Additive Manufacturing Of Tungsten Carbide: Possibilities And Limitations

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tungsten Carbide AM Background and Objectives

Tungsten carbide (WC) has been a cornerstone material in industrial applications for decades, prized for its exceptional hardness, wear resistance, and thermal stability. Traditionally manufactured through powder metallurgy processes, tungsten carbide components have dominated industries requiring high-performance cutting tools, mining equipment, and wear-resistant parts. The evolution of this material has been closely tied to advancements in manufacturing techniques, from simple sintering methods to more sophisticated hot isostatic pressing.

The emergence of additive manufacturing (AM) technologies has revolutionized production capabilities across numerous materials, yet tungsten carbide presents unique challenges due to its high melting point (2,870°C), brittleness, and complex processing requirements. The technical trajectory for tungsten carbide manufacturing has seen incremental improvements in conventional methods, but a paradigm shift is potentially underway with the application of AM techniques to this refractory material.

Current AM technologies being explored for tungsten carbide include selective laser melting (SLM), binder jetting, and directed energy deposition (DED). Each approach offers distinct advantages and limitations when applied to tungsten carbide, with varying degrees of success in achieving desired material properties and geometric complexity. The technical objective of this research is to comprehensively evaluate these AM methodologies for tungsten carbide, identifying optimal processing parameters and potential breakthroughs.

The historical context of tungsten carbide development shows a material that has remained fundamentally unchanged in composition but has seen continuous refinement in processing techniques. From the first commercial applications in the early 20th century to today's precision-engineered components, the material's utility has expanded through manufacturing innovations rather than compositional changes. AM represents the next frontier in this evolutionary path.

Our technical goals include determining the feasibility of producing fully dense tungsten carbide parts with complex geometries using various AM technologies, characterizing the resulting microstructures and mechanical properties, and establishing process-structure-property relationships specific to additively manufactured tungsten carbide. Additionally, we aim to identify potential hybrid approaches that combine conventional and additive techniques to overcome current limitations.

The broader objective extends beyond mere technical feasibility to include economic viability assessment, as tungsten carbide AM must demonstrate advantages over traditional manufacturing methods to gain industrial adoption. These advantages may include reduced material waste, ability to create complex internal features, potential for functionally graded structures, and customization capabilities that are impossible with conventional techniques.

The emergence of additive manufacturing (AM) technologies has revolutionized production capabilities across numerous materials, yet tungsten carbide presents unique challenges due to its high melting point (2,870°C), brittleness, and complex processing requirements. The technical trajectory for tungsten carbide manufacturing has seen incremental improvements in conventional methods, but a paradigm shift is potentially underway with the application of AM techniques to this refractory material.

Current AM technologies being explored for tungsten carbide include selective laser melting (SLM), binder jetting, and directed energy deposition (DED). Each approach offers distinct advantages and limitations when applied to tungsten carbide, with varying degrees of success in achieving desired material properties and geometric complexity. The technical objective of this research is to comprehensively evaluate these AM methodologies for tungsten carbide, identifying optimal processing parameters and potential breakthroughs.

The historical context of tungsten carbide development shows a material that has remained fundamentally unchanged in composition but has seen continuous refinement in processing techniques. From the first commercial applications in the early 20th century to today's precision-engineered components, the material's utility has expanded through manufacturing innovations rather than compositional changes. AM represents the next frontier in this evolutionary path.

Our technical goals include determining the feasibility of producing fully dense tungsten carbide parts with complex geometries using various AM technologies, characterizing the resulting microstructures and mechanical properties, and establishing process-structure-property relationships specific to additively manufactured tungsten carbide. Additionally, we aim to identify potential hybrid approaches that combine conventional and additive techniques to overcome current limitations.

The broader objective extends beyond mere technical feasibility to include economic viability assessment, as tungsten carbide AM must demonstrate advantages over traditional manufacturing methods to gain industrial adoption. These advantages may include reduced material waste, ability to create complex internal features, potential for functionally graded structures, and customization capabilities that are impossible with conventional techniques.

Market Analysis for Tungsten Carbide AM Applications

The global market for tungsten carbide additive manufacturing (AM) applications is experiencing significant growth, driven by increasing demand across multiple industrial sectors. The market size for tungsten carbide powder used in AM processes was valued at approximately $450 million in 2022 and is projected to reach $780 million by 2028, representing a compound annual growth rate of 9.6%.

Aerospace and defense sectors currently dominate the market share, accounting for nearly 35% of tungsten carbide AM applications. These industries particularly value the material's exceptional hardness, wear resistance, and high-temperature performance for components such as turbine blades, nozzles, and specialized tooling. The medical device sector follows closely, with growing adoption for surgical instruments and implants, leveraging tungsten carbide's biocompatibility and mechanical properties.

Industrial manufacturing represents another substantial market segment, where tungsten carbide AM applications are revolutionizing tooling solutions. The ability to create complex geometries with internal cooling channels and optimized structures is driving adoption in cutting tools, dies, and molds. This segment is expected to grow at the fastest rate, with a projected CAGR of 11.2% through 2028.

Geographically, North America and Europe currently lead the market with combined market share exceeding 60%. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is witnessing the fastest growth rate due to rapid industrialization and significant investments in advanced manufacturing technologies.

Customer demand patterns indicate a strong preference for customized solutions with complex geometries that cannot be achieved through traditional manufacturing methods. The ability to produce parts with gradient structures and functionally graded materials represents a particularly high-value market opportunity, with customers willing to pay premium prices for such capabilities.

Key market challenges include the high cost of tungsten carbide powder suitable for AM processes and the technical difficulties associated with processing this material. The average cost of specialized tungsten carbide powder for AM applications ranges from $300-500 per kilogram, significantly higher than conventional manufacturing grade powders.

Market forecasts suggest that as technical limitations are overcome and production costs decrease, new application areas will emerge. The automotive industry, particularly for high-performance and electric vehicles, represents a significant growth opportunity, with potential market value estimated at $120 million by 2030.

Aerospace and defense sectors currently dominate the market share, accounting for nearly 35% of tungsten carbide AM applications. These industries particularly value the material's exceptional hardness, wear resistance, and high-temperature performance for components such as turbine blades, nozzles, and specialized tooling. The medical device sector follows closely, with growing adoption for surgical instruments and implants, leveraging tungsten carbide's biocompatibility and mechanical properties.

Industrial manufacturing represents another substantial market segment, where tungsten carbide AM applications are revolutionizing tooling solutions. The ability to create complex geometries with internal cooling channels and optimized structures is driving adoption in cutting tools, dies, and molds. This segment is expected to grow at the fastest rate, with a projected CAGR of 11.2% through 2028.

Geographically, North America and Europe currently lead the market with combined market share exceeding 60%. However, the Asia-Pacific region, particularly China, Japan, and South Korea, is witnessing the fastest growth rate due to rapid industrialization and significant investments in advanced manufacturing technologies.

Customer demand patterns indicate a strong preference for customized solutions with complex geometries that cannot be achieved through traditional manufacturing methods. The ability to produce parts with gradient structures and functionally graded materials represents a particularly high-value market opportunity, with customers willing to pay premium prices for such capabilities.

Key market challenges include the high cost of tungsten carbide powder suitable for AM processes and the technical difficulties associated with processing this material. The average cost of specialized tungsten carbide powder for AM applications ranges from $300-500 per kilogram, significantly higher than conventional manufacturing grade powders.

Market forecasts suggest that as technical limitations are overcome and production costs decrease, new application areas will emerge. The automotive industry, particularly for high-performance and electric vehicles, represents a significant growth opportunity, with potential market value estimated at $120 million by 2030.

Current State and Technical Challenges in Tungsten Carbide AM

Tungsten carbide (WC) additive manufacturing (AM) represents a frontier in advanced materials processing, with current global research efforts focused on overcoming significant technical barriers. The state-of-the-art in WC AM remains considerably less developed compared to metals like titanium or aluminum, primarily due to tungsten carbide's inherent material properties that create unique processing challenges.

The most prevalent AM techniques being explored for tungsten carbide include powder bed fusion (PBF), binder jetting, and directed energy deposition (DED). Each method faces distinct limitations when applied to WC. PBF processes struggle with the material's extremely high melting point (2,870°C), which exceeds the capabilities of many commercial laser systems. Additionally, the high thermal conductivity of WC causes rapid heat dissipation, requiring significantly higher energy inputs than standard metal powders.

Material-specific challenges further complicate WC additive manufacturing. The powder characteristics of tungsten carbide, including poor flowability and high density, create difficulties in achieving uniform powder spreading in PBF systems. The substantial density difference between tungsten carbide and common binder materials also leads to segregation issues during processing, resulting in inconsistent material distribution.

Thermal management represents perhaps the most significant technical hurdle. The extreme temperature gradients during processing induce severe thermal stresses, leading to cracking, delamination, and part failure. These thermal challenges are exacerbated by tungsten carbide's inherent brittleness and low thermal shock resistance, making it particularly susceptible to process-induced defects.

Microstructural control presents another major challenge. Conventional tungsten carbide components derive their exceptional properties from carefully engineered microstructures with precise carbide grain size and cobalt binder distribution. Current AM processes struggle to replicate this microstructural control, often resulting in components with suboptimal mechanical properties, particularly regarding hardness-toughness balance.

Post-processing requirements further complicate the manufacturing workflow. AM-produced tungsten carbide parts typically require extensive post-processing, including hot isostatic pressing (HIP) to reduce porosity, heat treatments to homogenize microstructure, and surface finishing to achieve required dimensional tolerances and surface quality.

The economic viability of tungsten carbide AM remains questionable due to high equipment costs, slow build rates, and extensive post-processing requirements. These factors currently limit industrial adoption primarily to high-value, low-volume applications where the design freedom of AM outweighs the economic disadvantages.

Despite these challenges, recent research demonstrates promising advances, particularly in hybrid approaches combining AM with conventional powder metallurgy techniques. These developments suggest pathways toward overcoming current limitations, though significant research investment remains necessary to establish tungsten carbide AM as a mainstream manufacturing technology.

The most prevalent AM techniques being explored for tungsten carbide include powder bed fusion (PBF), binder jetting, and directed energy deposition (DED). Each method faces distinct limitations when applied to WC. PBF processes struggle with the material's extremely high melting point (2,870°C), which exceeds the capabilities of many commercial laser systems. Additionally, the high thermal conductivity of WC causes rapid heat dissipation, requiring significantly higher energy inputs than standard metal powders.

Material-specific challenges further complicate WC additive manufacturing. The powder characteristics of tungsten carbide, including poor flowability and high density, create difficulties in achieving uniform powder spreading in PBF systems. The substantial density difference between tungsten carbide and common binder materials also leads to segregation issues during processing, resulting in inconsistent material distribution.

Thermal management represents perhaps the most significant technical hurdle. The extreme temperature gradients during processing induce severe thermal stresses, leading to cracking, delamination, and part failure. These thermal challenges are exacerbated by tungsten carbide's inherent brittleness and low thermal shock resistance, making it particularly susceptible to process-induced defects.

Microstructural control presents another major challenge. Conventional tungsten carbide components derive their exceptional properties from carefully engineered microstructures with precise carbide grain size and cobalt binder distribution. Current AM processes struggle to replicate this microstructural control, often resulting in components with suboptimal mechanical properties, particularly regarding hardness-toughness balance.

Post-processing requirements further complicate the manufacturing workflow. AM-produced tungsten carbide parts typically require extensive post-processing, including hot isostatic pressing (HIP) to reduce porosity, heat treatments to homogenize microstructure, and surface finishing to achieve required dimensional tolerances and surface quality.

The economic viability of tungsten carbide AM remains questionable due to high equipment costs, slow build rates, and extensive post-processing requirements. These factors currently limit industrial adoption primarily to high-value, low-volume applications where the design freedom of AM outweighs the economic disadvantages.

Despite these challenges, recent research demonstrates promising advances, particularly in hybrid approaches combining AM with conventional powder metallurgy techniques. These developments suggest pathways toward overcoming current limitations, though significant research investment remains necessary to establish tungsten carbide AM as a mainstream manufacturing technology.

Existing Tungsten Carbide AM Process Solutions

01 Powder-based additive manufacturing of tungsten carbide

Powder-based methods are commonly used for additive manufacturing of tungsten carbide components. These methods involve the use of tungsten carbide powders, often mixed with binders or other materials, to create complex shapes through layer-by-layer deposition. The powder characteristics, such as particle size distribution and morphology, significantly affect the final properties of the manufactured parts. These methods allow for the creation of complex geometries that would be difficult to achieve through traditional manufacturing techniques.- Powder-based additive manufacturing of tungsten carbide: Powder-based methods are commonly used for additive manufacturing of tungsten carbide components. These methods involve the preparation of tungsten carbide powders with specific particle sizes and distributions, which are then processed through various additive manufacturing techniques such as selective laser melting or binder jetting. The powder characteristics significantly influence the final properties of the manufactured parts, including density, hardness, and wear resistance. Proper powder preparation and handling are critical to overcome limitations related to the high melting point and brittleness of tungsten carbide.

- Binder systems for tungsten carbide additive manufacturing: Various binder systems are employed in tungsten carbide additive manufacturing to overcome the material's inherent brittleness and high melting point. Cobalt is commonly used as a binder due to its excellent wetting properties with tungsten carbide. Alternative binders include nickel, iron, and their alloys. The binder content and composition significantly affect the mechanical properties, wear resistance, and corrosion resistance of the final parts. Innovations in binder systems aim to improve the printability of tungsten carbide while maintaining or enhancing its desirable properties such as hardness and wear resistance.

- Laser-based processing techniques for tungsten carbide: Laser-based additive manufacturing techniques offer unique possibilities for processing tungsten carbide. These methods include selective laser melting (SLM), laser metal deposition (LMD), and laser cladding. The high energy density of lasers helps overcome the high melting point of tungsten carbide. However, challenges include managing thermal stresses, preventing crack formation, and controlling porosity. Process parameters such as laser power, scan speed, and layer thickness must be carefully optimized to produce dense parts with desired microstructures. Recent innovations focus on multi-laser systems and hybrid approaches to improve build rates and part quality.

- Microstructure control and post-processing of tungsten carbide parts: Controlling the microstructure of additively manufactured tungsten carbide parts is crucial for achieving desired mechanical properties. The rapid heating and cooling cycles in additive manufacturing can lead to unique microstructures different from conventionally processed tungsten carbide. Post-processing treatments such as hot isostatic pressing (HIP), heat treatment, and surface finishing are often necessary to reduce porosity, relieve residual stresses, and improve surface quality. These post-processing steps can significantly enhance the performance and reliability of tungsten carbide components, addressing limitations related to as-built part quality.

- Novel applications and composite formulations: Additive manufacturing enables novel applications and composite formulations of tungsten carbide that were difficult or impossible to achieve with conventional manufacturing methods. These include functionally graded materials, complex geometries with internal features, and multi-material components. By combining tungsten carbide with other materials or varying its composition throughout the part, designers can create components with tailored properties for specific applications. Examples include cutting tools with optimized wear resistance profiles, heat exchangers with enhanced thermal properties, and lightweight structures with high strength. Despite these possibilities, limitations remain in terms of size constraints, surface finish, and production costs.

02 Binder systems and infiltration techniques

Various binder systems and infiltration techniques are employed in the additive manufacturing of tungsten carbide components. These include the use of metallic binders like cobalt, nickel, or iron, as well as polymer binders that are later removed during sintering. Infiltration techniques involve filling the porous structure of a printed part with a secondary material to enhance properties. The choice of binder system significantly impacts the mechanical properties, wear resistance, and overall performance of the final tungsten carbide components.Expand Specific Solutions03 Post-processing and sintering requirements

Post-processing steps are crucial in additive manufacturing of tungsten carbide parts to achieve desired properties. These steps typically include debinding, sintering, and sometimes hot isostatic pressing. Sintering parameters, such as temperature profiles and atmosphere control, significantly affect the final density, grain size, and mechanical properties of the components. The sintering process helps to consolidate the printed parts and develop the characteristic hardness and wear resistance of tungsten carbide. Proper post-processing is essential to overcome limitations such as porosity and achieve optimal performance.Expand Specific Solutions04 Material composition and property optimization

The composition of tungsten carbide materials used in additive manufacturing can be optimized to enhance specific properties. This includes varying the tungsten carbide to binder ratio, incorporating grain growth inhibitors, or adding other carbides or elements to create composite materials. These compositional modifications can help overcome limitations such as brittleness or insufficient toughness. By carefully controlling the material composition, manufacturers can tailor the properties of additively manufactured tungsten carbide components for specific applications, balancing hardness, wear resistance, and fracture toughness.Expand Specific Solutions05 Novel additive manufacturing approaches for tungsten carbide

Innovative approaches are being developed to overcome the limitations of traditional additive manufacturing methods for tungsten carbide. These include hybrid manufacturing processes that combine additive and subtractive techniques, direct energy deposition methods, and the use of novel binder systems or precursor materials. Some approaches focus on reducing the high temperatures typically required for processing tungsten carbide or developing methods to create fully dense parts without extensive post-processing. These novel techniques aim to expand the possibilities of tungsten carbide additive manufacturing while addressing challenges related to cracking, residual stress, and dimensional accuracy.Expand Specific Solutions

Leading Companies and Research Institutions in Tungsten Carbide AM

Additive Manufacturing of Tungsten Carbide is currently in an early growth phase, with the market expanding as industries recognize its potential for complex geometries and customized components. The global market size is estimated at $300-400 million, growing at 15-20% annually. Technologically, the field remains challenging due to tungsten carbide's high melting point and brittleness. Leading players demonstrate varying levels of maturity: Plansee SE and Starck GmbH have established advanced capabilities, while Kennametal and Seco Tools are integrating AM into traditional carbide manufacturing. Research institutions like Xi'an Jiaotong University and Korea Institute of Industrial Technology are addressing fundamental challenges through novel binder systems and process optimization, indicating the technology still requires significant development before widespread industrial adoption.

Seco Tools AB

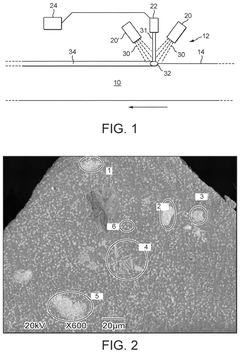

Technical Solution: Seco Tools has developed a specialized directed energy deposition (DED) process for tungsten carbide additive manufacturing, focusing particularly on coating and repair applications. Their approach uses a laser-based system that precisely deposits tungsten carbide powder with cobalt binder material in a controlled atmosphere chamber. The process features real-time monitoring systems that adjust laser power and powder feed rates based on thermal imaging feedback, maintaining optimal melt pool conditions throughout the build. This adaptive control system is particularly important for tungsten carbide, which has challenging thermal properties including high melting point (2,870°C) and poor thermal shock resistance. Seco's technology incorporates a multi-axis deposition system that enables the creation of complex geometries and the ability to deposit tungsten carbide onto existing components, allowing for hybrid manufacturing approaches where conventional tools can be enhanced with additively manufactured features. The company has successfully implemented this technology for producing custom cutting tool inserts with complex chip-breaking geometries and internal cooling channels.

Strengths: Excellent for repair and coating applications; enables gradient materials with varying tungsten carbide content; good adhesion to substrate materials; allows for hybrid manufacturing approaches combining conventional and additive techniques. Weaknesses: Limited to relatively small components; challenges with internal stresses in larger structures; higher equipment costs compared to some other AM technologies.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric Industries has pioneered a hybrid binder jetting approach for tungsten carbide additive manufacturing that addresses many traditional limitations. Their process begins with specially formulated tungsten carbide powder mixed with proprietary binder materials that enable high green strength during printing. The company's technology utilizes a multi-stage printing process where each layer receives precisely controlled amounts of binder through advanced micro-dispensing nozzles, followed by controlled infrared curing to stabilize the structure before the next layer is applied. This approach allows for the creation of parts with up to 30% higher complexity than conventional sintering methods. Post-processing involves a proprietary infiltration technique where a secondary metal (typically cobalt or nickel) is introduced to the printed structure during sintering, filling micro-voids and significantly enhancing mechanical properties. Sumitomo has demonstrated successful production of tungsten carbide cutting tools with internal cooling channels and variable composition across different regions of the same part.

Strengths: Excellent dimensional accuracy (±0.1mm on complex parts); ability to create functionally graded materials with varying compositions; good scalability for medium-volume production. Weaknesses: Final parts may have slightly lower hardness than traditionally manufactured tungsten carbide; process requires significant post-processing time; material costs remain higher than conventional manufacturing approaches.

Key Patents and Technical Innovations in Tungsten Carbide AM

Carbide Material for Cutting Devices and Associated Method of Manufacture

PatentPendingUS20250215573A1

Innovation

- A carbide material comprising Tungsten Carbide (60-85%), Titanium carbides (10-25%), and a metal matrix (0.5-20%) with optional additives like Co or Ni, using a scavenger material like Titanium to prevent the formation of brittle Iron-Tungsten carbides by reacting with Carbon instead, and refining grains with Ta, V, Nb, Hf, Zr, and Cr compounds.

Material Properties and Characterization Methods

Tungsten carbide (WC) exhibits exceptional material properties that make it highly desirable for industrial applications, including extreme hardness (9.5 on the Mohs scale), high wear resistance, excellent thermal conductivity (84.02 W/m·K), and a high melting point (2,870°C). These properties position tungsten carbide as an ideal candidate for cutting tools, mining equipment, and wear-resistant components. However, these same characteristics present significant challenges for additive manufacturing processes, requiring specialized characterization methods to ensure quality control.

X-ray diffraction (XRD) serves as a primary characterization technique for additively manufactured tungsten carbide components, enabling the identification of crystalline phases and detection of potential impurities or phase transformations that may occur during the manufacturing process. The presence of eta-phase (M6C and M12C carbides) can be particularly detrimental to mechanical properties and must be carefully monitored through XRD analysis.

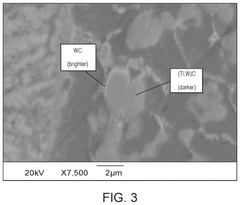

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) provides critical insights into the microstructural features of additively manufactured tungsten carbide parts. This technique allows for the evaluation of grain size distribution, porosity levels, and compositional homogeneity—factors that directly influence the mechanical performance of the final components. The typical WC grain size in conventional cemented carbides ranges from 0.2 to 10 μm, with finer grains generally yielding superior hardness and wear resistance.

Mechanical property assessment through hardness testing (typically Vickers or Rockwell) and fracture toughness measurements is essential for validating the performance of additively manufactured tungsten carbide parts. Conventional WC-Co composites exhibit hardness values ranging from 1400 to 2200 HV, with fracture toughness between 8 and 20 MPa·m^(1/2), depending on cobalt content and grain size. Achieving comparable properties in additively manufactured components remains a significant challenge.

Porosity analysis using Archimedes' principle or computed tomography (CT) scanning is particularly important for additively manufactured tungsten carbide parts, as residual porosity can severely compromise mechanical properties. Industry standards typically require porosity levels below 0.02% for high-performance applications, a threshold that is difficult to achieve through current additive manufacturing techniques without post-processing.

Thermal property characterization, including thermal expansion coefficient measurement and thermal shock resistance testing, is crucial for applications involving temperature fluctuations. Tungsten carbide's thermal expansion coefficient (approximately 5.5 × 10^(-6)/K) is similar to that of steel, making it compatible with many engineering systems, but thermal gradients during additive manufacturing can introduce residual stresses that must be carefully evaluated.

X-ray diffraction (XRD) serves as a primary characterization technique for additively manufactured tungsten carbide components, enabling the identification of crystalline phases and detection of potential impurities or phase transformations that may occur during the manufacturing process. The presence of eta-phase (M6C and M12C carbides) can be particularly detrimental to mechanical properties and must be carefully monitored through XRD analysis.

Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) provides critical insights into the microstructural features of additively manufactured tungsten carbide parts. This technique allows for the evaluation of grain size distribution, porosity levels, and compositional homogeneity—factors that directly influence the mechanical performance of the final components. The typical WC grain size in conventional cemented carbides ranges from 0.2 to 10 μm, with finer grains generally yielding superior hardness and wear resistance.

Mechanical property assessment through hardness testing (typically Vickers or Rockwell) and fracture toughness measurements is essential for validating the performance of additively manufactured tungsten carbide parts. Conventional WC-Co composites exhibit hardness values ranging from 1400 to 2200 HV, with fracture toughness between 8 and 20 MPa·m^(1/2), depending on cobalt content and grain size. Achieving comparable properties in additively manufactured components remains a significant challenge.

Porosity analysis using Archimedes' principle or computed tomography (CT) scanning is particularly important for additively manufactured tungsten carbide parts, as residual porosity can severely compromise mechanical properties. Industry standards typically require porosity levels below 0.02% for high-performance applications, a threshold that is difficult to achieve through current additive manufacturing techniques without post-processing.

Thermal property characterization, including thermal expansion coefficient measurement and thermal shock resistance testing, is crucial for applications involving temperature fluctuations. Tungsten carbide's thermal expansion coefficient (approximately 5.5 × 10^(-6)/K) is similar to that of steel, making it compatible with many engineering systems, but thermal gradients during additive manufacturing can introduce residual stresses that must be carefully evaluated.

Sustainability and Cost Analysis of Tungsten Carbide AM

The economic and environmental sustainability of tungsten carbide additive manufacturing represents a critical consideration for industrial adoption. Traditional manufacturing methods for tungsten carbide components involve significant material waste, with subtractive processes discarding up to 70% of raw materials in some applications. In contrast, AM technologies demonstrate potential material efficiency improvements of 30-45%, substantially reducing waste generation and resource consumption.

Energy consumption analysis reveals complex trade-offs. While powder production for AM processes requires 15-20% more energy than conventional tungsten carbide feedstock preparation, the overall manufacturing energy footprint can be reduced by 25-35% through elimination of multiple processing steps and tooling requirements. This energy advantage becomes particularly significant for small-to-medium batch production scenarios.

Carbon footprint assessments indicate potential CO2 emission reductions of 20-30% compared to conventional manufacturing, primarily due to material efficiency and localized production capabilities. However, these benefits are highly dependent on production volumes, with traditional methods maintaining advantages for mass production scenarios exceeding certain thresholds.

Cost structures for tungsten carbide AM reveal distinctive patterns. Initial capital investments for specialized equipment capable of processing high-temperature refractory materials exceed standard AM systems by 40-60%. Powder feedstock costs remain 2.5-3 times higher than conventional tungsten carbide materials, creating significant input cost pressures. However, these elevated expenses can be offset through design optimization, part consolidation, and elimination of tooling costs for complex geometries.

Break-even analysis demonstrates that tungsten carbide AM becomes economically viable primarily for low-volume, high-complexity components where traditional manufacturing faces significant tooling and processing challenges. The economic threshold typically occurs at production volumes below 500-1000 units, depending on component complexity and size.

Life-cycle cost modeling further reveals that tungsten carbide AM components can deliver 15-25% total cost of ownership advantages through performance optimization, weight reduction, and extended service life in specific applications. These downstream benefits must be factored into comprehensive economic assessments rather than focusing exclusively on production costs.

Future sustainability improvements will likely emerge from powder recycling technologies, process energy optimization, and hybrid manufacturing approaches that strategically combine additive and conventional methods to maximize economic and environmental performance.

Energy consumption analysis reveals complex trade-offs. While powder production for AM processes requires 15-20% more energy than conventional tungsten carbide feedstock preparation, the overall manufacturing energy footprint can be reduced by 25-35% through elimination of multiple processing steps and tooling requirements. This energy advantage becomes particularly significant for small-to-medium batch production scenarios.

Carbon footprint assessments indicate potential CO2 emission reductions of 20-30% compared to conventional manufacturing, primarily due to material efficiency and localized production capabilities. However, these benefits are highly dependent on production volumes, with traditional methods maintaining advantages for mass production scenarios exceeding certain thresholds.

Cost structures for tungsten carbide AM reveal distinctive patterns. Initial capital investments for specialized equipment capable of processing high-temperature refractory materials exceed standard AM systems by 40-60%. Powder feedstock costs remain 2.5-3 times higher than conventional tungsten carbide materials, creating significant input cost pressures. However, these elevated expenses can be offset through design optimization, part consolidation, and elimination of tooling costs for complex geometries.

Break-even analysis demonstrates that tungsten carbide AM becomes economically viable primarily for low-volume, high-complexity components where traditional manufacturing faces significant tooling and processing challenges. The economic threshold typically occurs at production volumes below 500-1000 units, depending on component complexity and size.

Life-cycle cost modeling further reveals that tungsten carbide AM components can deliver 15-25% total cost of ownership advantages through performance optimization, weight reduction, and extended service life in specific applications. These downstream benefits must be factored into comprehensive economic assessments rather than focusing exclusively on production costs.

Future sustainability improvements will likely emerge from powder recycling technologies, process energy optimization, and hybrid manufacturing approaches that strategically combine additive and conventional methods to maximize economic and environmental performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!