3D Current Collectors For Long Cycle Life In Aqueous Zinc Ion Batteries

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

3D Current Collector Technology Background and Objectives

The evolution of energy storage technologies has witnessed significant advancements over the past decade, with zinc-ion batteries (ZIBs) emerging as promising candidates for next-generation energy storage systems. Aqueous ZIBs have garnered substantial attention due to their inherent safety, environmental friendliness, and cost-effectiveness compared to lithium-ion batteries. However, the widespread adoption of aqueous ZIBs has been hindered by their limited cycle life, primarily attributed to the dendrite formation and corrosion issues associated with zinc anodes during repeated charge-discharge cycles.

The development of 3D current collectors represents a pivotal technological innovation aimed at addressing these fundamental challenges. Traditional 2D current collectors provide limited surface area for active material deposition, resulting in uneven current distribution and accelerated electrode degradation. In contrast, 3D architectures offer enhanced surface area, improved electrolyte penetration, and more uniform current distribution, potentially extending the cycle life of aqueous ZIBs significantly.

The historical trajectory of current collector technology began with simple metal foils, evolving through various surface treatments and coatings, and has now entered the era of three-dimensional structures. This evolution has been driven by the increasing demands for higher energy density, faster charging capabilities, and longer cycle life in battery systems. The transition from 2D to 3D architectures represents a paradigm shift in current collector design philosophy.

Recent research has demonstrated that 3D current collectors can effectively mitigate zinc dendrite formation by providing preferential nucleation sites and guiding uniform zinc deposition. Various 3D structures, including foams, meshes, and hierarchical architectures, have been explored with promising results. These structures not only suppress dendrite growth but also accommodate volume changes during cycling, thereby enhancing the mechanical stability of the electrode-electrolyte interface.

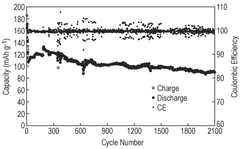

The primary objectives of advancing 3D current collector technology for aqueous ZIBs include: extending cycle life beyond 1000 cycles at practical current densities; achieving uniform zinc deposition with minimal dendrite formation; developing scalable and cost-effective fabrication methods for 3D structures; and optimizing the interface between the current collector and active materials to minimize contact resistance and enhance electron transport.

Additionally, research aims to understand the fundamental mechanisms governing the interaction between 3D current collectors and zinc electrodeposition processes. This includes investigating the influence of surface chemistry, pore structure, and mechanical properties on dendrite suppression and electrode performance. The ultimate goal is to establish design principles for next-generation 3D current collectors that can enable aqueous ZIBs with comparable cycle life to commercial lithium-ion batteries while maintaining their inherent advantages in safety, cost, and environmental impact.

The development of 3D current collectors represents a pivotal technological innovation aimed at addressing these fundamental challenges. Traditional 2D current collectors provide limited surface area for active material deposition, resulting in uneven current distribution and accelerated electrode degradation. In contrast, 3D architectures offer enhanced surface area, improved electrolyte penetration, and more uniform current distribution, potentially extending the cycle life of aqueous ZIBs significantly.

The historical trajectory of current collector technology began with simple metal foils, evolving through various surface treatments and coatings, and has now entered the era of three-dimensional structures. This evolution has been driven by the increasing demands for higher energy density, faster charging capabilities, and longer cycle life in battery systems. The transition from 2D to 3D architectures represents a paradigm shift in current collector design philosophy.

Recent research has demonstrated that 3D current collectors can effectively mitigate zinc dendrite formation by providing preferential nucleation sites and guiding uniform zinc deposition. Various 3D structures, including foams, meshes, and hierarchical architectures, have been explored with promising results. These structures not only suppress dendrite growth but also accommodate volume changes during cycling, thereby enhancing the mechanical stability of the electrode-electrolyte interface.

The primary objectives of advancing 3D current collector technology for aqueous ZIBs include: extending cycle life beyond 1000 cycles at practical current densities; achieving uniform zinc deposition with minimal dendrite formation; developing scalable and cost-effective fabrication methods for 3D structures; and optimizing the interface between the current collector and active materials to minimize contact resistance and enhance electron transport.

Additionally, research aims to understand the fundamental mechanisms governing the interaction between 3D current collectors and zinc electrodeposition processes. This includes investigating the influence of surface chemistry, pore structure, and mechanical properties on dendrite suppression and electrode performance. The ultimate goal is to establish design principles for next-generation 3D current collectors that can enable aqueous ZIBs with comparable cycle life to commercial lithium-ion batteries while maintaining their inherent advantages in safety, cost, and environmental impact.

Market Analysis for Aqueous Zinc Ion Batteries

The global market for aqueous zinc-ion batteries (AZIBs) is experiencing significant growth, driven by increasing demand for safe, cost-effective, and environmentally friendly energy storage solutions. Unlike lithium-ion batteries, AZIBs utilize abundant zinc resources, non-flammable aqueous electrolytes, and simpler manufacturing processes, positioning them as a promising alternative for large-scale energy storage applications.

Current market valuations indicate that the global zinc-ion battery market reached approximately $182 million in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 11.5% through 2030. This growth trajectory is particularly notable in regions with aggressive renewable energy integration targets, including Asia-Pacific, Europe, and North America.

The market segmentation reveals distinct application sectors for AZIBs, with grid energy storage representing the largest share at 45%, followed by consumer electronics (25%), electric vehicles (15%), and other applications (15%). The grid storage segment is experiencing the fastest growth due to increasing renewable energy deployment and the need for reliable backup power systems.

Key market drivers include the inherent safety advantages of aqueous electrolytes, eliminating thermal runaway risks associated with organic electrolytes in lithium-ion batteries. Additionally, the abundance of zinc resources contributes to lower material costs, with zinc being approximately 20 times less expensive than lithium on a per-weight basis.

However, market penetration faces challenges related to the technical limitations of conventional AZIBs, particularly their limited cycle life due to zinc dendrite formation and electrode degradation. This is where 3D current collectors represent a critical technological advancement, potentially extending cycle life from the current industry standard of 500-1000 cycles to over 5000 cycles.

Market analysis indicates that companies investing in advanced 3D current collector technologies could capture premium segments of the AZIB market, with potential price premiums of 30-40% for long-cycle-life products. Early adopters of this technology are likely to establish significant competitive advantages in high-value applications such as telecommunication backup systems and grid-scale storage.

Regional market dynamics show Asia-Pacific leading with 45% market share, followed by Europe (30%) and North America (20%). China dominates manufacturing capacity, while research advancements in 3D current collectors are concentrated in research institutions across North America, Europe, and East Asia.

The market forecast suggests that successful commercialization of AZIBs with 3D current collectors could accelerate market growth to a CAGR of 15-18% by 2025, potentially reaching a market value of $500 million by 2028, with long-cycle-life applications representing the highest-margin segment of this emerging market.

Current market valuations indicate that the global zinc-ion battery market reached approximately $182 million in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 11.5% through 2030. This growth trajectory is particularly notable in regions with aggressive renewable energy integration targets, including Asia-Pacific, Europe, and North America.

The market segmentation reveals distinct application sectors for AZIBs, with grid energy storage representing the largest share at 45%, followed by consumer electronics (25%), electric vehicles (15%), and other applications (15%). The grid storage segment is experiencing the fastest growth due to increasing renewable energy deployment and the need for reliable backup power systems.

Key market drivers include the inherent safety advantages of aqueous electrolytes, eliminating thermal runaway risks associated with organic electrolytes in lithium-ion batteries. Additionally, the abundance of zinc resources contributes to lower material costs, with zinc being approximately 20 times less expensive than lithium on a per-weight basis.

However, market penetration faces challenges related to the technical limitations of conventional AZIBs, particularly their limited cycle life due to zinc dendrite formation and electrode degradation. This is where 3D current collectors represent a critical technological advancement, potentially extending cycle life from the current industry standard of 500-1000 cycles to over 5000 cycles.

Market analysis indicates that companies investing in advanced 3D current collector technologies could capture premium segments of the AZIB market, with potential price premiums of 30-40% for long-cycle-life products. Early adopters of this technology are likely to establish significant competitive advantages in high-value applications such as telecommunication backup systems and grid-scale storage.

Regional market dynamics show Asia-Pacific leading with 45% market share, followed by Europe (30%) and North America (20%). China dominates manufacturing capacity, while research advancements in 3D current collectors are concentrated in research institutions across North America, Europe, and East Asia.

The market forecast suggests that successful commercialization of AZIBs with 3D current collectors could accelerate market growth to a CAGR of 15-18% by 2025, potentially reaching a market value of $500 million by 2028, with long-cycle-life applications representing the highest-margin segment of this emerging market.

Technical Challenges in 3D Current Collectors

Despite the promising potential of 3D current collectors in aqueous zinc ion batteries (AZIBs), several significant technical challenges impede their widespread implementation and optimal performance. The primary challenge lies in the complex manufacturing processes required for 3D structures. Traditional fabrication methods like chemical vapor deposition and electrodeposition often struggle to create uniform, defect-free 3D architectures at scale. The intricate geometries demand precise control over deposition parameters, which becomes increasingly difficult as structural complexity increases.

Material compatibility presents another substantial hurdle. The 3D current collectors must maintain excellent electrical conductivity while simultaneously exhibiting strong chemical stability in aqueous electrolytes. Many metallic materials that offer superior conductivity are prone to corrosion in the mildly acidic or alkaline environments typical of zinc-based electrolytes. This corrosion not only compromises structural integrity but also introduces unwanted side reactions that can degrade battery performance over time.

Interface engineering between the 3D current collector and active materials represents a critical challenge. Achieving uniform coating of active materials on complex 3D structures requires sophisticated deposition techniques. Poor adhesion between the current collector and active materials can lead to electrical disconnection during cycling, particularly under the mechanical stresses induced by zinc plating/stripping processes. This results in capacity fading and shortened cycle life.

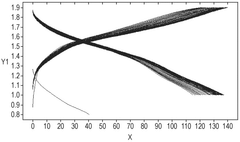

The dendrite formation issue, while mitigated by 3D structures, is not completely eliminated. The complex geometry of 3D current collectors can create localized high-current density regions that still promote dendrite growth. Controlling zinc deposition uniformly across the entire 3D architecture remains technically demanding, requiring precise engineering of surface properties and electrolyte distribution.

Cost and scalability concerns further complicate the implementation of 3D current collectors. Many advanced fabrication techniques that enable precise 3D architectures are laboratory-scale processes with limited throughput and high costs. Transitioning these methods to industrial-scale production while maintaining structural precision and performance represents a significant engineering challenge.

Additionally, the increased surface area of 3D structures can accelerate side reactions, particularly hydrogen evolution in aqueous systems. This parasitic reaction not only reduces coulombic efficiency but also creates safety concerns through gas generation. Developing surface treatments or coatings that selectively suppress these side reactions while maintaining the benefits of 3D architectures remains an ongoing research focus.

Material compatibility presents another substantial hurdle. The 3D current collectors must maintain excellent electrical conductivity while simultaneously exhibiting strong chemical stability in aqueous electrolytes. Many metallic materials that offer superior conductivity are prone to corrosion in the mildly acidic or alkaline environments typical of zinc-based electrolytes. This corrosion not only compromises structural integrity but also introduces unwanted side reactions that can degrade battery performance over time.

Interface engineering between the 3D current collector and active materials represents a critical challenge. Achieving uniform coating of active materials on complex 3D structures requires sophisticated deposition techniques. Poor adhesion between the current collector and active materials can lead to electrical disconnection during cycling, particularly under the mechanical stresses induced by zinc plating/stripping processes. This results in capacity fading and shortened cycle life.

The dendrite formation issue, while mitigated by 3D structures, is not completely eliminated. The complex geometry of 3D current collectors can create localized high-current density regions that still promote dendrite growth. Controlling zinc deposition uniformly across the entire 3D architecture remains technically demanding, requiring precise engineering of surface properties and electrolyte distribution.

Cost and scalability concerns further complicate the implementation of 3D current collectors. Many advanced fabrication techniques that enable precise 3D architectures are laboratory-scale processes with limited throughput and high costs. Transitioning these methods to industrial-scale production while maintaining structural precision and performance represents a significant engineering challenge.

Additionally, the increased surface area of 3D structures can accelerate side reactions, particularly hydrogen evolution in aqueous systems. This parasitic reaction not only reduces coulombic efficiency but also creates safety concerns through gas generation. Developing surface treatments or coatings that selectively suppress these side reactions while maintaining the benefits of 3D architectures remains an ongoing research focus.

Current 3D Collector Solutions for Zinc Batteries

01 3D carbon-based current collectors for enhanced cycle life

Three-dimensional carbon-based materials such as carbon foam, carbon cloth, and carbon nanotubes can be used as current collectors in aqueous zinc ion batteries. These materials provide high surface area, excellent electrical conductivity, and mechanical stability, which help to accommodate volume changes during cycling and facilitate ion transport. The porous structure allows for better electrolyte penetration and zinc ion diffusion, resulting in improved cycle life and rate capability of the batteries.- 3D carbon-based current collectors for enhanced cycle life: Three-dimensional carbon-based materials such as carbon foam, carbon cloth, and carbon nanotubes can be used as current collectors in aqueous zinc ion batteries. These materials provide high surface area, excellent electrical conductivity, and structural stability, which help to accommodate volume changes during cycling. The porous structure allows for better electrolyte penetration and ion diffusion, resulting in improved cycle life and rate capability of the batteries.

- Metal-based 3D current collectors with zinc deposition control: Metal-based 3D current collectors, including copper foam, nickel foam, and stainless steel mesh, can effectively control zinc deposition behavior in aqueous zinc ion batteries. These structures provide uniform current distribution and nucleation sites for zinc deposition, preventing dendrite formation and electrode degradation. The improved zinc plating/stripping efficiency leads to enhanced cycling stability and extended battery life.

- Surface-modified 3D current collectors for improved wettability: Surface modification of 3D current collectors with functional groups or coatings can improve the wettability and interaction with aqueous electrolytes. Treatments such as plasma etching, chemical oxidation, or coating with hydrophilic materials enhance the electrolyte-electrode interface, promoting uniform ion distribution and reducing interfacial resistance. These modifications result in more stable cycling performance and longer battery life.

- Composite 3D current collectors with protective layers: Composite 3D current collectors incorporating protective layers or coatings can mitigate side reactions between the current collector and the electrolyte. These protective layers, such as carbon coatings, metal oxides, or polymers, prevent corrosion and hydrogen evolution, which are common issues in aqueous zinc ion batteries. The enhanced electrochemical stability of these composite structures contributes to improved cycle life and overall battery performance.

- Hierarchical 3D current collectors with multi-scale porosity: Hierarchical 3D current collectors with multi-scale porosity combine macro, micro, and nano-sized pores to optimize ion transport and electrode kinetics. These structures provide both high surface area for reaction sites and efficient mass transport pathways for electrolyte penetration. The hierarchical architecture helps maintain structural integrity during cycling, accommodates volume changes, and facilitates rapid ion diffusion, resulting in significantly improved cycle life for aqueous zinc ion batteries.

02 Metal-based 3D current collectors with anti-corrosion properties

Metal-based three-dimensional current collectors with anti-corrosion treatments can significantly enhance the cycle life of aqueous zinc ion batteries. These collectors, typically made from copper, nickel, or stainless steel with 3D structures like foams, meshes, or arrays, are treated with protective coatings to resist the corrosive aqueous environment. The 3D structure provides larger surface area for zinc deposition while the anti-corrosion properties prevent degradation during long-term cycling, resulting in more stable performance and extended battery lifespan.Expand Specific Solutions03 Composite 3D current collectors with conductive polymers

Composite three-dimensional current collectors incorporating conductive polymers offer improved cycle life for aqueous zinc ion batteries. These collectors combine the mechanical strength of traditional substrates with the electrochemical stability of conductive polymers like polypyrrole, polyaniline, or PEDOT. The polymer coating helps regulate zinc deposition, prevent dendrite formation, and resist corrosion in the aqueous electrolyte. The synergistic effect of the 3D structure and conductive polymer coating results in more uniform current distribution and stable zinc plating/stripping processes over extended cycles.Expand Specific Solutions04 Hierarchical porous 3D current collectors for uniform zinc deposition

Hierarchical porous three-dimensional current collectors feature multi-scale porosity that promotes uniform zinc deposition and dissolution during battery cycling. These structures combine macro, micro, and nano-sized pores to optimize electrolyte infiltration, ion transport, and reaction kinetics. The hierarchical design helps distribute current density evenly across the electrode surface, mitigating dendrite formation and electrode pulverization. This architecture accommodates volume changes during cycling while maintaining structural integrity, significantly extending the cycle life of aqueous zinc ion batteries.Expand Specific Solutions05 Surface-modified 3D current collectors with functional groups

Surface modification of three-dimensional current collectors with functional groups enhances the cycle life of aqueous zinc ion batteries. By introducing specific functional groups such as hydroxyl, carboxyl, or amino groups onto the surface of 3D current collectors, the zinc ion affinity and deposition behavior can be regulated. These functional groups create preferential nucleation sites for zinc deposition, guide uniform metal growth, and suppress dendrite formation. The modified surfaces also improve wettability with the electrolyte and strengthen the interface stability, resulting in more reversible zinc plating/stripping processes and extended battery lifespan.Expand Specific Solutions

Critical Patents in 3D Current Collector Design

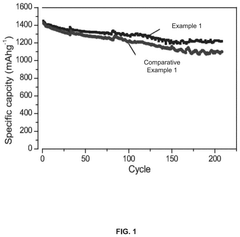

Preparation methods of composite current collectors for zinc secondary batteries, negative electrode plates, and zinc secondary batteries

PatentActiveUS20240363869A1

Innovation

- A composite current collector is developed by interposing carbon cloth between zinc mesh layers, filling mesh pores with tin, and coating with a conductive paste containing graphene and conductive polymer, enhancing electrical conductivity and reducing corrosion.

battery

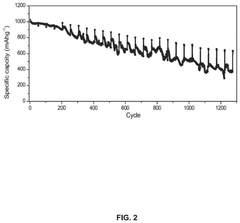

PatentWO2025114546A1

Innovation

- The development of an aqueous zinc-ion battery with a thick manganese oxide-carbon composite cathode and a zinc powder-carbon composite anode, along with a thin solid zinc ion separator to suppress dendrite growth. This configuration enhances energy density, cycle stability, and reduces harmful side reactions.

Material Sustainability and Environmental Impact

The sustainability aspects of 3D current collectors for aqueous zinc-ion batteries (AZIBs) represent a critical dimension in evaluating their long-term viability. Traditional current collectors often utilize environmentally problematic materials such as heavy metals or rare earth elements, creating significant ecological concerns throughout their lifecycle. In contrast, emerging 3D current collector designs offer promising pathways toward enhanced sustainability through material selection optimization and structural efficiency.

Carbon-based 3D current collectors demonstrate particular promise from an environmental perspective, as they can be derived from renewable resources or even waste materials. Recent research has shown that biomass-derived carbon frameworks can serve as effective 3D current collectors while significantly reducing the environmental footprint compared to conventional metallic alternatives. These materials require less energy-intensive processing and avoid the environmental damage associated with mining operations.

The manufacturing processes for 3D current collectors also present important sustainability considerations. Additive manufacturing techniques, including 3D printing, enable more precise material deposition and reduced waste generation compared to traditional subtractive manufacturing methods. However, these processes must be further optimized to minimize energy consumption and eliminate toxic solvents or additives that may be required during fabrication.

End-of-life management represents another crucial aspect of environmental impact assessment. The complex three-dimensional structures of these current collectors can potentially complicate recycling efforts. Research indicates that designing 3D current collectors with disassembly and material recovery in mind could significantly improve their lifecycle sustainability. Some promising approaches include developing collectors with easily separable components or incorporating materials that facilitate selective recovery processes.

Water usage and contamination risks are particularly relevant for aqueous zinc-ion battery systems. The 3D current collectors must be designed to minimize leaching of potentially harmful substances into the electrolyte during long-term cycling. Studies have demonstrated that surface functionalization of 3D current collectors can reduce undesirable side reactions while enhancing electrochemical performance, thereby extending battery lifetime and reducing waste generation.

Carbon footprint analysis of various 3D current collector manufacturing routes reveals significant variability depending on material selection and processing methods. Life cycle assessments indicate that while the initial production energy requirements may be higher for some advanced 3D structures, their superior performance and longevity can result in net environmental benefits over the complete battery lifecycle. This highlights the importance of holistic sustainability evaluation rather than focusing solely on manufacturing impacts.

Carbon-based 3D current collectors demonstrate particular promise from an environmental perspective, as they can be derived from renewable resources or even waste materials. Recent research has shown that biomass-derived carbon frameworks can serve as effective 3D current collectors while significantly reducing the environmental footprint compared to conventional metallic alternatives. These materials require less energy-intensive processing and avoid the environmental damage associated with mining operations.

The manufacturing processes for 3D current collectors also present important sustainability considerations. Additive manufacturing techniques, including 3D printing, enable more precise material deposition and reduced waste generation compared to traditional subtractive manufacturing methods. However, these processes must be further optimized to minimize energy consumption and eliminate toxic solvents or additives that may be required during fabrication.

End-of-life management represents another crucial aspect of environmental impact assessment. The complex three-dimensional structures of these current collectors can potentially complicate recycling efforts. Research indicates that designing 3D current collectors with disassembly and material recovery in mind could significantly improve their lifecycle sustainability. Some promising approaches include developing collectors with easily separable components or incorporating materials that facilitate selective recovery processes.

Water usage and contamination risks are particularly relevant for aqueous zinc-ion battery systems. The 3D current collectors must be designed to minimize leaching of potentially harmful substances into the electrolyte during long-term cycling. Studies have demonstrated that surface functionalization of 3D current collectors can reduce undesirable side reactions while enhancing electrochemical performance, thereby extending battery lifetime and reducing waste generation.

Carbon footprint analysis of various 3D current collector manufacturing routes reveals significant variability depending on material selection and processing methods. Life cycle assessments indicate that while the initial production energy requirements may be higher for some advanced 3D structures, their superior performance and longevity can result in net environmental benefits over the complete battery lifecycle. This highlights the importance of holistic sustainability evaluation rather than focusing solely on manufacturing impacts.

Manufacturing Scalability Assessment

The manufacturing scalability of 3D current collectors for aqueous zinc ion batteries (AZIBs) represents a critical factor in their commercial viability. Current laboratory-scale fabrication methods for 3D current collectors include electrodeposition, chemical vapor deposition, and template-assisted growth techniques. While these methods yield excellent performance in research settings, they face significant challenges when transitioning to industrial-scale production.

Mass production of 3D current collectors requires consideration of several key factors. Equipment requirements for large-scale manufacturing include specialized electrodeposition tanks, high-temperature furnaces for thermal treatments, and precision control systems. These capital investments can be substantial, with estimated costs ranging from $2-5 million for a medium-scale production line capable of producing 10,000 m² of 3D current collectors annually.

Material throughput represents another critical consideration. Current laboratory processes typically produce 3D current collectors at rates of 1-10 cm²/hour, which is inadequate for commercial applications. Industrial viability would require scaling to at least 1-5 m²/hour, necessitating significant process optimization and equipment redesign.

Quality control challenges increase exponentially with production scale. Maintaining uniform 3D structures across large surface areas requires advanced monitoring systems and process controls. Defect rates must be kept below 0.1% for battery applications, which becomes increasingly difficult as production volumes increase.

Cost analysis reveals that material costs currently dominate the production expense, with precious metals like gold and platinum often used in laboratory settings. Transitioning to more abundant materials such as nickel, copper, and carbon-based structures is essential for economic viability. Current production costs range from $200-500/m² but must decrease to $20-50/m² to compete with conventional battery technologies.

Environmental considerations and regulatory compliance add another layer of complexity. Chemical waste from electrodeposition processes requires proper treatment, and energy consumption for high-temperature processes must be optimized. Regulatory frameworks in different regions may impose varying requirements for manufacturing facilities.

Recent advancements in roll-to-roll processing and additive manufacturing show promise for overcoming these scalability challenges. Several companies, including Tesla and CATL, have filed patents related to scaled production of 3D electrode structures, indicating growing industrial interest in this technology despite the remaining hurdles to full-scale commercialization.

Mass production of 3D current collectors requires consideration of several key factors. Equipment requirements for large-scale manufacturing include specialized electrodeposition tanks, high-temperature furnaces for thermal treatments, and precision control systems. These capital investments can be substantial, with estimated costs ranging from $2-5 million for a medium-scale production line capable of producing 10,000 m² of 3D current collectors annually.

Material throughput represents another critical consideration. Current laboratory processes typically produce 3D current collectors at rates of 1-10 cm²/hour, which is inadequate for commercial applications. Industrial viability would require scaling to at least 1-5 m²/hour, necessitating significant process optimization and equipment redesign.

Quality control challenges increase exponentially with production scale. Maintaining uniform 3D structures across large surface areas requires advanced monitoring systems and process controls. Defect rates must be kept below 0.1% for battery applications, which becomes increasingly difficult as production volumes increase.

Cost analysis reveals that material costs currently dominate the production expense, with precious metals like gold and platinum often used in laboratory settings. Transitioning to more abundant materials such as nickel, copper, and carbon-based structures is essential for economic viability. Current production costs range from $200-500/m² but must decrease to $20-50/m² to compete with conventional battery technologies.

Environmental considerations and regulatory compliance add another layer of complexity. Chemical waste from electrodeposition processes requires proper treatment, and energy consumption for high-temperature processes must be optimized. Regulatory frameworks in different regions may impose varying requirements for manufacturing facilities.

Recent advancements in roll-to-roll processing and additive manufacturing show promise for overcoming these scalability challenges. Several companies, including Tesla and CATL, have filed patents related to scaled production of 3D electrode structures, indicating growing industrial interest in this technology despite the remaining hurdles to full-scale commercialization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!