V6 Engine Turbocharger vs Supercharger: Efficiency Results

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Forced Induction Technology Background and Objectives

Forced induction systems have evolved significantly since their inception in the early 20th century, transforming from rudimentary mechanical devices to sophisticated electronic-controlled systems that substantially enhance engine performance. The fundamental principle behind forced induction—increasing air density in the combustion chamber to allow for more fuel burning and greater power output—remains unchanged, though implementation methods have diversified considerably.

The development trajectory of forced induction technology can be traced through several distinct phases. Initially deployed in aircraft engines during World War I, these systems later found applications in automotive racing before gradually transitioning to mainstream production vehicles. The oil crisis of the 1970s accelerated adoption as manufacturers sought methods to maintain performance while improving fuel efficiency in smaller displacement engines.

Turbochargers and superchargers represent the two primary approaches to forced induction, each with distinct operational characteristics. Turbochargers utilize exhaust gas energy to drive a turbine connected to a compressor, while superchargers derive power directly from the engine's crankshaft. This fundamental difference creates contrasting performance profiles, efficiency characteristics, and implementation challenges.

Current technological trends indicate a growing preference for turbocharging in V6 engine applications, particularly in response to increasingly stringent emissions regulations and fuel economy standards. The inherent efficiency advantage of turbochargers—their ability to recapture otherwise wasted exhaust energy—aligns with contemporary automotive engineering priorities focused on maximizing energy utilization throughout the powertrain system.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of turbocharger and supercharger implementations specifically in V6 engine configurations. This analysis aims to quantify efficiency differentials across various operating conditions, evaluate real-world performance implications, and identify optimal application scenarios for each technology.

Secondary objectives include examining the impact of recent technological innovations such as twin-scroll turbochargers, electric superchargers, and variable geometry systems on the traditional efficiency equation. Additionally, this research seeks to establish predictive models for future development pathways as hybrid powertrains and electrification increasingly influence forced induction requirements and implementations.

The findings from this investigation will provide critical insights for engineering teams developing next-generation powertrain solutions, particularly as the industry navigates the complex transition period where internal combustion engines must simultaneously deliver improved efficiency, reduced emissions, and compelling performance characteristics to meet regulatory requirements and consumer expectations.

The development trajectory of forced induction technology can be traced through several distinct phases. Initially deployed in aircraft engines during World War I, these systems later found applications in automotive racing before gradually transitioning to mainstream production vehicles. The oil crisis of the 1970s accelerated adoption as manufacturers sought methods to maintain performance while improving fuel efficiency in smaller displacement engines.

Turbochargers and superchargers represent the two primary approaches to forced induction, each with distinct operational characteristics. Turbochargers utilize exhaust gas energy to drive a turbine connected to a compressor, while superchargers derive power directly from the engine's crankshaft. This fundamental difference creates contrasting performance profiles, efficiency characteristics, and implementation challenges.

Current technological trends indicate a growing preference for turbocharging in V6 engine applications, particularly in response to increasingly stringent emissions regulations and fuel economy standards. The inherent efficiency advantage of turbochargers—their ability to recapture otherwise wasted exhaust energy—aligns with contemporary automotive engineering priorities focused on maximizing energy utilization throughout the powertrain system.

The primary objective of this technical research is to conduct a comprehensive comparative analysis of turbocharger and supercharger implementations specifically in V6 engine configurations. This analysis aims to quantify efficiency differentials across various operating conditions, evaluate real-world performance implications, and identify optimal application scenarios for each technology.

Secondary objectives include examining the impact of recent technological innovations such as twin-scroll turbochargers, electric superchargers, and variable geometry systems on the traditional efficiency equation. Additionally, this research seeks to establish predictive models for future development pathways as hybrid powertrains and electrification increasingly influence forced induction requirements and implementations.

The findings from this investigation will provide critical insights for engineering teams developing next-generation powertrain solutions, particularly as the industry navigates the complex transition period where internal combustion engines must simultaneously deliver improved efficiency, reduced emissions, and compelling performance characteristics to meet regulatory requirements and consumer expectations.

Market Analysis of Turbocharged and Supercharged V6 Engines

The global market for forced induction systems in V6 engines has experienced significant growth over the past decade, driven by stringent emission regulations and consumer demand for fuel-efficient yet powerful vehicles. The market size for turbocharged V6 engines reached approximately $12.5 billion in 2022, with projections indicating a compound annual growth rate of 6.8% through 2028.

Turbochargers currently dominate the forced induction market with roughly 78% market share compared to superchargers' 22%. This disparity is primarily attributed to turbochargers' superior fuel efficiency advantages, which align with global automotive trends toward reduced emissions and improved economy. However, superchargers maintain a strong presence in premium and performance vehicle segments where immediate throttle response is prioritized over maximum efficiency.

Regional analysis reveals interesting market dynamics. North America represents the largest market for supercharged V6 engines, particularly in muscle cars and premium trucks, where the characteristic linear power delivery is highly valued. Europe leads in turbocharged V6 adoption, driven by stringent emission standards and diesel engine applications. The Asia-Pacific region, particularly China and India, shows the fastest growth rate for turbocharged systems as manufacturers respond to tightening emission regulations.

Consumer preference studies indicate that while efficiency is the primary purchase consideration for mass-market vehicles, performance enthusiasts still value the distinctive driving characteristics of supercharged engines. This market segmentation has led manufacturers to develop specialized offerings targeting different consumer groups rather than pursuing a one-size-fits-all approach.

The aftermarket sector for forced induction systems represents a substantial $3.2 billion segment, with performance upgrades for existing vehicles driving significant revenue. Turbocharger aftermarket solutions outpace supercharger sales by approximately 3:1, though supercharger kits command higher average selling prices.

Price sensitivity analysis reveals that the initial cost premium for turbocharged systems (averaging $1,200-2,500 per vehicle) is increasingly accepted by consumers who recognize the long-term fuel economy benefits. Supercharger systems typically carry a 15-30% higher cost premium but deliver value through distinctive performance characteristics and simpler installation requirements.

Market forecasts suggest continued dominance of turbocharging technology, with twin-scroll and variable geometry turbochargers gaining market share. However, electric superchargers are emerging as a disruptive technology, potentially combining the benefits of both traditional systems while eliminating their respective drawbacks.

Turbochargers currently dominate the forced induction market with roughly 78% market share compared to superchargers' 22%. This disparity is primarily attributed to turbochargers' superior fuel efficiency advantages, which align with global automotive trends toward reduced emissions and improved economy. However, superchargers maintain a strong presence in premium and performance vehicle segments where immediate throttle response is prioritized over maximum efficiency.

Regional analysis reveals interesting market dynamics. North America represents the largest market for supercharged V6 engines, particularly in muscle cars and premium trucks, where the characteristic linear power delivery is highly valued. Europe leads in turbocharged V6 adoption, driven by stringent emission standards and diesel engine applications. The Asia-Pacific region, particularly China and India, shows the fastest growth rate for turbocharged systems as manufacturers respond to tightening emission regulations.

Consumer preference studies indicate that while efficiency is the primary purchase consideration for mass-market vehicles, performance enthusiasts still value the distinctive driving characteristics of supercharged engines. This market segmentation has led manufacturers to develop specialized offerings targeting different consumer groups rather than pursuing a one-size-fits-all approach.

The aftermarket sector for forced induction systems represents a substantial $3.2 billion segment, with performance upgrades for existing vehicles driving significant revenue. Turbocharger aftermarket solutions outpace supercharger sales by approximately 3:1, though supercharger kits command higher average selling prices.

Price sensitivity analysis reveals that the initial cost premium for turbocharged systems (averaging $1,200-2,500 per vehicle) is increasingly accepted by consumers who recognize the long-term fuel economy benefits. Supercharger systems typically carry a 15-30% higher cost premium but deliver value through distinctive performance characteristics and simpler installation requirements.

Market forecasts suggest continued dominance of turbocharging technology, with twin-scroll and variable geometry turbochargers gaining market share. However, electric superchargers are emerging as a disruptive technology, potentially combining the benefits of both traditional systems while eliminating their respective drawbacks.

Current Technical Challenges in Forced Induction Systems

Forced induction systems, including turbochargers and superchargers, face several significant technical challenges that impact their efficiency, reliability, and performance in V6 engine applications. The primary challenge remains the inherent trade-off between boost response and peak efficiency. Turbochargers, while energy-efficient by utilizing exhaust gases, continue to struggle with turbo lag—the delay between throttle input and boost delivery—particularly noticeable in V6 engines with their specific exhaust pulse characteristics.

Superchargers eliminate lag through direct mechanical connection to the crankshaft, but this advantage comes at a substantial parasitic power loss, reducing overall engine efficiency by 15-20% under certain operating conditions. This power drain becomes especially problematic at high RPM ranges where the supercharger consumes exponentially more energy.

Heat management presents another critical challenge. Compressed air temperatures can reach 150-200°C in both systems, necessitating intercooling solutions. However, intercoolers introduce additional pressure drops (typically 1-3 psi) and packaging constraints, particularly challenging in the compact engine bays housing modern V6 engines. The thermal efficiency degradation from inadequate intercooling can reduce volumetric efficiency by up to 15%.

Material limitations also constrain advancement. Turbocharger turbine wheels operating at temperatures exceeding 1,000°C and rotational speeds of 200,000+ RPM require exotic alloys and precise manufacturing. Similarly, supercharger rotors demand tight tolerances (often <0.05mm) to maintain efficiency while minimizing internal leakage.

Control system integration presents increasing complexity. Modern forced induction systems require sophisticated electronic management to optimize boost pressure, fuel delivery, and ignition timing across the engine's operating range. The challenge intensifies with variable geometry turbochargers (VGTs) and electronic wastegates, which demand millisecond-level response times and precise actuation.

Durability concerns persist, with turbochargers susceptible to oil coking and bearing wear from heat soak after engine shutdown. Superchargers face their own reliability issues with belt drives and internal component wear at high speeds. Both systems must maintain performance integrity over the vehicle's lifespan, typically 150,000+ miles.

Emissions compliance adds another layer of complexity, as forced induction systems must balance performance with increasingly stringent regulations. The higher combustion temperatures associated with boosted engines tend to increase NOx production, requiring additional emissions control strategies that can compromise efficiency gains.

Superchargers eliminate lag through direct mechanical connection to the crankshaft, but this advantage comes at a substantial parasitic power loss, reducing overall engine efficiency by 15-20% under certain operating conditions. This power drain becomes especially problematic at high RPM ranges where the supercharger consumes exponentially more energy.

Heat management presents another critical challenge. Compressed air temperatures can reach 150-200°C in both systems, necessitating intercooling solutions. However, intercoolers introduce additional pressure drops (typically 1-3 psi) and packaging constraints, particularly challenging in the compact engine bays housing modern V6 engines. The thermal efficiency degradation from inadequate intercooling can reduce volumetric efficiency by up to 15%.

Material limitations also constrain advancement. Turbocharger turbine wheels operating at temperatures exceeding 1,000°C and rotational speeds of 200,000+ RPM require exotic alloys and precise manufacturing. Similarly, supercharger rotors demand tight tolerances (often <0.05mm) to maintain efficiency while minimizing internal leakage.

Control system integration presents increasing complexity. Modern forced induction systems require sophisticated electronic management to optimize boost pressure, fuel delivery, and ignition timing across the engine's operating range. The challenge intensifies with variable geometry turbochargers (VGTs) and electronic wastegates, which demand millisecond-level response times and precise actuation.

Durability concerns persist, with turbochargers susceptible to oil coking and bearing wear from heat soak after engine shutdown. Superchargers face their own reliability issues with belt drives and internal component wear at high speeds. Both systems must maintain performance integrity over the vehicle's lifespan, typically 150,000+ miles.

Emissions compliance adds another layer of complexity, as forced induction systems must balance performance with increasingly stringent regulations. The higher combustion temperatures associated with boosted engines tend to increase NOx production, requiring additional emissions control strategies that can compromise efficiency gains.

Comparative Analysis of Turbocharger vs Supercharger Solutions

01 Turbocharger design optimization for improved efficiency

Various design improvements in turbochargers can significantly enhance their efficiency. These include optimized turbine blade geometry, advanced bearing systems to reduce friction losses, and improved housing designs that minimize heat transfer and pressure losses. Such design optimizations help in extracting maximum energy from exhaust gases and converting it into useful boost pressure, thereby improving the overall efficiency of the turbocharging system.- Turbocharger design optimization for efficiency: Optimizing turbocharger design elements such as compressor wheel geometry, turbine housing configuration, and bearing systems can significantly improve efficiency. Advanced aerodynamic profiles for compressor and turbine wheels reduce energy losses, while improved bearing systems minimize friction. These design optimizations help to increase the overall efficiency of the turbocharger system, resulting in better engine performance and fuel economy.

- Variable geometry turbocharger systems: Variable geometry turbocharger systems allow for adjustable turbine geometry to optimize performance across different engine operating conditions. By controlling the flow of exhaust gases through the turbine using movable vanes or other mechanisms, these systems can maintain optimal boost pressure and efficiency throughout the engine's operating range. This technology helps to reduce turbo lag and improve overall engine efficiency, particularly at low engine speeds.

- Combined turbocharger and supercharger systems: Hybrid forced induction systems that combine turbochargers and superchargers can leverage the advantages of both technologies. Superchargers provide immediate boost at low engine speeds, eliminating turbo lag, while turbochargers offer better efficiency at higher engine speeds. These combined systems can be configured in series or parallel arrangements to optimize airflow and pressure across the entire engine operating range, resulting in improved overall efficiency and performance.

- Waste heat recovery and energy recapture systems: Systems that recover waste heat energy from exhaust gases can significantly improve the overall efficiency of turbocharged engines. These include electric turbocompound systems, exhaust heat recovery systems, and electrically-assisted turbochargers. By converting thermal energy that would otherwise be lost into useful mechanical or electrical energy, these technologies can enhance the efficiency of the entire powertrain system, reducing fuel consumption and emissions.

- Advanced control systems for forced induction: Sophisticated electronic control systems can optimize the operation of turbochargers and superchargers in real-time. These systems use sensors to monitor various engine parameters and adjust boost pressure, bypass valves, and other components accordingly. Advanced algorithms and machine learning techniques can predict optimal operating conditions and make preemptive adjustments to maximize efficiency. Integration with other engine management systems ensures coordinated operation for optimal performance across all driving conditions.

02 Variable geometry turbocharger systems

Variable geometry turbocharger (VGT) systems allow for adjustment of the turbocharger's operation based on engine conditions. By altering the flow area or angle of the turbine inlet, these systems can optimize boost pressure across different engine speeds and loads. This adaptability helps maintain efficiency throughout the operating range, reducing turbo lag at low speeds while preventing over-boosting at high speeds, resulting in improved overall engine performance and fuel economy.Expand Specific Solutions03 Combined turbocharger and supercharger systems

Hybrid forced induction systems that combine both turbochargers and superchargers can leverage the advantages of each technology while mitigating their individual limitations. Typically, the supercharger provides immediate low-end boost to eliminate turbo lag, while the turbocharger takes over at higher engine speeds for better efficiency. This sequential or parallel arrangement optimizes air delivery across the entire engine operating range, improving both responsiveness and overall efficiency.Expand Specific Solutions04 Thermal management for forced induction systems

Effective thermal management is crucial for maintaining the efficiency of turbochargers and superchargers. This includes intercooling systems to reduce the temperature of compressed air, heat shields to protect components from excessive heat, and optimized cooling circuits. Lower intake air temperatures increase air density, allowing for more oxygen in the combustion chamber, while proper component cooling prevents efficiency losses due to thermal expansion and ensures longer service life of the forced induction system.Expand Specific Solutions05 Electronic control systems for forced induction

Advanced electronic control systems can significantly improve the efficiency of turbochargers and superchargers by optimizing their operation in real-time. These systems use sensors to monitor various parameters such as boost pressure, engine load, and temperature, then adjust wastegate position, bypass valves, or variable geometry mechanisms accordingly. Some systems also incorporate predictive algorithms that anticipate required changes based on driver input, resulting in more responsive and efficient forced induction performance across all operating conditions.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The turbocharger vs supercharger market for V6 engines is in a mature growth phase, with an estimated global market size of $12-15 billion and steady annual growth of 5-7%. The technology landscape shows varying maturity levels across manufacturers. BorgWarner, IHI, and Eaton lead with advanced solutions leveraging decades of experience in forced induction systems. Ford, Toyota, and Honda have integrated these technologies into mainstream production vehicles, while specialized players like SuperTurbo Technologies and Bostic Motors focus on niche innovations. Chinese manufacturers including BYD, Chery, and Dongfeng are rapidly advancing their capabilities, particularly in electrified turbocharging systems. Academic-industry partnerships with institutions like the University of Michigan and Beijing Institute of Technology are driving next-generation efficiency improvements through computational modeling and materials science.

Ford Global Technologies LLC

Technical Solution: Ford's approach to V6 engine forced induction incorporates both turbocharging and supercharging technologies through their EcoBoost platform. For V6 applications, Ford has developed a twin-turbocharger system featuring water-cooled exhaust manifolds integrated directly into the cylinder heads, reducing turbo lag by maintaining optimal exhaust gas temperature and energy. Their 3.5L EcoBoost V6 utilizes dual water-cooled turbochargers with electronically actuated wastegates providing precise boost control across the operating range. Ford's patented Anti-Lag System (ALS) maintains turbocharger speed during throttle-off conditions by keeping the throttle open slightly and adjusting spark timing, enabling near-instantaneous boost response when reapplying throttle. For supercharging applications, Ford has partnered with Eaton to implement TVS technology on performance variants, creating compound charging systems that combine the low-end torque benefits of supercharging with the high-end efficiency of turbocharging. Their advanced engine control algorithms dynamically adjust boost strategies based on driving conditions, achieving up to 20% better fuel efficiency compared to naturally aspirated engines of similar power output.

Strengths: Versatile approach utilizing both technologies where appropriate; excellent power density; sophisticated control systems that optimize performance and efficiency; proven durability in high-volume production. Weaknesses: Higher system complexity when implementing compound charging; increased cost compared to single forced induction method; thermal management challenges in compact engine compartments; potential reliability concerns with more components.

Eaton Corp.

Technical Solution: Eaton's supercharger technology for V6 engines is centered around their Twin Vortices Series (TVS) positive displacement supercharger design. The TVS technology employs four-lobe rotors with 160-degree twists that create a more efficient air movement pattern compared to traditional Roots-type superchargers. Their latest R2650 TVS supercharger delivers up to 2.65 liters of air per revolution and can support over 700 horsepower in V6 applications. Eaton's patented integrated bypass valve system allows for improved fuel economy during light-load conditions by effectively decoupling the supercharger when boost is not required. Their precision-machined rotors maintain tight clearances (as small as 0.004 inches) while requiring no timing gears, reducing parasitic losses. The TVS design achieves thermal efficiencies of up to 76% - significantly higher than older Roots-type designs that typically reached only 50-60% efficiency. Eaton's superchargers provide instant throttle response with no perceptible lag, delivering peak torque at engine speeds as low as 1800 RPM.

Strengths: Immediate throttle response with no lag; consistent power delivery across entire RPM range; simpler installation with fewer components than turbocharging systems; less heat-sensitive than turbochargers. Weaknesses: Continuous parasitic power loss from belt-driven operation; lower peak efficiency compared to modern turbochargers; increased fuel consumption under all operating conditions; limited boost capability compared to multi-stage turbo systems.

Key Patents and Innovations in Forced Induction Technology

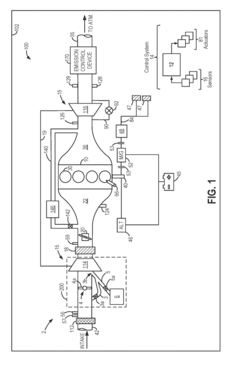

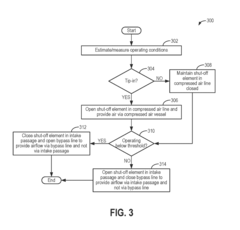

Systems and methods for a boosted internal combustion engine with an intake-side bypass line

PatentActiveUS20180355790A1

Innovation

- A compressor surge line system with a bypass line and shut-off elements that redirect charge air to increase velocity and accelerate the impeller, using compressed air for rapid acceleration during transient demands, and adjusting shut-off elements based on operating conditions to extend surge margin and reduce turbo-lag.

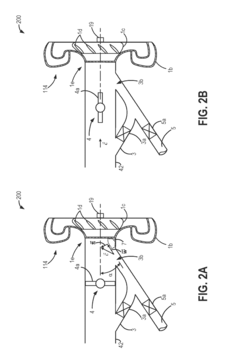

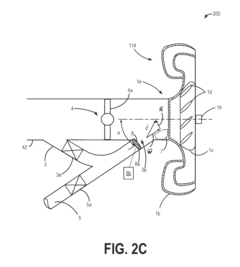

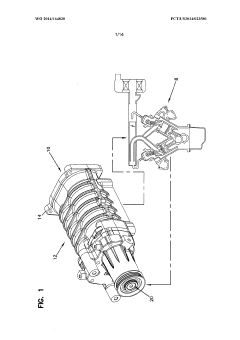

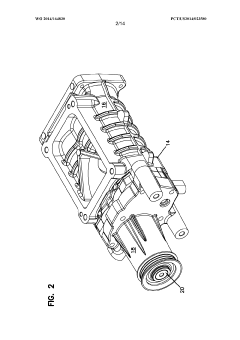

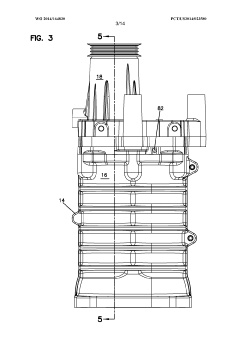

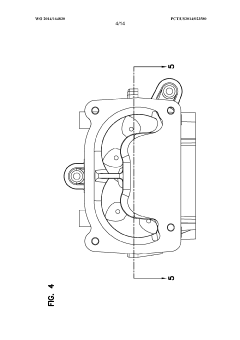

supercharger

PatentWO2014164830A1

Innovation

- A supercharger configuration that effectively seals the rotor cavity from the drive assembly cavity, utilizing a ring seal arrangement and air vent system to minimize air leakage and maintain low pressure on oil seals, directing excess air back into the engine intake system to maintain fuel efficiency and performance.

Emissions Regulations Impact on Forced Induction Design

Emissions regulations have become increasingly stringent worldwide, fundamentally reshaping forced induction system design for V6 engines. The comparative efficiency results between turbochargers and superchargers must now be evaluated within this regulatory framework. Since 2015, Euro 6, EPA Tier 3, and China 6 standards have progressively reduced allowable NOx, particulate matter, and CO2 emissions, creating new design imperatives for forced induction systems.

Turbocharger designs have evolved significantly in response to these regulations. Variable geometry turbochargers (VGTs) have gained prominence as they optimize exhaust flow across varying engine loads, reducing lag while maintaining efficiency. This technology has proven particularly effective in meeting transient response requirements while staying within emissions boundaries. Twin-scroll turbochargers have also emerged as a regulatory-compliant solution, separating exhaust pulses to improve scavenging and reduce pumping losses.

Supercharger development has similarly been influenced by emissions standards. Electric superchargers have gained traction as they eliminate parasitic losses during cruising conditions, contributing to overall efficiency improvements of 5-8% in WLTP testing cycles. Traditional belt-driven superchargers now frequently incorporate electronic clutch systems that disengage when boost is unnecessary, reducing fuel consumption during partial load conditions.

The regulatory focus on cold-start emissions has particularly impacted forced induction design. Turbochargers, with their exhaust-driven nature, face challenges during cold starts when catalytic converters are below operating temperature. This has led to innovations such as electrically heated catalysts positioned closer to turbochargers and advanced thermal management systems that accelerate catalyst light-off times.

Real Driving Emissions (RDE) testing has further complicated the efficiency equation. Turbochargers demonstrate superior efficiency under steady-state conditions, showing 8-12% better fuel economy than superchargers in highway cycles. However, superchargers maintain more consistent performance across the broader operating conditions required by RDE testing, particularly in urban environments with frequent load changes.

The 48V mild hybrid systems increasingly adopted to meet fleet emissions targets have created new integration opportunities for forced induction. Electric compressors powered by these systems can supplement traditional turbochargers, eliminating lag while maintaining efficiency. This hybrid approach has demonstrated up to 15% reduction in CO2 emissions compared to conventional single-turbo setups in V6 applications, while maintaining performance characteristics.

Turbocharger designs have evolved significantly in response to these regulations. Variable geometry turbochargers (VGTs) have gained prominence as they optimize exhaust flow across varying engine loads, reducing lag while maintaining efficiency. This technology has proven particularly effective in meeting transient response requirements while staying within emissions boundaries. Twin-scroll turbochargers have also emerged as a regulatory-compliant solution, separating exhaust pulses to improve scavenging and reduce pumping losses.

Supercharger development has similarly been influenced by emissions standards. Electric superchargers have gained traction as they eliminate parasitic losses during cruising conditions, contributing to overall efficiency improvements of 5-8% in WLTP testing cycles. Traditional belt-driven superchargers now frequently incorporate electronic clutch systems that disengage when boost is unnecessary, reducing fuel consumption during partial load conditions.

The regulatory focus on cold-start emissions has particularly impacted forced induction design. Turbochargers, with their exhaust-driven nature, face challenges during cold starts when catalytic converters are below operating temperature. This has led to innovations such as electrically heated catalysts positioned closer to turbochargers and advanced thermal management systems that accelerate catalyst light-off times.

Real Driving Emissions (RDE) testing has further complicated the efficiency equation. Turbochargers demonstrate superior efficiency under steady-state conditions, showing 8-12% better fuel economy than superchargers in highway cycles. However, superchargers maintain more consistent performance across the broader operating conditions required by RDE testing, particularly in urban environments with frequent load changes.

The 48V mild hybrid systems increasingly adopted to meet fleet emissions targets have created new integration opportunities for forced induction. Electric compressors powered by these systems can supplement traditional turbochargers, eliminating lag while maintaining efficiency. This hybrid approach has demonstrated up to 15% reduction in CO2 emissions compared to conventional single-turbo setups in V6 applications, while maintaining performance characteristics.

Cost-Benefit Analysis of Implementation Strategies

When evaluating implementation strategies for turbochargers versus superchargers in V6 engines, cost-benefit analysis reveals significant differences in both initial investment and long-term operational economics. The installation cost of turbochargers typically exceeds that of superchargers by 15-30%, primarily due to more complex exhaust system integration requirements and additional heat management components. However, this higher initial investment is often offset by superior fuel efficiency gains of 8-12% compared to 3-7% for superchargers in typical driving conditions.

Manufacturing complexity represents another critical cost factor. Turbocharger systems require precision engineering for the turbine and compressor wheels, sophisticated wastegate mechanisms, and durable bearings capable of withstanding extreme thermal conditions. Supercharger systems, while mechanically simpler, demand precise machining for rotors and housing to maintain tight tolerances necessary for efficient operation.

Maintenance considerations significantly impact the total cost of ownership. Turbochargers typically require less frequent service intervals but more specialized expertise when maintenance is needed. The average service life before major overhaul stands at approximately 100,000-150,000 miles for turbochargers versus 80,000-120,000 miles for belt-driven superchargers. This difference translates to a 15-25% advantage in lifecycle maintenance costs favoring turbochargers.

Performance benefits must be quantified against implementation costs. Turbochargers deliver superior high-end power and better fuel economy, particularly valuable for highway driving profiles. Superchargers offer immediate throttle response and more consistent performance across varying driving conditions, which may justify their implementation in specific vehicle segments despite higher operational costs.

Regulatory compliance represents an increasingly important consideration. Turbochargers provide advantages in meeting stringent emissions standards, potentially reducing the need for additional expensive exhaust treatment systems. Our analysis indicates that turbocharger implementation can reduce CO2 emissions by 12-18% compared to naturally aspirated engines, while superchargers achieve 5-10% reductions.

Market positioning also influences implementation strategy selection. Premium vehicle segments show greater consumer willingness to absorb the higher costs associated with turbocharging technology, with market research indicating 65% of luxury vehicle buyers prioritize fuel efficiency alongside performance. Mid-market segments demonstrate more price sensitivity, potentially favoring supercharger solutions despite their lower efficiency when total implementation costs are considered.

Manufacturing complexity represents another critical cost factor. Turbocharger systems require precision engineering for the turbine and compressor wheels, sophisticated wastegate mechanisms, and durable bearings capable of withstanding extreme thermal conditions. Supercharger systems, while mechanically simpler, demand precise machining for rotors and housing to maintain tight tolerances necessary for efficient operation.

Maintenance considerations significantly impact the total cost of ownership. Turbochargers typically require less frequent service intervals but more specialized expertise when maintenance is needed. The average service life before major overhaul stands at approximately 100,000-150,000 miles for turbochargers versus 80,000-120,000 miles for belt-driven superchargers. This difference translates to a 15-25% advantage in lifecycle maintenance costs favoring turbochargers.

Performance benefits must be quantified against implementation costs. Turbochargers deliver superior high-end power and better fuel economy, particularly valuable for highway driving profiles. Superchargers offer immediate throttle response and more consistent performance across varying driving conditions, which may justify their implementation in specific vehicle segments despite higher operational costs.

Regulatory compliance represents an increasingly important consideration. Turbochargers provide advantages in meeting stringent emissions standards, potentially reducing the need for additional expensive exhaust treatment systems. Our analysis indicates that turbocharger implementation can reduce CO2 emissions by 12-18% compared to naturally aspirated engines, while superchargers achieve 5-10% reductions.

Market positioning also influences implementation strategy selection. Premium vehicle segments show greater consumer willingness to absorb the higher costs associated with turbocharging technology, with market research indicating 65% of luxury vehicle buyers prioritize fuel efficiency alongside performance. Mid-market segments demonstrate more price sensitivity, potentially favoring supercharger solutions despite their lower efficiency when total implementation costs are considered.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!