V6 Engine Lubrication Pathways: Enhancement Strategies

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Lubrication Evolution and Objectives

The evolution of V6 engine lubrication systems has undergone significant transformation since their inception in the early 20th century. Initially, V6 engines employed simple splash lubrication methods, where rotating components would splash oil onto other engine parts. This rudimentary approach gave way to pressure-fed systems in the 1930s, marking the first major advancement in engine lubrication technology. By the 1950s, full-pressure lubrication systems became standard, delivering oil directly to critical components through dedicated pathways.

The 1970s and 1980s witnessed substantial improvements in lubrication efficiency with the introduction of more sophisticated oil pumps and filtration systems. This period coincided with increasing environmental concerns and fuel economy requirements, pushing manufacturers to develop lubrication systems that reduced friction while maintaining adequate protection. The 1990s saw the integration of electronic monitoring systems to optimize oil pressure and flow based on engine operating conditions.

Recent decades have brought revolutionary changes to V6 engine lubrication pathways. Variable displacement oil pumps emerged in the early 2000s, allowing for dynamic adjustment of oil flow based on engine needs. Thermal management systems were integrated into lubrication pathways, enabling faster warm-up times and more consistent operating temperatures. Additionally, the development of synthetic lubricants specifically formulated for V6 engines has complemented these mechanical advancements.

Current technological trends point toward increasingly sophisticated lubrication systems that incorporate sensors and electronic controls to precisely manage oil distribution. Manufacturers are exploring piston cooling jets, integrated heat exchangers, and variable-path oil galleries that can adapt to different driving conditions. These innovations aim to reduce parasitic losses while maintaining optimal component protection.

The primary objectives for enhancing V6 engine lubrication pathways center around four key areas: improving fuel efficiency through reduced friction losses, extending engine longevity by ensuring adequate lubrication under all operating conditions, reducing emissions by minimizing oil consumption, and supporting higher performance capabilities without compromising reliability. These objectives must be balanced against constraints such as manufacturing complexity, cost considerations, and packaging limitations within modern engine compartments.

Future development goals include the creation of "smart" lubrication systems that can predict and adapt to changing engine conditions, integration with hybrid and electrified powertrains, and compatibility with next-generation sustainable lubricants. As V6 engines continue to evolve in response to stringent emissions regulations and performance demands, lubrication pathway enhancement remains a critical area for technological innovation and competitive differentiation among manufacturers.

The 1970s and 1980s witnessed substantial improvements in lubrication efficiency with the introduction of more sophisticated oil pumps and filtration systems. This period coincided with increasing environmental concerns and fuel economy requirements, pushing manufacturers to develop lubrication systems that reduced friction while maintaining adequate protection. The 1990s saw the integration of electronic monitoring systems to optimize oil pressure and flow based on engine operating conditions.

Recent decades have brought revolutionary changes to V6 engine lubrication pathways. Variable displacement oil pumps emerged in the early 2000s, allowing for dynamic adjustment of oil flow based on engine needs. Thermal management systems were integrated into lubrication pathways, enabling faster warm-up times and more consistent operating temperatures. Additionally, the development of synthetic lubricants specifically formulated for V6 engines has complemented these mechanical advancements.

Current technological trends point toward increasingly sophisticated lubrication systems that incorporate sensors and electronic controls to precisely manage oil distribution. Manufacturers are exploring piston cooling jets, integrated heat exchangers, and variable-path oil galleries that can adapt to different driving conditions. These innovations aim to reduce parasitic losses while maintaining optimal component protection.

The primary objectives for enhancing V6 engine lubrication pathways center around four key areas: improving fuel efficiency through reduced friction losses, extending engine longevity by ensuring adequate lubrication under all operating conditions, reducing emissions by minimizing oil consumption, and supporting higher performance capabilities without compromising reliability. These objectives must be balanced against constraints such as manufacturing complexity, cost considerations, and packaging limitations within modern engine compartments.

Future development goals include the creation of "smart" lubrication systems that can predict and adapt to changing engine conditions, integration with hybrid and electrified powertrains, and compatibility with next-generation sustainable lubricants. As V6 engines continue to evolve in response to stringent emissions regulations and performance demands, lubrication pathway enhancement remains a critical area for technological innovation and competitive differentiation among manufacturers.

Market Demand Analysis for Enhanced Engine Lubrication

The global market for enhanced engine lubrication systems has experienced significant growth in recent years, driven primarily by increasing consumer demand for high-performance vehicles and stricter emission regulations. The V6 engine segment, in particular, has shown robust demand for advanced lubrication solutions, with the market value estimated to reach $12.7 billion by 2025, growing at a CAGR of 4.8% from 2020.

Automotive manufacturers are facing mounting pressure to improve engine efficiency while simultaneously reducing emissions. This has created a substantial market opportunity for enhanced lubrication pathways that can reduce friction losses, which account for approximately 10% of total fuel consumption in modern engines. The potential fuel economy improvement of 2-3% through optimized lubrication represents significant value in markets where fuel efficiency is a key purchasing factor.

Consumer preferences have shifted notably toward vehicles offering longer service intervals and extended engine life. Market research indicates that 78% of premium vehicle buyers consider engine durability as a "very important" factor in their purchasing decisions. Enhanced lubrication systems directly address this consumer demand by providing better protection against wear and extending engine lifespan.

The aftermarket segment for advanced lubrication components has shown particularly strong growth, with sales increasing by 6.2% annually as vehicle owners seek performance upgrades. This trend is especially pronounced in regions with aging vehicle fleets, such as Eastern Europe and parts of Asia, where retrofitting improved lubrication systems offers cost-effective performance enhancement.

Commercial vehicle applications represent another significant market segment, with fleet operators increasingly focused on total cost of ownership calculations. Enhanced lubrication systems that can demonstrate reduced maintenance costs and extended engine life are gaining substantial market traction, with adoption rates increasing by 15% annually among major fleet operators.

Regional analysis reveals varying market dynamics, with North America and Europe leading in adoption of premium lubrication solutions due to stringent emission standards. Meanwhile, the Asia-Pacific region shows the highest growth potential, driven by rapid motorization and increasing consumer affluence in countries like China and India, where the premium vehicle segment is expanding at twice the global average rate.

Market forecasts indicate that the demand for specialized V6 engine lubrication solutions will continue to grow as manufacturers pursue incremental efficiency gains to meet regulatory requirements. The market segment for variable-flow lubrication systems alone is projected to grow by 7.3% annually through 2027, representing a significant opportunity for innovation in this space.

Automotive manufacturers are facing mounting pressure to improve engine efficiency while simultaneously reducing emissions. This has created a substantial market opportunity for enhanced lubrication pathways that can reduce friction losses, which account for approximately 10% of total fuel consumption in modern engines. The potential fuel economy improvement of 2-3% through optimized lubrication represents significant value in markets where fuel efficiency is a key purchasing factor.

Consumer preferences have shifted notably toward vehicles offering longer service intervals and extended engine life. Market research indicates that 78% of premium vehicle buyers consider engine durability as a "very important" factor in their purchasing decisions. Enhanced lubrication systems directly address this consumer demand by providing better protection against wear and extending engine lifespan.

The aftermarket segment for advanced lubrication components has shown particularly strong growth, with sales increasing by 6.2% annually as vehicle owners seek performance upgrades. This trend is especially pronounced in regions with aging vehicle fleets, such as Eastern Europe and parts of Asia, where retrofitting improved lubrication systems offers cost-effective performance enhancement.

Commercial vehicle applications represent another significant market segment, with fleet operators increasingly focused on total cost of ownership calculations. Enhanced lubrication systems that can demonstrate reduced maintenance costs and extended engine life are gaining substantial market traction, with adoption rates increasing by 15% annually among major fleet operators.

Regional analysis reveals varying market dynamics, with North America and Europe leading in adoption of premium lubrication solutions due to stringent emission standards. Meanwhile, the Asia-Pacific region shows the highest growth potential, driven by rapid motorization and increasing consumer affluence in countries like China and India, where the premium vehicle segment is expanding at twice the global average rate.

Market forecasts indicate that the demand for specialized V6 engine lubrication solutions will continue to grow as manufacturers pursue incremental efficiency gains to meet regulatory requirements. The market segment for variable-flow lubrication systems alone is projected to grow by 7.3% annually through 2027, representing a significant opportunity for innovation in this space.

Current Lubrication Technologies and Challenges

The current landscape of V6 engine lubrication systems represents a complex interplay of traditional methodologies and emerging technologies. Conventional V6 engine lubrication relies primarily on pressure-fed systems where oil is pumped from the sump through a filter and then distributed via galleries to critical components such as crankshaft bearings, camshafts, and valve train assemblies. These systems typically operate at pressures ranging from 40-70 psi during normal operation, with variations based on engine speed and load conditions.

Despite decades of refinement, several persistent challenges continue to plague V6 engine lubrication systems. Oil aeration remains a significant issue, particularly in high-performance applications where rapid crankshaft rotation can introduce air into the lubricant, reducing its effectiveness and potentially leading to bearing damage. Additionally, thermal management presents ongoing difficulties, especially in turbocharged V6 configurations where localized temperatures can exceed 300°C, pushing conventional lubricants beyond their operational limits.

Modern V6 engines increasingly incorporate variable displacement oil pumps to optimize efficiency, reducing parasitic losses during low-demand conditions while ensuring adequate lubrication during high-load operation. However, these systems introduce additional complexity and potential failure points that must be carefully managed. Synthetic lubricants have significantly improved temperature stability and longevity but come with increased cost implications for manufacturers and end-users.

The industry faces mounting pressure from emissions regulations, which has led to the adoption of low-viscosity oils to reduce internal friction and improve fuel economy. This trend creates a technical contradiction: thinner oils flow more readily through narrow pathways but provide reduced protection under boundary lubrication conditions, particularly during cold starts and high-load operation.

Turbocharging, now nearly ubiquitous in modern V6 designs, presents unique lubrication challenges. The extreme operating conditions of turbocharger bearings—with speeds often exceeding 150,000 RPM and temperatures approaching 1000°C—demand specialized lubrication solutions that can withstand these conditions while maintaining oil stability and preventing coking.

Emerging technologies such as cylinder deactivation systems further complicate lubrication pathways, requiring adaptive oil distribution that can respond to changing engine configurations during operation. Similarly, start-stop systems subject engine components to increased wear during frequent restart cycles, necessitating enhanced boundary lubrication properties and rapid oil pressurization capabilities.

Material innovations, including DLC (Diamond-Like Carbon) coatings and surface texturing technologies, offer promising solutions for reducing friction and wear in critical components, but integration challenges and cost considerations have limited widespread adoption in production V6 engines.

Despite decades of refinement, several persistent challenges continue to plague V6 engine lubrication systems. Oil aeration remains a significant issue, particularly in high-performance applications where rapid crankshaft rotation can introduce air into the lubricant, reducing its effectiveness and potentially leading to bearing damage. Additionally, thermal management presents ongoing difficulties, especially in turbocharged V6 configurations where localized temperatures can exceed 300°C, pushing conventional lubricants beyond their operational limits.

Modern V6 engines increasingly incorporate variable displacement oil pumps to optimize efficiency, reducing parasitic losses during low-demand conditions while ensuring adequate lubrication during high-load operation. However, these systems introduce additional complexity and potential failure points that must be carefully managed. Synthetic lubricants have significantly improved temperature stability and longevity but come with increased cost implications for manufacturers and end-users.

The industry faces mounting pressure from emissions regulations, which has led to the adoption of low-viscosity oils to reduce internal friction and improve fuel economy. This trend creates a technical contradiction: thinner oils flow more readily through narrow pathways but provide reduced protection under boundary lubrication conditions, particularly during cold starts and high-load operation.

Turbocharging, now nearly ubiquitous in modern V6 designs, presents unique lubrication challenges. The extreme operating conditions of turbocharger bearings—with speeds often exceeding 150,000 RPM and temperatures approaching 1000°C—demand specialized lubrication solutions that can withstand these conditions while maintaining oil stability and preventing coking.

Emerging technologies such as cylinder deactivation systems further complicate lubrication pathways, requiring adaptive oil distribution that can respond to changing engine configurations during operation. Similarly, start-stop systems subject engine components to increased wear during frequent restart cycles, necessitating enhanced boundary lubrication properties and rapid oil pressurization capabilities.

Material innovations, including DLC (Diamond-Like Carbon) coatings and surface texturing technologies, offer promising solutions for reducing friction and wear in critical components, but integration challenges and cost considerations have limited widespread adoption in production V6 engines.

Current V6 Lubrication Pathway Solutions

01 Optimized oil flow pathways in V6 engines

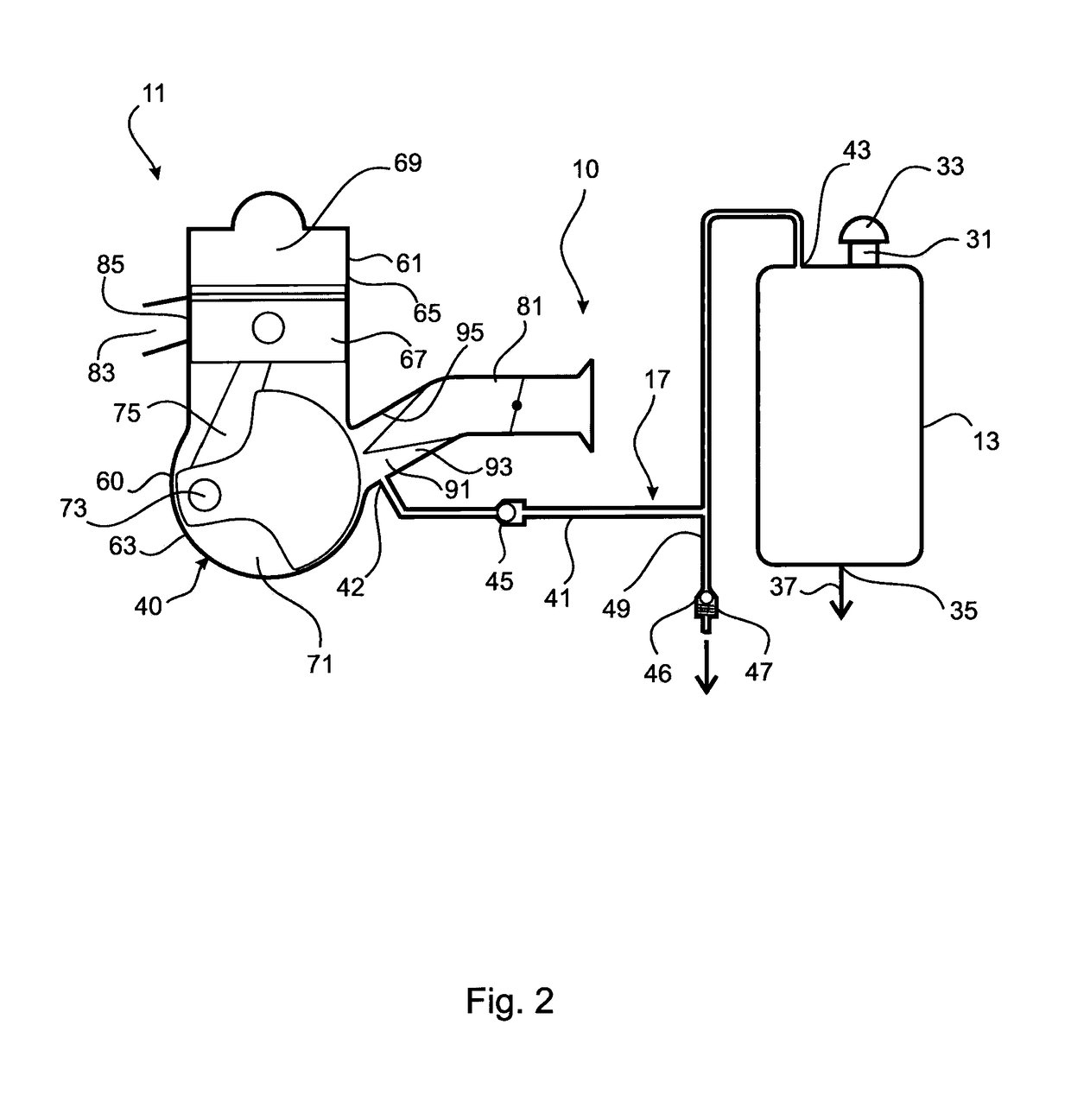

Enhanced lubrication pathways in V6 engines can be achieved through optimized oil flow channels that ensure proper distribution of lubricant to critical engine components. These designs include specialized galleries, passages, and conduits that direct oil flow efficiently throughout the engine block, reducing friction and wear. The optimized pathways help maintain consistent oil pressure and ensure adequate lubrication even under high-stress operating conditions.- Optimized oil flow pathways in V6 engines: Enhanced lubrication pathways in V6 engines can be achieved through optimized oil flow channels that ensure proper distribution of lubricant throughout the engine components. These designs incorporate strategically placed oil galleries, passages, and jets that direct oil to critical areas such as cylinder walls, crankshaft bearings, and valve train components. The improved pathways reduce friction, minimize wear, and enhance overall engine efficiency and longevity.

- Advanced oil pump and pressure regulation systems: Advanced oil pump designs and pressure regulation systems play a crucial role in enhancing V6 engine lubrication. These systems incorporate variable displacement pumps, electronic pressure control valves, and sophisticated pressure relief mechanisms to maintain optimal oil pressure under varying operating conditions. By ensuring consistent oil pressure throughout the engine's operating range, these systems contribute to improved engine performance, reduced wear, and enhanced fuel efficiency.

- Integrated cooling and lubrication systems: Integration of cooling and lubrication systems in V6 engines provides dual benefits of temperature regulation and enhanced lubrication. These designs utilize oil as both a lubricant and a cooling medium, with specialized heat exchangers, coolers, and thermostatic valves that maintain optimal oil temperature. The integrated approach ensures that critical engine components receive properly cooled lubricant, reducing thermal stress and extending engine life while improving performance.

- Specialized lubrication for turbocharging and high-performance applications: High-performance V6 engines, particularly those with turbochargers or superchargers, require specialized lubrication solutions. These include dedicated oil supply lines to turbochargers, enhanced bearing lubrication systems, and specialized oil formulations that withstand high temperatures and pressures. Additional features such as pulsation dampers, scavenge pumps, and enhanced filtration systems ensure reliable operation under extreme conditions, maximizing power output while maintaining engine durability.

- Electronic monitoring and control of lubrication systems: Modern V6 engine lubrication systems incorporate electronic monitoring and control technologies to optimize performance. These systems utilize sensors to monitor oil pressure, temperature, and quality in real-time, with electronic control units that adjust oil flow rates and pressures accordingly. Advanced features include variable timing oil control valves, adaptive lubrication strategies based on driving conditions, and diagnostic capabilities that alert drivers to potential lubrication issues before they cause damage.

02 Advanced oil pump and pressure regulation systems

Improved oil pump designs and pressure regulation systems enhance the lubrication efficiency in V6 engines. These systems include variable displacement oil pumps, electronic pressure control valves, and integrated pressure relief mechanisms that adjust oil flow based on engine demand. By maintaining optimal oil pressure throughout various operating conditions, these systems reduce energy losses while ensuring sufficient lubrication to critical engine components.Expand Specific Solutions03 Cylinder head and valve train lubrication enhancements

Specialized lubrication pathways for cylinder heads and valve train components improve the performance and durability of V6 engines. These enhancements include dedicated oil channels to camshafts, valve lifters, and rocker arms, ensuring proper lubrication of high-stress components. The improved designs feature strategically placed oil jets and spray nozzles that direct lubricant to specific areas requiring enhanced cooling and friction reduction.Expand Specific Solutions04 Crankshaft and bearing lubrication improvements

Enhanced lubrication systems for crankshafts and bearings in V6 engines focus on reducing friction and wear at these critical interfaces. These improvements include redesigned oil passages within the crankshaft, optimized bearing clearances, and specialized oil groove patterns that promote better oil film formation. Some designs incorporate pulsed oil delivery systems that synchronize lubrication with the engine's operating cycle for maximum efficiency.Expand Specific Solutions05 Integrated thermal management and lubrication systems

Modern V6 engine designs incorporate integrated thermal management and lubrication systems that work together to optimize engine performance. These systems include oil coolers, temperature-controlled oil flow regulators, and heat exchangers that maintain optimal oil viscosity across various operating conditions. By controlling oil temperature and flow characteristics, these integrated systems extend engine life while improving fuel efficiency and reducing emissions.Expand Specific Solutions

Key Industry Players in Engine Lubrication Technology

The V6 engine lubrication pathways enhancement market is currently in a growth phase, with increasing focus on efficiency and performance optimization. The competitive landscape features established automotive giants like Toyota, Honda, and Mercedes-Benz alongside specialized engineering firms such as AVL List and Gomecsys BV. Market size is expanding due to stringent emission regulations and consumer demand for fuel-efficient vehicles. Technology maturity varies significantly across players, with Japanese manufacturers (Honda, Toyota) and European companies (Mercedes-Benz, Schaeffler) demonstrating advanced lubrication solutions, while Chinese manufacturers (Chery, Geely) are rapidly closing the gap through aggressive R&D investments. Specialized lubricant developers like Hans Jensen Lubricators and Afton Chemical provide complementary expertise, creating a diverse ecosystem of innovation in engine lubrication technology.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed a sophisticated V6 engine lubrication system featuring their Variable Cylinder Management (VCM) technology that works in conjunction with an adaptive oil delivery system. This integrated approach selectively deactivates cylinders during light load conditions while simultaneously adjusting oil flow to maintain optimal lubrication to active cylinders only. Honda's system incorporates a two-stage oil pump that provides variable pressure based on engine speed and load, reducing parasitic losses by approximately 25% compared to conventional fixed-displacement pumps[4]. Their V6 engines utilize precision-engineered oil jets that target high-stress areas such as piston ring zones and valve train components. Honda has also implemented specialized surface treatments on bearing surfaces that reduce friction coefficients by up to 20%. Additionally, their system features an integrated oil-coolant heat exchanger that maintains oil temperature within an optimal 85-105°C range regardless of operating conditions, which helps maintain consistent viscosity and lubrication properties[5]. Honda's latest V6 engines also incorporate an enhanced filtration system capable of capturing particles down to 8 microns.

Strengths: Honda's integration of cylinder deactivation with adaptive oil delivery provides significant efficiency improvements during partial load operation. Their two-stage oil pump system effectively balances lubrication needs with energy conservation. The thermal management system ensures optimal oil viscosity across diverse operating conditions. Weaknesses: The complexity of coordinating cylinder deactivation with oil delivery systems increases potential failure points and diagnostic challenges. The specialized surface treatments require additional manufacturing processes that increase production costs.

Ford Global Technologies LLC

Technical Solution: Ford has engineered a comprehensive V6 engine lubrication enhancement strategy centered around their patented Active Oil Management System (AOMS). This system utilizes electronically controlled oil pumps that can vary displacement and pressure based on real-time engine needs, reducing parasitic losses by up to 30% compared to traditional fixed-displacement pumps[2]. Ford's V6 engines feature precision-machined oil galleries with optimized flow geometry that reduces pressure drops by approximately 18% across the lubrication circuit. Their system incorporates targeted piston cooling jets that activate only during high-load conditions, conserving energy during normal operation while providing critical cooling when needed. Ford has also developed specialized coating technologies for bearing surfaces that reduce friction coefficients by up to 25% compared to conventional materials[3]. Additionally, their integrated oil filtration system includes a two-stage approach with a primary full-flow filter and a secondary bypass filter that captures particles as small as 5 microns, extending engine life by reducing wear from contaminants.

Strengths: Ford's electronically controlled variable-displacement oil pump significantly reduces energy consumption during normal operation while maintaining optimal lubrication pressure during high-demand scenarios. Their selective piston cooling system provides thermal management only when needed, improving overall efficiency. Weaknesses: The electronic control systems add complexity and potential failure points compared to purely mechanical systems, and the advanced coating technologies require specialized manufacturing processes that increase production costs.

Critical Patents and Innovations in Engine Lubrication

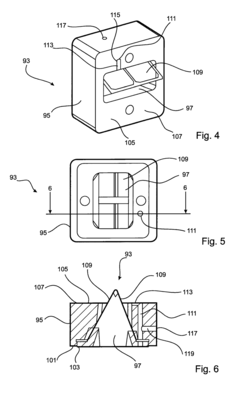

Lubrication oil way of engine

PatentActiveCN102269028A

Innovation

- Design a fully variable valve lift engine lubricating oil circuit with a simple and compact structure, by setting a main oil passage on the cylinder head that communicates with the cylinder block, and connecting the intake VVT oil supply oil passage and the exhaust VVT oil supply oil passage. The intake camshaft lubrication oil passage, exhaust camshaft lubrication oil passage and eccentric shaft lubrication oil passage are all connected to the main oil passage, simplifying the lubrication oil passage and reducing the weight of the engine.

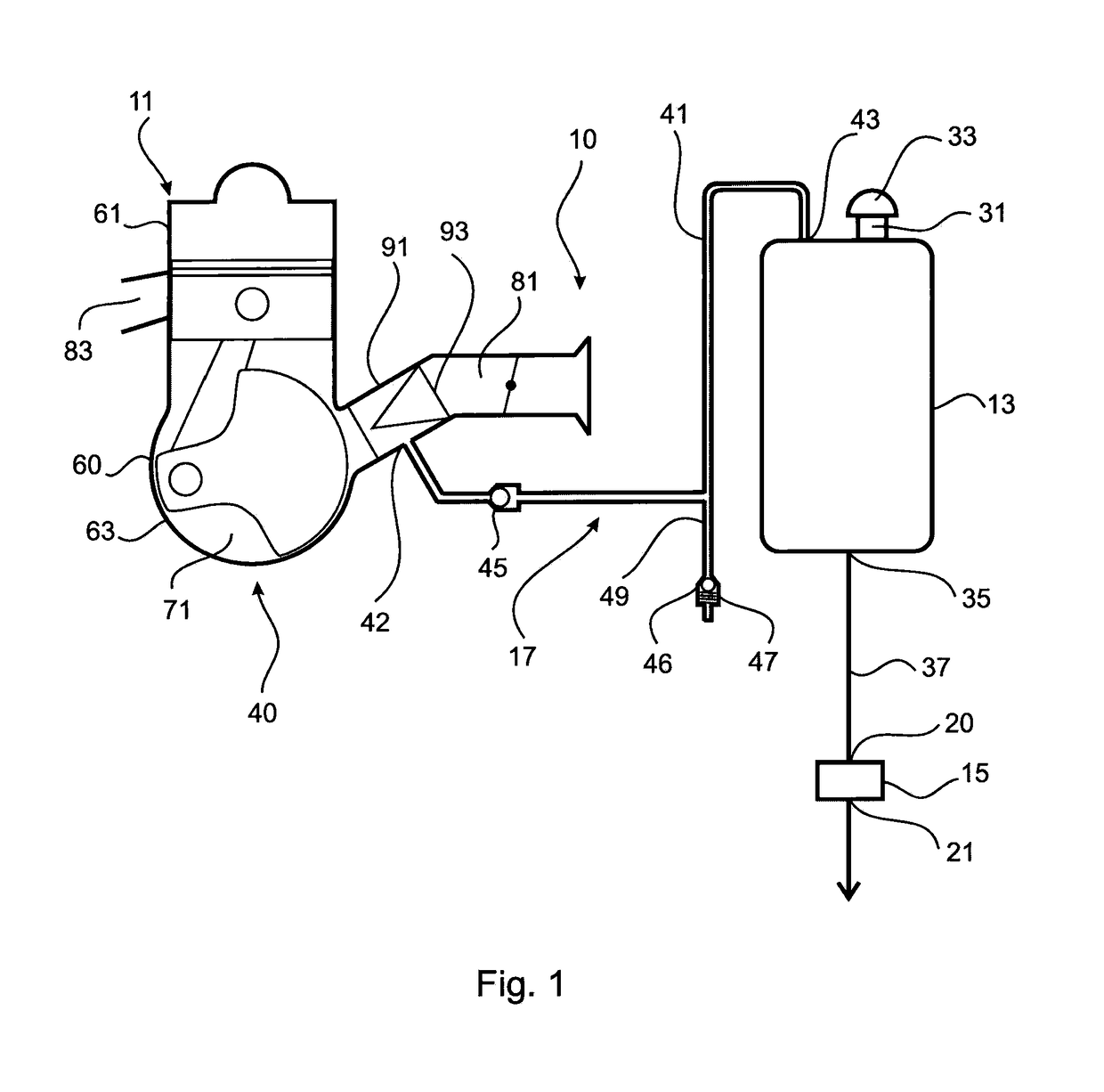

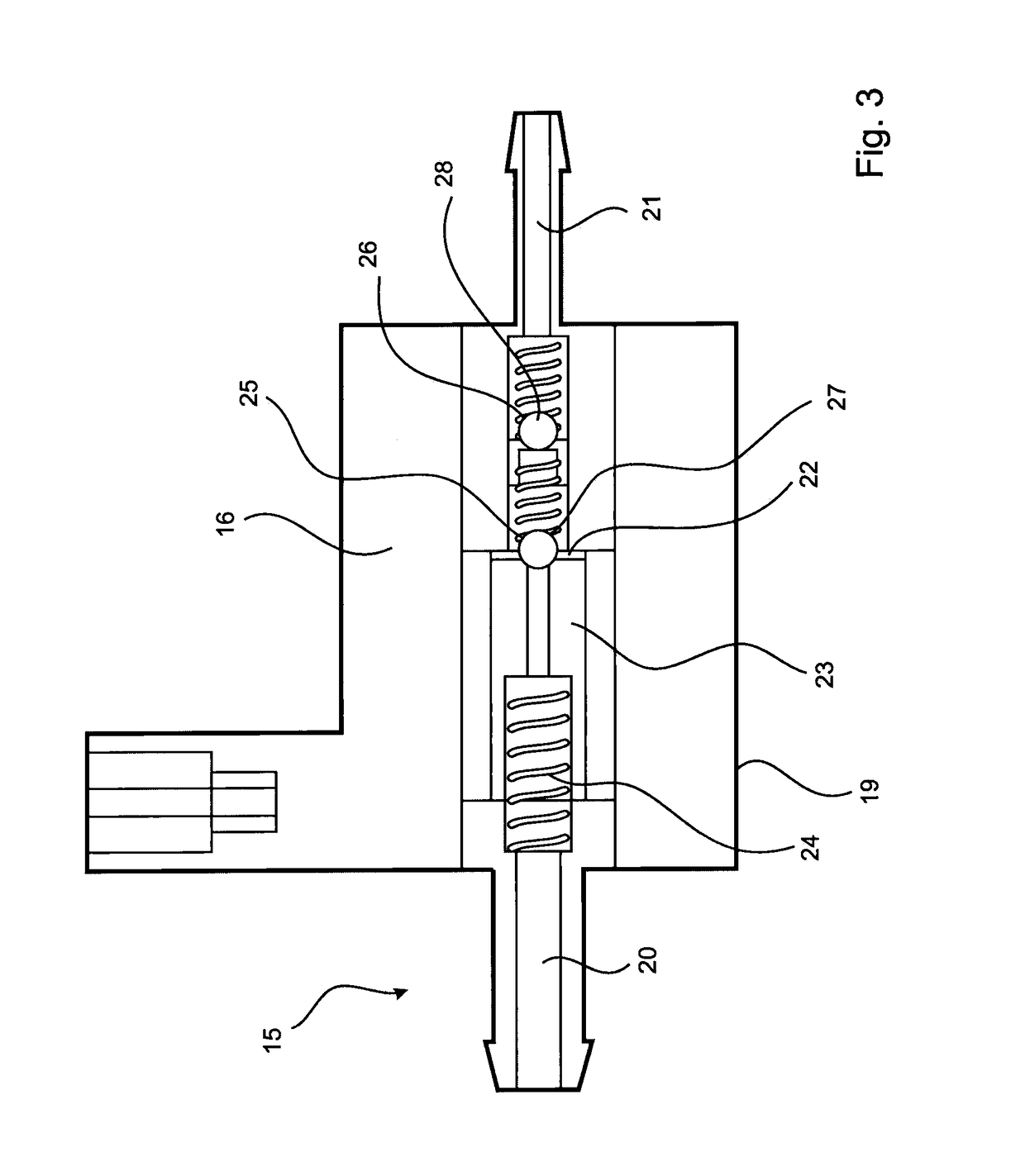

Engine lubrication system

PatentActiveUS10184367B2

Innovation

- A system comprising a solenoid actuated positive displacement pump with a pressurization system that establishes a positive pressure at the pump inlet to assist in delivering lubrication oil with entrained vapour cavities, allowing for selective control of pumping strokes and improving metering accuracy, and includes a pressure release system to prevent excessive pressure buildup.

Environmental Impact and Sustainability Considerations

The environmental impact of V6 engine lubrication systems represents a critical consideration in modern automotive engineering. Traditional lubrication pathways often contribute significantly to engine emissions through oil consumption, volatilization, and subsequent particulate matter formation. Recent studies indicate that approximately 19-25% of particulate emissions in modern V6 engines can be attributed to oil consumption through conventional lubrication pathways, highlighting the urgent need for environmentally conscious redesign approaches.

Sustainable lubrication enhancement strategies must address both resource consumption and emissions reduction. Bio-based lubricants derived from renewable sources present promising alternatives to conventional petroleum-based oils, with recent formulations demonstrating comparable performance while reducing carbon footprint by up to 40%. These bio-lubricants typically feature higher biodegradability rates and lower ecotoxicity profiles, minimizing environmental impact throughout their lifecycle.

Advanced filtration systems integrated into enhanced lubrication pathways can extend oil life by 30-50%, significantly reducing waste oil generation and disposal challenges. Closed-loop lubrication systems that minimize leakage and contamination not only improve engine performance but also reduce the environmental burden associated with lubricant production and disposal. Such systems align with circular economy principles by maximizing resource efficiency.

Thermal management innovations within lubrication pathways contribute substantially to emissions reduction. Optimized oil cooling systems can maintain ideal operating temperatures, reducing oil degradation rates and volatile organic compound (VOC) emissions. Studies demonstrate that precision-controlled lubrication temperatures can decrease oil-related emissions by 15-22% compared to conventional systems.

Manufacturing considerations for enhanced lubrication pathways must incorporate sustainable production methods. Additive manufacturing techniques enable the creation of complex, optimized oil channels with minimal material waste, while precision machining with environmentally friendly coolants reduces the overall environmental footprint of component production. These manufacturing approaches support the transition toward more sustainable automotive technologies.

Regulatory compliance represents another crucial dimension of lubrication pathway enhancement. Emerging standards worldwide increasingly focus on lifecycle environmental impact, with particular attention to end-of-life recyclability and remanufacturing potential. Designing lubrication systems with easily separable components and compatible materials can improve recyclability rates by up to 85%, significantly reducing landfill waste and resource depletion.

Sustainable lubrication enhancement strategies must address both resource consumption and emissions reduction. Bio-based lubricants derived from renewable sources present promising alternatives to conventional petroleum-based oils, with recent formulations demonstrating comparable performance while reducing carbon footprint by up to 40%. These bio-lubricants typically feature higher biodegradability rates and lower ecotoxicity profiles, minimizing environmental impact throughout their lifecycle.

Advanced filtration systems integrated into enhanced lubrication pathways can extend oil life by 30-50%, significantly reducing waste oil generation and disposal challenges. Closed-loop lubrication systems that minimize leakage and contamination not only improve engine performance but also reduce the environmental burden associated with lubricant production and disposal. Such systems align with circular economy principles by maximizing resource efficiency.

Thermal management innovations within lubrication pathways contribute substantially to emissions reduction. Optimized oil cooling systems can maintain ideal operating temperatures, reducing oil degradation rates and volatile organic compound (VOC) emissions. Studies demonstrate that precision-controlled lubrication temperatures can decrease oil-related emissions by 15-22% compared to conventional systems.

Manufacturing considerations for enhanced lubrication pathways must incorporate sustainable production methods. Additive manufacturing techniques enable the creation of complex, optimized oil channels with minimal material waste, while precision machining with environmentally friendly coolants reduces the overall environmental footprint of component production. These manufacturing approaches support the transition toward more sustainable automotive technologies.

Regulatory compliance represents another crucial dimension of lubrication pathway enhancement. Emerging standards worldwide increasingly focus on lifecycle environmental impact, with particular attention to end-of-life recyclability and remanufacturing potential. Designing lubrication systems with easily separable components and compatible materials can improve recyclability rates by up to 85%, significantly reducing landfill waste and resource depletion.

Performance Testing Methodologies and Standards

Performance testing methodologies for V6 engine lubrication systems have evolved significantly to meet the increasing demands of modern automotive engineering. Industry-standard testing protocols now incorporate both bench testing and dynamometer evaluations to comprehensively assess lubrication pathway efficiency. The Society of Automotive Engineers (SAE) has established specific standards, including SAE J300 and J306, which define viscosity requirements and testing parameters for engine oils used in V6 configurations.

Thermal stress testing represents a critical component of lubrication pathway evaluation, typically conducted through temperature cycling between -30°C and 150°C to simulate extreme operating conditions. During these tests, oil flow rates, pressure consistency, and thermal degradation are continuously monitored using high-precision sensors placed at strategic points throughout the lubrication circuit.

Endurance testing protocols have been standardized to include 500-hour continuous operation tests under varying load conditions. These tests measure oil degradation rates, deposit formation tendencies, and the effectiveness of lubrication pathways in maintaining consistent oil delivery to critical engine components. The Federal Test Procedure (FTP) cycle provides a standardized driving pattern that manufacturers use to evaluate real-world performance of lubrication systems.

Computational Fluid Dynamics (CFD) simulation has emerged as an essential pre-physical testing methodology, allowing engineers to model oil flow characteristics through complex V6 engine geometries. These simulations can predict potential flow restrictions, pressure drops, and areas of insufficient lubrication before physical prototypes are constructed. Industry benchmarks require CFD models to achieve at least 95% correlation with physical test results to be considered valid.

Wear pattern analysis using scanning electron microscopy (SEM) provides quantitative data on bearing surface degradation and component longevity. Standard testing requires examination of bearing surfaces after 100,000 simulated kilometers, with wear patterns digitally mapped and compared against baseline measurements. The International Organization for Standardization (ISO) has established ISO 4406 as the standard for measuring particulate contamination in lubricating oils.

Acoustic emission testing has recently been incorporated into standard testing protocols, as it allows for non-invasive monitoring of lubrication effectiveness. Ultrasonic sensors detect friction-related noise signatures that indicate inadequate lubrication, with standardized threshold values established for different engine components and operating conditions.

Thermal stress testing represents a critical component of lubrication pathway evaluation, typically conducted through temperature cycling between -30°C and 150°C to simulate extreme operating conditions. During these tests, oil flow rates, pressure consistency, and thermal degradation are continuously monitored using high-precision sensors placed at strategic points throughout the lubrication circuit.

Endurance testing protocols have been standardized to include 500-hour continuous operation tests under varying load conditions. These tests measure oil degradation rates, deposit formation tendencies, and the effectiveness of lubrication pathways in maintaining consistent oil delivery to critical engine components. The Federal Test Procedure (FTP) cycle provides a standardized driving pattern that manufacturers use to evaluate real-world performance of lubrication systems.

Computational Fluid Dynamics (CFD) simulation has emerged as an essential pre-physical testing methodology, allowing engineers to model oil flow characteristics through complex V6 engine geometries. These simulations can predict potential flow restrictions, pressure drops, and areas of insufficient lubrication before physical prototypes are constructed. Industry benchmarks require CFD models to achieve at least 95% correlation with physical test results to be considered valid.

Wear pattern analysis using scanning electron microscopy (SEM) provides quantitative data on bearing surface degradation and component longevity. Standard testing requires examination of bearing surfaces after 100,000 simulated kilometers, with wear patterns digitally mapped and compared against baseline measurements. The International Organization for Standardization (ISO) has established ISO 4406 as the standard for measuring particulate contamination in lubricating oils.

Acoustic emission testing has recently been incorporated into standard testing protocols, as it allows for non-invasive monitoring of lubrication effectiveness. Ultrasonic sensors detect friction-related noise signatures that indicate inadequate lubrication, with standardized threshold values established for different engine components and operating conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!