V6 Engine Cylinder Deactivation: Feasibility and Results

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

V6 Engine Cylinder Deactivation Background and Objectives

Cylinder deactivation technology in V6 engines represents a significant advancement in automotive engineering, evolving from early experiments in the 1980s to sophisticated systems widely implemented today. This technology fundamentally alters engine operation by selectively disabling cylinders during light-load conditions, maintaining performance while substantially improving fuel efficiency. The historical progression shows a clear trajectory from rudimentary mechanical systems to today's electronically controlled, seamlessly integrated solutions that can adapt in real-time to driving conditions.

The primary objective of cylinder deactivation in V6 engines is to optimize the balance between performance and fuel economy—addressing the inherent inefficiency of larger displacement engines during partial load operation. By temporarily transforming a V6 into a V3 or V4 configuration, the technology aims to reduce pumping losses and improve thermal efficiency while maintaining the power reserve that consumers expect from six-cylinder engines.

Recent technological evolution has been driven by increasingly stringent global emissions regulations, particularly in Europe, North America, and Asia, where carbon dioxide reduction targets have accelerated adoption of efficiency technologies. Simultaneously, consumer expectations for both performance and economy have created market pressure for solutions that deliver both attributes without compromise.

The technical foundation of modern cylinder deactivation systems involves sophisticated valve control mechanisms, precise engine management software, and advanced NVH (Noise, Vibration, Harshness) mitigation strategies. These systems must seamlessly transition between full and partial cylinder operation without perceptible changes to driver experience—a significant engineering challenge that has been progressively overcome through multiple generations of development.

Current development goals focus on expanding the operating range where deactivation can be employed, reducing transition time between modes, and integrating with other efficiency technologies such as turbocharging, direct injection, and electrification. The convergence of these technologies represents the frontier of internal combustion efficiency engineering.

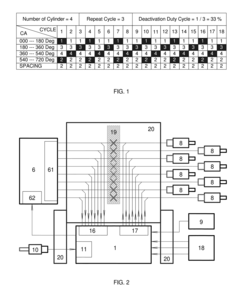

Looking forward, cylinder deactivation technology is expected to evolve toward more dynamic systems capable of deactivating any cylinder at any time based on instantaneous operating conditions, rather than switching between predetermined patterns. This "dynamic skip fire" approach represents the next evolutionary step, potentially unlocking additional efficiency gains while further refining the driving experience.

As the automotive industry navigates the transition toward electrification, cylinder deactivation remains a critical bridge technology that extends the viability and efficiency of internal combustion engines, particularly in markets where infrastructure or cost constraints limit rapid electric vehicle adoption.

The primary objective of cylinder deactivation in V6 engines is to optimize the balance between performance and fuel economy—addressing the inherent inefficiency of larger displacement engines during partial load operation. By temporarily transforming a V6 into a V3 or V4 configuration, the technology aims to reduce pumping losses and improve thermal efficiency while maintaining the power reserve that consumers expect from six-cylinder engines.

Recent technological evolution has been driven by increasingly stringent global emissions regulations, particularly in Europe, North America, and Asia, where carbon dioxide reduction targets have accelerated adoption of efficiency technologies. Simultaneously, consumer expectations for both performance and economy have created market pressure for solutions that deliver both attributes without compromise.

The technical foundation of modern cylinder deactivation systems involves sophisticated valve control mechanisms, precise engine management software, and advanced NVH (Noise, Vibration, Harshness) mitigation strategies. These systems must seamlessly transition between full and partial cylinder operation without perceptible changes to driver experience—a significant engineering challenge that has been progressively overcome through multiple generations of development.

Current development goals focus on expanding the operating range where deactivation can be employed, reducing transition time between modes, and integrating with other efficiency technologies such as turbocharging, direct injection, and electrification. The convergence of these technologies represents the frontier of internal combustion efficiency engineering.

Looking forward, cylinder deactivation technology is expected to evolve toward more dynamic systems capable of deactivating any cylinder at any time based on instantaneous operating conditions, rather than switching between predetermined patterns. This "dynamic skip fire" approach represents the next evolutionary step, potentially unlocking additional efficiency gains while further refining the driving experience.

As the automotive industry navigates the transition toward electrification, cylinder deactivation remains a critical bridge technology that extends the viability and efficiency of internal combustion engines, particularly in markets where infrastructure or cost constraints limit rapid electric vehicle adoption.

Market Demand Analysis for Fuel-Efficient V6 Engines

The global automotive industry is witnessing a significant shift toward fuel-efficient technologies, with V6 engines featuring cylinder deactivation technology gaining substantial market traction. Current market analysis indicates that fuel economy remains a primary purchase consideration for consumers across major automotive markets, with 68% of North American buyers and 74% of European consumers citing fuel efficiency as a critical factor in their vehicle selection process.

The market for V6 engines with advanced fuel-saving technologies is projected to grow at a compound annual growth rate of 5.7% through 2028, driven by increasingly stringent emissions regulations worldwide. In particular, the Corporate Average Fuel Economy (CAFE) standards in the United States and the European CO2 emissions targets are creating strong regulatory pressure for manufacturers to improve engine efficiency.

Consumer preference data reveals a notable trend: while the market share of smaller turbocharged engines continues to expand, a significant segment of consumers still prefers the power delivery characteristics of V6 engines, creating an ideal opportunity for cylinder deactivation technology. This technology effectively bridges the gap between performance expectations and fuel economy demands.

Regional market analysis shows varying adoption rates, with North America leading in cylinder deactivation implementation, followed by Europe and emerging adoption in Asia-Pacific markets. The premium and mid-range vehicle segments demonstrate the strongest demand, with cylinder deactivation technology increasingly becoming a standard feature in vehicles priced above $35,000.

Fleet operators represent another significant market segment, with commercial fleets increasingly factoring lifetime fuel costs into their purchasing decisions. The total cost of ownership calculations strongly favor vehicles equipped with fuel-saving technologies like cylinder deactivation, especially for high-mileage applications.

Market forecasts indicate that by 2025, approximately 42% of all new V6-equipped vehicles globally will feature some form of cylinder deactivation technology. This represents a substantial growth opportunity, with the total addressable market estimated at 7.3 million units annually.

Consumer awareness studies suggest that while the technology's benefits are clear to industry professionals, there remains a significant knowledge gap among end consumers. Only 31% of surveyed vehicle buyers could accurately describe how cylinder deactivation functions, highlighting the need for improved marketing and education efforts to fully capitalize on market potential.

The market for V6 engines with advanced fuel-saving technologies is projected to grow at a compound annual growth rate of 5.7% through 2028, driven by increasingly stringent emissions regulations worldwide. In particular, the Corporate Average Fuel Economy (CAFE) standards in the United States and the European CO2 emissions targets are creating strong regulatory pressure for manufacturers to improve engine efficiency.

Consumer preference data reveals a notable trend: while the market share of smaller turbocharged engines continues to expand, a significant segment of consumers still prefers the power delivery characteristics of V6 engines, creating an ideal opportunity for cylinder deactivation technology. This technology effectively bridges the gap between performance expectations and fuel economy demands.

Regional market analysis shows varying adoption rates, with North America leading in cylinder deactivation implementation, followed by Europe and emerging adoption in Asia-Pacific markets. The premium and mid-range vehicle segments demonstrate the strongest demand, with cylinder deactivation technology increasingly becoming a standard feature in vehicles priced above $35,000.

Fleet operators represent another significant market segment, with commercial fleets increasingly factoring lifetime fuel costs into their purchasing decisions. The total cost of ownership calculations strongly favor vehicles equipped with fuel-saving technologies like cylinder deactivation, especially for high-mileage applications.

Market forecasts indicate that by 2025, approximately 42% of all new V6-equipped vehicles globally will feature some form of cylinder deactivation technology. This represents a substantial growth opportunity, with the total addressable market estimated at 7.3 million units annually.

Consumer awareness studies suggest that while the technology's benefits are clear to industry professionals, there remains a significant knowledge gap among end consumers. Only 31% of surveyed vehicle buyers could accurately describe how cylinder deactivation functions, highlighting the need for improved marketing and education efforts to fully capitalize on market potential.

Current State and Technical Challenges of Cylinder Deactivation

Cylinder deactivation technology has evolved significantly over the past three decades, with major advancements occurring since the early 2000s. Currently, this technology is widely implemented in production vehicles across multiple manufacturers, particularly in V6 and V8 engines. The fundamental principle involves selectively deactivating cylinders during light-load conditions to improve fuel efficiency while maintaining performance capabilities when needed.

The current state of V6 cylinder deactivation technology primarily employs two mechanisms: cam-phasing systems and solenoid-actuated hydraulic systems. The most prevalent implementation in V6 engines is the deactivation of three cylinders (typically one bank), creating a temporary inline-three configuration during light-load operation. This approach has demonstrated fuel economy improvements of 5-15% in real-world driving conditions, with the greatest benefits observed during highway cruising.

Despite widespread adoption, cylinder deactivation technology faces several significant technical challenges. Noise, vibration, and harshness (NVH) issues remain prominent, particularly during transition phases between full-cylinder and deactivated states. The inherent imbalance created when operating with deactivated cylinders requires sophisticated engine mounting systems and careful calibration to mitigate undesirable vibrations that can propagate through the vehicle structure.

Thermal management presents another substantial challenge. Deactivated cylinders cool more rapidly than active ones, creating temperature differentials that can affect emissions control systems and potentially lead to uneven thermal expansion/contraction cycles. This temperature variation can accelerate component wear and potentially compromise long-term durability if not properly managed.

Control system complexity represents a significant hurdle, as the engine management system must seamlessly transition between operating modes while maintaining optimal combustion parameters. The decision algorithms determining when to activate or deactivate cylinders must process multiple inputs including throttle position, vehicle speed, engine load, and environmental conditions to ensure appropriate mode selection without compromising drivability.

Emissions compliance during mode transitions remains challenging, particularly with increasingly stringent regulations. The momentary combustion instability during cylinder reactivation can produce transient emissions spikes that must be carefully managed to maintain regulatory compliance.

Manufacturing complexity and cost considerations continue to impact widespread adoption, particularly in lower-cost vehicle segments. The additional components required for cylinder deactivation systems, including specialized valve lifters, oil control valves, and enhanced engine control modules, increase production costs and assembly complexity.

Global market adoption varies significantly, with North American and European markets showing stronger implementation rates compared to emerging markets, where simpler engine architectures often dominate due to cost constraints and different regulatory environments.

The current state of V6 cylinder deactivation technology primarily employs two mechanisms: cam-phasing systems and solenoid-actuated hydraulic systems. The most prevalent implementation in V6 engines is the deactivation of three cylinders (typically one bank), creating a temporary inline-three configuration during light-load operation. This approach has demonstrated fuel economy improvements of 5-15% in real-world driving conditions, with the greatest benefits observed during highway cruising.

Despite widespread adoption, cylinder deactivation technology faces several significant technical challenges. Noise, vibration, and harshness (NVH) issues remain prominent, particularly during transition phases between full-cylinder and deactivated states. The inherent imbalance created when operating with deactivated cylinders requires sophisticated engine mounting systems and careful calibration to mitigate undesirable vibrations that can propagate through the vehicle structure.

Thermal management presents another substantial challenge. Deactivated cylinders cool more rapidly than active ones, creating temperature differentials that can affect emissions control systems and potentially lead to uneven thermal expansion/contraction cycles. This temperature variation can accelerate component wear and potentially compromise long-term durability if not properly managed.

Control system complexity represents a significant hurdle, as the engine management system must seamlessly transition between operating modes while maintaining optimal combustion parameters. The decision algorithms determining when to activate or deactivate cylinders must process multiple inputs including throttle position, vehicle speed, engine load, and environmental conditions to ensure appropriate mode selection without compromising drivability.

Emissions compliance during mode transitions remains challenging, particularly with increasingly stringent regulations. The momentary combustion instability during cylinder reactivation can produce transient emissions spikes that must be carefully managed to maintain regulatory compliance.

Manufacturing complexity and cost considerations continue to impact widespread adoption, particularly in lower-cost vehicle segments. The additional components required for cylinder deactivation systems, including specialized valve lifters, oil control valves, and enhanced engine control modules, increase production costs and assembly complexity.

Global market adoption varies significantly, with North American and European markets showing stronger implementation rates compared to emerging markets, where simpler engine architectures often dominate due to cost constraints and different regulatory environments.

Current Cylinder Deactivation Implementation Methods

01 Cylinder deactivation mechanisms for V6 engines

Various mechanisms can be implemented in V6 engines to achieve cylinder deactivation, which involves selectively disabling cylinders during light load conditions. These mechanisms typically include specialized valve control systems that can keep intake and exhaust valves closed for deactivated cylinders. The implementation often requires modifications to the valve train, such as switchable hydraulic lash adjusters or solenoid-controlled oil pressure systems that can alter the operation of rocker arms or lifters.- Cylinder deactivation mechanisms for V6 engines: Various mechanisms can be implemented in V6 engines to achieve cylinder deactivation, which involves selectively disabling cylinders during light load conditions. These mechanisms typically include specialized valve control systems, hydraulic lash adjusters, and solenoid-controlled oil pressure systems that can deactivate the valve train of specific cylinders. The deactivation mechanisms can be integrated with the engine control unit to determine optimal timing for cylinder activation and deactivation based on driving conditions.

- Fuel efficiency improvements through cylinder deactivation: Cylinder deactivation in V6 engines significantly improves fuel efficiency by reducing pumping losses and increasing thermal efficiency during partial load operations. When fewer cylinders are active, the remaining cylinders operate at higher specific loads, improving combustion efficiency. Studies show that V6 engines with cylinder deactivation can achieve fuel economy improvements of 5-15% depending on driving conditions, with the greatest benefits observed during highway cruising where engine load is relatively constant and moderate.

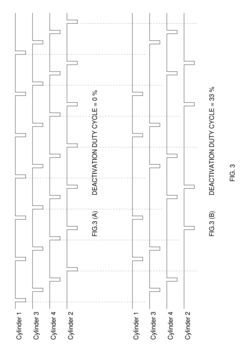

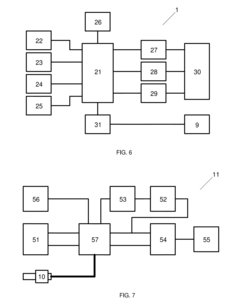

- Control strategies for smooth transition during cylinder activation/deactivation: Advanced control strategies are essential for ensuring smooth transitions when activating or deactivating cylinders in V6 engines. These strategies involve precise timing of fuel injection, ignition timing adjustments, and torque management to minimize NVH (Noise, Vibration, and Harshness) issues. Sophisticated algorithms monitor engine parameters such as crankshaft position, engine load, and vehicle speed to determine optimal transition points. Some systems incorporate predictive models to anticipate driver demands and prepare the engine for mode changes, ensuring seamless operation that is imperceptible to the driver.

- NVH management in V6 engines with cylinder deactivation: Managing noise, vibration, and harshness is a critical challenge in V6 engines with cylinder deactivation. Various technologies have been developed to address NVH issues, including active engine mounts that counteract vibrations, enhanced sound insulation materials, and active noise cancellation systems. Some designs incorporate specific firing order modifications and balance shaft arrangements to minimize vibration when operating with deactivated cylinders. Additionally, specialized dampers and flywheel designs help smooth torque delivery during transitions between full and partial cylinder operation modes.

- Integration with other powertrain technologies: Cylinder deactivation in V6 engines can be integrated with other advanced powertrain technologies to further enhance performance and efficiency. These complementary technologies include variable valve timing, direct injection, turbocharging, and hybrid electric systems. The integration allows for more flexible engine operation across a wider range of conditions. For example, combining cylinder deactivation with mild hybridization enables more aggressive deactivation strategies while using electric torque to smooth transitions and fill torque gaps. Advanced control systems coordinate these various technologies to optimize overall powertrain efficiency while maintaining performance targets.

02 Fuel efficiency improvements through cylinder deactivation

Cylinder deactivation in V6 engines can significantly improve fuel efficiency by reducing pumping losses during partial load operation. When certain cylinders are deactivated, the active cylinders operate at higher specific loads, improving thermal efficiency. Studies show that V6 engines with cylinder deactivation can achieve fuel economy improvements of 5-15% depending on driving conditions, with the greatest benefits observed during highway cruising where partial load operation is common.Expand Specific Solutions03 Control strategies for V6 cylinder deactivation

Sophisticated control strategies are essential for effective cylinder deactivation in V6 engines. These strategies determine when to activate or deactivate cylinders based on parameters such as engine load, speed, temperature, and driver demand. Advanced control algorithms can manage the transition between full and partial cylinder operation to maintain smooth performance. Some systems incorporate predictive elements that anticipate driving conditions to optimize the timing of cylinder activation changes, minimizing NVH (Noise, Vibration, Harshness) issues during transitions.Expand Specific Solutions04 NVH challenges and solutions in V6 cylinder deactivation

Cylinder deactivation in V6 engines presents significant NVH (Noise, Vibration, Harshness) challenges due to changes in firing order and torque delivery. Solutions include active engine mounts that counteract vibrations, exhaust system modifications to manage sound quality changes, and careful calibration of transition points. Some systems employ torque smoothing strategies during mode transitions or incorporate balance shaft modifications to address the unique vibration characteristics of partial cylinder operation. Advanced acoustic engineering is often required to maintain acceptable sound quality when operating with deactivated cylinders.Expand Specific Solutions05 Variable displacement configurations for V6 engines

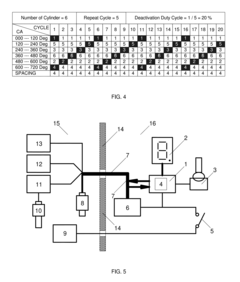

V6 engines can implement various cylinder deactivation configurations, including deactivating one bank (3 cylinders), alternating cylinders, or specific cylinder combinations optimized for balance. Each configuration offers different trade-offs between efficiency, smoothness, and implementation complexity. Some advanced systems allow for multiple deactivation modes, enabling the engine to run on 3, 4, or all 6 cylinders depending on load conditions. The specific firing order and V-angle of the engine influence which deactivation patterns provide optimal results in terms of balance and efficiency.Expand Specific Solutions

Major Manufacturers and Competitive Landscape

Cylinder deactivation technology in V6 engines is currently in a growth phase, with the market expanding due to increasing fuel efficiency demands and emissions regulations. The global market for this technology is estimated to reach $5-7 billion by 2027, growing at 6-8% CAGR. Leading players include established automotive manufacturers like Ford, GM, Honda, and Hyundai, alongside specialized component suppliers such as Eaton, Schaeffler, Delphi, and BorgWarner. The technology has reached moderate maturity in premium segments but is now transitioning to mass-market applications. Ford, GM, and Honda have achieved commercial implementation, while companies like Cummins, Eaton, and Schaeffler continue advancing the technology through innovations in valve control systems, thermal management, and NVH reduction to improve efficiency and performance.

Ford Global Technologies LLC

Technical Solution: Ford's cylinder deactivation technology for V6 engines employs a sophisticated valve control system that selectively deactivates specific cylinders during light load conditions. Their system utilizes oil pressure-activated switching roller finger followers (SRFFs) that enable seamless transitions between full cylinder operation and deactivation modes. Ford's implementation includes advanced control algorithms that monitor multiple vehicle parameters including throttle position, vehicle speed, and engine load to determine optimal deactivation timing. Their system can operate in various patterns, deactivating either one cylinder bank (3 cylinders) or alternating cylinders based on driving conditions. Ford has reported fuel economy improvements of 4-6% in real-world driving conditions and up to 10% in highway cruising scenarios through their Dynamic Skip Fire (DSF) technology integration with cylinder deactivation.

Strengths: Ford's system offers excellent integration with existing powertrain control modules, providing smooth transitions between modes with minimal NVH (Noise, Vibration, Harshness) issues. Their technology is highly adaptable across different V6 engine configurations. Weaknesses: The system adds complexity to the valvetrain, potentially increasing maintenance costs over vehicle lifetime, and requires precise calibration to maintain performance across varying driving conditions.

Honda Motor Co., Ltd.

Technical Solution: Honda's Variable Cylinder Management (VCM) system for V6 engines represents one of the most refined implementations of cylinder deactivation technology in the market. Their system employs VTEC (Variable Valve Timing and Lift Electronic Control) technology combined with sophisticated solenoid-operated oil control valves to deactivate the rear bank of cylinders (cylinders 3, 4, and 5) during light load conditions. Honda's implementation includes proprietary synchronization algorithms that ensure seamless transitions between 3-cylinder and 6-cylinder operation modes. The system utilizes active engine mounts and noise cancellation technology to minimize NVH issues commonly associated with cylinder deactivation. Honda's VCM system has demonstrated fuel economy improvements of 5-12% depending on driving conditions, with particularly strong results in highway cruising scenarios where the system can maintain deactivation for extended periods. Recent iterations incorporate predictive control elements that anticipate load changes based on topographical data and driving patterns.

Strengths: Honda's system offers exceptional refinement with virtually imperceptible mode transitions and minimal vibration during cylinder deactivation. The integration with active noise cancellation technology effectively addresses NVH concerns. Weaknesses: The system adds significant complexity to the engine design, potentially increasing manufacturing costs, and the fuel economy benefits are less pronounced in city driving conditions with frequent load changes.

Key Patents and Technical Innovations in Cylinder Deactivation

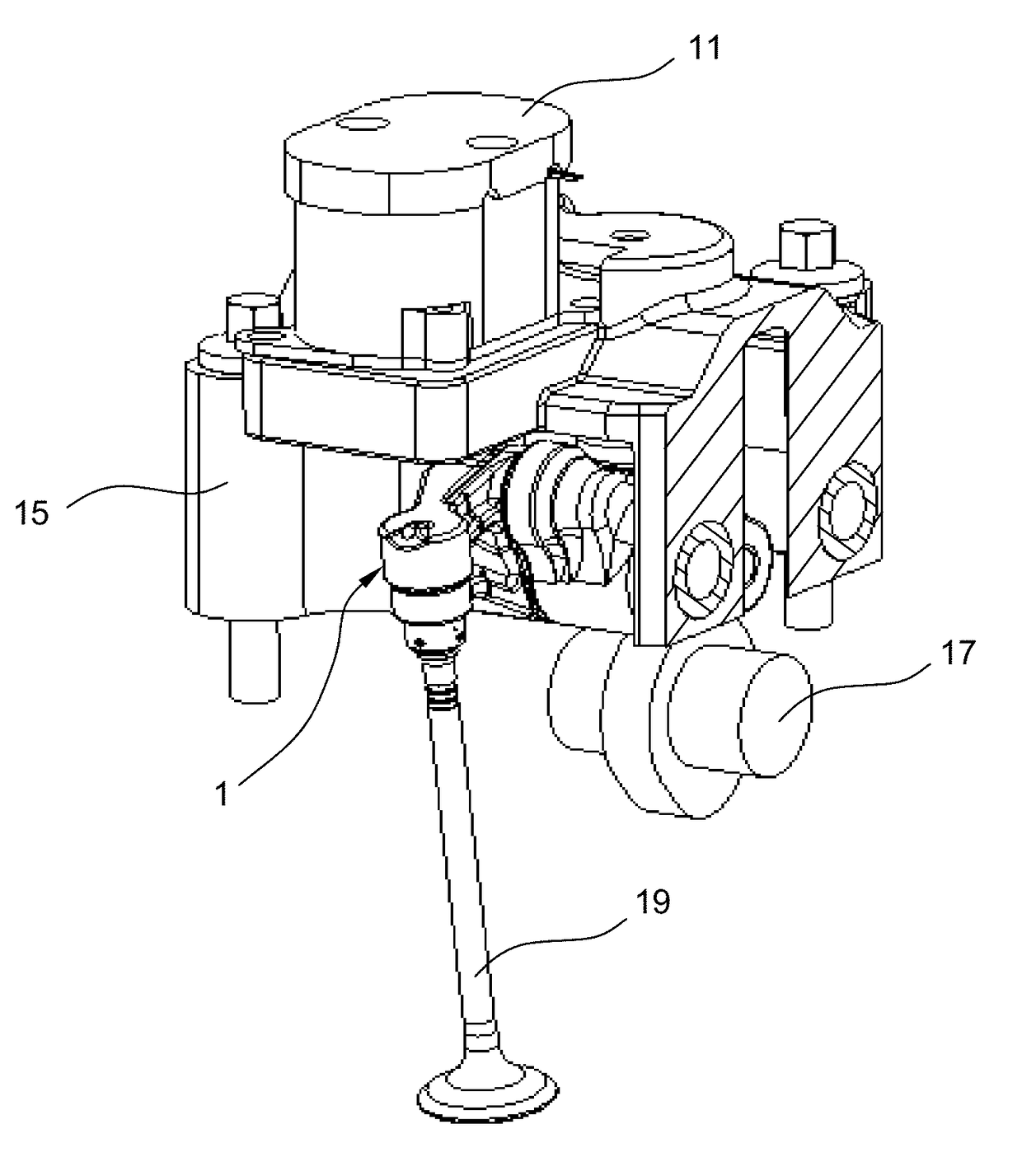

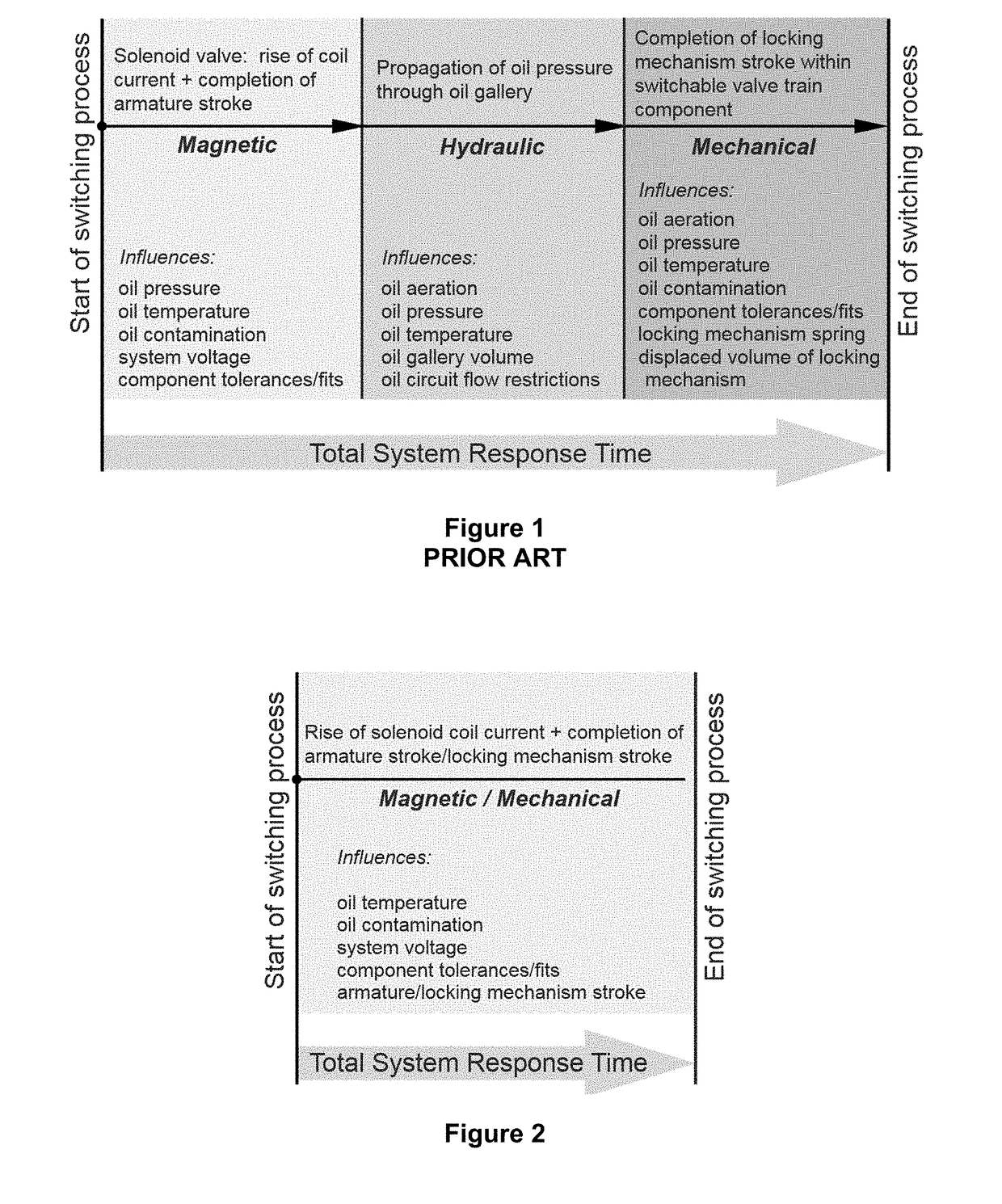

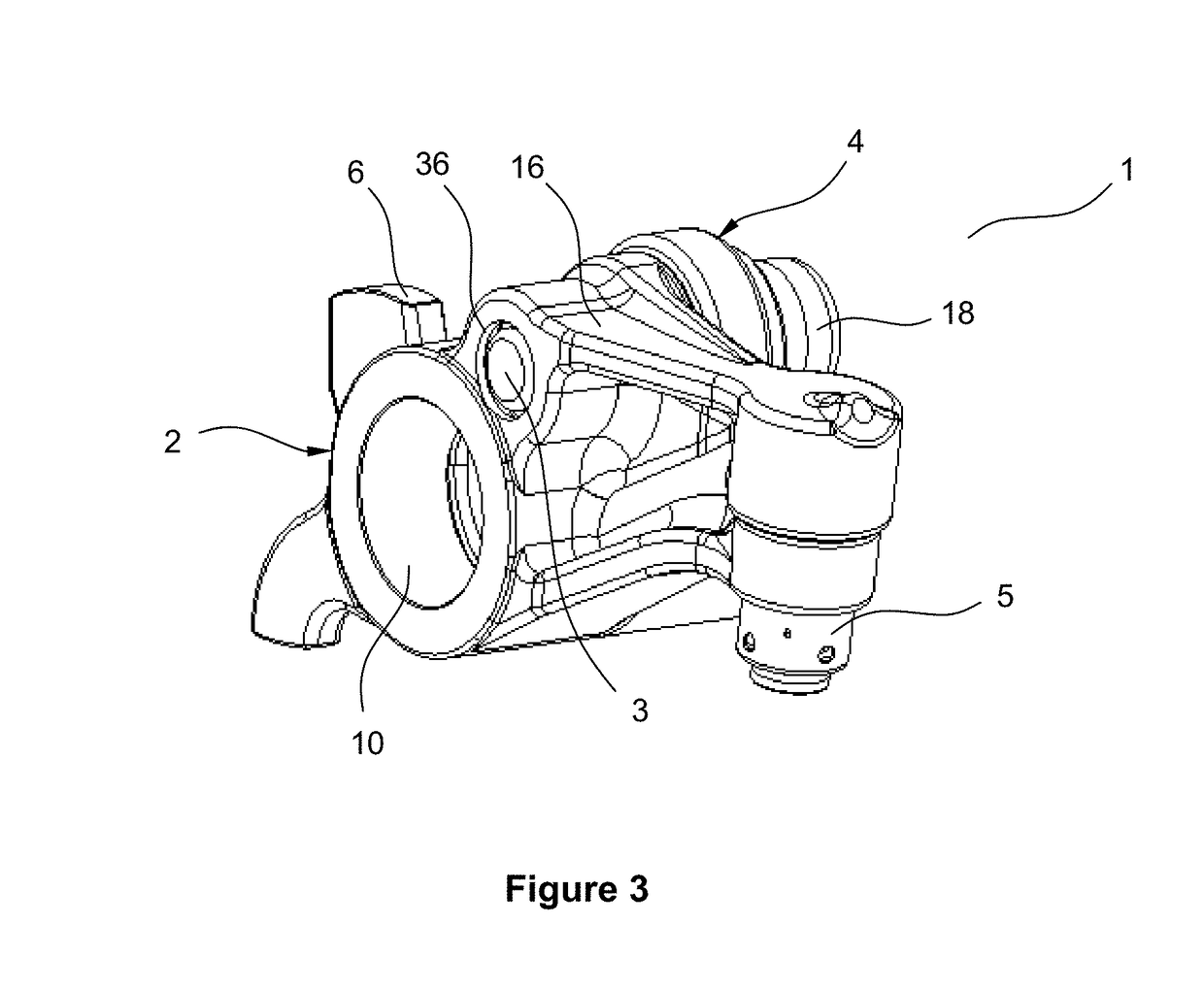

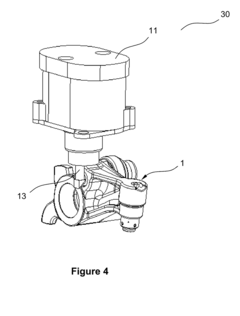

Fast acting switching valve train system for valve deactivation

PatentActiveUS20170198610A1

Innovation

- A fast-acting switchable rocker arm system with an electro-mechanical actuator assembly that eliminates the need for oil pressure to actuate the locking mechanism, allowing for direct mechanical actuation between the actuator pin and shuttle pin, reducing system response time and eliminating the need for oil galleries.

Dynamic Cylinder Deactivation with Residual Heat Recovery

PatentInactiveUS20150152795A1

Innovation

- Dynamic Cylinder Deactivation (DCD) method, which electronically controls fuel injection to deactivate and reactivate cylinders alternately, maintaining thermal and mechanical balance, and utilizing residual heat for improved efficiency.

Emissions Regulations Impact on Cylinder Deactivation Technology

Emissions regulations worldwide have become increasingly stringent over the past two decades, serving as a primary catalyst for the development and implementation of cylinder deactivation technology in V6 engines. The European Union's Euro 6d standards and the United States' EPA Tier 3 regulations have established progressively lower limits for nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter emissions, compelling automotive manufacturers to adopt innovative technologies for improved fuel efficiency and reduced emissions.

Cylinder deactivation technology has emerged as a direct response to these regulatory pressures, offering a viable pathway to meet emissions targets while maintaining performance standards. By temporarily shutting down cylinders during light-load conditions, this technology reduces pumping losses and improves thermal efficiency, resulting in CO2 emissions reductions of approximately 5-15% depending on driving conditions and implementation specifics.

The Corporate Average Fuel Economy (CAFE) standards in the United States have been particularly influential, requiring fleet-wide average fuel economy to reach 54.5 mpg by 2025. This aggressive target has accelerated the adoption of cylinder deactivation systems across various vehicle segments, especially in V6-powered SUVs and light trucks where fuel consumption improvements are most needed to meet regulatory requirements.

China's implementation of China 6 emissions standards, comparable to Euro 6 in stringency, has created another significant market driver for cylinder deactivation technology. With the world's largest automotive market enforcing stricter emissions controls, global manufacturers have prioritized cylinder deactivation as a cost-effective compliance strategy compared to full powertrain electrification.

Real Driving Emissions (RDE) testing, now mandatory in many jurisdictions, has further emphasized the importance of cylinder deactivation. Unlike laboratory testing cycles, RDE evaluates emissions performance during actual on-road driving, where cylinder deactivation technology demonstrates particular effectiveness in variable load conditions typical of everyday use.

The regulatory landscape continues to evolve, with several regions announcing future standards that will further restrict emissions. California's Advanced Clean Cars II program and the EU's proposed Euro 7 standards represent the next wave of regulations that will likely accelerate cylinder deactivation technology refinement and deployment. These upcoming standards focus not only on tailpipe emissions but also on lifecycle carbon footprint, creating additional incentives for manufacturers to optimize internal combustion efficiency through technologies like cylinder deactivation.

Cylinder deactivation technology has emerged as a direct response to these regulatory pressures, offering a viable pathway to meet emissions targets while maintaining performance standards. By temporarily shutting down cylinders during light-load conditions, this technology reduces pumping losses and improves thermal efficiency, resulting in CO2 emissions reductions of approximately 5-15% depending on driving conditions and implementation specifics.

The Corporate Average Fuel Economy (CAFE) standards in the United States have been particularly influential, requiring fleet-wide average fuel economy to reach 54.5 mpg by 2025. This aggressive target has accelerated the adoption of cylinder deactivation systems across various vehicle segments, especially in V6-powered SUVs and light trucks where fuel consumption improvements are most needed to meet regulatory requirements.

China's implementation of China 6 emissions standards, comparable to Euro 6 in stringency, has created another significant market driver for cylinder deactivation technology. With the world's largest automotive market enforcing stricter emissions controls, global manufacturers have prioritized cylinder deactivation as a cost-effective compliance strategy compared to full powertrain electrification.

Real Driving Emissions (RDE) testing, now mandatory in many jurisdictions, has further emphasized the importance of cylinder deactivation. Unlike laboratory testing cycles, RDE evaluates emissions performance during actual on-road driving, where cylinder deactivation technology demonstrates particular effectiveness in variable load conditions typical of everyday use.

The regulatory landscape continues to evolve, with several regions announcing future standards that will further restrict emissions. California's Advanced Clean Cars II program and the EU's proposed Euro 7 standards represent the next wave of regulations that will likely accelerate cylinder deactivation technology refinement and deployment. These upcoming standards focus not only on tailpipe emissions but also on lifecycle carbon footprint, creating additional incentives for manufacturers to optimize internal combustion efficiency through technologies like cylinder deactivation.

NVH Challenges and Solutions in Cylinder Deactivation Systems

Cylinder deactivation technology, while offering significant fuel economy benefits, introduces unique noise, vibration, and harshness (NVH) challenges that must be addressed for successful implementation in V6 engines. The fundamental issue stems from the altered firing sequence and torque delivery when operating with deactivated cylinders, creating uneven power pulses that manifest as vibrations throughout the powertrain and vehicle structure.

Primary NVH concerns include increased torsional vibrations in the crankshaft and drivetrain, which occur at different frequencies than in full-cylinder operation. These vibrations typically present in the 30-50 Hz range, coinciding with frequencies that can resonate with vehicle components and be particularly perceptible to occupants. Additionally, the transition between active and deactivated modes creates momentary torque fluctuations that, if not properly managed, result in noticeable jerking or shuddering.

Acoustic challenges also emerge as the engine sound character changes dramatically during cylinder deactivation. The firing frequency shifts from a balanced six-cylinder sound to an uneven three-cylinder sound profile, often perceived as rougher and less refined. This acoustic signature can penetrate the cabin through both airborne and structure-borne pathways, potentially degrading the perceived quality of the vehicle.

Industry solutions have evolved through several generations of refinement. Modern approaches employ active engine mounts that counteract vibrations through electronically controlled hydraulic systems that adapt to changing engine conditions. These mounts can be tuned specifically to target the frequencies associated with cylinder deactivation operation. Complementary to this, advanced torque smoothing algorithms in the engine control module precisely adjust ignition timing and throttle position during mode transitions to minimize torque fluctuations.

Acoustic management solutions include active noise cancellation systems that use strategically placed microphones to detect unwanted engine sounds and counteract them through the vehicle's audio system. Some manufacturers have implemented active exhaust systems with variable valve timing to maintain a consistent exhaust note regardless of cylinder deactivation status.

Structural improvements in engine design specifically address NVH concerns through optimized crankshaft counterweights, dual-mass flywheels with enhanced damping characteristics, and redesigned engine mounts with frequency-dependent stiffness properties. Advanced materials with superior damping characteristics are increasingly used in critical components to absorb vibrations before they propagate through the vehicle structure.

Testing protocols have also evolved to specifically evaluate NVH performance during cylinder deactivation, with manufacturers developing specialized metrics and acceptance criteria focused on the unique challenges of this technology. These comprehensive approaches have enabled the successful implementation of cylinder deactivation in premium V6 applications where NVH expectations are particularly demanding.

Primary NVH concerns include increased torsional vibrations in the crankshaft and drivetrain, which occur at different frequencies than in full-cylinder operation. These vibrations typically present in the 30-50 Hz range, coinciding with frequencies that can resonate with vehicle components and be particularly perceptible to occupants. Additionally, the transition between active and deactivated modes creates momentary torque fluctuations that, if not properly managed, result in noticeable jerking or shuddering.

Acoustic challenges also emerge as the engine sound character changes dramatically during cylinder deactivation. The firing frequency shifts from a balanced six-cylinder sound to an uneven three-cylinder sound profile, often perceived as rougher and less refined. This acoustic signature can penetrate the cabin through both airborne and structure-borne pathways, potentially degrading the perceived quality of the vehicle.

Industry solutions have evolved through several generations of refinement. Modern approaches employ active engine mounts that counteract vibrations through electronically controlled hydraulic systems that adapt to changing engine conditions. These mounts can be tuned specifically to target the frequencies associated with cylinder deactivation operation. Complementary to this, advanced torque smoothing algorithms in the engine control module precisely adjust ignition timing and throttle position during mode transitions to minimize torque fluctuations.

Acoustic management solutions include active noise cancellation systems that use strategically placed microphones to detect unwanted engine sounds and counteract them through the vehicle's audio system. Some manufacturers have implemented active exhaust systems with variable valve timing to maintain a consistent exhaust note regardless of cylinder deactivation status.

Structural improvements in engine design specifically address NVH concerns through optimized crankshaft counterweights, dual-mass flywheels with enhanced damping characteristics, and redesigned engine mounts with frequency-dependent stiffness properties. Advanced materials with superior damping characteristics are increasingly used in critical components to absorb vibrations before they propagate through the vehicle structure.

Testing protocols have also evolved to specifically evaluate NVH performance during cylinder deactivation, with manufacturers developing specialized metrics and acceptance criteria focused on the unique challenges of this technology. These comprehensive approaches have enabled the successful implementation of cylinder deactivation in premium V6 applications where NVH expectations are particularly demanding.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!