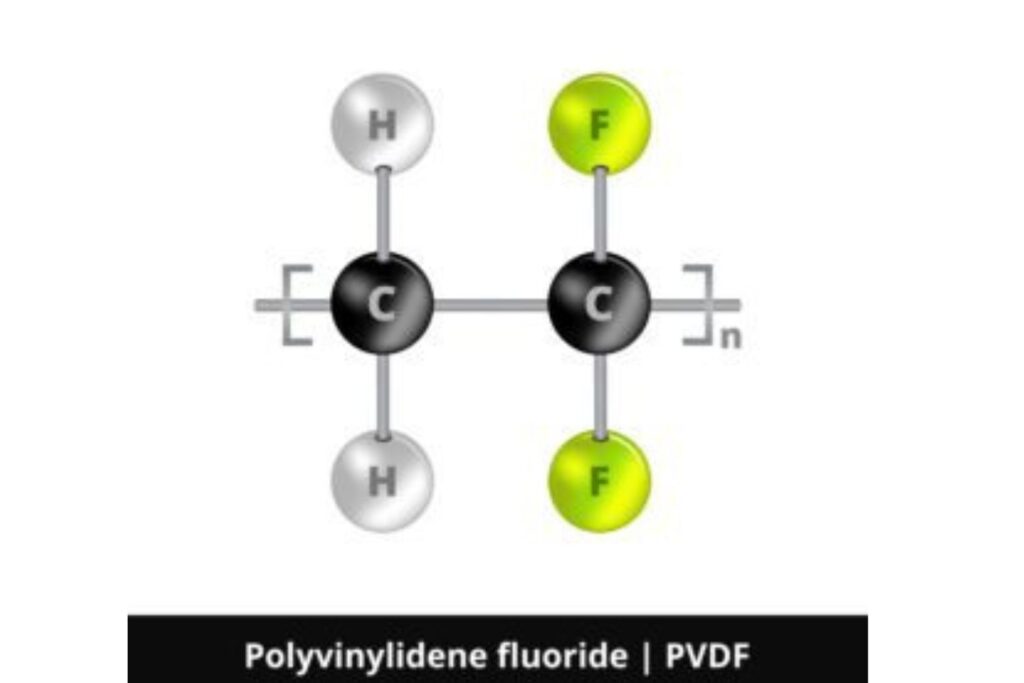

Polyvinylidene fluoride (PVDF) is a highly non-reactive and pure thermoplastic fluoropolymer with exceptional chemical resistance, thermal stability, and piezoelectric behavior. As modern industries pursue materials that are multifunctional, lightweight, and environmentally resilient, PVDF emerges as a critical enabler across energy, electronics, healthcare, and smart systems.

From boosting battery performance to improving biocompatible implants and powering next-gen wearables, PVDF is transitioning from niche uses to broad industrial adoption. This article explores the composition and key properties of PVDF, categorizes its core application domains, compares its benefits and limitations, and provides a forward-looking perspective—powered by insights from PatSnap Eureka AI Agent.

Material Composition & Key Properties

PVDF (–(CH₂–CF₂)ₙ–) is synthesized by polymerizing vinylidene difluoride (VDF). Its semi-crystalline nature allows it to possess both amorphous and crystalline phases, giving rise to its unique mechanical strength, chemical resistance, and piezoelectric behavior.

📌 Key Properties

- High thermal stability (melting point ~177°C)

- Excellent chemical and UV resistance

- Intrinsic piezoelectric and ferroelectric properties

- High dielectric strength and low permeability

- Soluble in select polar solvents (e.g., DMF, acetone)

🔬 Processing Methods

- Casting/Extrusion for films and membranes

- Electrospinning for nanofibers

- Melt compounding for composites

- Poling to induce piezoelectricity

| Property | PVDF | PTFE | PET |

|---|---|---|---|

| Chemical Resistance | Excellent | Superior | Moderate |

| Piezoelectricity | Yes | No | No |

| Processability | Good | Difficult | Easy |

| Biocompatibility | High | High | Moderate |

| Optical Clarity | Moderate (in film form) | Opaque | High |

Application Domains

Energy & Electronics

The global demand for energy-efficient, high-performance systems is driving innovation in battery, solar, and computing technologies. PVDF’s high dielectric constant, flexibility, and electroactive behavior make it indispensable in capacitors, solar cells, smart grids, and data storage components.

PVDF acts as a binder and separator in lithium-ion batteries, boosts photovoltaic efficiency in solar modules, and offers lightweight, flexible substrates in smart circuits. Its ability to endure harsh electrical and environmental stress makes it ideal for next-generation electronics.

Related Reports:

- PVDF in Energy Storage: Boosting Battery Performance

- PVDF: Key Trends in Flexible Electronics Manufacturing

- PVDF in Advanced Computing: Boosting Memory Storage

- PVDF in Transparent Electronics: Driving Innovation Forward

- PVDF in Renewable Energy: Increasing Solar Panel Efficiency

- PVDF in Smart Grids: Reliability Enhancement Strategies

- PVDF in Flexible Circuit Design: Reducing Material Complexity

- How to Enhance PVDF Functionality in Solar Cells?

Biomedical & Healthcare

Medical technology is advancing toward miniaturized, implantable, and responsive devices. PVDF offers high biocompatibility, excellent acoustic transmission, and durability, enabling advanced medical implants, wearables, and drug delivery systems.

It supports long-term use in therapeutic and diagnostic tools, including bone scaffolds, glucose sensors, and ultrasound equipment. Piezoelectric PVDF is particularly valuable in transducers and acoustic imaging.

Related Reports:

- PVDF Applications in Healthcare: Revolutionizing Bone Implants

- PVDF Benefits for Biocompatibility: Advancing Medical Devices

- PVDF in Biometric Monitoring Devices: Improving Accuracy

- PVDF Innovations in Biomedical Ultrasound Equipment

- Leveraging PVDF’s Flexibility in Implantable Devices

- How to Implement PVDF in Efficient Drug Delivery Systems?

- How to Use PVDF in Bio-Conductive Polymer Developments?

- How to Develop PVDF for Advanced Wearable Glucose Monitoring?

Membranes & Filtration

Clean water and process purification are global priorities. PVDF’s hydrophobicity, chemical inertness, and thermal resistance make it a go-to material in microfiltration, ultrafiltration, and wastewater systems.

Its ability to form porous structures via phase inversion enhances its filtration performance. Recent advancements aim at anti-fouling capabilities, reduced maintenance costs, and improved system integration in industrial and agricultural domains.

Related Reports:

- PVDF Evolution: Monitoring Advances in Membrane Technology

- Research on PVDF Membranes: Water Purification Breakthroughs

- How to Use PVDF in Filtration Systems for Improved Efficiency?

- PVDF in Anti-Fouling Membranes: Reducing Maintenance Costs

- PVDF in Waste Water Management: Enhancing System Capacity

- PVDF Solutions in Mine Application Filtering: Enhanced Safety

- Why is PVDF Used for Membranes? Discover The Benefits of PVDF Membranes

- How Does Methanol Activated PVDF Membrane?

Sensors, Robotics & Smart Materials

As robotics and IoT evolve, the need for responsive materials grows. PVDF’s piezoelectric and electrostrictive effects are ideal for sensors, actuators, and vibration energy harvesting. It enables signal detection in wearable electronics, structural health systems, and remote monitoring environments.

Its low acoustic impedance also makes it a preferred candidate in sonar, pressure sensors, and smart garments.

Related Reports:

- Future of PVDF in Wearables: Enhancing Sensor Sensitivity

- PVDF in Robotics: Superior Actuator Technologies

- PVDF’s Role in Energy Harvesting from Mechanical Stress

- PVDF in Structural Health Monitoring: Ensuring Engineering Safety

- PVDF in Environmental Sensors: Monitoring for Change

- How to Increase PVDF Efficiency in Piezoelectric Sensors?

- How to Enhance PVDF Function in Electroresponsive Coatings?

- How to Use PVDF to Achieve Enhanced Signal Detection?

Coatings & Structural Applications

Harsh outdoor environments, industrial operations, and architectural durability all demand protective, long-lasting coatings. PVDF’s weatherability, UV resistance, and mechanical flexibility make it a staple in paints, building panels, and fire-resistant systems.

It’s used in transparent films, optical coatings, and insulation layers. Ongoing research focuses on refining adhesion, enhancing clarity, and supporting sustainable construction initiatives.

Related Reports:

- How to Optimize PVDF Coatings for Durability?

- PVDF in Construction: Advancements in Durability Solutions

- PVDF’s Role in Corrosion-Resistant Coatings: Extending Lifespan

- How to Repaint A PVDF Finish?

- PVDF in Fire Safety Solutions: Meeting High Standards

- How to Develop PVDF for Advanced Thermal Insulation Solutions?

- PVDF’s Role in Sustainable Architecture: Building the Future

- How to Enhance PVDF in Flexible Display Technologies?

Comparative Advantages & Limitations

PVDF’s widespread adoption stems from its multi-functionality across industries. Yet, it does face constraints in cost, recyclability, and fine-tuning its electroactive phases.

✅ Advantages

- Strong resistance to acids, bases, and solvents

- Excellent weatherability and UV stability

- Piezoelectric and pyroelectric properties for sensing

- Low water absorption and high mechanical strength

- Easily processable for films, fibers, and coatings

- High thermal insulation and flame resistance

Limitations

- Relatively high production cost

- Non-biodegradable under natural conditions

- Requires specialized solvents for processing

- Complex poling techniques for activating piezoelectricity

- Limited electrical conductivity without fillers

Future Outlook & Research Frontiers

Looking forward, PVDF is well-positioned for breakthroughs in multiple next-gen technologies. Research is especially active in scaling sustainable production methods and enhancing the electrical responsiveness of PVDF composites.

Key Emerging Trends

- Sustainable PVDF: Green synthesis methods and recyclable formulations

- Bio-integrated electronics: PVDF-based interfaces in neuroprosthetics and soft robotics

- Next-gen piezoelectrics: Nanostructured PVDF for energy harvesting and wearable sensors

- Advanced composites: PVDF-carbon nanotube and PVDF-MXene hybrids for smart packaging

- IoT-ready materials: Flexible, low-power sensors for smart homes and agriculture

- AI-assisted design: Simulation-driven molecular tailoring for improved efficiency

From Lab to Market

- 2025: Pilot-scale production of PVDF-based piezoelectric inks

- 2026: Mass adoption in implantable wearables and drug delivery patches

- 2027: Integration into self-powered microelectronics and neural interfaces

Conclusion & Key Takeaways

PVDF is more than a niche fluoropolymer—it’s an innovation enabler across diverse sectors. Its unmatched versatility in membranes, electronics, sensors, and biocompatible devices makes it a front-runner in the race toward smarter, more efficient, and sustainable technologies.

For engineers, researchers, and manufacturers seeking to design next-gen systems, PVDF offers a rare combination of processability, responsiveness, and robustness.

Now is the ideal time to invest in understanding, utilizing, and innovating with PVDF.

Accelerate Innovation with PatSnap Eureka

Material innovation is complex. Staying ahead means accessing the right tools to decode technology signals, visualize trends, and benchmark patents.

PatSnap Eureka AI Agent enables your R&D and product teams to:

- Explore emerging PVDF trends in real time

- Visualize innovation landscapes and white spaces

- Compare top competitors and leading research

👉 Ready to unlock the full potential of PVDF? Request a demo of PatSnap Eureka today.