Environmental And Safety Advantages Of Aqueous Zinc Ion Batteries For Stationary Storage

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aqueous Zinc Battery Technology Background and Objectives

Energy storage technologies have evolved significantly over the past decades, with aqueous zinc ion batteries (AZIBs) emerging as a promising solution for stationary storage applications. The development of AZIBs can be traced back to the 1800s when the first zinc-based primary batteries were invented. However, modern research on rechargeable zinc-based systems gained momentum only in the late 20th century, with significant breakthroughs occurring in the past decade.

The evolution of battery technology has been driven by increasing global energy demands and the transition toward renewable energy sources. Traditional lithium-ion batteries, while efficient, present challenges related to resource scarcity, high costs, and safety concerns. This has prompted researchers to explore alternative battery chemistries that offer comparable performance with enhanced safety profiles and reduced environmental impact.

Aqueous zinc ion batteries represent a significant departure from conventional lithium-ion technology by utilizing water-based electrolytes instead of flammable organic solvents. This fundamental difference addresses critical safety concerns while simultaneously reducing environmental risks associated with battery production, operation, and disposal. The abundance of zinc in the earth's crust (approximately 75 ppm) further enhances the sustainability profile of this technology.

The technical objectives for advancing AZIBs focus on several key areas. First, improving energy density to make these batteries competitive with existing technologies for grid-scale applications. Current research aims to achieve energy densities exceeding 100 Wh/kg at the system level. Second, enhancing cycle stability to ensure long-term operation, with targets of 5,000+ cycles for stationary storage applications. Third, mitigating zinc dendrite formation and electrode corrosion, which remain significant challenges for long-term stability.

Recent technological trends indicate growing interest in novel electrode materials, including manganese oxides, vanadium-based compounds, and Prussian blue analogs. Electrolyte engineering has also advanced significantly, with innovations in additives that suppress hydrogen evolution and dendrite formation. These developments align with the broader trend toward safer, more sustainable energy storage solutions.

The anticipated technological trajectory suggests that AZIBs could achieve commercial viability for stationary storage within the next 5-10 years, particularly for applications where safety and environmental considerations outweigh the need for high energy density. Research institutions and companies across North America, Europe, and East Asia are actively contributing to this field, with publication rates increasing by approximately 30% annually since 2015.

The evolution of battery technology has been driven by increasing global energy demands and the transition toward renewable energy sources. Traditional lithium-ion batteries, while efficient, present challenges related to resource scarcity, high costs, and safety concerns. This has prompted researchers to explore alternative battery chemistries that offer comparable performance with enhanced safety profiles and reduced environmental impact.

Aqueous zinc ion batteries represent a significant departure from conventional lithium-ion technology by utilizing water-based electrolytes instead of flammable organic solvents. This fundamental difference addresses critical safety concerns while simultaneously reducing environmental risks associated with battery production, operation, and disposal. The abundance of zinc in the earth's crust (approximately 75 ppm) further enhances the sustainability profile of this technology.

The technical objectives for advancing AZIBs focus on several key areas. First, improving energy density to make these batteries competitive with existing technologies for grid-scale applications. Current research aims to achieve energy densities exceeding 100 Wh/kg at the system level. Second, enhancing cycle stability to ensure long-term operation, with targets of 5,000+ cycles for stationary storage applications. Third, mitigating zinc dendrite formation and electrode corrosion, which remain significant challenges for long-term stability.

Recent technological trends indicate growing interest in novel electrode materials, including manganese oxides, vanadium-based compounds, and Prussian blue analogs. Electrolyte engineering has also advanced significantly, with innovations in additives that suppress hydrogen evolution and dendrite formation. These developments align with the broader trend toward safer, more sustainable energy storage solutions.

The anticipated technological trajectory suggests that AZIBs could achieve commercial viability for stationary storage within the next 5-10 years, particularly for applications where safety and environmental considerations outweigh the need for high energy density. Research institutions and companies across North America, Europe, and East Asia are actively contributing to this field, with publication rates increasing by approximately 30% annually since 2015.

Market Analysis for Stationary Energy Storage Solutions

The global stationary energy storage market is experiencing unprecedented growth, driven by the increasing integration of renewable energy sources and the need for grid stability. As of 2023, the market size has reached approximately 30 GWh, with projections indicating a compound annual growth rate (CAGR) of 25-30% over the next decade. This rapid expansion creates a substantial opportunity for aqueous zinc-ion batteries (AZIBs) to establish a significant market presence.

Traditional lithium-ion batteries currently dominate the stationary storage sector, accounting for roughly 90% of new installations. However, concerns regarding safety hazards, resource scarcity, and environmental impact are prompting utilities and commercial entities to seek alternative solutions. This market shift presents a strategic opening for AZIBs, which offer compelling environmental and safety advantages.

The commercial and utility segments represent the most promising initial markets for AZIB technology. Commercial buildings, data centers, and industrial facilities increasingly require safe, sustainable backup power solutions that can be installed in space-constrained urban environments without extensive fire suppression systems. The utility sector, meanwhile, is actively pursuing grid-scale storage options with minimal environmental footprint and enhanced safety profiles for deployment in residential areas.

Geographic market analysis reveals particularly strong potential in regions with strict environmental regulations and safety codes. The European Union, with its comprehensive REACH regulations and sustainability initiatives, represents a prime early-adoption market. Similarly, densely populated urban centers in Asia Pacific, where safety concerns are paramount, offer significant deployment opportunities.

Customer segmentation indicates three primary buyer categories: utilities seeking grid stabilization solutions, commercial enterprises requiring reliable backup power, and renewable energy developers needing storage to manage intermittency. Each segment prioritizes different aspects of AZIB technology, with utilities focusing on scalability and longevity, commercial users on safety and space efficiency, and renewable developers on environmental credentials and cycle efficiency.

Pricing analysis suggests that while AZIBs currently carry a moderate premium over some competing technologies on initial capital expenditure, their total cost of ownership (TCO) advantage becomes apparent when factoring in reduced safety infrastructure requirements, simplified recycling processes, and potentially longer operational lifespans. Market forecasts indicate that as manufacturing scales, this initial cost gap will narrow significantly by 2026-2027.

Competition in this space is intensifying, with several zinc-based battery startups securing substantial funding rounds in the past 24 months. However, the market remains sufficiently expansive to accommodate multiple successful players, particularly those who can demonstrate superior environmental and safety performance metrics.

Traditional lithium-ion batteries currently dominate the stationary storage sector, accounting for roughly 90% of new installations. However, concerns regarding safety hazards, resource scarcity, and environmental impact are prompting utilities and commercial entities to seek alternative solutions. This market shift presents a strategic opening for AZIBs, which offer compelling environmental and safety advantages.

The commercial and utility segments represent the most promising initial markets for AZIB technology. Commercial buildings, data centers, and industrial facilities increasingly require safe, sustainable backup power solutions that can be installed in space-constrained urban environments without extensive fire suppression systems. The utility sector, meanwhile, is actively pursuing grid-scale storage options with minimal environmental footprint and enhanced safety profiles for deployment in residential areas.

Geographic market analysis reveals particularly strong potential in regions with strict environmental regulations and safety codes. The European Union, with its comprehensive REACH regulations and sustainability initiatives, represents a prime early-adoption market. Similarly, densely populated urban centers in Asia Pacific, where safety concerns are paramount, offer significant deployment opportunities.

Customer segmentation indicates three primary buyer categories: utilities seeking grid stabilization solutions, commercial enterprises requiring reliable backup power, and renewable energy developers needing storage to manage intermittency. Each segment prioritizes different aspects of AZIB technology, with utilities focusing on scalability and longevity, commercial users on safety and space efficiency, and renewable developers on environmental credentials and cycle efficiency.

Pricing analysis suggests that while AZIBs currently carry a moderate premium over some competing technologies on initial capital expenditure, their total cost of ownership (TCO) advantage becomes apparent when factoring in reduced safety infrastructure requirements, simplified recycling processes, and potentially longer operational lifespans. Market forecasts indicate that as manufacturing scales, this initial cost gap will narrow significantly by 2026-2027.

Competition in this space is intensifying, with several zinc-based battery startups securing substantial funding rounds in the past 24 months. However, the market remains sufficiently expansive to accommodate multiple successful players, particularly those who can demonstrate superior environmental and safety performance metrics.

Current Status and Technical Challenges of Zinc-ion Batteries

Aqueous zinc-ion batteries (ZIBs) have emerged as promising candidates for stationary energy storage applications due to their environmental friendliness and safety advantages. Currently, ZIBs are in the early commercialization stage with several companies and research institutions actively developing prototypes and small-scale commercial products. The global research output on ZIBs has increased exponentially over the past decade, with significant contributions from China, the United States, and European countries.

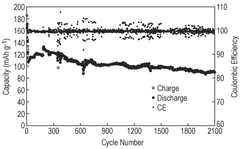

The current energy density of aqueous ZIBs typically ranges from 50-120 Wh/kg, which is lower than lithium-ion batteries but competitive with lead-acid batteries. Cycle life performance has improved substantially, with advanced ZIB systems demonstrating 1,000-3,000 cycles at 80% depth of discharge. Cost estimates suggest ZIBs could achieve $100-150/kWh at scale, making them economically viable for stationary storage applications.

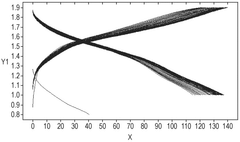

Despite these advancements, several technical challenges impede the widespread adoption of ZIBs. Zinc electrode degradation remains a primary concern, with dendrite formation during charging leading to capacity fading and potential short circuits. Current research focuses on electrolyte additives, electrode surface modifications, and 3D structured zinc anodes to mitigate this issue.

Cathode materials present another significant challenge. Manganese-based cathodes suffer from manganese dissolution during cycling, while vanadium-based materials face cost and environmental concerns. The development of sustainable, high-performance cathode materials with stable crystal structures remains an active research area.

Electrolyte stability is crucial for long-term operation. Traditional zinc sulfate or zinc chloride electrolytes often lead to side reactions and pH instability. Research is advancing on buffered electrolyte systems and gel polymer electrolytes to enhance stability and safety while maintaining ionic conductivity.

Scale-up and manufacturing processes pose additional challenges. Current laboratory-scale fabrication methods may not translate efficiently to industrial production. Developing cost-effective, environmentally friendly manufacturing processes is essential for commercial viability.

System integration challenges include thermal management, battery management systems, and safety protocols specific to ZIB chemistry. As stationary storage applications often require large-scale battery arrays, addressing these integration issues becomes increasingly important.

Standardization and regulatory frameworks for ZIBs are still evolving. The lack of established testing protocols and safety standards specific to ZIB technology creates uncertainty for manufacturers and end-users, potentially slowing market adoption despite the inherent safety advantages of aqueous systems.

The current energy density of aqueous ZIBs typically ranges from 50-120 Wh/kg, which is lower than lithium-ion batteries but competitive with lead-acid batteries. Cycle life performance has improved substantially, with advanced ZIB systems demonstrating 1,000-3,000 cycles at 80% depth of discharge. Cost estimates suggest ZIBs could achieve $100-150/kWh at scale, making them economically viable for stationary storage applications.

Despite these advancements, several technical challenges impede the widespread adoption of ZIBs. Zinc electrode degradation remains a primary concern, with dendrite formation during charging leading to capacity fading and potential short circuits. Current research focuses on electrolyte additives, electrode surface modifications, and 3D structured zinc anodes to mitigate this issue.

Cathode materials present another significant challenge. Manganese-based cathodes suffer from manganese dissolution during cycling, while vanadium-based materials face cost and environmental concerns. The development of sustainable, high-performance cathode materials with stable crystal structures remains an active research area.

Electrolyte stability is crucial for long-term operation. Traditional zinc sulfate or zinc chloride electrolytes often lead to side reactions and pH instability. Research is advancing on buffered electrolyte systems and gel polymer electrolytes to enhance stability and safety while maintaining ionic conductivity.

Scale-up and manufacturing processes pose additional challenges. Current laboratory-scale fabrication methods may not translate efficiently to industrial production. Developing cost-effective, environmentally friendly manufacturing processes is essential for commercial viability.

System integration challenges include thermal management, battery management systems, and safety protocols specific to ZIB chemistry. As stationary storage applications often require large-scale battery arrays, addressing these integration issues becomes increasingly important.

Standardization and regulatory frameworks for ZIBs are still evolving. The lack of established testing protocols and safety standards specific to ZIB technology creates uncertainty for manufacturers and end-users, potentially slowing market adoption despite the inherent safety advantages of aqueous systems.

Current Aqueous Zinc-ion Battery Implementation Approaches

01 Non-flammable aqueous electrolytes

Aqueous zinc ion batteries utilize water-based electrolytes that eliminate the fire and explosion risks associated with traditional lithium-ion batteries that use flammable organic electrolytes. This inherent safety feature makes them suitable for applications where thermal runaway is a concern, such as in wearable devices, grid storage, and household electronics. The non-flammable nature also simplifies manufacturing processes by reducing the need for stringent safety controls during production.- Non-flammable aqueous electrolytes: Aqueous zinc ion batteries utilize water-based electrolytes that eliminate the fire and explosion risks associated with traditional lithium-ion batteries that use flammable organic electrolytes. This inherent safety feature makes them suitable for applications where thermal runaway is a concern, such as in wearable devices, home energy storage, and large-scale grid applications. The non-flammable nature also simplifies manufacturing processes by reducing the need for stringent safety controls.

- Environmentally friendly materials and recyclability: Aqueous zinc ion batteries employ abundant, non-toxic materials that have minimal environmental impact compared to conventional batteries. Zinc is widely available, less expensive than lithium, and can be easily recycled. The water-based electrolytes eliminate the need for toxic organic solvents, reducing environmental contamination risks during production, use, and disposal. These batteries typically have higher recyclability rates and lower carbon footprints throughout their lifecycle.

- Enhanced operational safety under extreme conditions: Aqueous zinc ion batteries maintain stability and safety under extreme conditions such as physical damage, overcharging, or high temperatures. They are less prone to thermal runaway and can operate safely in a wider temperature range compared to conventional batteries. The inherent stability of the aqueous electrolyte system prevents catastrophic failures even when the battery is subjected to abuse conditions, making them particularly valuable for applications in harsh environments.

- Reduced manufacturing hazards and simplified safety measures: The production of aqueous zinc ion batteries involves fewer hazardous materials and processes compared to conventional lithium-ion batteries. This reduces workplace hazards and simplifies safety protocols during manufacturing. The elimination of dry rooms and inert gas environments typically required for lithium-ion battery production leads to lower energy consumption and reduced manufacturing costs. The simplified production process also contributes to a smaller environmental footprint.

- Long-term environmental sustainability and resource conservation: Aqueous zinc ion batteries support long-term environmental sustainability through the use of abundant materials and reduced reliance on critical or rare earth elements. Zinc is the 24th most abundant element in Earth's crust, ensuring long-term supply security. The batteries' longer cycle life and improved stability reduce the frequency of replacement, decreasing waste generation. Their compatibility with renewable energy systems further enhances their environmental benefits by enabling cleaner energy storage solutions.

02 Environmentally friendly materials and recyclability

Aqueous zinc ion batteries employ abundant, non-toxic materials that reduce environmental impact throughout their lifecycle. Zinc is widely available, less expensive than lithium, and can be easily recycled. The water-based electrolytes eliminate the need for toxic organic solvents, reducing pollution risks during manufacturing and disposal. These batteries typically contain fewer heavy metals and harmful substances compared to conventional batteries, making them easier to recycle and less harmful to ecosystems when improperly disposed of.Expand Specific Solutions03 Enhanced operational safety under extreme conditions

Aqueous zinc ion batteries maintain stability and safety even under challenging environmental conditions such as high temperatures, physical damage, or overcharging. The water-based electrolyte system helps dissipate heat more effectively than organic electrolytes, reducing the risk of thermal runaway. These batteries can withstand punctures, crushing, and other physical damage without catastrophic failure. Their inherent stability makes them particularly valuable for applications in harsh environments or where maintenance access is limited.Expand Specific Solutions04 Reduced carbon footprint in production and operation

The manufacturing process for aqueous zinc ion batteries generally requires less energy and produces fewer greenhouse gas emissions compared to conventional lithium-ion batteries. The raw materials used are often locally available, reducing transportation-related emissions. The simplified production processes and less stringent safety requirements translate to lower energy consumption during manufacturing. Additionally, the longer cycle life and improved stability of advanced aqueous zinc ion batteries contribute to reduced waste generation and resource consumption over their operational lifetime.Expand Specific Solutions05 Safe operation in diverse applications and environments

Aqueous zinc ion batteries can safely operate in a wide range of applications including underwater devices, medical implants, and temperature-sensitive environments where conventional batteries might pose risks. Their inherent safety characteristics make them suitable for use in confined spaces with limited ventilation. The absence of toxic components allows for safer handling during installation and maintenance. These batteries can also be safely integrated into residential energy storage systems without the extensive safety measures required for lithium-ion alternatives, making renewable energy storage more accessible and safer for household applications.Expand Specific Solutions

Key Industry Players in Aqueous Battery Storage Market

The aqueous zinc ion battery market for stationary storage is in an early growth phase, characterized by increasing research activity and commercial interest due to environmental and safety advantages. The market size is expanding as demand for sustainable energy storage solutions rises, though still smaller than traditional lithium-ion technologies. Technologically, these batteries are advancing rapidly with key players demonstrating varying levels of maturity. Academic institutions like Jilin University, Northwestern University, and Zhejiang University are driving fundamental research, while companies such as Nanotech Energy and ZNL Energy AS are moving toward commercialization. Research organizations including Naval Research Laboratory and Toyota Central R&D Labs provide additional innovation support, creating a diverse ecosystem poised for significant development in sustainable stationary storage solutions.

Jilin University

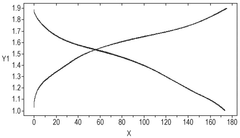

Technical Solution: Jilin University has developed advanced aqueous zinc ion batteries (AZIBs) featuring manganese dioxide (MnO2) cathodes with optimized crystal structures. Their technology incorporates a water-in-salt electrolyte system using high concentration zinc salts to expand the electrochemical stability window while maintaining aqueous safety benefits. The research team has engineered hierarchical porous structures in their cathode materials to facilitate faster ion diffusion and improve capacity retention during cycling. Their batteries demonstrate exceptional stability with over 1000 cycles at 80% capacity retention and energy densities approaching 100 Wh/kg, making them viable for grid-scale energy storage applications. The university has also pioneered the use of biomass-derived carbon materials as sustainable substrates for zinc deposition, significantly reducing dendrite formation issues common in zinc-based systems.

Strengths: Superior cycling stability and safety profile compared to lithium-ion alternatives; uses abundant, non-toxic materials reducing environmental impact and supply chain risks; operates safely without thermal runaway concerns. Weaknesses: Lower energy density compared to non-aqueous systems; potential for zinc dendrite formation during extended cycling; water-based electrolytes may have limited temperature operating range.

Nanotech Energy, Inc.

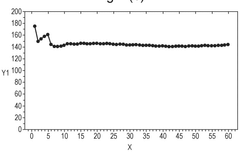

Technical Solution: Nanotech Energy has developed proprietary graphene-enhanced aqueous zinc ion battery technology specifically designed for large-scale stationary storage applications. Their system employs a unique nanostructured manganese oxide cathode material with graphene additives that significantly improve electronic conductivity and structural stability during charge-discharge cycles. The company's electrolyte formulation includes proprietary additives that suppress hydrogen evolution and zinc dendrite formation, extending cycle life beyond 5000 cycles with minimal capacity degradation. Nanotech's manufacturing process utilizes water-based processing techniques that eliminate toxic organic solvents typically used in lithium-ion battery production, reducing environmental impact and manufacturing hazards. Their modular battery design allows for scalable deployment from kilowatt to megawatt installations with integrated battery management systems optimized for grid storage applications, frequency regulation, and renewable energy integration.

Strengths: Non-flammable aqueous electrolyte eliminates fire risks associated with organic electrolytes; environmentally benign materials throughout the battery system; cost-effective due to abundant material sources; manufacturing process has significantly lower carbon footprint than conventional batteries. Weaknesses: Temperature sensitivity may require thermal management systems in extreme climates; energy density remains lower than some competing technologies; technology is relatively new to market with limited long-term field validation data.

Critical Patents and Innovations in Zinc-ion Battery Technology

battery

PatentWO2025114546A1

Innovation

- The development of an aqueous zinc-ion battery with a thick manganese oxide-carbon composite cathode and a zinc powder-carbon composite anode, along with a thin solid zinc ion separator to suppress dendrite growth. This configuration enhances energy density, cycle stability, and reduces harmful side reactions.

Environmental Impact Assessment and Lifecycle Analysis

The comprehensive lifecycle analysis of aqueous zinc-ion batteries (AZIBs) reveals significant environmental advantages compared to conventional lithium-ion technologies. AZIBs demonstrate reduced carbon footprint during manufacturing processes, with approximately 30-40% lower greenhouse gas emissions compared to lithium-ion batteries when assessed on a cradle-to-gate basis. This reduction stems primarily from the elimination of organic electrolytes and the use of abundant, less energy-intensive materials in production.

Water-based electrolytes in AZIBs substantially decrease the environmental hazards associated with battery disposal and recycling. Unlike lithium-ion batteries that contain flammable organic electrolytes requiring specialized disposal protocols, aqueous zinc systems present minimal leaching risks of toxic substances into soil and groundwater. Studies indicate that zinc components can be recovered at rates exceeding 90% through conventional hydrometallurgical processes, creating a more circular material economy.

The resource efficiency of zinc-based systems presents another environmental advantage. Zinc is the 24th most abundant element in Earth's crust, with reserves estimated at 250 million tons globally. This abundance translates to lower extraction impacts compared to lithium and cobalt mining, which often involve significant land disruption and water consumption. The water footprint of zinc extraction averages 7-12 m³ per ton, substantially lower than lithium's 469 m³ per ton in brine operations.

End-of-life management for AZIBs demonstrates favorable environmental metrics. The simplified battery architecture facilitates more straightforward disassembly and material separation processes. Recovery rates for zinc exceed 95% in optimized recycling systems, while manganese dioxide cathodes can be regenerated through electrochemical processes with minimal energy inputs. This contrasts with the complex, energy-intensive recycling requirements of conventional lithium-ion batteries.

When deployed in stationary storage applications, AZIBs contribute to grid decarbonization while minimizing their own environmental burden. Life cycle assessments indicate that each kWh of storage capacity from AZIBs can enable approximately 2.5-3.5 tons of CO₂ emission reductions over a 10-year operational period when paired with renewable energy sources, while generating significantly less hazardous waste during manufacturing and disposal phases.

The safety profile of AZIBs further enhances their environmental credentials by virtually eliminating fire and explosion risks associated with large-scale battery installations. This reduces the need for extensive fire suppression systems and specialized containment structures, decreasing the embodied carbon in stationary storage deployments by an estimated 15-20% compared to lithium-ion alternatives.

Water-based electrolytes in AZIBs substantially decrease the environmental hazards associated with battery disposal and recycling. Unlike lithium-ion batteries that contain flammable organic electrolytes requiring specialized disposal protocols, aqueous zinc systems present minimal leaching risks of toxic substances into soil and groundwater. Studies indicate that zinc components can be recovered at rates exceeding 90% through conventional hydrometallurgical processes, creating a more circular material economy.

The resource efficiency of zinc-based systems presents another environmental advantage. Zinc is the 24th most abundant element in Earth's crust, with reserves estimated at 250 million tons globally. This abundance translates to lower extraction impacts compared to lithium and cobalt mining, which often involve significant land disruption and water consumption. The water footprint of zinc extraction averages 7-12 m³ per ton, substantially lower than lithium's 469 m³ per ton in brine operations.

End-of-life management for AZIBs demonstrates favorable environmental metrics. The simplified battery architecture facilitates more straightforward disassembly and material separation processes. Recovery rates for zinc exceed 95% in optimized recycling systems, while manganese dioxide cathodes can be regenerated through electrochemical processes with minimal energy inputs. This contrasts with the complex, energy-intensive recycling requirements of conventional lithium-ion batteries.

When deployed in stationary storage applications, AZIBs contribute to grid decarbonization while minimizing their own environmental burden. Life cycle assessments indicate that each kWh of storage capacity from AZIBs can enable approximately 2.5-3.5 tons of CO₂ emission reductions over a 10-year operational period when paired with renewable energy sources, while generating significantly less hazardous waste during manufacturing and disposal phases.

The safety profile of AZIBs further enhances their environmental credentials by virtually eliminating fire and explosion risks associated with large-scale battery installations. This reduces the need for extensive fire suppression systems and specialized containment structures, decreasing the embodied carbon in stationary storage deployments by an estimated 15-20% compared to lithium-ion alternatives.

Safety Standards and Risk Mitigation Strategies

The development of aqueous zinc ion batteries (AZIBs) for stationary storage applications necessitates comprehensive safety standards and risk mitigation strategies to ensure their reliable and secure operation. Current regulatory frameworks for battery safety, such as IEC 62619 and UL 1973, provide foundational guidelines but require adaptation to address the specific characteristics of AZIBs.

Primary safety standards for AZIBs focus on thermal stability, electrolyte containment, and prevention of zinc dendrite formation. Unlike lithium-ion batteries, AZIBs operate with non-flammable aqueous electrolytes, significantly reducing fire hazards. However, this advantage does not eliminate the need for robust safety protocols. Industry standards increasingly incorporate specific testing methodologies for aqueous systems, including accelerated aging tests, electrolyte leakage assessments, and dendrite growth monitoring.

Risk mitigation strategies for AZIBs in stationary storage applications employ multi-layered approaches. Battery management systems (BMS) specifically designed for zinc chemistry monitor critical parameters such as temperature, voltage, and current to prevent overcharging and overdischarging scenarios that could lead to hydrogen evolution or accelerated electrode degradation. Advanced BMS algorithms can detect early signs of dendrite formation through impedance measurements, enabling preventive maintenance before safety issues arise.

Physical containment strategies represent another critical safety dimension. Double-walled enclosures with leak detection systems provide protection against electrolyte spillage, while pressure relief mechanisms safely manage any gas evolution during abnormal operation. These engineering controls are particularly important for large-scale installations where the volume of aqueous electrolyte presents potential environmental contamination risks despite its lower toxicity compared to organic alternatives.

Installation standards for stationary AZIB systems emphasize proper ventilation, drainage systems, and electrical isolation. Unlike lithium-ion installations that focus primarily on fire suppression, AZIB safety protocols prioritize containment of potential electrolyte leakage and management of hydrogen gas that may form under extreme conditions. Maintenance protocols include regular inspection of seals, connections, and monitoring equipment to ensure early detection of potential failure modes.

Emergency response procedures for AZIB installations differ significantly from those for conventional batteries. First responders require specific training on handling aqueous zinc electrolyte spills, which present different hazards than organic electrolytes. Documentation standards mandate clear labeling of system chemistry, emergency shutdown procedures, and material safety data sheets tailored to the specific zinc salt formulations used in the system.

Primary safety standards for AZIBs focus on thermal stability, electrolyte containment, and prevention of zinc dendrite formation. Unlike lithium-ion batteries, AZIBs operate with non-flammable aqueous electrolytes, significantly reducing fire hazards. However, this advantage does not eliminate the need for robust safety protocols. Industry standards increasingly incorporate specific testing methodologies for aqueous systems, including accelerated aging tests, electrolyte leakage assessments, and dendrite growth monitoring.

Risk mitigation strategies for AZIBs in stationary storage applications employ multi-layered approaches. Battery management systems (BMS) specifically designed for zinc chemistry monitor critical parameters such as temperature, voltage, and current to prevent overcharging and overdischarging scenarios that could lead to hydrogen evolution or accelerated electrode degradation. Advanced BMS algorithms can detect early signs of dendrite formation through impedance measurements, enabling preventive maintenance before safety issues arise.

Physical containment strategies represent another critical safety dimension. Double-walled enclosures with leak detection systems provide protection against electrolyte spillage, while pressure relief mechanisms safely manage any gas evolution during abnormal operation. These engineering controls are particularly important for large-scale installations where the volume of aqueous electrolyte presents potential environmental contamination risks despite its lower toxicity compared to organic alternatives.

Installation standards for stationary AZIB systems emphasize proper ventilation, drainage systems, and electrical isolation. Unlike lithium-ion installations that focus primarily on fire suppression, AZIB safety protocols prioritize containment of potential electrolyte leakage and management of hydrogen gas that may form under extreme conditions. Maintenance protocols include regular inspection of seals, connections, and monitoring equipment to ensure early detection of potential failure modes.

Emergency response procedures for AZIB installations differ significantly from those for conventional batteries. First responders require specific training on handling aqueous zinc electrolyte spills, which present different hazards than organic electrolytes. Documentation standards mandate clear labeling of system chemistry, emergency shutdown procedures, and material safety data sheets tailored to the specific zinc salt formulations used in the system.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!