Optimizing V6 Engine Cylinder Balance for Power Stability

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Development History and Performance Goals

The V6 engine configuration emerged in the early 20th century, with significant development occurring in the 1950s when compact, lightweight powertrains became increasingly desirable. The inherent design of V6 engines—featuring two banks of three cylinders arranged in a "V" formation—offered an excellent compromise between the smoothness of larger V8 engines and the fuel efficiency of smaller inline-four configurations. Early V6 designs struggled with balance issues due to the inherent firing order imbalances, leading to unwanted vibrations that compromised both performance and durability.

The 1980s marked a turning point with the introduction of advanced balancing techniques, including split-pin crankshafts and counter-rotating balance shafts, which significantly improved V6 refinement. By the 1990s, V6 engines had become mainstream in mid-size vehicles, offering improved power-to-weight ratios while meeting increasingly stringent emissions standards. The early 2000s saw further advancements with variable valve timing, direct injection, and turbocharging technologies being integrated into V6 architectures.

Modern V6 engines aim to achieve several critical performance goals. Primary among these is power stability—the consistent delivery of torque across the RPM range without fluctuations or hesitations. This stability is directly influenced by cylinder balance, where each cylinder contributes equally to the engine's power output. When cylinders operate with varying combustion efficiency, power delivery becomes uneven, resulting in vibration, reduced performance, and increased mechanical stress.

Another key performance goal is fuel efficiency optimization while maintaining power output. This balance has become increasingly important as global emissions regulations tighten. Engineers strive to achieve specific power outputs (horsepower per liter) that compete with larger displacement engines while maintaining the fuel economy advantages of smaller powerplants. Current industry benchmarks target 80-100 horsepower per liter for naturally aspirated V6 engines and significantly higher figures for turbocharged variants.

Durability and longevity represent additional critical goals in V6 development. Properly balanced cylinders reduce mechanical stress on engine components, extending service life and reducing warranty claims. Modern V6 engines are typically designed to operate reliably for at least 150,000 miles before major service, with premium applications targeting even longer service intervals.

The evolution of V6 technology continues to be driven by the pursuit of perfect cylinder balance, as this fundamental characteristic influences virtually all other performance metrics. Recent technological trends focus on integrating electronic control systems that can dynamically adjust fuel delivery, ignition timing, and valve actuation to compensate for cylinder-to-cylinder variations, further optimizing the balance and stability that define exceptional V6 performance.

The 1980s marked a turning point with the introduction of advanced balancing techniques, including split-pin crankshafts and counter-rotating balance shafts, which significantly improved V6 refinement. By the 1990s, V6 engines had become mainstream in mid-size vehicles, offering improved power-to-weight ratios while meeting increasingly stringent emissions standards. The early 2000s saw further advancements with variable valve timing, direct injection, and turbocharging technologies being integrated into V6 architectures.

Modern V6 engines aim to achieve several critical performance goals. Primary among these is power stability—the consistent delivery of torque across the RPM range without fluctuations or hesitations. This stability is directly influenced by cylinder balance, where each cylinder contributes equally to the engine's power output. When cylinders operate with varying combustion efficiency, power delivery becomes uneven, resulting in vibration, reduced performance, and increased mechanical stress.

Another key performance goal is fuel efficiency optimization while maintaining power output. This balance has become increasingly important as global emissions regulations tighten. Engineers strive to achieve specific power outputs (horsepower per liter) that compete with larger displacement engines while maintaining the fuel economy advantages of smaller powerplants. Current industry benchmarks target 80-100 horsepower per liter for naturally aspirated V6 engines and significantly higher figures for turbocharged variants.

Durability and longevity represent additional critical goals in V6 development. Properly balanced cylinders reduce mechanical stress on engine components, extending service life and reducing warranty claims. Modern V6 engines are typically designed to operate reliably for at least 150,000 miles before major service, with premium applications targeting even longer service intervals.

The evolution of V6 technology continues to be driven by the pursuit of perfect cylinder balance, as this fundamental characteristic influences virtually all other performance metrics. Recent technological trends focus on integrating electronic control systems that can dynamically adjust fuel delivery, ignition timing, and valve actuation to compensate for cylinder-to-cylinder variations, further optimizing the balance and stability that define exceptional V6 performance.

Market Analysis for Balanced V6 Engine Applications

The V6 engine market has experienced significant growth over the past decade, driven by the increasing demand for balanced performance and fuel efficiency in mid-size to premium vehicles. Currently, the global market for V6 engines is valued at approximately 42 billion USD, with a compound annual growth rate of 3.7% projected through 2028. This growth trajectory is particularly pronounced in the premium automotive segment, where balanced power delivery is a critical differentiator for manufacturers.

The automotive industry represents the largest application sector for balanced V6 engines, accounting for nearly 78% of total market volume. Within this sector, SUVs and crossovers have emerged as the fastest-growing vehicle category utilizing V6 engines, with sales increasing by 5.2% annually. This trend is particularly evident in North America and China, where consumer preferences continue to shift toward larger vehicles that require the power stability offered by well-balanced V6 configurations.

Marine applications constitute the second-largest market segment at 14% of total V6 engine applications. The demand for balanced power delivery in marine environments is especially critical due to the unique operational challenges posed by water resistance and varying load conditions. The remaining 8% is distributed across industrial applications, including generators, pumps, and specialized equipment where consistent power output is essential for operational reliability.

Regional analysis reveals that North America leads V6 engine consumption at 38% of global market share, followed by Europe (27%), Asia-Pacific (24%), and other regions (11%). China represents the fastest-growing market with a 6.3% annual growth rate, driven by increasing consumer affluence and preference for premium vehicles with superior performance characteristics.

Consumer demand patterns indicate a growing preference for engines that deliver not only raw power but consistent, balanced performance across various operating conditions. Market research shows that 67% of premium vehicle buyers consider power stability and smooth acceleration as "very important" purchasing factors, highlighting the commercial significance of cylinder balance optimization technologies.

The aftermarket segment for V6 engine balancing solutions is also expanding rapidly, with a market value of 3.8 billion USD and growing at 4.5% annually. This includes diagnostic tools, replacement components, and performance enhancement products specifically designed to improve cylinder balance in existing engines.

Pricing analysis indicates that consumers are willing to pay a premium of 8-12% for vehicles featuring advanced cylinder balancing technologies, particularly when these technologies are marketed as enhancing both performance and fuel efficiency. This price elasticity suggests significant revenue potential for manufacturers who successfully implement and market optimized V6 cylinder balance solutions.

The automotive industry represents the largest application sector for balanced V6 engines, accounting for nearly 78% of total market volume. Within this sector, SUVs and crossovers have emerged as the fastest-growing vehicle category utilizing V6 engines, with sales increasing by 5.2% annually. This trend is particularly evident in North America and China, where consumer preferences continue to shift toward larger vehicles that require the power stability offered by well-balanced V6 configurations.

Marine applications constitute the second-largest market segment at 14% of total V6 engine applications. The demand for balanced power delivery in marine environments is especially critical due to the unique operational challenges posed by water resistance and varying load conditions. The remaining 8% is distributed across industrial applications, including generators, pumps, and specialized equipment where consistent power output is essential for operational reliability.

Regional analysis reveals that North America leads V6 engine consumption at 38% of global market share, followed by Europe (27%), Asia-Pacific (24%), and other regions (11%). China represents the fastest-growing market with a 6.3% annual growth rate, driven by increasing consumer affluence and preference for premium vehicles with superior performance characteristics.

Consumer demand patterns indicate a growing preference for engines that deliver not only raw power but consistent, balanced performance across various operating conditions. Market research shows that 67% of premium vehicle buyers consider power stability and smooth acceleration as "very important" purchasing factors, highlighting the commercial significance of cylinder balance optimization technologies.

The aftermarket segment for V6 engine balancing solutions is also expanding rapidly, with a market value of 3.8 billion USD and growing at 4.5% annually. This includes diagnostic tools, replacement components, and performance enhancement products specifically designed to improve cylinder balance in existing engines.

Pricing analysis indicates that consumers are willing to pay a premium of 8-12% for vehicles featuring advanced cylinder balancing technologies, particularly when these technologies are marketed as enhancing both performance and fuel efficiency. This price elasticity suggests significant revenue potential for manufacturers who successfully implement and market optimized V6 cylinder balance solutions.

Current Cylinder Balance Challenges and Limitations

V6 engine cylinder balance represents a critical aspect of engine performance that directly impacts power delivery, fuel efficiency, and overall vehicle drivability. Current cylinder balance technologies face several significant challenges that limit optimal engine performance and stability. These limitations stem from both inherent design constraints and technological barriers that have yet to be fully overcome.

The primary challenge in V6 cylinder balancing lies in the inherent asymmetry of the V6 configuration. Unlike inline engines, the V-arrangement creates uneven firing intervals that generate natural vibrations and torque fluctuations. Even with modern firing order optimizations, these inherent imbalances remain difficult to completely eliminate, particularly during transient operations such as rapid acceleration or load changes.

Sensor technology limitations present another significant obstacle. Current cylinder pressure sensors lack the precision, durability, and cost-effectiveness needed for widespread implementation in production vehicles. Most systems rely on indirect measurements like crankshaft position sensors and knock sensors, which cannot provide real-time, cylinder-specific combustion data with sufficient accuracy to enable perfect balancing across all operating conditions.

Computational constraints further compound these challenges. Real-time cylinder balance adjustments require sophisticated algorithms that must process multiple sensor inputs and make instantaneous adjustments. Current ECU processing capabilities, while advanced, still face limitations in handling the complex calculations required for predictive cylinder balancing across the entire operating range of modern V6 engines.

Fuel delivery systems present additional complications. Even with direct injection technology, achieving perfectly equal fuel distribution across all cylinders remains challenging due to variations in injector performance, fuel pressure fluctuations, and cylinder-to-cylinder differences in air-fuel mixing dynamics. These variations become more pronounced as engines age, further complicating balance maintenance over the vehicle's lifetime.

Environmental factors introduce yet another layer of complexity. Temperature variations across the engine block, particularly during cold starts or under heavy loads, create uneven thermal expansion that affects cylinder compression ratios and combustion efficiency. Current thermal management systems cannot fully compensate for these dynamic thermal gradients.

Manufacturing tolerances, while continuously improving, still contribute to cylinder-to-cylinder variations. Minute differences in piston rings, valve seats, combustion chamber geometry, and port designs create unique combustion characteristics for each cylinder that cannot be completely standardized during production, necessitating more sophisticated adaptive balancing technologies.

Current calibration methodologies also present limitations. Most cylinder balance calibrations are performed under steady-state conditions that do not adequately represent real-world driving scenarios. The resulting calibrations often represent compromises that work reasonably well across operating conditions but fail to achieve optimal balance in specific situations.

The primary challenge in V6 cylinder balancing lies in the inherent asymmetry of the V6 configuration. Unlike inline engines, the V-arrangement creates uneven firing intervals that generate natural vibrations and torque fluctuations. Even with modern firing order optimizations, these inherent imbalances remain difficult to completely eliminate, particularly during transient operations such as rapid acceleration or load changes.

Sensor technology limitations present another significant obstacle. Current cylinder pressure sensors lack the precision, durability, and cost-effectiveness needed for widespread implementation in production vehicles. Most systems rely on indirect measurements like crankshaft position sensors and knock sensors, which cannot provide real-time, cylinder-specific combustion data with sufficient accuracy to enable perfect balancing across all operating conditions.

Computational constraints further compound these challenges. Real-time cylinder balance adjustments require sophisticated algorithms that must process multiple sensor inputs and make instantaneous adjustments. Current ECU processing capabilities, while advanced, still face limitations in handling the complex calculations required for predictive cylinder balancing across the entire operating range of modern V6 engines.

Fuel delivery systems present additional complications. Even with direct injection technology, achieving perfectly equal fuel distribution across all cylinders remains challenging due to variations in injector performance, fuel pressure fluctuations, and cylinder-to-cylinder differences in air-fuel mixing dynamics. These variations become more pronounced as engines age, further complicating balance maintenance over the vehicle's lifetime.

Environmental factors introduce yet another layer of complexity. Temperature variations across the engine block, particularly during cold starts or under heavy loads, create uneven thermal expansion that affects cylinder compression ratios and combustion efficiency. Current thermal management systems cannot fully compensate for these dynamic thermal gradients.

Manufacturing tolerances, while continuously improving, still contribute to cylinder-to-cylinder variations. Minute differences in piston rings, valve seats, combustion chamber geometry, and port designs create unique combustion characteristics for each cylinder that cannot be completely standardized during production, necessitating more sophisticated adaptive balancing technologies.

Current calibration methodologies also present limitations. Most cylinder balance calibrations are performed under steady-state conditions that do not adequately represent real-world driving scenarios. The resulting calibrations often represent compromises that work reasonably well across operating conditions but fail to achieve optimal balance in specific situations.

Current Cylinder Balance Optimization Techniques

01 Cylinder balance detection methods

Various methods are employed to detect and monitor cylinder balance in V6 engines. These include using sensors to measure exhaust gas temperature, pressure variations, or vibration patterns across cylinders. Advanced diagnostic systems can analyze these measurements to identify imbalances between cylinders, allowing for early detection of potential issues that could affect engine performance and efficiency.- Cylinder balance detection methods: Various methods are employed to detect cylinder balance in V6 engines, including pressure sensors, vibration analysis, and exhaust gas monitoring. These detection systems help identify imbalances between cylinders by measuring combustion efficiency, pressure variations, and exhaust gas composition. Early detection of cylinder imbalance allows for timely maintenance and prevents engine damage or performance degradation.

- Electronic control systems for cylinder balancing: Advanced electronic control systems are used to maintain cylinder balance in V6 engines. These systems utilize engine control units (ECUs) that continuously monitor and adjust fuel injection timing, ignition timing, and air-fuel ratios for each cylinder. By making real-time adjustments based on sensor data, these electronic systems ensure optimal combustion across all cylinders, improving engine performance, fuel efficiency, and reducing emissions.

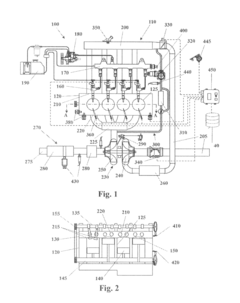

- Mechanical design solutions for V6 cylinder balance: Specific mechanical design elements are incorporated into V6 engines to achieve better cylinder balance. These include optimized crankshaft configurations, counterweights, firing order arrangements, and specialized intake and exhaust manifold designs. The physical arrangement of cylinders and connecting components significantly impacts the engine's balance characteristics, with modern designs focusing on reducing vibration and improving overall engine smoothness.

- Vibration reduction techniques for V6 engines: Various vibration reduction techniques are employed to improve cylinder balance in V6 engines. These include balance shafts, harmonic balancers, tuned mass dampers, and specialized engine mounts. These components work to counteract the inherent vibrations caused by the V6 configuration, particularly those resulting from uneven firing intervals or cylinder-to-cylinder variations, thereby enhancing engine smoothness and longevity.

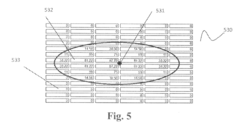

- Testing and calibration procedures for cylinder balance: Specialized testing and calibration procedures are essential for maintaining optimal V6 engine cylinder balance. These include dynamometer testing, compression testing, cylinder contribution tests, and fuel injector calibration. Regular diagnostic procedures help identify imbalances between cylinders and allow for precise adjustments to fuel delivery, ignition timing, and valve operation, ensuring consistent power delivery and minimizing wear across all cylinders.

02 Fuel injection control for cylinder balancing

Fuel injection control systems are designed to optimize cylinder balance in V6 engines by precisely adjusting the amount of fuel delivered to each cylinder. These systems use feedback from various sensors to make real-time adjustments to injection timing and duration, ensuring that each cylinder receives the appropriate fuel-air mixture for balanced combustion, which improves engine smoothness, performance, and emissions.Expand Specific Solutions03 Mechanical balancing mechanisms

V6 engines employ various mechanical components and designs to achieve cylinder balance. These include counterweights, balance shafts, and specific crankshaft configurations that offset the inherent vibrations caused by the V6 layout. The positioning of cylinders at specific angles and the firing order are also carefully engineered to minimize vibration and ensure smooth operation across the entire RPM range.Expand Specific Solutions04 Electronic control systems for cylinder balancing

Advanced electronic control units (ECUs) manage cylinder balance in V6 engines through sophisticated algorithms that continuously monitor engine parameters. These systems can adjust ignition timing, valve timing, and other variables to compensate for cylinder-to-cylinder variations. Some systems incorporate adaptive learning capabilities that adjust parameters over time based on operating conditions to maintain optimal balance throughout the engine's life.Expand Specific Solutions05 Testing and calibration equipment

Specialized equipment and procedures are used for testing and calibrating cylinder balance in V6 engines. These include dynamometers, pressure transducers, and computerized diagnostic tools that can measure power output, combustion pressure, and other parameters for each cylinder. Calibration procedures may involve adjusting mechanical components or reprogramming electronic control modules to achieve optimal balance across all cylinders.Expand Specific Solutions

Leading Manufacturers and Competition in V6 Engine Market

The V6 engine cylinder balance optimization market is in a mature growth phase, with established players focusing on power stability innovations. The global market size for engine optimization technologies exceeds $15 billion, driven by increasing demand for fuel-efficient, high-performance engines. Leading automotive manufacturers like Toyota, Honda, Hyundai, and Ford dominate with advanced cylinder balancing technologies, while specialized engineering firms such as BorgWarner, AVL List, and Southwest Research Institute provide cutting-edge solutions. The technology has reached high maturity levels with companies like Cummins, Weichai Power, and Vitesco Technologies pushing boundaries through electronic control systems and real-time monitoring capabilities. Asian manufacturers including SAIC Motor and Chery Automobile are rapidly closing technological gaps with established Western counterparts.

Ford Global Technologies LLC

Technical Solution: Ford has developed an advanced cylinder balance optimization system for V6 engines that utilizes real-time combustion pressure sensing and individual cylinder fuel injection control. Their technology incorporates adaptive learning algorithms that continuously monitor and adjust fuel delivery, ignition timing, and valve timing for each cylinder independently. Ford's system employs closed-loop control with knock sensors and exhaust gas temperature monitoring to maintain optimal balance across all operating conditions. The technology includes a proprietary calibration methodology that accounts for manufacturing variations and component wear over time, ensuring consistent power delivery throughout the engine's lifecycle. Ford has also integrated this system with their EcoBoost technology, allowing for precise cylinder balance even under varying boost pressure conditions.

Strengths: Exceptional integration with turbocharging systems; comprehensive adaptive learning capabilities; proven reliability in production vehicles. Weaknesses: System complexity requires sophisticated ECU processing power; higher implementation cost compared to traditional systems; requires additional sensors that increase maintenance complexity.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive V6 cylinder balance optimization system centered around their D-4S (Direct injection 4-stroke gasoline engine Superior version) technology. This system uniquely combines both port and direct injection methods to optimize combustion across all cylinders under varying operating conditions. Toyota's approach incorporates VVT-iE (Variable Valve Timing-intelligent by Electric motor) that uses electric motor actuation for intake valve timing precision regardless of engine oil temperature or pressure. Their cylinder balance technology utilizes individual cylinder ionization current sensing to detect combustion quality variations between cylinders and make real-time adjustments. Toyota has implemented advanced ECU algorithms that continuously monitor and adjust fuel delivery timing, quantity, and injection pattern for each cylinder independently. The system also features adaptive learning capabilities that compensate for component wear and manufacturing variations over time.

Strengths: Exceptional reliability and durability; dual injection system provides flexibility across operating conditions; precise electric valve timing control enables consistent cylinder balance. Weaknesses: System complexity increases manufacturing costs; requires more sophisticated maintenance procedures; slightly higher weight compared to simpler systems.

Key Patents and Innovations in V6 Cylinder Balancing

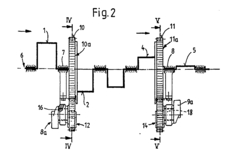

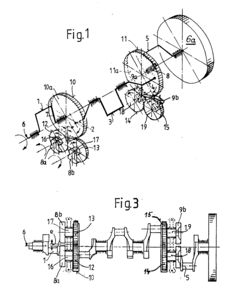

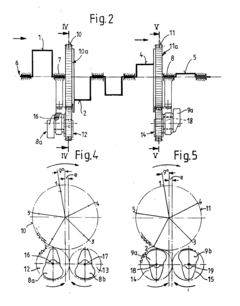

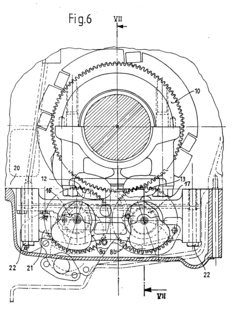

Balancing of the second order couple of a 5 cylinder in-line combustion engine

PatentInactiveEP0462411A1

Innovation

- The balancer shafts are driven from the third and eighth cheeks of the crankshaft, with balancing masses positioned below the bearing points, allowing for integration within the crankcase without significant modification, and are offset to cancel out inertial forces, eliminating second-order moments of inertia.

Method of controlling the fuel injection in an internal combustion engine

PatentActiveUS20150051813A1

Innovation

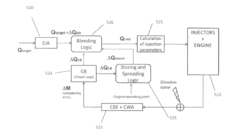

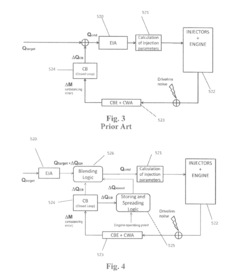

- A method that estimates and stores injector fuel quantity deviations in a map, blending estimated and stored corrections to balance fuel injection quantities across cylinders, using a combination of closed-loop and open-loop controls, with adjustments for production tolerances and injector drift, to ensure reliable torque equalization.

Emissions Regulations Impact on V6 Engine Design

Emissions regulations have become a pivotal factor in shaping modern V6 engine design, particularly concerning cylinder balance optimization for power stability. Since the early 2000s, increasingly stringent standards like Euro 6, EPA Tier 3, and California's LEV III have forced manufacturers to fundamentally rethink combustion efficiency and emissions control strategies in V6 configurations.

The regulatory landscape has created a complex optimization challenge where engineers must balance power delivery stability against emissions compliance. NOx, particulate matter, and CO2 limits have directly influenced firing order designs and cylinder deactivation technologies. For instance, selective cylinder shutdown during partial load conditions must maintain harmonic balance while simultaneously reducing emissions—a technical compromise that wasn't necessary in pre-regulation era engines.

Exhaust gas recirculation (EGR) systems, mandated by emissions standards, introduce additional variables to cylinder balance equations. The uneven distribution of recirculated exhaust gases across cylinders can create combustion variations that destabilize power output. This has prompted the development of sophisticated cylinder-specific EGR control strategies and feedback systems to maintain balance while meeting emissions targets.

Catalytic converter efficiency requirements have also impacted cylinder balance approaches. Modern V6 engines often employ cylinder-specific fuel mapping and ignition timing adjustments to ensure optimal exhaust temperature profiles for catalyst operation. These adjustments inherently affect power balance between cylinders and require compensation through advanced engine management systems.

The introduction of real-world driving emissions (RDE) testing in Europe and similar protocols globally has further complicated V6 cylinder balance optimization. Engineers must now ensure stable power delivery across a much wider operating envelope than traditional laboratory test cycles required, necessitating more sophisticated balance control algorithms that adapt to varying driving conditions.

Cold-start emissions regulations have particularly influenced V6 cylinder balance strategies, as manufacturers implement cylinder-specific enrichment patterns and variable valve timing profiles to rapidly reach catalyst light-off temperatures. These strategies create temporary imbalances that must be carefully managed to maintain drivability during warm-up phases.

Looking forward, upcoming regulations like Euro 7 and next-generation CAFE standards will likely push V6 designs toward even more aggressive cylinder deactivation, potentially operating as effective 3-cylinder or 4-cylinder engines under many conditions. This evolution will demand revolutionary approaches to maintaining power stability while meeting increasingly stringent emissions targets.

The regulatory landscape has created a complex optimization challenge where engineers must balance power delivery stability against emissions compliance. NOx, particulate matter, and CO2 limits have directly influenced firing order designs and cylinder deactivation technologies. For instance, selective cylinder shutdown during partial load conditions must maintain harmonic balance while simultaneously reducing emissions—a technical compromise that wasn't necessary in pre-regulation era engines.

Exhaust gas recirculation (EGR) systems, mandated by emissions standards, introduce additional variables to cylinder balance equations. The uneven distribution of recirculated exhaust gases across cylinders can create combustion variations that destabilize power output. This has prompted the development of sophisticated cylinder-specific EGR control strategies and feedback systems to maintain balance while meeting emissions targets.

Catalytic converter efficiency requirements have also impacted cylinder balance approaches. Modern V6 engines often employ cylinder-specific fuel mapping and ignition timing adjustments to ensure optimal exhaust temperature profiles for catalyst operation. These adjustments inherently affect power balance between cylinders and require compensation through advanced engine management systems.

The introduction of real-world driving emissions (RDE) testing in Europe and similar protocols globally has further complicated V6 cylinder balance optimization. Engineers must now ensure stable power delivery across a much wider operating envelope than traditional laboratory test cycles required, necessitating more sophisticated balance control algorithms that adapt to varying driving conditions.

Cold-start emissions regulations have particularly influenced V6 cylinder balance strategies, as manufacturers implement cylinder-specific enrichment patterns and variable valve timing profiles to rapidly reach catalyst light-off temperatures. These strategies create temporary imbalances that must be carefully managed to maintain drivability during warm-up phases.

Looking forward, upcoming regulations like Euro 7 and next-generation CAFE standards will likely push V6 designs toward even more aggressive cylinder deactivation, potentially operating as effective 3-cylinder or 4-cylinder engines under many conditions. This evolution will demand revolutionary approaches to maintaining power stability while meeting increasingly stringent emissions targets.

NVH Considerations in V6 Cylinder Balance Solutions

Noise, Vibration, and Harshness (NVH) considerations represent a critical dimension in the optimization of V6 engine cylinder balance for power stability. The inherent design characteristics of V6 engines create unique NVH challenges that must be addressed through sophisticated engineering solutions to ensure passenger comfort and vehicle quality perception.

V6 engines typically generate primary and secondary order vibrations due to their firing sequence and piston movement patterns. When cylinder balance is compromised, these vibrations can amplify significantly, creating not only power instability but also undesirable tactile and auditory feedback throughout the vehicle structure. Research indicates that even minor imbalances of 3-5% between cylinders can increase vibration amplitude by up to 40% at certain engine speeds.

Advanced modal analysis techniques have revealed that V6 engines with 60-degree bank angles exhibit different NVH characteristics compared to 90-degree configurations. The 60-degree V6 designs inherently produce more second-order vibrations requiring additional balancing mechanisms, while 90-degree configurations may introduce challenges in packaging and weight distribution that indirectly affect NVH performance.

Modern cylinder balance optimization strategies must incorporate real-time NVH monitoring systems that can detect subtle changes in vibration patterns before they become perceptible to occupants. Accelerometers strategically positioned on engine mounts and chassis connection points provide valuable data for adaptive control algorithms that can adjust fuel delivery and ignition timing to maintain optimal balance.

Material selection plays a significant role in NVH management for V6 engines. Composite materials with specific damping characteristics are increasingly being utilized for engine covers and intake manifolds to attenuate high-frequency vibrations. Meanwhile, hydraulic engine mounts with variable damping properties have demonstrated effectiveness in isolating low-frequency vibrations that typically occur during cylinder imbalance conditions.

The integration of active noise cancellation technologies represents an emerging approach to addressing NVH issues related to cylinder imbalance. These systems use strategically placed microphones to detect combustion-related noise patterns and generate counter-phase sound waves through the vehicle's audio system, effectively neutralizing undesirable engine sounds before they reach occupant perception thresholds.

Testing protocols for cylinder balance solutions must include comprehensive NVH evaluation across the entire operating range of the engine, with particular attention to transition points where cylinder deactivation or variable valve timing adjustments occur. These transition events often represent the most challenging scenarios for maintaining acceptable NVH characteristics while optimizing power stability and fuel efficiency.

V6 engines typically generate primary and secondary order vibrations due to their firing sequence and piston movement patterns. When cylinder balance is compromised, these vibrations can amplify significantly, creating not only power instability but also undesirable tactile and auditory feedback throughout the vehicle structure. Research indicates that even minor imbalances of 3-5% between cylinders can increase vibration amplitude by up to 40% at certain engine speeds.

Advanced modal analysis techniques have revealed that V6 engines with 60-degree bank angles exhibit different NVH characteristics compared to 90-degree configurations. The 60-degree V6 designs inherently produce more second-order vibrations requiring additional balancing mechanisms, while 90-degree configurations may introduce challenges in packaging and weight distribution that indirectly affect NVH performance.

Modern cylinder balance optimization strategies must incorporate real-time NVH monitoring systems that can detect subtle changes in vibration patterns before they become perceptible to occupants. Accelerometers strategically positioned on engine mounts and chassis connection points provide valuable data for adaptive control algorithms that can adjust fuel delivery and ignition timing to maintain optimal balance.

Material selection plays a significant role in NVH management for V6 engines. Composite materials with specific damping characteristics are increasingly being utilized for engine covers and intake manifolds to attenuate high-frequency vibrations. Meanwhile, hydraulic engine mounts with variable damping properties have demonstrated effectiveness in isolating low-frequency vibrations that typically occur during cylinder imbalance conditions.

The integration of active noise cancellation technologies represents an emerging approach to addressing NVH issues related to cylinder imbalance. These systems use strategically placed microphones to detect combustion-related noise patterns and generate counter-phase sound waves through the vehicle's audio system, effectively neutralizing undesirable engine sounds before they reach occupant perception thresholds.

Testing protocols for cylinder balance solutions must include comprehensive NVH evaluation across the entire operating range of the engine, with particular attention to transition points where cylinder deactivation or variable valve timing adjustments occur. These transition events often represent the most challenging scenarios for maintaining acceptable NVH characteristics while optimizing power stability and fuel efficiency.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!