V6 Engine vs V8 Engine: Performance Metrics Comparison

SEP 3, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 vs V8 Engine Evolution and Objectives

The evolution of automotive engine design has witnessed significant transformations over the decades, with V6 and V8 configurations emerging as dominant architectures for performance vehicles. The V6 engine first gained prominence in the 1950s as manufacturers sought more compact alternatives to inline-six designs while maintaining smooth operation. Meanwhile, V8 engines have been a staple in high-performance applications since the early 20th century, with their development accelerating dramatically during the American muscle car era of the 1960s.

Recent technological advancements have dramatically reshaped both engine types. Direct injection, variable valve timing, cylinder deactivation, and turbocharging have revolutionized these traditional configurations, enabling smaller displacement engines to generate power previously requiring larger displacements. This evolution reflects the industry's response to increasingly stringent emissions regulations while maintaining consumer expectations for performance.

The historical performance gap between V6 and V8 engines has narrowed considerably. Modern turbocharged V6 engines can now produce power outputs that rival naturally aspirated V8s from just a decade ago, while offering improved fuel efficiency. This convergence represents a significant technological achievement and has profound implications for vehicle design and market positioning.

The primary objective of comparing V6 and V8 engines extends beyond simple power metrics. Contemporary analysis must consider the complete performance envelope, including torque curves, power-to-weight ratios, thermal efficiency, and NVH (Noise, Vibration, Harshness) characteristics. Additionally, real-world performance metrics such as acceleration times, passing power, and towing capability provide crucial context for understanding the practical implications of engine architecture choices.

Fuel efficiency has become an increasingly critical factor in engine development trajectories. The industry trend toward downsizing and turbocharging V6 engines represents a strategic response to regulatory pressures while preserving performance characteristics. Simultaneously, V8 engines have evolved through technologies like cylinder deactivation and variable displacement to remain viable in an increasingly efficiency-conscious market.

Looking forward, both engine configurations face existential challenges from electrification. However, the technical knowledge gained from optimizing these internal combustion architectures continues to inform hybrid powertrain development. The performance metrics comparison between V6 and V8 engines thus serves not only to document current capabilities but also to establish benchmarks against which emerging technologies will be measured.

Recent technological advancements have dramatically reshaped both engine types. Direct injection, variable valve timing, cylinder deactivation, and turbocharging have revolutionized these traditional configurations, enabling smaller displacement engines to generate power previously requiring larger displacements. This evolution reflects the industry's response to increasingly stringent emissions regulations while maintaining consumer expectations for performance.

The historical performance gap between V6 and V8 engines has narrowed considerably. Modern turbocharged V6 engines can now produce power outputs that rival naturally aspirated V8s from just a decade ago, while offering improved fuel efficiency. This convergence represents a significant technological achievement and has profound implications for vehicle design and market positioning.

The primary objective of comparing V6 and V8 engines extends beyond simple power metrics. Contemporary analysis must consider the complete performance envelope, including torque curves, power-to-weight ratios, thermal efficiency, and NVH (Noise, Vibration, Harshness) characteristics. Additionally, real-world performance metrics such as acceleration times, passing power, and towing capability provide crucial context for understanding the practical implications of engine architecture choices.

Fuel efficiency has become an increasingly critical factor in engine development trajectories. The industry trend toward downsizing and turbocharging V6 engines represents a strategic response to regulatory pressures while preserving performance characteristics. Simultaneously, V8 engines have evolved through technologies like cylinder deactivation and variable displacement to remain viable in an increasingly efficiency-conscious market.

Looking forward, both engine configurations face existential challenges from electrification. However, the technical knowledge gained from optimizing these internal combustion architectures continues to inform hybrid powertrain development. The performance metrics comparison between V6 and V8 engines thus serves not only to document current capabilities but also to establish benchmarks against which emerging technologies will be measured.

Market Demand Analysis for Engine Configurations

The automotive market has witnessed a significant shift in consumer preferences regarding engine configurations over the past decade. V6 and V8 engines occupy distinct segments within the market, with demand patterns shaped by various factors including fuel economy concerns, environmental regulations, and evolving performance expectations.

Consumer demand for V8 engines remains strong in specific market segments, particularly in luxury vehicles, high-performance sports cars, and full-size trucks. North American markets show continued preference for V8 configurations, with approximately 22% of new vehicle sales featuring V8 engines. This segment values the characteristic power delivery and acoustic signature that V8 engines provide, with consumers willing to accept higher fuel consumption for these attributes.

Meanwhile, V6 engines have experienced substantial growth in market share, expanding from traditional mid-size applications into segments previously dominated by V8 configurations. This transition has been particularly evident in the premium SUV and light truck markets, where advanced V6 designs with turbocharging or supercharging deliver comparable performance metrics to naturally aspirated V8 engines while offering improved fuel efficiency.

Market research indicates that the global demand for V6 engines is projected to grow at a compound annual rate of 3.7% through 2028, outpacing the 1.9% growth rate for V8 configurations. This differential is largely attributed to stringent emissions regulations in European and Asian markets, where taxation policies increasingly penalize larger displacement engines regardless of actual emissions output.

Fleet operators represent another significant market segment, with their purchasing decisions heavily influenced by total cost of ownership calculations. The operational cost advantage of V6 engines, which typically consume 15-25% less fuel than comparable V8 units, has driven substantial adoption in commercial applications where performance requirements can be satisfied by modern V6 designs.

Emerging markets present a more complex demand picture, with status-conscious consumers in developing economies often preferring V8 configurations in premium vehicles, while simultaneously showing strong adoption of efficient V6 options in mainstream models. This dichotomy reflects the market segmentation occurring globally, where V8 engines are increasingly positioned as premium or specialized options rather than mainstream configurations.

Industry forecasts suggest that while absolute sales volumes for both engine types will continue to grow in the near term, their relative market positions will evolve, with V6 configurations gaining share in traditional V8 strongholds through continued advances in power density and efficiency technologies.

Consumer demand for V8 engines remains strong in specific market segments, particularly in luxury vehicles, high-performance sports cars, and full-size trucks. North American markets show continued preference for V8 configurations, with approximately 22% of new vehicle sales featuring V8 engines. This segment values the characteristic power delivery and acoustic signature that V8 engines provide, with consumers willing to accept higher fuel consumption for these attributes.

Meanwhile, V6 engines have experienced substantial growth in market share, expanding from traditional mid-size applications into segments previously dominated by V8 configurations. This transition has been particularly evident in the premium SUV and light truck markets, where advanced V6 designs with turbocharging or supercharging deliver comparable performance metrics to naturally aspirated V8 engines while offering improved fuel efficiency.

Market research indicates that the global demand for V6 engines is projected to grow at a compound annual rate of 3.7% through 2028, outpacing the 1.9% growth rate for V8 configurations. This differential is largely attributed to stringent emissions regulations in European and Asian markets, where taxation policies increasingly penalize larger displacement engines regardless of actual emissions output.

Fleet operators represent another significant market segment, with their purchasing decisions heavily influenced by total cost of ownership calculations. The operational cost advantage of V6 engines, which typically consume 15-25% less fuel than comparable V8 units, has driven substantial adoption in commercial applications where performance requirements can be satisfied by modern V6 designs.

Emerging markets present a more complex demand picture, with status-conscious consumers in developing economies often preferring V8 configurations in premium vehicles, while simultaneously showing strong adoption of efficient V6 options in mainstream models. This dichotomy reflects the market segmentation occurring globally, where V8 engines are increasingly positioned as premium or specialized options rather than mainstream configurations.

Industry forecasts suggest that while absolute sales volumes for both engine types will continue to grow in the near term, their relative market positions will evolve, with V6 configurations gaining share in traditional V8 strongholds through continued advances in power density and efficiency technologies.

Current Technical Limitations and Challenges

Despite the widespread adoption of both V6 and V8 engines across various vehicle segments, several technical limitations and challenges persist when comparing their performance metrics. The fundamental architectural differences between these engine configurations create inherent constraints that engineers continue to grapple with in pursuit of optimal performance.

V6 engines face challenges related to their inherent balance characteristics. While more compact than V8s, they typically require balance shafts to mitigate vibration issues, adding complexity, weight, and potential failure points. This additional hardware can reduce overall efficiency and increase maintenance requirements. Furthermore, the narrower V-angle in most V6 designs (typically 60 degrees) creates packaging challenges when attempting to incorporate advanced intake and exhaust systems.

Thermal management represents another significant challenge, particularly for high-performance applications. V6 engines, with their more compact design, often experience greater heat concentration, potentially leading to thermal efficiency losses and increased cooling system requirements. This becomes especially problematic when attempting to extract V8-level performance from a V6 platform.

For V8 engines, the primary limitations revolve around weight, fuel efficiency, and emissions compliance. The additional cylinders, larger displacement, and more extensive supporting hardware contribute to a weight penalty that affects vehicle dynamics and efficiency. This becomes increasingly problematic as manufacturers face stringent fuel economy and emissions regulations worldwide.

Comparative testing methodologies present another challenge in accurately benchmarking these engine configurations. Standardized testing protocols often fail to capture real-world performance differences across varied driving conditions. Dynamometer testing may not fully represent the dynamic load changes experienced during actual driving, while track testing introduces variables that can obscure engine-specific performance attributes.

The integration of modern technologies like turbocharging, direct injection, and variable valve timing has narrowed the performance gap between V6 and V8 engines, but has simultaneously introduced new complexities in making direct comparisons. A turbocharged V6 may outperform a naturally aspirated V8 in certain metrics while underperforming in others, making absolute performance rankings increasingly nuanced.

Cost considerations also present challenges, as the higher manufacturing complexity of V8 engines must be justified by measurable performance benefits. This becomes particularly relevant as electrification technologies advance, potentially rendering traditional displacement advantages less significant in overall vehicle performance metrics.

V6 engines face challenges related to their inherent balance characteristics. While more compact than V8s, they typically require balance shafts to mitigate vibration issues, adding complexity, weight, and potential failure points. This additional hardware can reduce overall efficiency and increase maintenance requirements. Furthermore, the narrower V-angle in most V6 designs (typically 60 degrees) creates packaging challenges when attempting to incorporate advanced intake and exhaust systems.

Thermal management represents another significant challenge, particularly for high-performance applications. V6 engines, with their more compact design, often experience greater heat concentration, potentially leading to thermal efficiency losses and increased cooling system requirements. This becomes especially problematic when attempting to extract V8-level performance from a V6 platform.

For V8 engines, the primary limitations revolve around weight, fuel efficiency, and emissions compliance. The additional cylinders, larger displacement, and more extensive supporting hardware contribute to a weight penalty that affects vehicle dynamics and efficiency. This becomes increasingly problematic as manufacturers face stringent fuel economy and emissions regulations worldwide.

Comparative testing methodologies present another challenge in accurately benchmarking these engine configurations. Standardized testing protocols often fail to capture real-world performance differences across varied driving conditions. Dynamometer testing may not fully represent the dynamic load changes experienced during actual driving, while track testing introduces variables that can obscure engine-specific performance attributes.

The integration of modern technologies like turbocharging, direct injection, and variable valve timing has narrowed the performance gap between V6 and V8 engines, but has simultaneously introduced new complexities in making direct comparisons. A turbocharged V6 may outperform a naturally aspirated V8 in certain metrics while underperforming in others, making absolute performance rankings increasingly nuanced.

Cost considerations also present challenges, as the higher manufacturing complexity of V8 engines must be justified by measurable performance benefits. This becomes particularly relevant as electrification technologies advance, potentially rendering traditional displacement advantages less significant in overall vehicle performance metrics.

Contemporary Engine Design Solutions

01 Engine Performance Monitoring Systems

Systems for monitoring and analyzing performance metrics of V6 and V8 engines, including real-time data collection and processing. These systems track various parameters such as power output, fuel efficiency, temperature, and pressure to optimize engine performance. Advanced monitoring technologies enable early detection of potential issues and facilitate preventive maintenance, ultimately extending engine life and maintaining optimal performance levels.- Engine Performance Monitoring Systems: Advanced monitoring systems for V6 and V8 engines that collect and analyze performance metrics in real-time. These systems track various parameters such as power output, fuel efficiency, temperature, and pressure to optimize engine performance. The monitoring technology enables early detection of potential issues and provides diagnostic information for maintenance purposes, ultimately extending engine life and maintaining optimal performance levels.

- Comparative Analysis of V6 and V8 Engine Efficiency: Methods and systems for comparing the efficiency metrics between V6 and V8 engines under various operating conditions. These comparative analyses evaluate fuel consumption, power-to-weight ratios, thermal efficiency, and emissions output. The technologies enable manufacturers and users to make informed decisions about engine selection based on specific performance requirements and use cases, balancing power needs with efficiency considerations.

- Performance Optimization Algorithms: Specialized algorithms designed to optimize V6 and V8 engine performance by adjusting operational parameters in real-time. These algorithms process data from multiple sensors to fine-tune fuel injection timing, valve timing, ignition timing, and air-fuel ratios. The technology adapts to changing driving conditions and driver behavior patterns to maximize power output while maintaining efficiency and reducing emissions.

- Cloud-Based Engine Performance Analytics: Cloud computing systems that collect and analyze V6 and V8 engine performance data across multiple vehicles to identify trends and optimization opportunities. These systems aggregate performance metrics from numerous engines to establish benchmarks and identify factors affecting performance. The technology enables manufacturers to develop improvements based on real-world usage patterns and provides users with comparative performance insights against similar engines.

- Predictive Maintenance Based on Performance Metrics: Systems that utilize V6 and V8 engine performance metrics to predict maintenance needs before failures occur. These predictive systems monitor deviations from normal operating parameters to identify early warning signs of component wear or potential failures. The technology helps schedule maintenance interventions at optimal times, reducing downtime and preventing catastrophic failures while extending engine lifespan through timely interventions.

02 Comparative Analysis of V6 and V8 Engine Efficiency

Methods for comparing the efficiency metrics between V6 and V8 engines under various operating conditions. These comparative analyses evaluate fuel consumption, power-to-weight ratios, thermal efficiency, and emissions output. The methodologies help in determining optimal engine configurations for specific applications, considering factors such as vehicle weight, intended use, and environmental regulations.Expand Specific Solutions03 Performance Optimization Algorithms

Algorithmic approaches to optimize V6 and V8 engine performance through electronic control units and software solutions. These algorithms dynamically adjust engine parameters such as timing, fuel injection, and air intake based on real-time performance data. Machine learning techniques are employed to continuously improve engine response and efficiency across varying driving conditions and load requirements.Expand Specific Solutions04 Diagnostic Systems for Engine Performance Evaluation

Diagnostic tools and methodologies specifically designed to evaluate and troubleshoot performance issues in V6 and V8 engines. These systems utilize sensor networks to collect comprehensive data on engine operation, enabling precise identification of performance bottlenecks or mechanical problems. The diagnostic capabilities include trend analysis and predictive modeling to forecast potential failures before they impact vehicle operation.Expand Specific Solutions05 Performance Metrics Visualization and Reporting

Systems for visualizing and reporting engine performance metrics through user interfaces and automated reporting tools. These solutions transform complex engine data into comprehensible visual representations, allowing engineers and end-users to interpret performance trends easily. The reporting frameworks support decision-making processes related to engine maintenance, upgrades, and operational adjustments to achieve optimal performance.Expand Specific Solutions

Key Performance Metrics and Benchmarking Methods

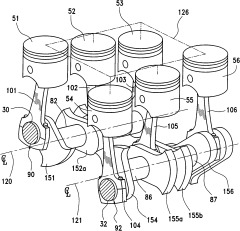

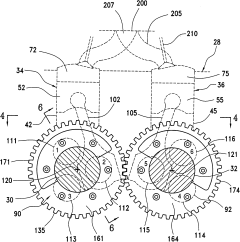

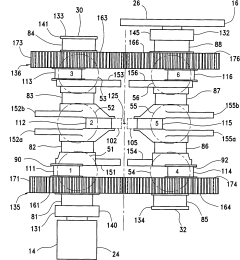

Double-crankshaft engine having reverse rotation inertial mass and vehicle with the same

PatentInactiveCN201367943Y

Innovation

- Design a symmetrically constructed double-crank internal combustion engine by installing two series of cooperating pistons and cylinders in the cylinder block, and using interconnected first and second crankshafts with gear sets and mass blocks respectively to achieve reverse reaction. Toward rotation and balance, eliminate gear vibration and sound, and achieve balance by optimizing piston motion and inertia distribution.

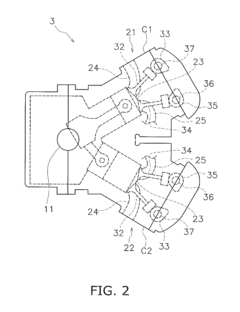

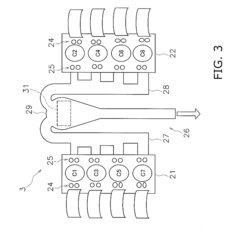

V8 engine and outboard motor

PatentActiveUS20160341097A1

Innovation

- A V8 engine design with a simple construction featuring aggregated exhaust pathways and adjustable exhaust cams, where the central angle of exhaust cams for each cylinder is optimized to minimize valve overlap and reduce exhaust interference, allowing for even firing intervals and improved exhaust gas management.

Fuel Efficiency and Emissions Considerations

Fuel efficiency represents a critical differentiating factor between V6 and V8 engines, with significant implications for both consumer economics and environmental impact. V6 engines typically demonstrate 15-30% better fuel economy compared to their V8 counterparts, primarily due to reduced displacement and fewer cylinders. This efficiency advantage translates to approximately 3-5 miles per gallon improvement in combined driving conditions, which can result in substantial cost savings over a vehicle's lifetime.

The environmental implications of this efficiency gap are equally significant. V6 engines generally produce fewer carbon emissions per mile driven, with studies indicating a reduction of approximately 10-20% in CO2 output compared to equivalent V8 configurations. This difference becomes increasingly important as global emissions regulations continue to tighten across major automotive markets.

Modern engineering advancements have narrowed this efficiency gap through technologies like cylinder deactivation, which allows V8 engines to operate on fewer cylinders during light load conditions. When implemented effectively, this technology can improve V8 fuel economy by 5-15% during highway cruising. Similarly, turbocharging and direct injection have enhanced V6 efficiency while maintaining competitive power outputs.

Emissions compliance represents another key consideration in the V6 versus V8 comparison. V8 engines typically require more complex and costly emissions control systems to meet stringent regulations like Euro 6d and EPA Tier 3 standards. These additional components can increase manufacturing costs and maintenance requirements over the vehicle's lifespan.

The efficiency equation is further complicated by driving patterns and vehicle applications. In stop-and-go urban environments, the V6 advantage becomes more pronounced, while highway cruising at consistent speeds can minimize the efficiency gap. Additionally, when considering total lifecycle emissions, manufacturing complexity must be factored in, as V8 engines often require more raw materials and energy to produce.

Recent market trends indicate a shift toward downsized turbocharged V6 engines in segments traditionally dominated by V8s, particularly in luxury sedans and mid-size SUVs. This transition reflects both regulatory pressures and changing consumer priorities regarding fuel costs and environmental impact. However, in applications requiring sustained high-load operation, such as towing or performance driving, V8 engines may demonstrate relatively better efficiency-to-output ratios under those specific conditions.

The environmental implications of this efficiency gap are equally significant. V6 engines generally produce fewer carbon emissions per mile driven, with studies indicating a reduction of approximately 10-20% in CO2 output compared to equivalent V8 configurations. This difference becomes increasingly important as global emissions regulations continue to tighten across major automotive markets.

Modern engineering advancements have narrowed this efficiency gap through technologies like cylinder deactivation, which allows V8 engines to operate on fewer cylinders during light load conditions. When implemented effectively, this technology can improve V8 fuel economy by 5-15% during highway cruising. Similarly, turbocharging and direct injection have enhanced V6 efficiency while maintaining competitive power outputs.

Emissions compliance represents another key consideration in the V6 versus V8 comparison. V8 engines typically require more complex and costly emissions control systems to meet stringent regulations like Euro 6d and EPA Tier 3 standards. These additional components can increase manufacturing costs and maintenance requirements over the vehicle's lifespan.

The efficiency equation is further complicated by driving patterns and vehicle applications. In stop-and-go urban environments, the V6 advantage becomes more pronounced, while highway cruising at consistent speeds can minimize the efficiency gap. Additionally, when considering total lifecycle emissions, manufacturing complexity must be factored in, as V8 engines often require more raw materials and energy to produce.

Recent market trends indicate a shift toward downsized turbocharged V6 engines in segments traditionally dominated by V8s, particularly in luxury sedans and mid-size SUVs. This transition reflects both regulatory pressures and changing consumer priorities regarding fuel costs and environmental impact. However, in applications requiring sustained high-load operation, such as towing or performance driving, V8 engines may demonstrate relatively better efficiency-to-output ratios under those specific conditions.

Cost-Benefit Analysis of V6 vs V8 Implementations

When evaluating the implementation of V6 versus V8 engines, a comprehensive cost-benefit analysis reveals significant economic implications across multiple dimensions. Initial acquisition costs represent the most immediate financial consideration, with V8 engines typically commanding a 15-30% premium over comparable V6 alternatives. This price differential stems from the additional materials, manufacturing complexity, and engineering requirements inherent in V8 designs.

Fuel economy presents perhaps the most substantial ongoing cost factor. V8 engines generally consume 20-40% more fuel than their V6 counterparts, translating to approximately $500-1,200 in additional annual fuel expenditure for average drivers. This calculation assumes 15,000 miles driven annually with current fuel prices, though the exact differential varies based on driving patterns and specific engine technologies.

Maintenance costs also favor V6 implementations, with fewer components requiring service and replacement. Statistical data indicates V8 engines incur 10-25% higher maintenance costs over a 100,000-mile lifecycle, primarily due to additional spark plugs, more complex cooling systems, and increased oil capacity requirements.

Insurance premiums represent another hidden cost factor, with V8-equipped vehicles typically incurring 5-15% higher insurance rates due to their association with higher-performance vehicles and increased replacement costs. This translates to approximately $100-300 in additional annual insurance expenses for most consumers.

The performance benefits of V8 engines must be weighed against these increased costs. V8 implementations deliver 25-40% more horsepower and 30-45% greater torque on average, enabling superior towing capacity, acceleration, and high-speed performance. For commercial applications requiring heavy towing or hauling, these performance advantages may offset the higher operational costs through improved productivity and capability.

Resale value considerations partially mitigate the higher initial acquisition costs of V8 engines. Market data indicates V8-equipped vehicles typically retain 5-10% more of their original value after five years compared to V6 alternatives in the same vehicle platform, particularly in performance and luxury segments where V8 engines carry greater prestige.

Environmental compliance costs increasingly favor V6 implementations as emissions regulations tighten globally. Manufacturers face higher engineering and compliance costs for V8 engines, which typically produce 15-30% more carbon emissions. These regulatory pressures are gradually being reflected in taxation policies that penalize higher-displacement engines in many markets.

Fuel economy presents perhaps the most substantial ongoing cost factor. V8 engines generally consume 20-40% more fuel than their V6 counterparts, translating to approximately $500-1,200 in additional annual fuel expenditure for average drivers. This calculation assumes 15,000 miles driven annually with current fuel prices, though the exact differential varies based on driving patterns and specific engine technologies.

Maintenance costs also favor V6 implementations, with fewer components requiring service and replacement. Statistical data indicates V8 engines incur 10-25% higher maintenance costs over a 100,000-mile lifecycle, primarily due to additional spark plugs, more complex cooling systems, and increased oil capacity requirements.

Insurance premiums represent another hidden cost factor, with V8-equipped vehicles typically incurring 5-15% higher insurance rates due to their association with higher-performance vehicles and increased replacement costs. This translates to approximately $100-300 in additional annual insurance expenses for most consumers.

The performance benefits of V8 engines must be weighed against these increased costs. V8 implementations deliver 25-40% more horsepower and 30-45% greater torque on average, enabling superior towing capacity, acceleration, and high-speed performance. For commercial applications requiring heavy towing or hauling, these performance advantages may offset the higher operational costs through improved productivity and capability.

Resale value considerations partially mitigate the higher initial acquisition costs of V8 engines. Market data indicates V8-equipped vehicles typically retain 5-10% more of their original value after five years compared to V6 alternatives in the same vehicle platform, particularly in performance and luxury segments where V8 engines carry greater prestige.

Environmental compliance costs increasingly favor V6 implementations as emissions regulations tighten globally. Manufacturers face higher engineering and compliance costs for V8 engines, which typically produce 15-30% more carbon emissions. These regulatory pressures are gradually being reflected in taxation policies that penalize higher-displacement engines in many markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!