How to Enhance V6 Engine Turbocharger Performance

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Turbocharger Technology Background and Objectives

Turbocharging technology for V6 engines has evolved significantly since its inception in the early 20th century. Initially developed for aircraft engines during World War I, turbochargers found their way into automotive applications by the 1960s. The V6 engine configuration, with its balanced design and compact footprint, became a popular platform for turbocharging implementation in the 1980s as manufacturers sought to increase power output while maintaining fuel efficiency in response to stricter emissions regulations.

The evolution of V6 turbocharger technology has been marked by several key advancements, including the transition from single to twin-turbo configurations, the development of variable geometry turbochargers (VGT), and more recently, electric turbochargers. These innovations have progressively addressed the inherent challenges of turbocharging, such as turbo lag and heat management, while enhancing overall engine performance and efficiency.

Current market trends indicate a growing demand for turbocharged V6 engines across various vehicle segments, from luxury sedans to performance SUVs and trucks. This demand is driven by the dual requirements of increased power density and improved fuel economy, as well as the need to meet increasingly stringent global emissions standards. The ability of turbocharged V6 engines to deliver V8-like performance with better fuel efficiency positions them as a strategic technology in the automotive industry's transition toward more sustainable propulsion systems.

The primary technical objectives for enhancing V6 engine turbocharger performance center around four key areas: improving transient response to minimize turbo lag, optimizing boost pressure control for better power delivery across the RPM range, enhancing thermal efficiency to maximize energy recovery from exhaust gases, and ensuring durability under increased stress conditions. These objectives must be achieved while maintaining or improving emissions compliance and fuel economy.

Looking forward, the trajectory of V6 turbocharger technology is increasingly influenced by electrification trends. Hybrid-assisted turbocharging systems, including electric turbochargers and electric superchargers working in conjunction with traditional turbochargers, represent promising avenues for performance enhancement. Additionally, advanced materials science and computational fluid dynamics are enabling more precise design optimizations that were previously unattainable.

The ultimate goal of V6 turbocharger enhancement is to create a propulsion system that delivers immediate throttle response, consistent power delivery throughout the engine's operating range, optimal thermal efficiency, and robust reliability—all while meeting or exceeding emissions requirements and contributing to overall vehicle efficiency targets. This represents a complex engineering challenge that requires balancing multiple, sometimes competing, performance parameters.

The evolution of V6 turbocharger technology has been marked by several key advancements, including the transition from single to twin-turbo configurations, the development of variable geometry turbochargers (VGT), and more recently, electric turbochargers. These innovations have progressively addressed the inherent challenges of turbocharging, such as turbo lag and heat management, while enhancing overall engine performance and efficiency.

Current market trends indicate a growing demand for turbocharged V6 engines across various vehicle segments, from luxury sedans to performance SUVs and trucks. This demand is driven by the dual requirements of increased power density and improved fuel economy, as well as the need to meet increasingly stringent global emissions standards. The ability of turbocharged V6 engines to deliver V8-like performance with better fuel efficiency positions them as a strategic technology in the automotive industry's transition toward more sustainable propulsion systems.

The primary technical objectives for enhancing V6 engine turbocharger performance center around four key areas: improving transient response to minimize turbo lag, optimizing boost pressure control for better power delivery across the RPM range, enhancing thermal efficiency to maximize energy recovery from exhaust gases, and ensuring durability under increased stress conditions. These objectives must be achieved while maintaining or improving emissions compliance and fuel economy.

Looking forward, the trajectory of V6 turbocharger technology is increasingly influenced by electrification trends. Hybrid-assisted turbocharging systems, including electric turbochargers and electric superchargers working in conjunction with traditional turbochargers, represent promising avenues for performance enhancement. Additionally, advanced materials science and computational fluid dynamics are enabling more precise design optimizations that were previously unattainable.

The ultimate goal of V6 turbocharger enhancement is to create a propulsion system that delivers immediate throttle response, consistent power delivery throughout the engine's operating range, optimal thermal efficiency, and robust reliability—all while meeting or exceeding emissions requirements and contributing to overall vehicle efficiency targets. This represents a complex engineering challenge that requires balancing multiple, sometimes competing, performance parameters.

Market Demand Analysis for Enhanced Turbocharger Systems

The global market for enhanced turbocharger systems has witnessed substantial growth in recent years, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles with improved performance. The V6 engine segment specifically represents a significant portion of this market, as these engines balance power delivery with reasonable fuel economy in mid-size to large vehicles.

Market research indicates that the automotive turbocharger market was valued at approximately $16 billion in 2022, with projections suggesting growth to reach $25 billion by 2028, representing a compound annual growth rate of 7.8%. Within this broader market, enhanced performance turbochargers for V6 engines constitute a premium segment with higher profit margins and specialized applications.

Consumer behavior analysis reveals a growing preference for vehicles that deliver both power and efficiency. This trend is particularly evident in markets like North America and Europe, where V6-powered SUVs, crossovers, and premium sedans remain popular choices. Surveys indicate that 68% of consumers in these markets consider engine performance a critical factor in purchasing decisions, while 72% simultaneously express concern about fuel economy.

The commercial vehicle sector presents another substantial market opportunity. Medium-duty trucks and specialized commercial vehicles often utilize turbocharged V6 engines, with fleet operators increasingly demanding systems that can reduce operational costs through improved fuel efficiency while maintaining necessary power outputs for load-carrying capabilities.

Regionally, North America currently leads the market for enhanced V6 turbocharger systems, followed by Europe and rapidly growing Asian markets, particularly China and India. The latter regions are experiencing accelerated growth rates due to increasing vehicle production volumes and rising consumer affluence.

Industry forecasts suggest that technological advancements in turbocharger design will continue to drive market expansion. Specifically, innovations addressing turbo lag, heat management, and integration with hybrid powertrains are expected to create new market segments. The aftermarket for performance turbocharger upgrades also represents a significant opportunity, estimated at $3.2 billion globally with annual growth exceeding 9%.

Competition analysis reveals that OEM suppliers dominate the market, with tier-one automotive suppliers controlling approximately 75% of production. However, specialized performance aftermarket manufacturers have carved out profitable niches by offering enhanced turbocharger solutions that exceed OEM specifications for enthusiasts and specialized applications.

Market research indicates that the automotive turbocharger market was valued at approximately $16 billion in 2022, with projections suggesting growth to reach $25 billion by 2028, representing a compound annual growth rate of 7.8%. Within this broader market, enhanced performance turbochargers for V6 engines constitute a premium segment with higher profit margins and specialized applications.

Consumer behavior analysis reveals a growing preference for vehicles that deliver both power and efficiency. This trend is particularly evident in markets like North America and Europe, where V6-powered SUVs, crossovers, and premium sedans remain popular choices. Surveys indicate that 68% of consumers in these markets consider engine performance a critical factor in purchasing decisions, while 72% simultaneously express concern about fuel economy.

The commercial vehicle sector presents another substantial market opportunity. Medium-duty trucks and specialized commercial vehicles often utilize turbocharged V6 engines, with fleet operators increasingly demanding systems that can reduce operational costs through improved fuel efficiency while maintaining necessary power outputs for load-carrying capabilities.

Regionally, North America currently leads the market for enhanced V6 turbocharger systems, followed by Europe and rapidly growing Asian markets, particularly China and India. The latter regions are experiencing accelerated growth rates due to increasing vehicle production volumes and rising consumer affluence.

Industry forecasts suggest that technological advancements in turbocharger design will continue to drive market expansion. Specifically, innovations addressing turbo lag, heat management, and integration with hybrid powertrains are expected to create new market segments. The aftermarket for performance turbocharger upgrades also represents a significant opportunity, estimated at $3.2 billion globally with annual growth exceeding 9%.

Competition analysis reveals that OEM suppliers dominate the market, with tier-one automotive suppliers controlling approximately 75% of production. However, specialized performance aftermarket manufacturers have carved out profitable niches by offering enhanced turbocharger solutions that exceed OEM specifications for enthusiasts and specialized applications.

Current Turbocharger Technology Limitations and Challenges

Despite significant advancements in turbocharger technology, V6 engine turbocharging systems face several persistent limitations that impede optimal performance enhancement. The primary challenge remains turbo lag, which creates a noticeable delay between throttle input and power delivery. This phenomenon is particularly pronounced in V6 engines due to their unique exhaust pulse characteristics and manifold configurations, resulting in less efficient energy transfer to the turbine wheel compared to inline engine layouts.

Thermal management presents another critical challenge, as V6 turbochargers operate under extreme temperature conditions exceeding 1000°C at the turbine inlet. These thermal stresses accelerate component degradation and reduce service life, while also limiting the potential for higher boost pressures that could otherwise enhance performance. Current heat-resistant materials and cooling systems have not fully resolved these thermal constraints.

Packaging constraints pose significant engineering challenges specific to V6 configurations. The compact "V" layout creates limited space for optimal turbocharger placement, often forcing compromises in exhaust manifold design and turbocharger sizing. These spatial limitations frequently result in sub-optimal exhaust gas flow dynamics and increased back pressure, negatively impacting overall system efficiency.

Boost threshold optimization remains problematic, particularly in achieving the balance between low-end responsiveness and high-end power. Variable geometry turbochargers (VGT) have partially addressed this issue, but their complexity, cost, and reliability concerns have limited widespread adoption in high-performance V6 applications. Twin-scroll designs offer improvements but still struggle with the inherent exhaust pulse characteristics of V6 engines.

Efficiency losses throughout the system represent another significant limitation. Current turbocharger designs for V6 engines typically achieve peak efficiency of only 60-70%, with substantial energy losses occurring through heat dissipation, bearing friction, and aerodynamic inefficiencies within the compressor and turbine wheels. These losses directly impact fuel economy and performance potential.

Durability and reliability concerns persist, particularly under high-boost conditions. Bearing systems remain vulnerable to oil contamination and inadequate lubrication during extreme operating conditions. Additionally, compressor surge and turbine overspeeding during transient conditions continue to challenge control system development and mechanical design.

Finally, emissions compliance adds another layer of complexity, as turbocharger systems must now balance performance objectives with increasingly stringent emissions regulations. The integration of turbochargers with exhaust aftertreatment systems often creates competing design priorities that compromise optimal performance characteristics.

Thermal management presents another critical challenge, as V6 turbochargers operate under extreme temperature conditions exceeding 1000°C at the turbine inlet. These thermal stresses accelerate component degradation and reduce service life, while also limiting the potential for higher boost pressures that could otherwise enhance performance. Current heat-resistant materials and cooling systems have not fully resolved these thermal constraints.

Packaging constraints pose significant engineering challenges specific to V6 configurations. The compact "V" layout creates limited space for optimal turbocharger placement, often forcing compromises in exhaust manifold design and turbocharger sizing. These spatial limitations frequently result in sub-optimal exhaust gas flow dynamics and increased back pressure, negatively impacting overall system efficiency.

Boost threshold optimization remains problematic, particularly in achieving the balance between low-end responsiveness and high-end power. Variable geometry turbochargers (VGT) have partially addressed this issue, but their complexity, cost, and reliability concerns have limited widespread adoption in high-performance V6 applications. Twin-scroll designs offer improvements but still struggle with the inherent exhaust pulse characteristics of V6 engines.

Efficiency losses throughout the system represent another significant limitation. Current turbocharger designs for V6 engines typically achieve peak efficiency of only 60-70%, with substantial energy losses occurring through heat dissipation, bearing friction, and aerodynamic inefficiencies within the compressor and turbine wheels. These losses directly impact fuel economy and performance potential.

Durability and reliability concerns persist, particularly under high-boost conditions. Bearing systems remain vulnerable to oil contamination and inadequate lubrication during extreme operating conditions. Additionally, compressor surge and turbine overspeeding during transient conditions continue to challenge control system development and mechanical design.

Finally, emissions compliance adds another layer of complexity, as turbocharger systems must now balance performance objectives with increasingly stringent emissions regulations. The integration of turbochargers with exhaust aftertreatment systems often creates competing design priorities that compromise optimal performance characteristics.

Current V6 Turbocharger Enhancement Solutions

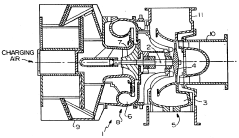

01 Turbocharger design for V6 engines

Specific turbocharger designs optimized for V6 engine configurations can significantly improve performance. These designs account for the unique exhaust pulse characteristics of V6 engines and often include specialized housing geometries, turbine wheel designs, and compressor configurations that maximize efficiency while minimizing lag. Advanced materials and manufacturing techniques allow for lighter, more responsive turbocharger components that can withstand higher temperatures and pressures.- Turbocharger design for V6 engines: Specific turbocharger designs can be implemented for V6 engines to enhance performance. These designs consider the unique exhaust flow characteristics of V6 engines and optimize the turbocharger geometry accordingly. Features such as twin-scroll turbines, variable geometry turbochargers, and optimized compressor wheel designs can significantly improve the turbocharging efficiency in V6 engines, resulting in better overall engine performance.

- Exhaust gas management systems: Effective exhaust gas management systems are crucial for optimizing turbocharger performance in V6 engines. These systems include exhaust manifold designs that minimize flow restrictions, exhaust gas recirculation systems that reduce emissions while maintaining performance, and waste gate controls that regulate boost pressure. Proper exhaust gas management ensures optimal turbocharger operation across different engine loads and speeds.

- Electronic control systems for turbocharger optimization: Advanced electronic control systems can significantly enhance turbocharger performance in V6 engines. These systems use sensors to monitor various engine parameters and adjust turbocharger operation accordingly. Features such as variable boost control, electronic waste gate actuation, and adaptive mapping based on driving conditions allow for optimized turbocharger performance across the entire engine operating range, improving both power output and fuel efficiency.

- Twin-turbo configurations for V6 engines: Twin-turbo configurations are particularly effective for V6 engines, with each turbocharger serving one bank of cylinders. This setup reduces turbo lag by using smaller turbochargers that spool up more quickly than a single larger unit. Various configurations include parallel twin-turbo systems where both turbochargers operate simultaneously, and sequential systems where one turbocharger operates at low engine speeds and both engage at higher speeds for maximum power output.

- Intercooling and charge air management: Effective intercooling and charge air management systems are essential for maximizing turbocharger performance in V6 engines. These systems cool the compressed air from the turbocharger before it enters the engine, increasing air density and allowing for more efficient combustion. Advanced intercooler designs, optimized ducting, and charge air distribution systems ensure that all cylinders receive an equal and cooled air charge, improving overall engine performance and reducing the risk of detonation.

02 Twin-turbo and sequential turbocharging systems

Twin-turbo and sequential turbocharging systems are commonly used in V6 engines to optimize performance across the entire RPM range. These systems may employ turbochargers of different sizes working in sequence or in parallel to reduce lag at low RPMs while maintaining boost at higher engine speeds. Advanced control systems manage the transition between turbochargers or adjust their operation based on driving conditions, significantly improving throttle response and overall engine efficiency.Expand Specific Solutions03 Exhaust manifold and wastegate optimization

Optimized exhaust manifold designs and wastegate systems are crucial for V6 turbocharger performance. Specialized manifold geometries that efficiently direct exhaust gases to the turbine while minimizing flow restrictions can significantly improve turbocharger response. Advanced wastegate designs with precise electronic control allow for optimal boost pressure management across various operating conditions, enhancing both performance and fuel efficiency while protecting engine components from excessive pressure.Expand Specific Solutions04 Intercooling and charge air management

Effective intercooling and charge air management systems are essential for maximizing V6 turbocharger performance. Advanced intercooler designs reduce the temperature of compressed air before it enters the engine, increasing air density and allowing for more efficient combustion. Sophisticated charge air management systems, including variable geometry components and electronic controls, optimize airflow based on engine load and speed, resulting in improved throttle response, increased power output, and better fuel economy.Expand Specific Solutions05 Electronic control and integration systems

Advanced electronic control systems are critical for optimizing V6 turbocharger performance. These systems continuously monitor and adjust turbocharger operation based on multiple parameters including engine speed, load, temperature, and driver input. Integration with other engine management systems allows for coordinated control of fuel injection, valve timing, and ignition to maximize efficiency and power output while maintaining reliability. Some systems also incorporate predictive algorithms that anticipate changes in driving conditions to further enhance responsiveness.Expand Specific Solutions

Key Industry Players in Turbocharger Manufacturing

The V6 engine turbocharger performance enhancement market is in a growth phase, with increasing demand driven by stringent emission regulations and consumer preference for fuel-efficient yet powerful engines. The global automotive turbocharger market is projected to reach approximately $24 billion by 2027, growing at a CAGR of around 6%. Technology maturity varies across players, with established manufacturers like BorgWarner, Garrett Motion, and IHI Corporation leading innovation through advanced variable geometry turbochargers and electric-assist technologies. Major automotive OEMs including Ford, GM, Toyota, Hyundai, and Audi are integrating sophisticated turbocharging solutions into their V6 platforms, while research institutions like Southwest Research Institute and Beijing Institute of Technology are advancing fundamental turbocharger aerodynamics and materials science to overcome traditional performance limitations.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive turbocharger enhancement system for their EcoBoost V6 engines, focusing on integrated solutions rather than standalone components. Their approach combines advanced twin-turbo configurations with innovative wastegate control strategies that dynamically adjust boost pressure based on real-time engine parameters. Ford's patented Active Wastegate Technology uses electronic actuators that respond 25% faster than pneumatic systems, allowing precise boost control throughout the RPM range. Their latest generation incorporates water-cooled bearing housings and integrated exhaust manifolds that reduce thermal mass by approximately 20%, improving cold-start emissions and turbo response. Ford has also pioneered anti-surge compressor housing designs that extend the usable compressor map by up to 15% on the surge line, enabling higher boost at lower engine speeds without compromising reliability.

Strengths: Seamless integration with Ford's comprehensive powertrain control systems; extensive real-world validation across diverse operating conditions; optimized for balance between performance and fuel economy. Weaknesses: Technologies primarily developed for Ford's specific engine architectures may require significant adaptation for other applications; optimization favors everyday driveability over maximum performance; some solutions prioritize cost-effectiveness over absolute performance.

Garrett Motion Technology (Shanghai) Co. Ltd.

Technical Solution: Garrett Motion has developed their G-Series turbochargers specifically optimized for V6 engine applications, featuring advanced aerodynamic designs that deliver up to 20% improvement in turbocharger efficiency. Their proprietary ball bearing technology reduces friction by approximately 50% compared to traditional journal bearings, enabling faster spool-up and improved transient response. Garrett's Variable Nozzle Turbine (VNT) technology incorporates electronically controlled vanes that continuously adjust the effective aspect ratio of the turbine housing, optimizing performance across the entire engine operating range. Their latest innovations include mixed-flow turbine wheel designs that combine radial and axial flow characteristics, providing a broader efficiency island and improved performance at higher pressure ratios. Garrett has also implemented advanced materials including Mar-M alloys in their turbine wheels, capable of withstanding temperatures up to 1050°C while maintaining structural integrity.

Strengths: Industry-leading aerodynamic efficiency across wide operating ranges; extensive application engineering support for OEMs; proven durability with specialized coatings and materials for extreme conditions. Weaknesses: Premium pricing structure compared to conventional turbocharger designs; complex VNT mechanisms require more sophisticated control systems; some configurations have more restrictive packaging requirements.

Critical Turbocharger Performance Patents and Innovations

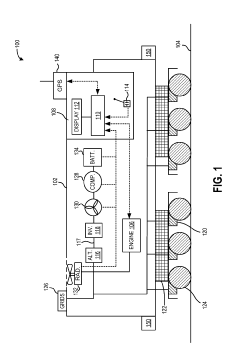

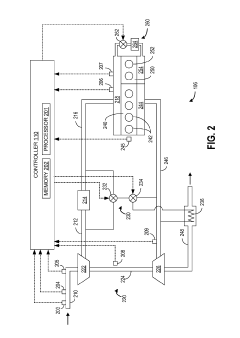

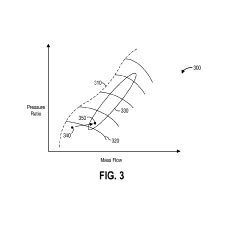

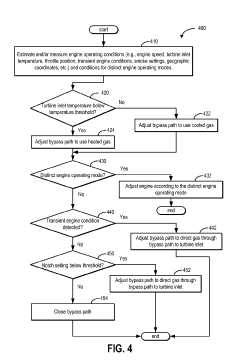

Method and system for controlling engine performance

PatentActiveUS10343757B2

Innovation

- A method and system that includes a bypass path to selectively route gas from downstream of the compressor to upstream of the turbine, adjusting gas flow to improve turbocharger efficiency and airflow, thereby enhancing engine performance across various operating conditions.

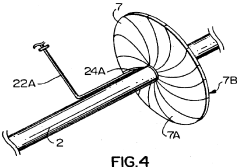

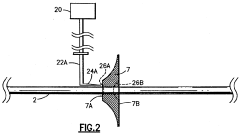

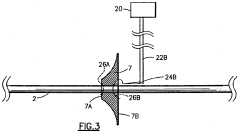

Apparatus and method for improving the performance of a turbocharger-equipped engine

PatentInactiveUS5255514A

Innovation

- An apparatus comprising a conduit means that delivers ion vapors to a region of negligible air pressure adjacent the turbocharger's compressor wheel, using nozzle means to direct the flow and potentially including pumping means for uniform pressure, allowing the vapors to be supplied without degradation through the compressor wheel, which may have holes for minimal interference.

Emissions Regulations Impact on Turbocharger Development

Emissions regulations have become a pivotal factor in turbocharger development for V6 engines, creating both challenges and opportunities for performance enhancement. Since the early 2000s, increasingly stringent standards like Euro 6, EPA Tier 3, and China 6 have fundamentally altered the design parameters for turbocharging systems. These regulations have progressively reduced allowable NOx, particulate matter, and CO2 emissions, forcing manufacturers to reimagine turbocharger technology beyond its traditional role of performance enhancement.

The regulatory landscape has driven significant technological adaptations in turbocharger design. Variable geometry turbochargers (VGT) have gained prominence as they allow precise control of boost pressure across different engine loads, optimizing both performance and emissions compliance. Additionally, electric turbochargers and hybrid turbo systems have emerged as solutions to reduce turbo lag while maintaining emissions compliance, particularly beneficial for V6 engines where balanced performance is crucial.

Material science has also evolved in response to emissions requirements. High-temperature resistant alloys and ceramic components have been developed to withstand the increased thermal stress from exhaust gas recirculation (EGR) systems, which are commonly paired with turbochargers to reduce NOx emissions. These materials enable turbochargers to maintain efficiency and durability despite operating in more challenging thermal environments.

The integration of turbochargers with aftertreatment systems represents another significant development. Modern V6 turbocharger systems must be designed to work harmoniously with selective catalytic reduction (SCR), diesel particulate filters (DPF), and gasoline particulate filters (GPF). This integration requires sophisticated control algorithms and sensor technology to balance performance with emissions compliance across various driving conditions.

Regional variations in emissions standards have created a complex global market for turbocharger technology. Manufacturers must develop flexible turbocharging solutions that can be adapted to meet different regulatory requirements across markets. This has led to modular turbocharger designs and scalable technologies that can be configured to meet specific regional emissions targets while maintaining performance characteristics.

Looking forward, upcoming regulations like Euro 7 and equivalent standards in other regions will further tighten emissions limits, potentially accelerating the shift toward electrified turbocharging solutions. These regulations will likely drive innovation in areas such as low-inertia turbine designs, advanced wastegate control systems, and integrated electric motor-assisted turbochargers specifically optimized for V6 engine configurations.

The regulatory landscape has driven significant technological adaptations in turbocharger design. Variable geometry turbochargers (VGT) have gained prominence as they allow precise control of boost pressure across different engine loads, optimizing both performance and emissions compliance. Additionally, electric turbochargers and hybrid turbo systems have emerged as solutions to reduce turbo lag while maintaining emissions compliance, particularly beneficial for V6 engines where balanced performance is crucial.

Material science has also evolved in response to emissions requirements. High-temperature resistant alloys and ceramic components have been developed to withstand the increased thermal stress from exhaust gas recirculation (EGR) systems, which are commonly paired with turbochargers to reduce NOx emissions. These materials enable turbochargers to maintain efficiency and durability despite operating in more challenging thermal environments.

The integration of turbochargers with aftertreatment systems represents another significant development. Modern V6 turbocharger systems must be designed to work harmoniously with selective catalytic reduction (SCR), diesel particulate filters (DPF), and gasoline particulate filters (GPF). This integration requires sophisticated control algorithms and sensor technology to balance performance with emissions compliance across various driving conditions.

Regional variations in emissions standards have created a complex global market for turbocharger technology. Manufacturers must develop flexible turbocharging solutions that can be adapted to meet different regulatory requirements across markets. This has led to modular turbocharger designs and scalable technologies that can be configured to meet specific regional emissions targets while maintaining performance characteristics.

Looking forward, upcoming regulations like Euro 7 and equivalent standards in other regions will further tighten emissions limits, potentially accelerating the shift toward electrified turbocharging solutions. These regulations will likely drive innovation in areas such as low-inertia turbine designs, advanced wastegate control systems, and integrated electric motor-assisted turbochargers specifically optimized for V6 engine configurations.

Materials Science Advancements for Turbocharger Efficiency

Recent advancements in materials science have revolutionized turbocharger design and efficiency for V6 engines. Traditional turbocharger components manufactured from conventional nickel-based alloys are increasingly being replaced with titanium aluminide (TiAl) and gamma titanium aluminide (γ-TiAl) alloys. These materials offer superior strength-to-weight ratios and maintain structural integrity at temperatures exceeding 800°C, significantly enhancing turbocharger performance while reducing rotational inertia.

Ceramic materials, particularly silicon nitride (Si3N4) and silicon carbide (SiC), have emerged as breakthrough options for turbine wheels. These ceramics demonstrate exceptional heat resistance up to 1300°C and minimal thermal expansion, allowing for tighter clearances and improved efficiency. The reduced mass of ceramic components enables faster spool-up times, effectively minimizing turbo lag—a critical performance factor in V6 engine applications.

Carbon fiber reinforced polymers (CFRPs) and carbon-carbon composites are being implemented in non-rotating turbocharger components such as housings and heat shields. These materials provide substantial weight reduction while maintaining necessary structural properties. Additionally, their superior thermal insulation characteristics help maintain optimal operating temperatures and protect surrounding engine components from excessive heat.

Surface coating technologies have advanced considerably, with thermal barrier coatings (TBCs) like yttria-stabilized zirconia (YSZ) extending component lifespan by providing thermal insulation and oxidation resistance. Meanwhile, diamond-like carbon (DLC) coatings applied to bearing surfaces reduce friction and wear, improving overall turbocharger efficiency and responsiveness.

Additive manufacturing techniques have enabled the production of complex geometries previously impossible with traditional manufacturing methods. These techniques allow for optimized internal cooling channels, integrated wastegate mechanisms, and variable geometry components with reduced weight and enhanced aerodynamic properties. The ability to create lattice structures and topology-optimized designs has resulted in components that maintain strength while significantly reducing mass.

Hybrid material systems combining metals with ceramics or composites are showing promise in addressing the diverse thermal and mechanical demands of turbocharger operation. These systems strategically utilize different materials in specific areas of the turbocharger to optimize performance characteristics such as thermal management, rotational dynamics, and durability under high-stress conditions.

Looking forward, research into high-entropy alloys (HEAs) and metal matrix composites (MMCs) shows potential for creating turbocharger components with unprecedented combinations of high-temperature strength, oxidation resistance, and reduced density—key factors in pushing V6 engine turbocharger performance to new heights.

Ceramic materials, particularly silicon nitride (Si3N4) and silicon carbide (SiC), have emerged as breakthrough options for turbine wheels. These ceramics demonstrate exceptional heat resistance up to 1300°C and minimal thermal expansion, allowing for tighter clearances and improved efficiency. The reduced mass of ceramic components enables faster spool-up times, effectively minimizing turbo lag—a critical performance factor in V6 engine applications.

Carbon fiber reinforced polymers (CFRPs) and carbon-carbon composites are being implemented in non-rotating turbocharger components such as housings and heat shields. These materials provide substantial weight reduction while maintaining necessary structural properties. Additionally, their superior thermal insulation characteristics help maintain optimal operating temperatures and protect surrounding engine components from excessive heat.

Surface coating technologies have advanced considerably, with thermal barrier coatings (TBCs) like yttria-stabilized zirconia (YSZ) extending component lifespan by providing thermal insulation and oxidation resistance. Meanwhile, diamond-like carbon (DLC) coatings applied to bearing surfaces reduce friction and wear, improving overall turbocharger efficiency and responsiveness.

Additive manufacturing techniques have enabled the production of complex geometries previously impossible with traditional manufacturing methods. These techniques allow for optimized internal cooling channels, integrated wastegate mechanisms, and variable geometry components with reduced weight and enhanced aerodynamic properties. The ability to create lattice structures and topology-optimized designs has resulted in components that maintain strength while significantly reducing mass.

Hybrid material systems combining metals with ceramics or composites are showing promise in addressing the diverse thermal and mechanical demands of turbocharger operation. These systems strategically utilize different materials in specific areas of the turbocharger to optimize performance characteristics such as thermal management, rotational dynamics, and durability under high-stress conditions.

Looking forward, research into high-entropy alloys (HEAs) and metal matrix composites (MMCs) shows potential for creating turbocharger components with unprecedented combinations of high-temperature strength, oxidation resistance, and reduced density—key factors in pushing V6 engine turbocharger performance to new heights.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!