V6 Engine vs Boxer Engine: Performance and Stability

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Architecture Evolution and Objectives

Internal combustion engines have undergone significant architectural evolution since their inception in the late 19th century. The V6 and Boxer engine configurations represent two distinct approaches to solving fundamental engineering challenges related to power delivery, balance, and packaging efficiency. The V6 architecture emerged in the early 20th century as manufacturers sought more compact alternatives to inline engines while maintaining higher cylinder counts. Early V6 designs suffered from inherent balance issues until the introduction of offset crankpins and modern balancing techniques in the 1950s.

The Boxer engine, with its horizontally opposed cylinder layout, traces its origins to early aircraft applications where low profile and natural balance characteristics proved advantageous. Ferdinand Porsche's adoption of the configuration for automotive use in the 1930s established a legacy that continues in specific vehicle applications today.

Both engine architectures have evolved significantly through technological advancements in materials science, combustion efficiency, and manufacturing precision. The V6 configuration has seen widespread adoption across various vehicle segments due to its favorable compromise between the smoothness of larger V8 engines and the economy of smaller four-cylinder units. Modern V6 designs frequently incorporate variable valve timing, direct injection, and turbocharging to enhance performance while meeting increasingly stringent emissions standards.

The Boxer engine has followed a more specialized evolutionary path, with continuous refinement by manufacturers like Subaru and Porsche who have committed to the configuration for its unique performance characteristics. Recent developments include the integration of hybrid systems with these traditional architectures, demonstrating the adaptability of both designs to emerging powertrain requirements.

The primary technical objectives driving engine architecture development include optimizing power-to-weight ratios, minimizing vibration, enhancing thermal efficiency, and improving packaging flexibility. Secondary considerations encompass manufacturing cost, serviceability, and compatibility with vehicle dynamics requirements. The ongoing pursuit of these objectives has led to continuous refinement in both V6 and Boxer configurations.

Current technological trends indicate a convergence toward hybrid-compatible internal combustion engines that can function efficiently within electrified powertrains. This transition presents unique challenges and opportunities for both V6 and Boxer architectures as they adapt to new roles within increasingly complex propulsion systems. The fundamental characteristics that have defined these engine types continue to influence their application, even as the automotive industry progresses toward alternative power sources.

The Boxer engine, with its horizontally opposed cylinder layout, traces its origins to early aircraft applications where low profile and natural balance characteristics proved advantageous. Ferdinand Porsche's adoption of the configuration for automotive use in the 1930s established a legacy that continues in specific vehicle applications today.

Both engine architectures have evolved significantly through technological advancements in materials science, combustion efficiency, and manufacturing precision. The V6 configuration has seen widespread adoption across various vehicle segments due to its favorable compromise between the smoothness of larger V8 engines and the economy of smaller four-cylinder units. Modern V6 designs frequently incorporate variable valve timing, direct injection, and turbocharging to enhance performance while meeting increasingly stringent emissions standards.

The Boxer engine has followed a more specialized evolutionary path, with continuous refinement by manufacturers like Subaru and Porsche who have committed to the configuration for its unique performance characteristics. Recent developments include the integration of hybrid systems with these traditional architectures, demonstrating the adaptability of both designs to emerging powertrain requirements.

The primary technical objectives driving engine architecture development include optimizing power-to-weight ratios, minimizing vibration, enhancing thermal efficiency, and improving packaging flexibility. Secondary considerations encompass manufacturing cost, serviceability, and compatibility with vehicle dynamics requirements. The ongoing pursuit of these objectives has led to continuous refinement in both V6 and Boxer configurations.

Current technological trends indicate a convergence toward hybrid-compatible internal combustion engines that can function efficiently within electrified powertrains. This transition presents unique challenges and opportunities for both V6 and Boxer architectures as they adapt to new roles within increasingly complex propulsion systems. The fundamental characteristics that have defined these engine types continue to influence their application, even as the automotive industry progresses toward alternative power sources.

Market Demand Analysis for V6 and Boxer Engines

The global automotive engine market continues to evolve with changing consumer preferences, environmental regulations, and technological advancements. V6 and Boxer engines represent two distinct architectural approaches that serve different market segments and applications, each with unique performance characteristics and stability profiles.

Market research indicates that V6 engines maintain strong demand in mid-size to large passenger vehicles, luxury sedans, and light trucks. The North American market particularly favors V6 configurations, with approximately 28% of new vehicles sold featuring this engine type. This preference stems from the V6's balance of power, fuel efficiency, and cost-effectiveness compared to larger V8 alternatives. The compact design of V6 engines also allows for more flexible vehicle packaging, addressing the growing consumer demand for interior space without sacrificing performance.

Boxer engines, while occupying a smaller market share globally (approximately 5% of new vehicles), demonstrate remarkable brand loyalty and niche market strength. Subaru, the primary adopter of boxer engines in mass-market vehicles, has seen consistent sales growth in regions with challenging weather conditions such as the northeastern United States, Canada, and Scandinavian countries. This geographic distribution correlates directly with the boxer engine's inherent stability advantages in adverse driving conditions.

Consumer surveys reveal distinct preference patterns: performance-oriented buyers who prioritize handling dynamics and all-weather capability show stronger interest in boxer-equipped vehicles, while those seeking balanced power delivery and fuel economy in everyday driving scenarios gravitate toward V6 options. The premium segment shows particular interest in both engine types, with boxer configurations valued for their unique driving characteristics and V6 designs appreciated for their refinement and power delivery.

Industry forecasts project the global market for V6 engines to grow at a compound annual rate of 3.2% through 2028, driven by increasing demand for SUVs and crossovers in emerging markets. Meanwhile, boxer engine applications are expected to expand beyond their traditional niches, with potential adoption in hybrid powertrains where their low center of gravity offers packaging advantages for battery placement.

Environmental regulations are significantly reshaping market dynamics for both engine types. Manufacturers are investing heavily in improving the efficiency of V6 engines through technologies like direct injection, variable valve timing, and cylinder deactivation. Similarly, boxer engine development focuses on emissions reduction while preserving the configuration's inherent balance and stability benefits.

The aftermarket and performance modification sectors show robust demand for both engine types, with specialized tuning companies developing enhancement packages that capitalize on each architecture's strengths. This secondary market represents a significant value-added component, particularly for enthusiast-oriented vehicles.

Market research indicates that V6 engines maintain strong demand in mid-size to large passenger vehicles, luxury sedans, and light trucks. The North American market particularly favors V6 configurations, with approximately 28% of new vehicles sold featuring this engine type. This preference stems from the V6's balance of power, fuel efficiency, and cost-effectiveness compared to larger V8 alternatives. The compact design of V6 engines also allows for more flexible vehicle packaging, addressing the growing consumer demand for interior space without sacrificing performance.

Boxer engines, while occupying a smaller market share globally (approximately 5% of new vehicles), demonstrate remarkable brand loyalty and niche market strength. Subaru, the primary adopter of boxer engines in mass-market vehicles, has seen consistent sales growth in regions with challenging weather conditions such as the northeastern United States, Canada, and Scandinavian countries. This geographic distribution correlates directly with the boxer engine's inherent stability advantages in adverse driving conditions.

Consumer surveys reveal distinct preference patterns: performance-oriented buyers who prioritize handling dynamics and all-weather capability show stronger interest in boxer-equipped vehicles, while those seeking balanced power delivery and fuel economy in everyday driving scenarios gravitate toward V6 options. The premium segment shows particular interest in both engine types, with boxer configurations valued for their unique driving characteristics and V6 designs appreciated for their refinement and power delivery.

Industry forecasts project the global market for V6 engines to grow at a compound annual rate of 3.2% through 2028, driven by increasing demand for SUVs and crossovers in emerging markets. Meanwhile, boxer engine applications are expected to expand beyond their traditional niches, with potential adoption in hybrid powertrains where their low center of gravity offers packaging advantages for battery placement.

Environmental regulations are significantly reshaping market dynamics for both engine types. Manufacturers are investing heavily in improving the efficiency of V6 engines through technologies like direct injection, variable valve timing, and cylinder deactivation. Similarly, boxer engine development focuses on emissions reduction while preserving the configuration's inherent balance and stability benefits.

The aftermarket and performance modification sectors show robust demand for both engine types, with specialized tuning companies developing enhancement packages that capitalize on each architecture's strengths. This secondary market represents a significant value-added component, particularly for enthusiast-oriented vehicles.

Technical Comparison and Engineering Challenges

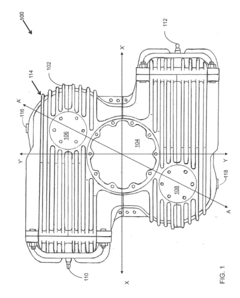

The V6 and Boxer engine configurations represent two fundamentally different approaches to internal combustion engine design, each with distinct performance characteristics and engineering challenges. The V6 engine arranges cylinders in two banks at an angle to each other, forming a "V" shape, while the Boxer engine positions cylinders horizontally opposed to each other, creating a flat, low-profile design.

From a performance perspective, V6 engines typically deliver higher power output relative to their size due to their compact design allowing for larger displacement within a given engine bay. This configuration enables manufacturers to achieve power outputs ranging from 250 to over 400 horsepower in standard production models. The V6 design also facilitates better thermal efficiency through centralized cooling systems and more uniform heat distribution across cylinder banks.

Boxer engines, conversely, excel in balance and stability. Their horizontally opposed cylinder arrangement naturally cancels out primary and secondary vibrations, resulting in exceptionally smooth operation even at high RPMs. This inherent balance eliminates the need for complex counterbalancing mechanisms required in many V6 designs, contributing to mechanical simplicity and reliability in long-term operation.

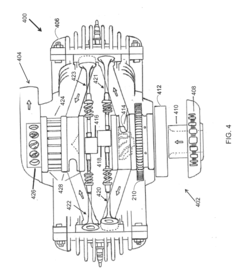

The engineering challenges for V6 engines primarily revolve around vibration management and thermal considerations. The inherent imbalance in V6 configurations, particularly in odd-firing designs, necessitates sophisticated harmonic balancers and carefully designed engine mounts. Additionally, the compact V-shape creates challenges in exhaust manifold design, often resulting in complex routing solutions that can impact thermal efficiency and increase manufacturing complexity.

For Boxer engines, the primary engineering challenges stem from their width and accessibility. The horizontal cylinder layout demands significant lateral space in the engine bay, limiting their application in vehicles with narrow engine compartments. This width also complicates routine maintenance procedures, with components like spark plugs and valve covers often difficult to access without substantial disassembly.

Lubrication systems present unique challenges for both configurations. V6 engines must ensure consistent oil delivery across both cylinder banks during high-G cornering and acceleration, while Boxer engines must overcome gravity-related oil pooling issues in the horizontally opposed cylinders, particularly during cold starts.

Modern engineering solutions have addressed many of these challenges through advanced materials and design innovations. V6 engines now incorporate integrated exhaust manifolds and variable valve timing to optimize performance across RPM ranges. Similarly, contemporary Boxer engines utilize asymmetric oil pumps and improved cylinder head designs to mitigate traditional lubrication concerns while maintaining their inherent balance advantages.

From a performance perspective, V6 engines typically deliver higher power output relative to their size due to their compact design allowing for larger displacement within a given engine bay. This configuration enables manufacturers to achieve power outputs ranging from 250 to over 400 horsepower in standard production models. The V6 design also facilitates better thermal efficiency through centralized cooling systems and more uniform heat distribution across cylinder banks.

Boxer engines, conversely, excel in balance and stability. Their horizontally opposed cylinder arrangement naturally cancels out primary and secondary vibrations, resulting in exceptionally smooth operation even at high RPMs. This inherent balance eliminates the need for complex counterbalancing mechanisms required in many V6 designs, contributing to mechanical simplicity and reliability in long-term operation.

The engineering challenges for V6 engines primarily revolve around vibration management and thermal considerations. The inherent imbalance in V6 configurations, particularly in odd-firing designs, necessitates sophisticated harmonic balancers and carefully designed engine mounts. Additionally, the compact V-shape creates challenges in exhaust manifold design, often resulting in complex routing solutions that can impact thermal efficiency and increase manufacturing complexity.

For Boxer engines, the primary engineering challenges stem from their width and accessibility. The horizontal cylinder layout demands significant lateral space in the engine bay, limiting their application in vehicles with narrow engine compartments. This width also complicates routine maintenance procedures, with components like spark plugs and valve covers often difficult to access without substantial disassembly.

Lubrication systems present unique challenges for both configurations. V6 engines must ensure consistent oil delivery across both cylinder banks during high-G cornering and acceleration, while Boxer engines must overcome gravity-related oil pooling issues in the horizontally opposed cylinders, particularly during cold starts.

Modern engineering solutions have addressed many of these challenges through advanced materials and design innovations. V6 engines now incorporate integrated exhaust manifolds and variable valve timing to optimize performance across RPM ranges. Similarly, contemporary Boxer engines utilize asymmetric oil pumps and improved cylinder head designs to mitigate traditional lubrication concerns while maintaining their inherent balance advantages.

Current Engineering Solutions and Design Approaches

01 V6 Engine Performance Characteristics

V6 engines are known for their compact design and balanced power delivery. The V-configuration allows for a shorter engine length compared to inline configurations, making them suitable for transverse mounting in front-wheel drive vehicles. V6 engines typically offer good power-to-weight ratios and smoother operation than four-cylinder engines due to their more frequent power strokes. The 60-degree V6 configuration is particularly noted for its natural balance, reducing the need for balance shafts and contributing to overall vehicle stability.- V6 Engine Performance Characteristics: V6 engines offer a balance of power and efficiency in a compact design. The V-configuration allows for shorter engine length compared to inline engines, making them suitable for transverse mounting in vehicles. V6 engines typically provide smooth operation due to their firing order and balance, delivering good acceleration and power output while maintaining reasonable fuel efficiency. The design allows for higher displacement in a more compact package, making them popular in mid-size to large vehicles.

- Boxer Engine Stability and Balance: Boxer engines feature horizontally opposed cylinders that move in and out on the same plane. This configuration provides inherent balance as the pistons move simultaneously in opposite directions, canceling out primary forces. The low center of gravity improves vehicle stability, handling, and cornering performance. The flat design allows for better weight distribution and reduces vibration, resulting in smoother operation. These characteristics make boxer engines particularly suitable for sports cars and vehicles where handling precision is prioritized.

- Comparative Fuel Efficiency and Emissions: The design differences between V6 and boxer engines impact their fuel efficiency and emissions performance. V6 engines typically offer better fuel economy in straight-line driving due to reduced friction and weight compared to larger V8 engines. Boxer engines, while heavier than some configurations, can achieve good efficiency through optimized combustion chamber design and reduced pumping losses. Modern versions of both engine types incorporate technologies such as direct injection, variable valve timing, and cylinder deactivation to improve fuel efficiency and reduce emissions while maintaining performance characteristics.

- Vibration and Noise Reduction Technologies: Both V6 and boxer engines employ various technologies to minimize vibration and noise. V6 engines often use balance shafts and carefully designed engine mounts to counteract inherent vibrations from the V-configuration. Boxer engines have natural vibration-canceling properties due to their opposed-piston layout, but require attention to secondary vibrations. Advanced materials, precision manufacturing, and computer-optimized designs help reduce noise, vibration, and harshness (NVH) in both engine types. Acoustic covers, sound-dampening materials, and isolation techniques further enhance the refinement of these engines in vehicle applications.

- Cooling System and Thermal Management: The different configurations of V6 and boxer engines necessitate specific approaches to cooling and thermal management. V6 engines typically have more compact cooling systems with centralized water jackets, while boxer engines require more extensive cooling channels due to their wider layout. Boxer engines benefit from better air cooling due to their increased surface area, but may face challenges with uniform temperature distribution. Both engine types employ advanced thermal management systems including variable-flow water pumps, electronic thermostats, and targeted cooling to optimize performance, efficiency, and emissions across various operating conditions.

02 Boxer Engine Stability Advantages

Boxer engines feature horizontally opposed cylinders that move in and out on the same horizontal plane. This configuration results in a lower center of gravity compared to V-type or inline engines, significantly enhancing vehicle stability, particularly during cornering. The opposed-piston layout naturally balances primary forces, resulting in reduced vibration and smoother operation. The flat, wide design of boxer engines allows for more optimal weight distribution in the vehicle chassis, further improving handling characteristics and road grip.Expand Specific Solutions03 Comparative Fuel Efficiency and Emissions

The design differences between V6 and boxer engines impact their fuel efficiency and emissions performance. V6 engines typically offer better fuel economy in certain applications due to their more compact design and reduced friction losses. Boxer engines, while potentially less space-efficient, can achieve comparable efficiency through optimized combustion chamber design and reduced pumping losses. Modern variants of both engine types incorporate advanced technologies such as direct injection, variable valve timing, and cylinder deactivation to improve fuel efficiency and reduce emissions while maintaining performance characteristics.Expand Specific Solutions04 Vibration and NVH Characteristics

Noise, vibration, and harshness (NVH) characteristics differ significantly between V6 and boxer engine configurations. V6 engines typically require balance shafts or specific firing orders to minimize vibration, particularly in 90-degree configurations. Boxer engines have inherently better primary and secondary balance due to their horizontally opposed layout, resulting in smoother operation without additional balancing mechanisms. The mounting systems for these engines also differ, with boxer engines often utilizing more rigid mounting points to take advantage of their balanced operation, while V6 engines may require more sophisticated isolation systems to manage vibration transfer to the vehicle chassis.Expand Specific Solutions05 Packaging and Integration Considerations

The physical configuration of V6 and boxer engines presents different packaging challenges and opportunities in vehicle design. V6 engines offer a compact length advantage, making them suitable for transverse mounting in front-wheel drive vehicles and allowing for shorter engine compartments. Boxer engines, while wider, provide a lower profile that can contribute to improved aerodynamics and allow for a lower hood line. The integration of auxiliary systems such as intake, exhaust, and cooling systems differs between these engine types, with boxer engines often requiring symmetrical designs for optimal performance, while V6 engines may allow for more asymmetrical packaging solutions to accommodate other vehicle components.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

The V6 vs Boxer engine competition landscape is currently in a mature market phase with established technologies, though innovations continue in performance optimization and efficiency. The global automotive engine market exceeds $70 billion annually, with V6 engines dominating mainstream applications while Boxer engines occupy a specialized niche. Leading manufacturers like Porsche and Subaru (not listed) have mastered Boxer engine technology, while BMW, Mercedes-Benz, Toyota, and Honda have significant V6 engine portfolios. Ford and BYD are investing in hybrid and electric adaptations of these configurations, while specialized players like Guangxi Yuchai Machinery focus on performance enhancements. The competitive advantage increasingly lies in balancing traditional performance metrics with emerging sustainability requirements.

Dr. Ing. h.c. F. Porsche AG

Technical Solution: Porsche has pioneered boxer engine technology for decades, particularly in their iconic 911 models. Their horizontally-opposed six-cylinder boxer engines feature cylinders arranged in two banks on opposite sides of the crankshaft, creating a naturally balanced configuration. Porsche's latest boxer engines incorporate direct fuel injection, variable valve timing, and twin turbochargers to optimize performance. The company's boxer design maintains a low center of gravity, with the engine positioned behind the rear axle in their flagship models, creating their distinctive handling characteristics. Porsche has continuously refined their boxer engine cooling systems to address historical challenges, implementing water-cooled designs that maintain optimal operating temperatures even under high-performance driving conditions.

Strengths: Lower center of gravity improving handling stability; naturally balanced operation reducing vibration; compact design allowing for rear-engine configuration. Weaknesses: More complex maintenance due to cylinder positioning; typically more expensive to manufacture than conventional V-configurations; historically faced cooling challenges in high-performance applications.

Honda Motor Co., Ltd.

Technical Solution: Honda has developed innovative approaches to both V6 and boxer engine designs. Their V6 engines, particularly in the Acura NSX and Honda Odyssey, feature Variable Cylinder Management (VCM) technology that can deactivate cylinders during light load conditions to improve fuel efficiency while maintaining performance capabilities when needed. Honda's V6 designs typically employ a 60-degree configuration with aluminum construction to optimize weight and packaging. For their boxer engines, primarily used in Gold Wing motorcycles, Honda has implemented a unique flat-six configuration that provides exceptional smoothness and a low center of gravity. Their motorcycle boxer engines feature liquid cooling, programmed fuel injection (PGM-FI), and integrated transmission systems that maximize efficiency and performance in the limited space available on a motorcycle platform.

Strengths: Exceptional engineering reliability across both engine types; innovative cylinder deactivation technology in V6 designs; refined NVH characteristics. Weaknesses: V6 designs have higher center of gravity than boxer configurations; boxer engines require more lateral space for installation; more complex valve train maintenance in their boxer implementations.

Key Patents and Technical Innovations

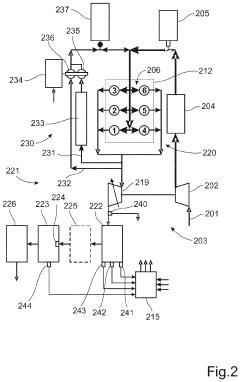

A method and a control system for controlling an internal combustion engine

PatentActiveUS20220163003A1

Innovation

- A method and control system that adjusts fuel injection in a four-stroke ICE to heat exhaust gases to a specific temperature by selectively regulating cylinder groups and altering fuel amounts in consecutive induction strokes, ensuring the DPF and SCR units operate effectively during low load conditions, thereby reducing the need for parked regeneration and extending component lifespan.

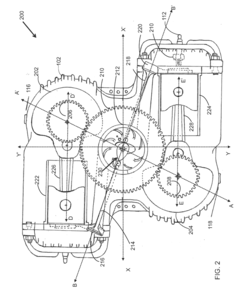

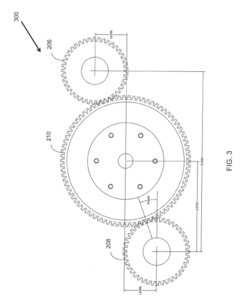

Engine assembly including cam for z-type engines

PatentActiveUS20190003380A1

Innovation

- A Z-twin engine design with horizontally opposed, vertically offset cylinders and a central shared camshaft driving angled side valves, coupled with dual counterbalancing cranks and a primary drive gear system, which reduces vibrations and increases efficiency by canceling out cylinder vibrations and simplifying the engine layout.

Fuel Efficiency and Emissions Performance

Fuel efficiency and emissions performance represent critical evaluation metrics in the comparison between V6 and Boxer engine configurations. The V6 engine typically demonstrates superior fuel economy in highway driving scenarios due to its more compact design and lower frontal area, which reduces aerodynamic drag. Modern V6 engines equipped with cylinder deactivation technology can further enhance efficiency by shutting down cylinders during light load conditions, effectively operating as a 3-cylinder engine when full power isn't required.

Boxer engines, while generally less fuel-efficient in standard configurations, offer unique advantages in specific applications. Their horizontally opposed cylinder layout creates excellent primary and secondary balance, reducing the need for additional balancing components that might otherwise consume power. This inherent efficiency becomes particularly evident in Subaru's implementation, where the boxer configuration facilitates symmetrical all-wheel drive systems with minimal drivetrain losses.

Emissions performance varies significantly between these engine types, influenced by combustion chamber design and thermal management characteristics. V6 engines typically achieve more consistent combustion temperatures across cylinders due to their more compact arrangement, allowing for more precise emissions control. Their centralized exhaust manifold placement also enables faster catalyst light-off times, critical for reducing cold-start emissions which constitute a significant portion of a vehicle's total emissions profile.

Boxer engines present unique challenges for emissions control due to their wider physical footprint requiring separate exhaust paths for each cylinder bank. This configuration often necessitates dual catalytic converters, increasing system complexity and cold-start emissions. However, the boxer's lower center of gravity reduces vehicle pitch during acceleration and braking, potentially allowing for more consistent operation of emissions systems under dynamic driving conditions.

Recent technological advancements have narrowed the efficiency gap between these configurations. Direct injection, variable valve timing, and turbocharging have been successfully implemented in both engine types, though integration complexity differs significantly. V6 engines generally benefit from more straightforward turbocharger implementation due to their centralized exhaust flow, while boxer engines require more complex exhaust routing but gain advantages from their inherently lower turbo positioning, reducing lag.

The regulatory landscape continues to drive innovation in both engine types, with manufacturers pursuing hybrid and mild-hybrid implementations to meet increasingly stringent emissions standards. V6 hybrid systems have demonstrated particular success in the luxury market segment, while boxer hybrids remain relatively rare but show promise in specialized applications where their unique balance characteristics complement electrification strategies.

Boxer engines, while generally less fuel-efficient in standard configurations, offer unique advantages in specific applications. Their horizontally opposed cylinder layout creates excellent primary and secondary balance, reducing the need for additional balancing components that might otherwise consume power. This inherent efficiency becomes particularly evident in Subaru's implementation, where the boxer configuration facilitates symmetrical all-wheel drive systems with minimal drivetrain losses.

Emissions performance varies significantly between these engine types, influenced by combustion chamber design and thermal management characteristics. V6 engines typically achieve more consistent combustion temperatures across cylinders due to their more compact arrangement, allowing for more precise emissions control. Their centralized exhaust manifold placement also enables faster catalyst light-off times, critical for reducing cold-start emissions which constitute a significant portion of a vehicle's total emissions profile.

Boxer engines present unique challenges for emissions control due to their wider physical footprint requiring separate exhaust paths for each cylinder bank. This configuration often necessitates dual catalytic converters, increasing system complexity and cold-start emissions. However, the boxer's lower center of gravity reduces vehicle pitch during acceleration and braking, potentially allowing for more consistent operation of emissions systems under dynamic driving conditions.

Recent technological advancements have narrowed the efficiency gap between these configurations. Direct injection, variable valve timing, and turbocharging have been successfully implemented in both engine types, though integration complexity differs significantly. V6 engines generally benefit from more straightforward turbocharger implementation due to their centralized exhaust flow, while boxer engines require more complex exhaust routing but gain advantages from their inherently lower turbo positioning, reducing lag.

The regulatory landscape continues to drive innovation in both engine types, with manufacturers pursuing hybrid and mild-hybrid implementations to meet increasingly stringent emissions standards. V6 hybrid systems have demonstrated particular success in the luxury market segment, while boxer hybrids remain relatively rare but show promise in specialized applications where their unique balance characteristics complement electrification strategies.

Manufacturing Cost and Complexity Analysis

The manufacturing processes for V6 and Boxer engines differ significantly, directly impacting production costs and resource requirements. V6 engines typically feature a more complex manufacturing process due to their V-shaped cylinder arrangement. This configuration necessitates specialized tooling and precision machining to ensure proper alignment of the two cylinder banks at the specified angle (usually 60° or 90°). The crankshaft for V6 engines requires intricate design and balancing to accommodate the firing order and minimize vibration, adding to manufacturing complexity.

Boxer engines, with their horizontally opposed cylinder layout, present different manufacturing challenges. While the flat design simplifies certain aspects of production, the wider footprint requires specialized assembly lines and handling equipment. The crankshaft design is generally simpler than that of a V6, with less complex counterweighting requirements, potentially reducing machining costs. However, the need for precise synchronization between opposing cylinders demands tight manufacturing tolerances.

Material costs vary between these engine types as well. V6 engines typically require more casting material for the engine block due to their compact, three-dimensional structure. The V-configuration often necessitates additional reinforcement in specific areas to maintain structural integrity under operational stress. Conversely, Boxer engines distribute material more evenly across their flat design but require a larger overall footprint of raw materials.

Component complexity also differs substantially. V6 engines contain more complex intake and exhaust manifold systems that must navigate the V-configuration efficiently. These components often require additional design iterations and validation testing, increasing development costs. Boxer engines benefit from symmetrical component design, potentially allowing for manufacturing economies through repeated parts, though their wider configuration can complicate peripheral system integration.

Labor requirements represent another significant cost factor. V6 engines typically demand more assembly steps due to their compact, layered design, increasing labor hours per unit. The tighter packaging also makes certain assembly operations more challenging, potentially requiring specialized training or equipment. Boxer engines, while having fewer total assembly steps, may require more specialized positioning equipment due to their wider configuration and the need to synchronize opposing cylinder assemblies.

Production scalability also impacts overall manufacturing economics. V6 production lines can often be more compact, allowing for greater production density in manufacturing facilities. Boxer engine production typically requires more floor space per unit, potentially limiting production volume in existing facilities and increasing facility overhead costs per engine produced.

Boxer engines, with their horizontally opposed cylinder layout, present different manufacturing challenges. While the flat design simplifies certain aspects of production, the wider footprint requires specialized assembly lines and handling equipment. The crankshaft design is generally simpler than that of a V6, with less complex counterweighting requirements, potentially reducing machining costs. However, the need for precise synchronization between opposing cylinders demands tight manufacturing tolerances.

Material costs vary between these engine types as well. V6 engines typically require more casting material for the engine block due to their compact, three-dimensional structure. The V-configuration often necessitates additional reinforcement in specific areas to maintain structural integrity under operational stress. Conversely, Boxer engines distribute material more evenly across their flat design but require a larger overall footprint of raw materials.

Component complexity also differs substantially. V6 engines contain more complex intake and exhaust manifold systems that must navigate the V-configuration efficiently. These components often require additional design iterations and validation testing, increasing development costs. Boxer engines benefit from symmetrical component design, potentially allowing for manufacturing economies through repeated parts, though their wider configuration can complicate peripheral system integration.

Labor requirements represent another significant cost factor. V6 engines typically demand more assembly steps due to their compact, layered design, increasing labor hours per unit. The tighter packaging also makes certain assembly operations more challenging, potentially requiring specialized training or equipment. Boxer engines, while having fewer total assembly steps, may require more specialized positioning equipment due to their wider configuration and the need to synchronize opposing cylinder assemblies.

Production scalability also impacts overall manufacturing economics. V6 production lines can often be more compact, allowing for greater production density in manufacturing facilities. Boxer engine production typically requires more floor space per unit, potentially limiting production volume in existing facilities and increasing facility overhead costs per engine produced.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!