methods analyze specific frequency bands associated with knock phenomena and apply various filtering techniques to isolate knock signals from background noise. By focusing on the frequency domain rather than just amplitude, these systems can achieve higher sensitivity and specificity in knock detection, allowing for more precise threshold setting and earlier intervention when knock occurs.Expand Specific Solutions05 Integration with engine control systems

Knock threshold detection systems for V6 engines are integrated with broader engine control systems to enable real-time adjustments to operating parameters. When knock is detected above the threshold, these systems can automatically modify ignition timing, fuel injection, valve timing, or boost pressure to mitigate knock while maintaining optimal performance. This integration allows for closed-loop control of engine operation based on knock feedback, balancing performance needs with engine protection requirements across varying operating conditions.Expand Specific Solutions

Key Players in Automotive Sensor Technology

The V6 engine knock threshold detection market is in a growth phase, with increasing demand for advanced sensor technologies to optimize engine performance and reduce emissions. The market is estimated to reach $3.5 billion by 2025, driven by stringent emission regulations and fuel efficiency requirements. Leading automotive manufacturers like Toyota, Ford, Honda, and Hyundai are competing with specialized component suppliers such as Bosch, DENSO, and Mitsubishi Electric. These companies are developing increasingly sophisticated knock detection systems using machine learning and IoT integration. Toyota and Bosch demonstrate the highest technical maturity with patented algorithms for real-time knock analysis, while emerging players like Weichai Power and Changan Automobile are rapidly advancing their capabilities through university partnerships and strategic acquisitions.

Toyota Motor Corp.

Technical Solution: Toyota has engineered a comprehensive knock detection system specifically for V6 engines that utilizes multiple sensing technologies and advanced signal processing. Their approach employs strategically positioned accelerometer-based knock sensors that capture vibration signatures from both cylinder banks of the V6 configuration. Toyota's system implements a sophisticated signal processing algorithm that performs real-time frequency analysis, focusing on the 6-10 kHz range where knock events in their V6 engines are most prominent. The technology features adaptive threshold determination that continuously adjusts based on engine operating conditions, ambient temperature, and fuel quality. Toyota's solution incorporates cylinder-specific calibration parameters that account for the unique acoustic properties of each cylinder in their V6 engine designs. Their system also utilizes crankshaft position correlation to precisely time the sampling window for knock detection, analyzing sensor data only during the critical combustion phase for each cylinder to maximize signal quality.

Strengths: Highly refined system with excellent reliability in production vehicles; precise cylinder-specific control enables optimal engine performance; adaptive thresholds maintain accuracy across varying conditions. Weaknesses: System requires extensive calibration during development; higher implementation cost compared to basic knock detection; may have reduced sensitivity during certain transient operating conditions.

DENSO Corp.

Technical Solution: DENSO has engineered a comprehensive knock detection system specifically optimized for V6 engines that integrates multiple sensing technologies. Their solution employs strategically placed piezoelectric knock sensors combined with proprietary signal processing algorithms to filter engine mechanical noise from actual knock events. DENSO's system features cylinder-selective knock control that can identify which specific cylinder among the V6 configuration is experiencing knock and adjust parameters accordingly. The technology incorporates adaptive threshold determination based on a statistical analysis of historical sensor data across various operating conditions. Their approach includes real-time frequency analysis that focuses on the 6-8 kHz range where V6 engine knock signatures are most prominent. DENSO's system also utilizes crankshaft position correlation to precisely time the sampling window for knock detection, improving accuracy by analyzing sensor data only during the critical combustion phase for each cylinder.

Strengths: Highly optimized for V6 engine architecture; cylinder-selective control enables precise interventions; proven reliability in production vehicles across multiple manufacturers. Weaknesses: System calibration requires extensive testing across different engine conditions; may have reduced sensitivity at very low engine speeds; higher implementation cost compared to basic knock detection systems.

Critical Sensor Technologies for Knock Detection

Engine knock detection system and method

PatentActiveUS7571635B2

Innovation

- A surface acoustic wave (SAW) sensor, such as a double-SAW sensor, is used to measure strain and engine torque, providing a wireless detection system that identifies engine knock through resonant frequency changes, allowing for accurate detection and control of engine operations.

Knock determination apparatus and method for engines

PatentActiveUS7356404B2

Innovation

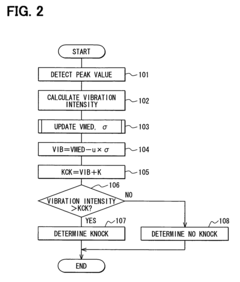

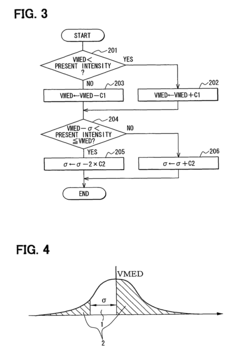

- A knock determination apparatus that sets a vibration intensity reference value in a region where the vibration intensity is smaller, using a mathematical expression to calculate a knock reference value with reduced influence from divergence, allowing for accurate detection of knocking while minimizing the impact of component variations and maintaining the shape of the vibration intensity distribution.

Calibration Methodologies for V6 Engine Applications

Calibration methodologies for V6 engine applications require systematic approaches to establish optimal knock threshold values. These methodologies typically begin with baseline testing under controlled conditions, where engines are operated across various load points and speed ranges to collect reference data. This initial calibration phase establishes fundamental relationships between sensor readings and actual knock events.

Statistical analysis forms the cornerstone of modern calibration approaches, employing techniques such as moving average filtering and standard deviation calculations to differentiate between normal combustion noise and genuine knock events. Advanced methodologies incorporate machine learning algorithms that can adapt to changing engine conditions and learn from historical data patterns, improving detection accuracy over time.

Real-world validation testing represents a critical phase in calibration methodology, requiring extensive road testing across diverse operating conditions. This includes varying ambient temperatures, altitudes, fuel qualities, and driving patterns to ensure robust threshold settings. Calibration engineers typically develop specific test cycles that deliberately induce borderline knock conditions to fine-tune sensor sensitivity.

Cylinder-specific calibration has emerged as a best practice for V6 engines due to inherent differences in combustion characteristics between cylinders. This approach recognizes that uniform threshold settings across all cylinders often result in suboptimal performance, with some cylinders experiencing damaging knock while others operate too conservatively. Modern calibration methodologies therefore establish individual threshold maps for each cylinder based on their unique acoustic signatures.

Closed-loop adaptation systems represent the most sophisticated calibration methodology, continuously adjusting knock thresholds based on real-time feedback. These systems employ complex algorithms that consider factors such as engine aging, component wear, and environmental variations to maintain optimal performance throughout the engine's lifecycle. Implementation typically involves establishing initial threshold maps through bench testing, followed by progressive refinement through field data collection.

Cross-validation between multiple sensor types has become increasingly important in calibration methodologies, with accelerometer data often compared against ion-sensing or in-cylinder pressure measurements to improve detection reliability. This multi-sensor approach helps calibration engineers establish more precise threshold boundaries by triangulating knock events through different detection principles.

Statistical analysis forms the cornerstone of modern calibration approaches, employing techniques such as moving average filtering and standard deviation calculations to differentiate between normal combustion noise and genuine knock events. Advanced methodologies incorporate machine learning algorithms that can adapt to changing engine conditions and learn from historical data patterns, improving detection accuracy over time.

Real-world validation testing represents a critical phase in calibration methodology, requiring extensive road testing across diverse operating conditions. This includes varying ambient temperatures, altitudes, fuel qualities, and driving patterns to ensure robust threshold settings. Calibration engineers typically develop specific test cycles that deliberately induce borderline knock conditions to fine-tune sensor sensitivity.

Cylinder-specific calibration has emerged as a best practice for V6 engines due to inherent differences in combustion characteristics between cylinders. This approach recognizes that uniform threshold settings across all cylinders often result in suboptimal performance, with some cylinders experiencing damaging knock while others operate too conservatively. Modern calibration methodologies therefore establish individual threshold maps for each cylinder based on their unique acoustic signatures.

Closed-loop adaptation systems represent the most sophisticated calibration methodology, continuously adjusting knock thresholds based on real-time feedback. These systems employ complex algorithms that consider factors such as engine aging, component wear, and environmental variations to maintain optimal performance throughout the engine's lifecycle. Implementation typically involves establishing initial threshold maps through bench testing, followed by progressive refinement through field data collection.

Cross-validation between multiple sensor types has become increasingly important in calibration methodologies, with accelerometer data often compared against ion-sensing or in-cylinder pressure measurements to improve detection reliability. This multi-sensor approach helps calibration engineers establish more precise threshold boundaries by triangulating knock events through different detection principles.

Environmental Factors Affecting Knock Sensor Performance

Engine knock detection accuracy is significantly influenced by various environmental factors that can alter sensor readings and threshold determinations. Temperature variations represent one of the most critical environmental influences, as knock sensors typically experience sensitivity shifts across different operating temperatures. In cold environments, sensors may exhibit reduced sensitivity, potentially missing early knock events, while high temperatures can sometimes trigger false positives due to thermal expansion effects on piezoelectric elements.

Humidity levels also play a substantial role in sensor performance, particularly in regions with dramatic seasonal changes. High humidity can affect the electrical properties of sensor connections and potentially introduce signal noise that complicates accurate threshold determination. This becomes especially problematic in coastal areas or during rainy seasons when moisture ingress may temporarily alter sensor characteristics.

Atmospheric pressure variations, often overlooked in controlled testing environments, significantly impact the knock threshold in real-world applications. Lower atmospheric pressure at high altitudes reduces air density, which alters combustion characteristics and consequently shifts optimal knock thresholds. V6 engines operating in mountainous regions may require different calibration parameters compared to those at sea level.

Vibration interference from road conditions represents another critical environmental factor. Rough terrain generates mechanical vibrations that can be misinterpreted as knock events, particularly challenging for V6 engines where the sensor must distinguish between normal operational vibrations and actual detonation events. This necessitates sophisticated filtering algorithms that can adapt to changing driving conditions.

Electromagnetic interference (EMI) from nearby electronic systems or external sources can corrupt knock sensor signals, particularly in modern vehicles with numerous electronic components. This interference varies significantly based on the vehicle's surroundings, from urban environments with high electromagnetic pollution to rural areas with different EMI profiles. Proper shielding and signal conditioning become essential for maintaining consistent threshold detection.

Fuel quality variations across different regions introduce another layer of environmental complexity. Varying octane ratings and fuel compositions directly affect knock tendencies, requiring adaptive threshold adjustments. Modern V6 engines must incorporate feedback mechanisms that can recognize these variations and adjust knock thresholds accordingly to maintain optimal performance while preventing engine damage.

Humidity levels also play a substantial role in sensor performance, particularly in regions with dramatic seasonal changes. High humidity can affect the electrical properties of sensor connections and potentially introduce signal noise that complicates accurate threshold determination. This becomes especially problematic in coastal areas or during rainy seasons when moisture ingress may temporarily alter sensor characteristics.

Atmospheric pressure variations, often overlooked in controlled testing environments, significantly impact the knock threshold in real-world applications. Lower atmospheric pressure at high altitudes reduces air density, which alters combustion characteristics and consequently shifts optimal knock thresholds. V6 engines operating in mountainous regions may require different calibration parameters compared to those at sea level.

Vibration interference from road conditions represents another critical environmental factor. Rough terrain generates mechanical vibrations that can be misinterpreted as knock events, particularly challenging for V6 engines where the sensor must distinguish between normal operational vibrations and actual detonation events. This necessitates sophisticated filtering algorithms that can adapt to changing driving conditions.

Electromagnetic interference (EMI) from nearby electronic systems or external sources can corrupt knock sensor signals, particularly in modern vehicles with numerous electronic components. This interference varies significantly based on the vehicle's surroundings, from urban environments with high electromagnetic pollution to rural areas with different EMI profiles. Proper shielding and signal conditioning become essential for maintaining consistent threshold detection.

Fuel quality variations across different regions introduce another layer of environmental complexity. Varying octane ratings and fuel compositions directly affect knock tendencies, requiring adaptive threshold adjustments. Modern V6 engines must incorporate feedback mechanisms that can recognize these variations and adjust knock thresholds accordingly to maintain optimal performance while preventing engine damage.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!