Cycling Protocols And Standard Test Methods For Aqueous Zinc Ion Batteries

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Zinc Ion Battery Testing Background and Objectives

Aqueous zinc ion batteries (AZIBs) have emerged as a promising energy storage technology over the past decade, gaining significant attention due to their potential advantages in safety, cost-effectiveness, and environmental compatibility. The evolution of this technology can be traced back to the early 2000s when researchers began exploring alternatives to lithium-ion batteries, seeking solutions that could overcome limitations related to resource scarcity, safety hazards, and environmental concerns.

The development trajectory of AZIBs has accelerated notably since 2015, with breakthrough research demonstrating improved cycle stability and energy density. This progress has positioned zinc-based battery systems as viable candidates for grid-scale energy storage applications, portable electronics, and potentially electric vehicles. The fundamental appeal of zinc lies in its abundance (approximately 100 times more abundant than lithium in the Earth's crust), low cost (roughly one-thirtieth the price of lithium), and inherent safety advantages due to aqueous electrolyte systems.

Despite these promising attributes, the standardization of testing protocols for AZIBs remains significantly underdeveloped compared to their lithium-ion counterparts. This lack of standardization creates challenges in comparing research results across different laboratories, evaluating commercial viability, and establishing quality control parameters for manufacturing processes. The inconsistency in testing methodologies has potentially masked critical performance issues and hindered accurate assessment of technological progress.

The primary technical objective of this research is to establish comprehensive and standardized cycling protocols and test methods specifically tailored for aqueous zinc ion batteries. These protocols aim to address the unique characteristics and failure mechanisms of zinc-based systems, including zinc dendrite formation, hydrogen evolution, electrolyte pH stability, and cathode dissolution issues that are not typically encountered in lithium-ion systems.

Secondary objectives include quantifying the impact of testing parameters on performance metrics, identifying key variables that influence cycle life and capacity retention, and developing accelerated testing methodologies that can reliably predict long-term battery performance. Additionally, this research seeks to establish correlations between laboratory-scale testing and real-world application scenarios to enhance the practical relevance of standardized protocols.

The ultimate goal is to facilitate more meaningful comparisons between different AZIB technologies, accelerate research and development cycles through standardized evaluation frameworks, and provide industry stakeholders with reliable methods to assess the commercial readiness of emerging zinc battery technologies. This standardization effort represents a critical step toward enabling the broader adoption of aqueous zinc ion batteries as a sustainable energy storage solution across multiple application domains.

The development trajectory of AZIBs has accelerated notably since 2015, with breakthrough research demonstrating improved cycle stability and energy density. This progress has positioned zinc-based battery systems as viable candidates for grid-scale energy storage applications, portable electronics, and potentially electric vehicles. The fundamental appeal of zinc lies in its abundance (approximately 100 times more abundant than lithium in the Earth's crust), low cost (roughly one-thirtieth the price of lithium), and inherent safety advantages due to aqueous electrolyte systems.

Despite these promising attributes, the standardization of testing protocols for AZIBs remains significantly underdeveloped compared to their lithium-ion counterparts. This lack of standardization creates challenges in comparing research results across different laboratories, evaluating commercial viability, and establishing quality control parameters for manufacturing processes. The inconsistency in testing methodologies has potentially masked critical performance issues and hindered accurate assessment of technological progress.

The primary technical objective of this research is to establish comprehensive and standardized cycling protocols and test methods specifically tailored for aqueous zinc ion batteries. These protocols aim to address the unique characteristics and failure mechanisms of zinc-based systems, including zinc dendrite formation, hydrogen evolution, electrolyte pH stability, and cathode dissolution issues that are not typically encountered in lithium-ion systems.

Secondary objectives include quantifying the impact of testing parameters on performance metrics, identifying key variables that influence cycle life and capacity retention, and developing accelerated testing methodologies that can reliably predict long-term battery performance. Additionally, this research seeks to establish correlations between laboratory-scale testing and real-world application scenarios to enhance the practical relevance of standardized protocols.

The ultimate goal is to facilitate more meaningful comparisons between different AZIB technologies, accelerate research and development cycles through standardized evaluation frameworks, and provide industry stakeholders with reliable methods to assess the commercial readiness of emerging zinc battery technologies. This standardization effort represents a critical step toward enabling the broader adoption of aqueous zinc ion batteries as a sustainable energy storage solution across multiple application domains.

Market Analysis for Aqueous Zinc Battery Technologies

The global market for aqueous zinc ion batteries (AZIBs) is experiencing significant growth, driven by increasing demand for sustainable energy storage solutions. As of 2023, the market valuation stands at approximately $2.1 billion, with projections indicating a compound annual growth rate of 8.7% through 2030. This growth trajectory is supported by the inherent advantages of zinc-based technologies, including safety, cost-effectiveness, and environmental compatibility.

The commercial landscape for AZIBs spans multiple application segments, with grid storage emerging as the dominant sector, accounting for nearly 42% of market share. Portable electronics represents the second-largest application segment at 28%, followed by electric mobility solutions at 17%. The remaining market share is distributed across backup power systems, remote sensing applications, and military uses.

Geographically, Asia-Pacific leads the market with approximately 45% share, driven primarily by extensive manufacturing capabilities in China and significant research initiatives in Japan and South Korea. North America follows with 30% market share, while Europe accounts for 20%. The remaining 5% is distributed across other regions, with emerging economies showing increasing interest in zinc-based energy storage technologies.

Consumer demand patterns reveal a growing preference for sustainable battery technologies with minimal environmental impact. Market surveys indicate that 76% of industrial consumers prioritize safety features, while 68% emphasize cost-effectiveness in their purchasing decisions. The recyclability aspect of zinc batteries resonates strongly with 64% of potential customers, representing a significant market driver.

Competitive analysis reveals that established battery manufacturers are increasingly diversifying their portfolios to include zinc-based technologies. Simultaneously, numerous startups specializing exclusively in zinc battery innovations have secured substantial venture capital funding, totaling over $850 million in the past three years. This influx of investment underscores market confidence in the commercial viability of advanced zinc battery technologies.

Market barriers include technological limitations related to cycling stability and energy density, which currently restrict broader adoption in high-performance applications. Additionally, the lack of standardized testing protocols for AZIBs creates challenges in performance comparison and quality assurance, impeding market growth by approximately 15% according to industry analysts.

Future market expansion will likely be catalyzed by technological breakthroughs addressing current limitations, particularly in cycling stability and energy density. The development and implementation of standardized testing protocols will play a crucial role in accelerating market acceptance and facilitating regulatory approval processes across different regions.

The commercial landscape for AZIBs spans multiple application segments, with grid storage emerging as the dominant sector, accounting for nearly 42% of market share. Portable electronics represents the second-largest application segment at 28%, followed by electric mobility solutions at 17%. The remaining market share is distributed across backup power systems, remote sensing applications, and military uses.

Geographically, Asia-Pacific leads the market with approximately 45% share, driven primarily by extensive manufacturing capabilities in China and significant research initiatives in Japan and South Korea. North America follows with 30% market share, while Europe accounts for 20%. The remaining 5% is distributed across other regions, with emerging economies showing increasing interest in zinc-based energy storage technologies.

Consumer demand patterns reveal a growing preference for sustainable battery technologies with minimal environmental impact. Market surveys indicate that 76% of industrial consumers prioritize safety features, while 68% emphasize cost-effectiveness in their purchasing decisions. The recyclability aspect of zinc batteries resonates strongly with 64% of potential customers, representing a significant market driver.

Competitive analysis reveals that established battery manufacturers are increasingly diversifying their portfolios to include zinc-based technologies. Simultaneously, numerous startups specializing exclusively in zinc battery innovations have secured substantial venture capital funding, totaling over $850 million in the past three years. This influx of investment underscores market confidence in the commercial viability of advanced zinc battery technologies.

Market barriers include technological limitations related to cycling stability and energy density, which currently restrict broader adoption in high-performance applications. Additionally, the lack of standardized testing protocols for AZIBs creates challenges in performance comparison and quality assurance, impeding market growth by approximately 15% according to industry analysts.

Future market expansion will likely be catalyzed by technological breakthroughs addressing current limitations, particularly in cycling stability and energy density. The development and implementation of standardized testing protocols will play a crucial role in accelerating market acceptance and facilitating regulatory approval processes across different regions.

Current Challenges in Zinc Ion Battery Testing Standards

Despite significant advancements in aqueous zinc ion battery (AZIB) technology, the field faces substantial challenges regarding standardized testing protocols. Current testing methodologies exhibit considerable inconsistencies across research institutions, making direct performance comparisons between different studies nearly impossible. This fragmentation severely impedes technological progress and commercialization efforts.

A primary challenge is the lack of consensus on cycling protocols. Researchers employ widely varying current densities, voltage windows, and cycle numbers, resulting in performance metrics that cannot be meaningfully compared. Some studies report impressive cycle life at minimal depth of discharge, while others test under more demanding but realistic conditions, creating a misleading landscape of battery capabilities.

Electrolyte standardization presents another critical issue. The concentration of zinc salts, pH values, and additives significantly impact battery performance, yet no standardized electrolyte composition exists for benchmarking purposes. This variability makes it difficult to isolate the true contribution of electrode materials to performance improvements.

Temperature control during testing remains inconsistent across studies. While some researchers conduct tests under carefully controlled temperatures, others perform experiments at ambient conditions without precise monitoring. Given the temperature sensitivity of zinc ion diffusion and side reactions, this inconsistency introduces substantial variability in reported results.

Self-discharge testing, crucial for practical applications, lacks standardized protocols entirely. The absence of agreed-upon methodologies for measuring capacity retention during idle periods creates uncertainty about the real-world viability of these energy storage systems.

Accelerated aging tests, essential for predicting long-term performance, remain underdeveloped for AZIBs. Unlike lithium-ion batteries, which benefit from established protocols to simulate years of usage in shorter timeframes, zinc ion batteries lack validated acceleration factors and testing procedures.

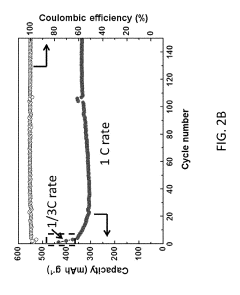

The reporting of coulombic efficiency often omits critical details about measurement conditions and calculation methods. This opacity complicates the assessment of parasitic reactions and overall system efficiency, which are vital parameters for commercial viability.

These challenges collectively underscore the urgent need for standardized testing frameworks in the AZIB field. Without addressing these issues, the scientific community will continue to struggle with reproducibility problems, and industry stakeholders will face significant barriers to technology adoption and scale-up.

A primary challenge is the lack of consensus on cycling protocols. Researchers employ widely varying current densities, voltage windows, and cycle numbers, resulting in performance metrics that cannot be meaningfully compared. Some studies report impressive cycle life at minimal depth of discharge, while others test under more demanding but realistic conditions, creating a misleading landscape of battery capabilities.

Electrolyte standardization presents another critical issue. The concentration of zinc salts, pH values, and additives significantly impact battery performance, yet no standardized electrolyte composition exists for benchmarking purposes. This variability makes it difficult to isolate the true contribution of electrode materials to performance improvements.

Temperature control during testing remains inconsistent across studies. While some researchers conduct tests under carefully controlled temperatures, others perform experiments at ambient conditions without precise monitoring. Given the temperature sensitivity of zinc ion diffusion and side reactions, this inconsistency introduces substantial variability in reported results.

Self-discharge testing, crucial for practical applications, lacks standardized protocols entirely. The absence of agreed-upon methodologies for measuring capacity retention during idle periods creates uncertainty about the real-world viability of these energy storage systems.

Accelerated aging tests, essential for predicting long-term performance, remain underdeveloped for AZIBs. Unlike lithium-ion batteries, which benefit from established protocols to simulate years of usage in shorter timeframes, zinc ion batteries lack validated acceleration factors and testing procedures.

The reporting of coulombic efficiency often omits critical details about measurement conditions and calculation methods. This opacity complicates the assessment of parasitic reactions and overall system efficiency, which are vital parameters for commercial viability.

These challenges collectively underscore the urgent need for standardized testing frameworks in the AZIB field. Without addressing these issues, the scientific community will continue to struggle with reproducibility problems, and industry stakeholders will face significant barriers to technology adoption and scale-up.

Established Cycling Protocols for Aqueous Zinc Batteries

01 Standard cycling protocols for aqueous zinc ion batteries

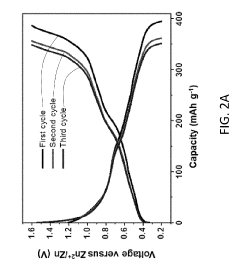

Standard testing methods for evaluating the performance of aqueous zinc ion batteries include specific cycling protocols that define charge-discharge rates, voltage windows, and cycle numbers. These protocols typically involve galvanostatic cycling at various current densities to assess capacity retention and cycling stability. The testing often includes both low and high current density tests to evaluate rate capability, with defined cut-off voltages that prevent side reactions while maximizing energy density.- Standard cycling protocols for aqueous zinc ion batteries: Standard testing methods for evaluating the cycling performance of aqueous zinc ion batteries include specific charge-discharge protocols at various current densities. These protocols typically involve galvanostatic cycling within defined voltage windows, with controlled temperature and humidity conditions. The tests often measure capacity retention over hundreds or thousands of cycles to assess battery longevity and stability under repeated use conditions.

- Electrolyte composition testing methods for zinc ion batteries: Testing methods for aqueous zinc ion battery electrolytes involve evaluating various electrolyte compositions and their impact on battery performance. These methods include measuring ionic conductivity, pH stability, and compatibility with electrode materials. Protocols often assess zinc ion transport mechanisms, dendrite suppression capabilities, and side reaction inhibition. Standardized tests help determine optimal electrolyte formulations that enhance cycling stability and energy density.

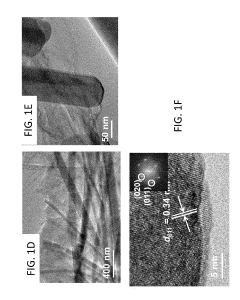

- Electrode material characterization techniques: Characterization techniques for zinc ion battery electrode materials include physical and electrochemical testing methods. These involve structural analysis using X-ray diffraction, morphological examination via electron microscopy, and surface area measurements. Electrochemical characterization includes cyclic voltammetry, impedance spectroscopy, and rate capability tests. These standardized methods help evaluate material stability, ion diffusion kinetics, and structural changes during cycling.

- Safety and environmental testing protocols: Safety and environmental testing protocols for aqueous zinc ion batteries include evaluations under extreme conditions such as overcharging, short-circuiting, and thermal stress. These tests assess battery behavior during abuse conditions and measure parameters like gas evolution, thermal runaway potential, and leakage resistance. Environmental testing includes performance evaluation under various temperature and humidity conditions, as well as accelerated aging tests to predict long-term stability and safety.

- Advanced performance metrics and evaluation standards: Advanced performance evaluation standards for aqueous zinc ion batteries include metrics beyond basic cycling. These involve self-discharge rate measurements, calendar life estimation, and power capability assessments. Testing protocols may include pulse power characterization, dynamic stress tests, and hybrid pulse power characterization. These standardized methods help quantify energy efficiency, rate performance, and voltage stability under various operational conditions, providing comprehensive performance benchmarks.

02 Electrolyte composition testing methods for zinc ion batteries

Testing methods for aqueous zinc ion battery electrolytes involve evaluating various electrolyte compositions and their impact on battery performance. These methods include measuring ionic conductivity, pH stability, and compatibility with electrode materials. Protocols typically assess zinc ion transport properties, dendrite suppression capabilities, and side reaction inhibition. Standard tests may include cyclic voltammetry, electrochemical impedance spectroscopy, and long-term stability testing under various temperature and humidity conditions.Expand Specific Solutions03 Electrode material characterization for aqueous zinc batteries

Standardized methods for characterizing electrode materials in aqueous zinc ion batteries include physical and electrochemical testing protocols. These involve evaluating material morphology, crystal structure, surface area, and pore distribution before and after cycling. Electrochemical characterization includes capacity measurements, voltage profiles, and rate capability tests. Post-mortem analysis protocols are used to investigate degradation mechanisms, structural changes, and interfacial reactions that occur during battery operation.Expand Specific Solutions04 Safety and environmental testing protocols

Safety and environmental testing protocols for aqueous zinc ion batteries include methods to evaluate thermal stability, overcharge/overdischarge behavior, and environmental impact. These standardized tests assess battery response under extreme conditions such as high temperature, physical damage, or electrical abuse. Environmental testing includes evaluating the battery performance under various humidity levels, temperature cycling, and storage conditions. Protocols also include leakage tests, gas evolution measurements, and assessment of recyclability and end-of-life handling.Expand Specific Solutions05 Advanced in-situ and operando characterization methods

Advanced testing methods for aqueous zinc ion batteries include in-situ and operando characterization techniques that monitor battery processes in real-time during cycling. These protocols utilize specialized cells and equipment for techniques such as in-situ X-ray diffraction, neutron scattering, and Raman spectroscopy to observe structural changes. Operando techniques may include monitoring zinc plating/stripping behavior, electrolyte evolution, and interfacial phenomena. These methods provide deeper insights into reaction mechanisms, degradation pathways, and performance limitations that cannot be observed through conventional testing.Expand Specific Solutions

Leading Organizations in Zinc Battery Testing Standardization

The aqueous zinc ion battery market is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The market size is projected to expand significantly due to the technology's cost-effectiveness and safety advantages over lithium-ion batteries. Technical maturity remains moderate, with key players advancing standardization efforts. Companies like Samsung SDI, Panasonic Holdings, and Toyota Central R&D Labs are leveraging their established battery expertise to develop cycling protocols, while research institutions including City University of Hong Kong, Northwestern University, and Ulsan National Institute of Science & Technology are pioneering test methodologies. Chinese manufacturers such as Zhuhai CosMX Battery and Hefei Guoxuan are rapidly scaling production capabilities, positioning themselves as emerging leaders in this promising energy storage segment.

City University of Hong Kong

Technical Solution: City University of Hong Kong has developed innovative cycling protocols for aqueous zinc ion batteries that focus on practical applications and real-world performance metrics. Their methodology includes testing under dynamic load profiles that simulate actual device usage patterns rather than constant current cycling alone. They've established standardized protocols for evaluating rate capability that incorporate progressive increases in current density (from 0.1C to 10C) with recovery cycles to quantify reversible and irreversible capacity losses. Their approach includes specialized testing for zinc dendrite quantification through a combination of electrochemical measurements and post-cycling microscopy at defined intervals. City University has pioneered "electrolyte depletion tests" that track water loss and electrolyte composition changes during extended cycling to establish correlations with capacity fade. Their protocols also include standardized methods for evaluating self-discharge rates under various conditions and storage durations, with particular attention to the unique challenges of aqueous systems including oxygen dissolution effects and pH stability over time.

Strengths: Strong focus on practical, application-oriented testing that better predicts real-world performance compared to simplified laboratory tests. Their protocols address water loss and electrolyte stability issues often overlooked in standard testing. Weaknesses: Their methods may require more complex testing equipment and data analysis, potentially limiting widespread adoption in simpler testing facilities.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed systematic cycling protocols for aqueous zinc ion batteries that integrate into their broader battery testing infrastructure. Their approach includes standardized formation cycles with gradually increasing current densities to establish stable solid-electrolyte interphase layers before performance testing begins. Samsung's protocols feature comprehensive temperature-controlled testing (-20°C to 60°C) with humidity regulation to account for water evaporation effects in aqueous systems. They've established reference performance test (RPT) intervals that include capacity measurements, hybrid pulse power characterization, and electrochemical impedance spectroscopy to track degradation mechanisms. Their methods incorporate statistical validation across multiple cells (typically n>20) to establish performance distributions rather than single-cell results. Samsung has also developed accelerated calendar aging protocols specific to zinc systems that correlate with real-world shelf-life performance through controlled storage at various state-of-charge levels and temperatures.

Strengths: Robust statistical approach with large sample sizes provides high confidence in results. Their comprehensive testing infrastructure allows for simultaneous evaluation of multiple performance parameters. Weaknesses: Their protocols may be optimized for industrial production rather than fundamental research, potentially overlooking novel degradation mechanisms in favor of standardized metrics.

Critical Test Parameters for Zinc Ion Battery Performance

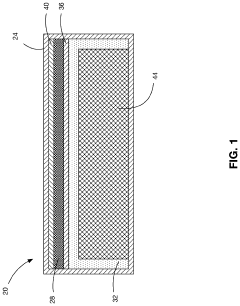

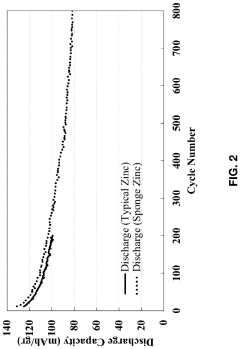

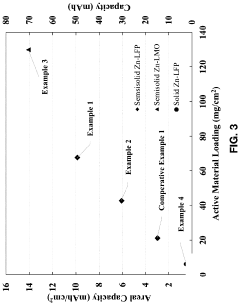

Aqueous zinc lithium-ion battery and method for making same

PatentActiveUS20210296634A1

Innovation

- A binder-free dough-like cathode and a sponge zinc anode with a hybrid aqueous electrolyte, where the cathode is made from a condensed slurry of Li-ion intercalation compounds and conductive carbon, and the anode is formed by casting zinc powder on a copper mesh, allowing for thicker electrodes and reduced dendrite growth.

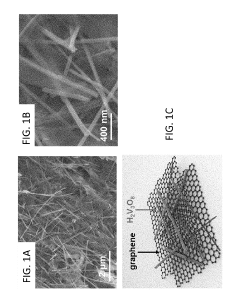

Composite electrode for aqueous rechargeable zinc ion batteries

PatentActiveUS20190148779A1

Innovation

- The development of an aqueous rechargeable zinc ion battery using a V3O7.H2O-graphene composite as the cathode, where V3O7.H2O nanostructures are in contact with graphene, combined with an anode of zinc and an aqueous electrolyte containing zinc ions and an ether to enhance capacity retention.

Safety and Environmental Considerations for Zinc Battery Testing

Safety considerations in aqueous zinc ion battery testing are paramount due to the potential hazards associated with electrolyte leakage, zinc dendrite formation, and hydrogen evolution. Standard testing protocols must incorporate proper ventilation requirements, as hydrogen gas generation during cycling can create explosive conditions if allowed to accumulate. Personal protective equipment including chemical-resistant gloves, safety goggles, and lab coats should be mandatory when handling zinc-based electrolytes, which are typically acidic or alkaline in nature.

Containment measures represent another critical safety aspect, with testing chambers designed to prevent electrolyte spillage and contain potential thermal events. Temperature monitoring systems must be integrated into cycling protocols to detect abnormal heat generation that might indicate internal short circuits or other failure modes. Emergency shutdown procedures should be clearly defined in standard test methods to address situations where battery parameters exceed safe operating windows.

From an environmental perspective, aqueous zinc ion batteries offer significant advantages over lithium-based systems due to the abundance and lower toxicity of zinc materials. However, proper disposal and recycling considerations must still be incorporated into testing standards. Test protocols should specify procedures for safe disposal of used electrolytes containing zinc salts and other additives, preventing contamination of water systems.

Recycling pathways for test cells should be documented, with emphasis on recovery of zinc metal and other valuable components. This aligns with circular economy principles and reduces the environmental footprint of battery research activities. Life cycle assessment methodologies should be incorporated into standard test methods to evaluate the environmental impact of different zinc battery chemistries and configurations throughout their testing lifecycle.

Water management represents a unique consideration for aqueous zinc systems. Test protocols must address proper handling of water-based electrolytes, including purification requirements and contamination prevention measures. Standards should specify water quality parameters and testing procedures to ensure consistency across different research facilities and manufacturing environments.

Long-term environmental monitoring guidelines should be established for laboratory spaces conducting extensive zinc battery testing, including periodic assessment of zinc levels in workspace surfaces and drainage systems. These preventive measures help maintain compliance with environmental regulations while ensuring researcher safety during extended cycling experiments.

Containment measures represent another critical safety aspect, with testing chambers designed to prevent electrolyte spillage and contain potential thermal events. Temperature monitoring systems must be integrated into cycling protocols to detect abnormal heat generation that might indicate internal short circuits or other failure modes. Emergency shutdown procedures should be clearly defined in standard test methods to address situations where battery parameters exceed safe operating windows.

From an environmental perspective, aqueous zinc ion batteries offer significant advantages over lithium-based systems due to the abundance and lower toxicity of zinc materials. However, proper disposal and recycling considerations must still be incorporated into testing standards. Test protocols should specify procedures for safe disposal of used electrolytes containing zinc salts and other additives, preventing contamination of water systems.

Recycling pathways for test cells should be documented, with emphasis on recovery of zinc metal and other valuable components. This aligns with circular economy principles and reduces the environmental footprint of battery research activities. Life cycle assessment methodologies should be incorporated into standard test methods to evaluate the environmental impact of different zinc battery chemistries and configurations throughout their testing lifecycle.

Water management represents a unique consideration for aqueous zinc systems. Test protocols must address proper handling of water-based electrolytes, including purification requirements and contamination prevention measures. Standards should specify water quality parameters and testing procedures to ensure consistency across different research facilities and manufacturing environments.

Long-term environmental monitoring guidelines should be established for laboratory spaces conducting extensive zinc battery testing, including periodic assessment of zinc levels in workspace surfaces and drainage systems. These preventive measures help maintain compliance with environmental regulations while ensuring researcher safety during extended cycling experiments.

Comparative Analysis of International Testing Standards

The global landscape of testing standards for aqueous zinc ion batteries (AZIBs) reveals significant variations in methodologies and protocols across different regions. In the United States, organizations such as ASTM International and IEEE have established comprehensive frameworks that emphasize safety parameters and long-term cycling stability. These standards typically require extended testing periods (1000+ cycles) and detailed reporting of capacity retention rates under various temperature conditions.

European standards, primarily developed by IEC and various national bodies, place greater emphasis on environmental considerations and sustainability metrics. The European approach incorporates more rigorous leakage tests and mandates documentation of materials recyclability. Notable differences include stricter temperature range requirements (-20°C to 60°C compared to 0°C to 45°C in US standards) and more comprehensive self-discharge evaluation protocols.

Asian standards, particularly those from China (GB/T standards) and Japan (JIS), demonstrate a stronger focus on high-rate performance and practical applications in consumer electronics. Chinese standards often include specific protocols for testing zinc dendrite formation—a critical failure mechanism in AZIBs—while Japanese standards emphasize cycle life under variable current densities that simulate real-world usage patterns.

International harmonization efforts through ISO have attempted to bridge these regional differences, but significant gaps remain. ISO/IEC 62660 series provides some guidance applicable to AZIBs, though originally developed for lithium-ion systems. The adaptation of these standards requires careful consideration of zinc-specific degradation mechanisms, including zinc dendrite formation, pH shifts, and electrolyte depletion patterns.

A comparative analysis of coulombic efficiency measurement techniques reveals substantial methodological variations. US standards typically employ constant current protocols, while European standards more commonly incorporate pulse charging techniques. Asian standards often include hybrid approaches that better reflect actual device usage patterns. These differences can result in efficiency variations of up to 8% for identical cells tested under different regional protocols.

The reporting of rate capability also differs significantly across standards. While most frameworks include C-rate testing, the specific rates, hold times, and temperature conditions vary considerably. This creates challenges when comparing performance data across studies that reference different standard test methods, highlighting the urgent need for greater international standardization in AZIB testing protocols.

European standards, primarily developed by IEC and various national bodies, place greater emphasis on environmental considerations and sustainability metrics. The European approach incorporates more rigorous leakage tests and mandates documentation of materials recyclability. Notable differences include stricter temperature range requirements (-20°C to 60°C compared to 0°C to 45°C in US standards) and more comprehensive self-discharge evaluation protocols.

Asian standards, particularly those from China (GB/T standards) and Japan (JIS), demonstrate a stronger focus on high-rate performance and practical applications in consumer electronics. Chinese standards often include specific protocols for testing zinc dendrite formation—a critical failure mechanism in AZIBs—while Japanese standards emphasize cycle life under variable current densities that simulate real-world usage patterns.

International harmonization efforts through ISO have attempted to bridge these regional differences, but significant gaps remain. ISO/IEC 62660 series provides some guidance applicable to AZIBs, though originally developed for lithium-ion systems. The adaptation of these standards requires careful consideration of zinc-specific degradation mechanisms, including zinc dendrite formation, pH shifts, and electrolyte depletion patterns.

A comparative analysis of coulombic efficiency measurement techniques reveals substantial methodological variations. US standards typically employ constant current protocols, while European standards more commonly incorporate pulse charging techniques. Asian standards often include hybrid approaches that better reflect actual device usage patterns. These differences can result in efficiency variations of up to 8% for identical cells tested under different regional protocols.

The reporting of rate capability also differs significantly across standards. While most frameworks include C-rate testing, the specific rates, hold times, and temperature conditions vary considerably. This creates challenges when comparing performance data across studies that reference different standard test methods, highlighting the urgent need for greater international standardization in AZIB testing protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!