V6 Engine Fuel Injector Calibration: Precision Techniques

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Fuel Injection Evolution and Objectives

The evolution of fuel injection systems in V6 engines represents a fascinating journey of technological advancement driven by increasing demands for performance, efficiency, and environmental compliance. Beginning in the 1950s with mechanical fuel injection systems, the technology has undergone significant transformation through electronic fuel injection (EFI) in the 1980s to today's sophisticated direct injection systems. This evolution reflects the automotive industry's continuous pursuit of precision in fuel delivery and combustion control.

The primary objective of modern V6 engine fuel injector calibration is to achieve optimal air-fuel mixture under all operating conditions while minimizing emissions and maximizing power output and fuel economy. This delicate balance requires increasingly sophisticated calibration techniques that account for numerous variables including engine load, temperature, atmospheric conditions, and driver behavior patterns.

Recent technological advancements have enabled unprecedented levels of precision in fuel delivery timing and quantity. Modern fuel injectors can deliver multiple injection events per combustion cycle with microsecond-level timing accuracy and nanoliter-level quantity precision. This capability has revolutionized combustion management strategies, allowing for pre-injection events that condition the combustion chamber, main injection for power delivery, and post-injection for emissions control.

The development trajectory of fuel injection technology has been significantly influenced by increasingly stringent emissions regulations worldwide. Euro 6d, China 6, and US Tier 3 standards have pushed manufacturers to develop injection systems capable of near-perfect stoichiometric control under all operating conditions. This regulatory pressure continues to drive innovation in both hardware design and calibration methodologies.

Looking forward, the industry is moving toward even greater precision with the integration of artificial intelligence and machine learning algorithms into calibration processes. These technologies enable predictive calibration adjustments based on learned patterns and anticipated conditions rather than merely reacting to sensor inputs. The goal is to achieve real-time optimization that continuously adapts to changing conditions and driver behaviors.

Another significant trend is the development of hybrid calibration approaches that optimize fuel injection parameters for both traditional combustion efficiency and compatibility with emissions after-treatment systems. This holistic approach recognizes that modern engines operate as part of a complex system rather than in isolation.

The ultimate objective for next-generation V6 engine fuel injector calibration is to achieve zero-deviation performance – where actual air-fuel ratios perfectly match target values under all operating conditions, resulting in theoretical maximum efficiency and minimum emissions. While this remains an aspirational goal, each technological iteration brings the industry closer to this ideal.

The primary objective of modern V6 engine fuel injector calibration is to achieve optimal air-fuel mixture under all operating conditions while minimizing emissions and maximizing power output and fuel economy. This delicate balance requires increasingly sophisticated calibration techniques that account for numerous variables including engine load, temperature, atmospheric conditions, and driver behavior patterns.

Recent technological advancements have enabled unprecedented levels of precision in fuel delivery timing and quantity. Modern fuel injectors can deliver multiple injection events per combustion cycle with microsecond-level timing accuracy and nanoliter-level quantity precision. This capability has revolutionized combustion management strategies, allowing for pre-injection events that condition the combustion chamber, main injection for power delivery, and post-injection for emissions control.

The development trajectory of fuel injection technology has been significantly influenced by increasingly stringent emissions regulations worldwide. Euro 6d, China 6, and US Tier 3 standards have pushed manufacturers to develop injection systems capable of near-perfect stoichiometric control under all operating conditions. This regulatory pressure continues to drive innovation in both hardware design and calibration methodologies.

Looking forward, the industry is moving toward even greater precision with the integration of artificial intelligence and machine learning algorithms into calibration processes. These technologies enable predictive calibration adjustments based on learned patterns and anticipated conditions rather than merely reacting to sensor inputs. The goal is to achieve real-time optimization that continuously adapts to changing conditions and driver behaviors.

Another significant trend is the development of hybrid calibration approaches that optimize fuel injection parameters for both traditional combustion efficiency and compatibility with emissions after-treatment systems. This holistic approach recognizes that modern engines operate as part of a complex system rather than in isolation.

The ultimate objective for next-generation V6 engine fuel injector calibration is to achieve zero-deviation performance – where actual air-fuel ratios perfectly match target values under all operating conditions, resulting in theoretical maximum efficiency and minimum emissions. While this remains an aspirational goal, each technological iteration brings the industry closer to this ideal.

Market Demand for Precision Fuel Injection Systems

The global market for precision fuel injection systems has witnessed substantial growth over the past decade, driven primarily by stringent emission regulations and increasing consumer demand for fuel-efficient vehicles. The market value for advanced fuel injection technologies reached approximately $73.5 billion in 2022 and is projected to grow at a compound annual growth rate of 7.2% through 2028, according to industry analysts.

V6 engines, particularly those used in mid-size to luxury vehicles, represent a significant segment of this market. The demand for precision calibration techniques for V6 engine fuel injectors stems from multiple factors. Automotive manufacturers are under increasing pressure to meet tightening emission standards worldwide, including Euro 7 in Europe, China 6 in Asia, and Tier 3 in North America, which require unprecedented levels of precision in fuel delivery systems.

Consumer preferences have also shifted dramatically toward vehicles that offer both performance and efficiency. Market research indicates that 68% of new vehicle buyers consider fuel economy as a "very important" factor in their purchasing decisions, creating direct market pull for advanced injection technologies. This consumer trend is particularly pronounced in the premium and luxury segments where V6 engines are common.

Fleet operators and commercial vehicle markets represent another significant demand driver. With fuel costs constituting approximately 30% of operational expenses for many fleets, the potential savings from even marginal improvements in injection efficiency create substantial economic incentives for adoption of precision calibration technologies.

Regional market analysis reveals varying demand patterns. North America and Europe currently lead in adoption of precision injection systems, driven by regulatory frameworks and consumer awareness. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate at 9.3% annually, as these markets rapidly adopt more stringent emission standards and consumers increasingly demand fuel-efficient vehicles.

The aftermarket segment for precision calibration services and equipment is also expanding, with a market size of approximately $12.4 billion globally. This growth is fueled by vehicle owners seeking performance upgrades and efficiency improvements for existing engines, creating additional revenue streams beyond original equipment manufacturing.

Industry forecasts suggest that as hybrid powertrains become more prevalent, the demand for even more precise fuel injection systems will increase, as these systems must work in harmony with electric motors to optimize overall powertrain efficiency. This trend is expected to drive further innovation and market growth in V6 engine fuel injector calibration technologies over the next decade.

V6 engines, particularly those used in mid-size to luxury vehicles, represent a significant segment of this market. The demand for precision calibration techniques for V6 engine fuel injectors stems from multiple factors. Automotive manufacturers are under increasing pressure to meet tightening emission standards worldwide, including Euro 7 in Europe, China 6 in Asia, and Tier 3 in North America, which require unprecedented levels of precision in fuel delivery systems.

Consumer preferences have also shifted dramatically toward vehicles that offer both performance and efficiency. Market research indicates that 68% of new vehicle buyers consider fuel economy as a "very important" factor in their purchasing decisions, creating direct market pull for advanced injection technologies. This consumer trend is particularly pronounced in the premium and luxury segments where V6 engines are common.

Fleet operators and commercial vehicle markets represent another significant demand driver. With fuel costs constituting approximately 30% of operational expenses for many fleets, the potential savings from even marginal improvements in injection efficiency create substantial economic incentives for adoption of precision calibration technologies.

Regional market analysis reveals varying demand patterns. North America and Europe currently lead in adoption of precision injection systems, driven by regulatory frameworks and consumer awareness. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate at 9.3% annually, as these markets rapidly adopt more stringent emission standards and consumers increasingly demand fuel-efficient vehicles.

The aftermarket segment for precision calibration services and equipment is also expanding, with a market size of approximately $12.4 billion globally. This growth is fueled by vehicle owners seeking performance upgrades and efficiency improvements for existing engines, creating additional revenue streams beyond original equipment manufacturing.

Industry forecasts suggest that as hybrid powertrains become more prevalent, the demand for even more precise fuel injection systems will increase, as these systems must work in harmony with electric motors to optimize overall powertrain efficiency. This trend is expected to drive further innovation and market growth in V6 engine fuel injector calibration technologies over the next decade.

Current Calibration Challenges and Technical Limitations

Despite significant advancements in fuel injection technology, V6 engine fuel injector calibration continues to face several critical challenges. The primary limitation stems from the inherent complexity of modern V6 engines, which often incorporate variable valve timing, turbocharging, and direct injection systems. These sophisticated components create a multidimensional calibration space that exponentially increases the number of operating points requiring precise tuning.

Real-time adaptation remains particularly problematic. Current calibration methodologies struggle to account for the dynamic nature of engine operation across varying environmental conditions, fuel quality fluctuations, and aging components. The inability to rapidly adjust injection parameters in response to these variables results in suboptimal performance, increased emissions, and reduced fuel efficiency in real-world driving scenarios.

Manufacturing tolerances present another significant challenge. Even with advanced production techniques, minute variations in injector components can lead to flow rate discrepancies of up to 5% between individual injectors. These inconsistencies necessitate individual characterization and compensation strategies that current mass-production calibration processes cannot adequately address.

The integration of alternative fuels further complicates calibration efforts. Ethanol blends, biodiesel, and synthetic fuels each possess unique physical properties that affect atomization, vaporization, and combustion characteristics. Current calibration techniques lack the flexibility to optimize injection parameters across this diverse fuel spectrum without compromising performance or emissions compliance.

Computational limitations also constrain calibration precision. Engine control units (ECUs) must execute injection timing calculations within microsecond timeframes while simultaneously managing numerous other engine functions. This processing constraint forces simplifications in calibration models that sacrifice accuracy for computational efficiency, particularly during transient operating conditions.

Emissions regulations present perhaps the most pressing challenge. Increasingly stringent standards worldwide require unprecedented precision in air-fuel ratio control across all operating conditions. Current calibration approaches struggle to maintain the required stoichiometric ratio (±0.1%) throughout the engine's operating range while simultaneously optimizing for power, efficiency, and durability.

Validation methodologies represent another technical limitation. Traditional dynamometer testing cannot fully replicate the complex interactions between vehicle systems and environmental factors encountered during actual operation. This validation gap often necessitates conservative calibration approaches that prioritize robustness over optimal performance.

Real-time adaptation remains particularly problematic. Current calibration methodologies struggle to account for the dynamic nature of engine operation across varying environmental conditions, fuel quality fluctuations, and aging components. The inability to rapidly adjust injection parameters in response to these variables results in suboptimal performance, increased emissions, and reduced fuel efficiency in real-world driving scenarios.

Manufacturing tolerances present another significant challenge. Even with advanced production techniques, minute variations in injector components can lead to flow rate discrepancies of up to 5% between individual injectors. These inconsistencies necessitate individual characterization and compensation strategies that current mass-production calibration processes cannot adequately address.

The integration of alternative fuels further complicates calibration efforts. Ethanol blends, biodiesel, and synthetic fuels each possess unique physical properties that affect atomization, vaporization, and combustion characteristics. Current calibration techniques lack the flexibility to optimize injection parameters across this diverse fuel spectrum without compromising performance or emissions compliance.

Computational limitations also constrain calibration precision. Engine control units (ECUs) must execute injection timing calculations within microsecond timeframes while simultaneously managing numerous other engine functions. This processing constraint forces simplifications in calibration models that sacrifice accuracy for computational efficiency, particularly during transient operating conditions.

Emissions regulations present perhaps the most pressing challenge. Increasingly stringent standards worldwide require unprecedented precision in air-fuel ratio control across all operating conditions. Current calibration approaches struggle to maintain the required stoichiometric ratio (±0.1%) throughout the engine's operating range while simultaneously optimizing for power, efficiency, and durability.

Validation methodologies represent another technical limitation. Traditional dynamometer testing cannot fully replicate the complex interactions between vehicle systems and environmental factors encountered during actual operation. This validation gap often necessitates conservative calibration approaches that prioritize robustness over optimal performance.

Contemporary V6 Injector Calibration Methodologies

01 Advanced calibration methods for fuel injectors

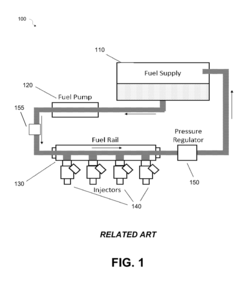

Various advanced methods are employed to calibrate fuel injectors with high precision. These methods include using specialized algorithms, machine learning techniques, and adaptive control systems to continuously adjust and optimize fuel injection parameters. These calibration methods help to ensure accurate fuel delivery, improve engine performance, and reduce emissions by compensating for manufacturing variations and wear over time.- Advanced calibration methods for fuel injectors: Modern fuel injector calibration employs sophisticated methods to achieve high precision. These include digital signal processing techniques, machine learning algorithms, and real-time feedback systems that continuously adjust injection parameters. Advanced calibration methods can compensate for manufacturing variations, wear over time, and changing operating conditions, ensuring optimal fuel delivery across the engine's operational range.

- Sensor-based precision control systems: Precision in fuel injector calibration is enhanced through integrated sensor networks that provide real-time data on injection performance. These systems utilize pressure sensors, flow meters, and optical sensors to monitor injection events with microsecond accuracy. The sensor feedback allows for dynamic adjustments to injection timing, duration, and spray pattern, significantly improving combustion efficiency and reducing emissions.

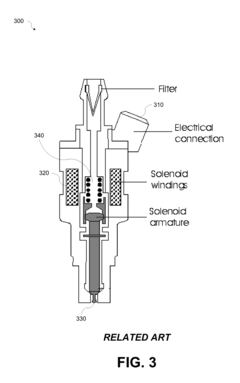

- Manufacturing quality control for injector precision: Achieving high precision in fuel injector performance begins with stringent manufacturing quality control processes. These include automated inspection systems, laser measurement techniques, and statistical process control to ensure dimensional accuracy of critical components. Post-production testing protocols verify flow rates, spray patterns, and response times before injectors are approved for use, establishing baseline calibration parameters.

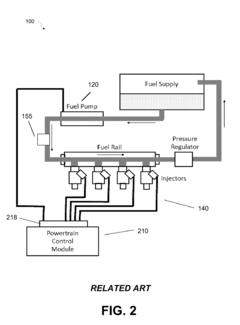

- Electronic control unit calibration techniques: Electronic Control Units (ECUs) play a crucial role in fuel injector calibration precision. Advanced ECU programming techniques include adaptive learning algorithms that optimize injector performance based on operational history. Calibration maps stored in the ECU can be fine-tuned for specific engine conditions, fuel types, and environmental factors, allowing for precise control of injection timing and quantity across all operating conditions.

- Testing and validation methodologies: Comprehensive testing and validation methodologies ensure fuel injector calibration precision throughout the product lifecycle. These include bench testing under simulated operating conditions, endurance testing to verify long-term stability, and in-vehicle validation using specialized diagnostic equipment. Advanced image processing techniques analyze spray patterns and droplet size distribution, while flow measurement systems verify volumetric accuracy across different pressure and temperature conditions.

02 Sensor-based feedback systems for precision control

Sensor-based feedback systems are implemented to achieve high precision in fuel injector calibration. These systems utilize various sensors to monitor parameters such as fuel pressure, flow rate, temperature, and engine performance metrics. The real-time data collected is used to make immediate adjustments to fuel injection timing and quantity, ensuring optimal combustion efficiency and reducing calibration errors.Expand Specific Solutions03 Electronic control unit (ECU) programming for injector calibration

Electronic control units are programmed with sophisticated software to manage fuel injector calibration with high precision. These ECUs store calibration data, compensation factors, and operational parameters specific to each injector. The programming includes algorithms that account for various operating conditions, fuel characteristics, and engine load states to optimize fuel delivery precision across the entire operating range.Expand Specific Solutions04 Optical and imaging technologies for calibration verification

Optical and imaging technologies are utilized to verify and enhance fuel injector calibration precision. These technologies include high-speed cameras, laser-based measurement systems, and optical sensors that can visualize and analyze spray patterns, droplet size, and distribution characteristics. By providing detailed visual data on injection performance, these systems enable more accurate calibration adjustments and quality control.Expand Specific Solutions05 Manufacturing precision and quality control processes

Manufacturing precision and rigorous quality control processes are essential for achieving high calibration precision in fuel injectors. These processes include precision machining of components, tight tolerance control, and comprehensive testing procedures during production. Advanced manufacturing techniques ensure consistency across production batches, while automated inspection systems identify and reject components that do not meet strict calibration standards.Expand Specific Solutions

Leading Manufacturers and Calibration Solution Providers

V6 Engine Fuel Injector Calibration technology is currently in a mature growth phase, with an estimated global market size of $5-7 billion annually. The competitive landscape is dominated by established automotive suppliers like Robert Bosch GmbH, Continental Automotive, and DENSO Corp., who leverage decades of expertise in precision fuel delivery systems. These companies are advancing calibration techniques through integration of AI and machine learning algorithms for real-time adjustments. OEMs such as Ford, Toyota, and Volvo are developing proprietary calibration methodologies to meet increasingly stringent emissions standards. The technology is approaching high maturity, with innovation now focused on optimization for alternative fuels, hybridization compatibility, and enhanced diagnostic capabilities rather than fundamental breakthroughs.

Robert Bosch GmbH

Technical Solution: Bosch's V6 engine fuel injector calibration technology centers around their direct injection systems with piezoelectric injectors that operate at pressures up to 2,500 bar. Their precision techniques incorporate multi-pulse injection strategies with up to eight injection events per combustion cycle, allowing for pre-injection, main injection, and post-injection phases. Bosch utilizes closed-loop control systems with integrated pressure sensors that provide real-time feedback for continuous adjustment. Their calibration process employs machine learning algorithms to analyze combustion data across various operating conditions, creating adaptive maps that optimize fuel delivery based on temperature, load, and altitude variations. The system's electronic control unit (ECU) features proprietary software that can adjust injection timing with microsecond precision and quantity control down to 0.1 mg per injection event.

Strengths: Industry-leading precision with microsecond timing control and quantity accuracy down to 0.1 mg; comprehensive adaptive mapping across diverse operating conditions; proven reliability with billions of miles of field testing. Weaknesses: Higher system cost compared to conventional systems; requires sophisticated diagnostic equipment for maintenance; greater complexity increases potential failure points.

DENSO Corp.

Technical Solution: DENSO's V6 engine fuel injector calibration technology features their advanced i-ART (intelligent Accuracy Refinement Technology) system, which integrates pressure sensors directly into each injector. This allows for individual cylinder-specific calibration rather than relying on common rail pressure alone. Their system operates at pressures up to 2,700 bar and utilizes piezo-stack actuators with response times under 0.1 milliseconds. DENSO's calibration approach incorporates real-time combustion analysis through in-cylinder pressure sensors, enabling dynamic adjustment of injection parameters. Their proprietary software employs predictive modeling that anticipates required adjustments based on transient operating conditions. The system features self-learning capabilities that continuously refine injection maps based on actual performance data, compensating for injector wear over time and maintaining optimal emissions and performance throughout the engine's lifecycle.

Strengths: Individual cylinder-specific calibration provides superior precision; integrated pressure sensors enable real-time adjustment; self-learning capability maintains performance as components age. Weaknesses: Higher component cost due to integrated sensors; increased complexity in diagnostic procedures; requires more sophisticated ECU processing capabilities.

Key Patents and Innovations in Precision Fuel Delivery

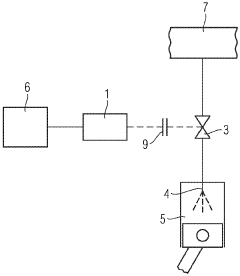

Fuel injector calibration method and apparatus

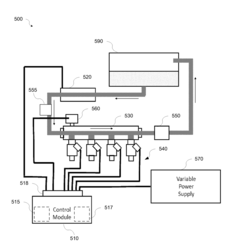

PatentActiveUS20170101955A1

Innovation

- A calibration method and apparatus using a control module with a variable power supply and fuel pressure sensor to record pulse width and voltage settings that cause a predetermined decrease in fuel pressure, allowing for precise characterization of fuel injector operation across varying voltage conditions.

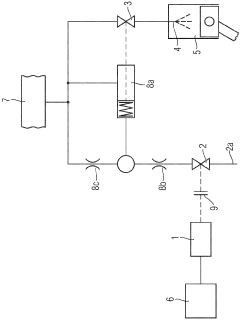

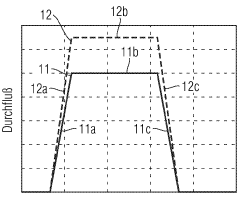

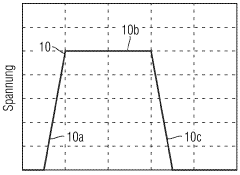

Method and device for the calibration of fuel injectors

PatentWO2008129008A2

Innovation

- A method that uses a piezoelectric element or magnetically acting element to adjust the electrical signal applied to the injection valve, allowing for real-time correction of fuel flow characteristics by modifying the voltage profile, thereby compensating for deviations in flow rate, dead time, and idle stroke errors, enabling efficient calibration of multiple fuel injectors with minimal deviations.

Emissions Regulations Impact on Calibration Requirements

Emissions regulations have become increasingly stringent worldwide, fundamentally transforming fuel injector calibration requirements for V6 engines. The European Union's Euro 6d standards, implemented in 2020, mandate nitrogen oxide (NOx) emissions below 80 mg/km and particulate matter emissions under 4.5 mg/km, requiring unprecedented precision in fuel delivery systems. Similarly, the United States EPA Tier 3 standards and California's CARB LEV III regulations have established similarly demanding thresholds that directly impact calibration parameters.

These regulatory frameworks have necessitated real-world driving emissions (RDE) testing protocols, compelling manufacturers to optimize fuel injector calibration across a much broader operating envelope than traditional laboratory cycles. This expansion has significantly increased calibration complexity, requiring adaptive strategies that maintain emissions compliance under varied driving conditions while preserving performance characteristics.

The regulatory focus on cold-start emissions has particularly influenced calibration requirements, as approximately 80% of total emissions occur during the first 120 seconds of operation. This has driven the development of specialized calibration maps for cold-start conditions, with multiple injection events precisely timed to optimize combustion stability while minimizing unburned hydrocarbons and particulate formation.

On-board diagnostics (OBD) requirements have further complicated calibration processes, as systems must now detect even minor deviations in injector performance that could potentially increase emissions. This has led to the implementation of sophisticated injector drift compensation algorithms that continuously adjust calibration parameters based on real-time feedback from lambda sensors and other emissions monitoring devices.

The global transition toward ultra-low sulfur fuels and increased biofuel content has introduced additional calibration challenges. Varying fuel compositions affect atomization characteristics, requiring calibration strategies that can adapt to different fuel properties while maintaining emissions compliance. This has prompted the development of fuel-adaptive calibration techniques that utilize closed-loop control systems to optimize injection timing and quantity based on detected fuel properties.

Looking forward, upcoming regulations like Euro 7 and EPA Tier 4 will likely impose even stricter emissions limits while expanding the conditions under which compliance must be maintained. This regulatory trajectory suggests that future calibration requirements will demand even greater precision, with potential requirements for sub-millisecond injection timing accuracy and milligram-level quantity control across all operating conditions.

These regulatory frameworks have necessitated real-world driving emissions (RDE) testing protocols, compelling manufacturers to optimize fuel injector calibration across a much broader operating envelope than traditional laboratory cycles. This expansion has significantly increased calibration complexity, requiring adaptive strategies that maintain emissions compliance under varied driving conditions while preserving performance characteristics.

The regulatory focus on cold-start emissions has particularly influenced calibration requirements, as approximately 80% of total emissions occur during the first 120 seconds of operation. This has driven the development of specialized calibration maps for cold-start conditions, with multiple injection events precisely timed to optimize combustion stability while minimizing unburned hydrocarbons and particulate formation.

On-board diagnostics (OBD) requirements have further complicated calibration processes, as systems must now detect even minor deviations in injector performance that could potentially increase emissions. This has led to the implementation of sophisticated injector drift compensation algorithms that continuously adjust calibration parameters based on real-time feedback from lambda sensors and other emissions monitoring devices.

The global transition toward ultra-low sulfur fuels and increased biofuel content has introduced additional calibration challenges. Varying fuel compositions affect atomization characteristics, requiring calibration strategies that can adapt to different fuel properties while maintaining emissions compliance. This has prompted the development of fuel-adaptive calibration techniques that utilize closed-loop control systems to optimize injection timing and quantity based on detected fuel properties.

Looking forward, upcoming regulations like Euro 7 and EPA Tier 4 will likely impose even stricter emissions limits while expanding the conditions under which compliance must be maintained. This regulatory trajectory suggests that future calibration requirements will demand even greater precision, with potential requirements for sub-millisecond injection timing accuracy and milligram-level quantity control across all operating conditions.

Real-world Performance Validation Techniques

Validation of fuel injector calibration techniques for V6 engines requires comprehensive real-world testing to ensure theoretical models translate effectively to actual driving conditions. Dynamometer testing serves as the primary validation method, allowing engineers to simulate various load conditions while precisely measuring fuel consumption, emissions, and power output. These controlled environments enable the isolation of specific variables affecting injector performance while maintaining consistency across test cycles.

Field testing represents the next critical validation phase, where calibrated engines undergo extensive road testing across diverse driving scenarios. This includes urban stop-and-go traffic, highway cruising, mountain driving, and extreme temperature conditions. Data logging systems capture real-time performance metrics including throttle position, air-fuel ratios, exhaust gas temperatures, and injection timing across these varied conditions, providing insights into how calibration parameters perform beyond laboratory settings.

Long-term durability validation constitutes another essential component of real-world performance assessment. Accelerated aging tests subject fuel injectors to extended operation cycles equivalent to 100,000+ miles of usage, evaluating deposit formation, spray pattern degradation, and flow rate consistency over time. These tests help identify potential calibration adjustments needed to maintain optimal performance throughout the engine's service life.

Cold-start performance validation specifically examines injector behavior during the critical first moments of engine operation. Engineers utilize climate-controlled chambers to simulate temperatures ranging from -40°F to 120°F, measuring parameters such as start time, emissions during warm-up, and fuel atomization quality. This data informs calibration refinements for consistent performance across all climate zones where the vehicle might operate.

Comparative A/B testing methodologies provide quantifiable validation by running identical engines with different calibration parameters under identical conditions. This approach enables precise measurement of performance differences resulting from specific calibration changes, supporting data-driven optimization decisions. Statistical analysis of these comparative tests helps establish confidence intervals for expected performance improvements.

Fleet testing represents the final validation stage, where calibrated engines are deployed in actual customer-equivalent usage patterns over extended periods. Telematics systems continuously monitor performance metrics, providing massive datasets that reveal subtle performance variations across different driving styles, geographic regions, and seasonal conditions. This real-world data often reveals edge cases and interaction effects not captured in controlled testing environments.

Field testing represents the next critical validation phase, where calibrated engines undergo extensive road testing across diverse driving scenarios. This includes urban stop-and-go traffic, highway cruising, mountain driving, and extreme temperature conditions. Data logging systems capture real-time performance metrics including throttle position, air-fuel ratios, exhaust gas temperatures, and injection timing across these varied conditions, providing insights into how calibration parameters perform beyond laboratory settings.

Long-term durability validation constitutes another essential component of real-world performance assessment. Accelerated aging tests subject fuel injectors to extended operation cycles equivalent to 100,000+ miles of usage, evaluating deposit formation, spray pattern degradation, and flow rate consistency over time. These tests help identify potential calibration adjustments needed to maintain optimal performance throughout the engine's service life.

Cold-start performance validation specifically examines injector behavior during the critical first moments of engine operation. Engineers utilize climate-controlled chambers to simulate temperatures ranging from -40°F to 120°F, measuring parameters such as start time, emissions during warm-up, and fuel atomization quality. This data informs calibration refinements for consistent performance across all climate zones where the vehicle might operate.

Comparative A/B testing methodologies provide quantifiable validation by running identical engines with different calibration parameters under identical conditions. This approach enables precise measurement of performance differences resulting from specific calibration changes, supporting data-driven optimization decisions. Statistical analysis of these comparative tests helps establish confidence intervals for expected performance improvements.

Fleet testing represents the final validation stage, where calibrated engines are deployed in actual customer-equivalent usage patterns over extended periods. Telematics systems continuously monitor performance metrics, providing massive datasets that reveal subtle performance variations across different driving styles, geographic regions, and seasonal conditions. This real-world data often reveals edge cases and interaction effects not captured in controlled testing environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!