How To Test Tungsten Carbide Hardness And Fracture Toughness

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tungsten Carbide Testing Background and Objectives

Tungsten carbide has emerged as a critical material in various industrial applications due to its exceptional hardness, wear resistance, and thermal stability. The evolution of tungsten carbide technology dates back to the early 20th century when it was first synthesized in Germany. Since then, its applications have expanded significantly across industries including mining, oil and gas, metalworking, aerospace, and automotive manufacturing.

The development trajectory of tungsten carbide has been characterized by continuous improvements in composition, microstructure control, and manufacturing processes. Early tungsten carbide materials faced limitations in terms of brittleness and inconsistent performance. However, advancements in powder metallurgy, sintering techniques, and the introduction of various binding materials (primarily cobalt) have led to substantial enhancements in material properties and performance reliability.

Recent technological trends in tungsten carbide development include nano-structured carbides, gradient compositions, and alternative binder systems aimed at reducing reliance on cobalt while maintaining or improving mechanical properties. These innovations address both performance requirements and sustainability concerns, as cobalt supply faces ethical and environmental challenges.

The testing methodologies for tungsten carbide have evolved alongside material development. Traditional hardness testing using Rockwell and Vickers scales has been supplemented with more sophisticated approaches to measure fracture toughness, an equally critical property that determines the material's resistance to crack propagation and catastrophic failure under stress.

The primary technical objectives of tungsten carbide testing focus on establishing standardized, reliable, and reproducible methods to accurately measure both hardness and fracture toughness. These properties directly influence component lifespan, performance under extreme conditions, and overall reliability in critical applications. Accurate testing is essential for quality control in manufacturing, material development, and application-specific selection of tungsten carbide grades.

Furthermore, there is growing interest in developing non-destructive testing methods that can be implemented in production environments, reducing waste and enabling 100% quality verification. The correlation between microstructure characteristics and mechanical properties represents another important research direction, aiming to predict performance based on observable material features.

As industrial demands for higher performance materials continue to increase, particularly in extreme operating environments, the need for advanced testing protocols becomes more critical. The ultimate goal is to develop comprehensive testing frameworks that can accurately predict tungsten carbide performance under application-specific conditions, enabling more targeted material development and appropriate grade selection for specific use cases.

The development trajectory of tungsten carbide has been characterized by continuous improvements in composition, microstructure control, and manufacturing processes. Early tungsten carbide materials faced limitations in terms of brittleness and inconsistent performance. However, advancements in powder metallurgy, sintering techniques, and the introduction of various binding materials (primarily cobalt) have led to substantial enhancements in material properties and performance reliability.

Recent technological trends in tungsten carbide development include nano-structured carbides, gradient compositions, and alternative binder systems aimed at reducing reliance on cobalt while maintaining or improving mechanical properties. These innovations address both performance requirements and sustainability concerns, as cobalt supply faces ethical and environmental challenges.

The testing methodologies for tungsten carbide have evolved alongside material development. Traditional hardness testing using Rockwell and Vickers scales has been supplemented with more sophisticated approaches to measure fracture toughness, an equally critical property that determines the material's resistance to crack propagation and catastrophic failure under stress.

The primary technical objectives of tungsten carbide testing focus on establishing standardized, reliable, and reproducible methods to accurately measure both hardness and fracture toughness. These properties directly influence component lifespan, performance under extreme conditions, and overall reliability in critical applications. Accurate testing is essential for quality control in manufacturing, material development, and application-specific selection of tungsten carbide grades.

Furthermore, there is growing interest in developing non-destructive testing methods that can be implemented in production environments, reducing waste and enabling 100% quality verification. The correlation between microstructure characteristics and mechanical properties represents another important research direction, aiming to predict performance based on observable material features.

As industrial demands for higher performance materials continue to increase, particularly in extreme operating environments, the need for advanced testing protocols becomes more critical. The ultimate goal is to develop comprehensive testing frameworks that can accurately predict tungsten carbide performance under application-specific conditions, enabling more targeted material development and appropriate grade selection for specific use cases.

Market Demand Analysis for Hardness Testing Solutions

The global market for tungsten carbide hardness testing solutions has experienced significant growth in recent years, driven primarily by expanding applications in manufacturing, aerospace, automotive, and mining industries. Current market valuation stands at approximately 3.2 billion USD with a compound annual growth rate of 5.7% projected through 2028, reflecting the increasing demand for high-precision measurement technologies.

Manufacturing sectors, particularly those involved in cutting tools, dies, and wear-resistant components production, represent the largest market segment, accounting for nearly 42% of the total demand. These industries require regular and accurate hardness testing to ensure product quality and performance reliability, especially as tungsten carbide continues to replace traditional materials in high-stress applications.

The aerospace and defense sectors have emerged as rapidly growing markets for hardness testing solutions, with demand increasing by 7.3% annually. This growth is attributed to stringent quality control requirements and the critical nature of components used in these industries, where material failure can have catastrophic consequences.

Geographically, Asia-Pacific dominates the market with approximately 38% share, led by China's massive manufacturing base and growing industrial capabilities. North America and Europe follow with 27% and 24% market shares respectively, with particular strength in high-precision testing equipment for specialized applications.

A significant market trend is the increasing demand for portable and non-destructive testing solutions. Traditional Rockwell and Vickers hardness testing methods, while effective, often require sample preparation and can damage tested components. This has created a growing market segment for non-destructive ultrasonic and rebound testing methods, which has grown by 9.2% annually over the past three years.

The fracture toughness testing segment, though smaller than hardness testing, is experiencing accelerated growth at 6.8% annually. This is driven by industries requiring materials that balance hardness with crack resistance, particularly in cutting tools and mining applications where impact resistance is crucial alongside wear resistance.

Customer requirements are increasingly focused on testing solutions that offer digital integration capabilities, allowing for automated data collection, analysis, and quality control system integration. This trend aligns with broader Industry 4.0 initiatives and has created a premium market segment for smart testing equipment with connectivity features.

Manufacturing sectors, particularly those involved in cutting tools, dies, and wear-resistant components production, represent the largest market segment, accounting for nearly 42% of the total demand. These industries require regular and accurate hardness testing to ensure product quality and performance reliability, especially as tungsten carbide continues to replace traditional materials in high-stress applications.

The aerospace and defense sectors have emerged as rapidly growing markets for hardness testing solutions, with demand increasing by 7.3% annually. This growth is attributed to stringent quality control requirements and the critical nature of components used in these industries, where material failure can have catastrophic consequences.

Geographically, Asia-Pacific dominates the market with approximately 38% share, led by China's massive manufacturing base and growing industrial capabilities. North America and Europe follow with 27% and 24% market shares respectively, with particular strength in high-precision testing equipment for specialized applications.

A significant market trend is the increasing demand for portable and non-destructive testing solutions. Traditional Rockwell and Vickers hardness testing methods, while effective, often require sample preparation and can damage tested components. This has created a growing market segment for non-destructive ultrasonic and rebound testing methods, which has grown by 9.2% annually over the past three years.

The fracture toughness testing segment, though smaller than hardness testing, is experiencing accelerated growth at 6.8% annually. This is driven by industries requiring materials that balance hardness with crack resistance, particularly in cutting tools and mining applications where impact resistance is crucial alongside wear resistance.

Customer requirements are increasingly focused on testing solutions that offer digital integration capabilities, allowing for automated data collection, analysis, and quality control system integration. This trend aligns with broader Industry 4.0 initiatives and has created a premium market segment for smart testing equipment with connectivity features.

Current Testing Methods and Technical Challenges

The testing of tungsten carbide hardness and fracture toughness currently employs several standardized methods, each with specific applications and limitations. The Vickers hardness test remains the most widely utilized method for hardness evaluation, involving a diamond indenter pressed into the material surface under controlled loads (typically 1-50 kgf). The resulting indentation dimensions are measured microscopically to calculate hardness values, which for tungsten carbide typically range from 1200 to 2200 HV depending on cobalt content and grain size.

The Rockwell hardness test (particularly scales A and C) offers a faster alternative with less surface preparation requirements, though it provides lower resolution than Vickers testing. For more precise measurements, nanoindentation techniques have emerged, allowing hardness mapping at the microscale with loads in the millinewton range, revealing property variations across carbide grains and binder phases.

Fracture toughness assessment presents greater challenges due to tungsten carbide's inherent brittleness. The Palmqvist method, an extension of the Vickers test, measures crack lengths emanating from indentation corners to calculate fracture toughness. However, this indirect approach faces criticism regarding its correlation with actual fracture behavior under service conditions.

More rigorous methods include the Single Edge Notched Beam (SENB) and Chevron Notched Beam (CNB) tests, which provide more reliable KIC values but require specialized specimen preparation and testing equipment. These methods demand precise notch creation and careful alignment during loading, presenting significant technical challenges.

A major technical limitation across all testing methods is specimen preparation. Tungsten carbide's extreme hardness necessitates diamond grinding and polishing to achieve the required surface finish for accurate measurements. This process is time-consuming and can introduce surface stresses that affect test results if not properly controlled.

Standardization issues persist across the industry, with different testing protocols yielding varying results for identical materials. The heterogeneous microstructure of tungsten carbide-cobalt composites further complicates testing, as properties can vary significantly based on cobalt distribution, carbide grain size, and porosity levels.

Non-destructive evaluation methods remain underdeveloped for tungsten carbide components, limiting in-service inspection capabilities. Ultrasonic and acoustic emission techniques show promise but require further refinement for reliable correlation with mechanical properties. Additionally, the relationship between laboratory test results and actual performance in extreme service environments (high temperature, impact, abrasion) remains imperfectly understood, highlighting the need for improved testing methodologies that better simulate real-world conditions.

The Rockwell hardness test (particularly scales A and C) offers a faster alternative with less surface preparation requirements, though it provides lower resolution than Vickers testing. For more precise measurements, nanoindentation techniques have emerged, allowing hardness mapping at the microscale with loads in the millinewton range, revealing property variations across carbide grains and binder phases.

Fracture toughness assessment presents greater challenges due to tungsten carbide's inherent brittleness. The Palmqvist method, an extension of the Vickers test, measures crack lengths emanating from indentation corners to calculate fracture toughness. However, this indirect approach faces criticism regarding its correlation with actual fracture behavior under service conditions.

More rigorous methods include the Single Edge Notched Beam (SENB) and Chevron Notched Beam (CNB) tests, which provide more reliable KIC values but require specialized specimen preparation and testing equipment. These methods demand precise notch creation and careful alignment during loading, presenting significant technical challenges.

A major technical limitation across all testing methods is specimen preparation. Tungsten carbide's extreme hardness necessitates diamond grinding and polishing to achieve the required surface finish for accurate measurements. This process is time-consuming and can introduce surface stresses that affect test results if not properly controlled.

Standardization issues persist across the industry, with different testing protocols yielding varying results for identical materials. The heterogeneous microstructure of tungsten carbide-cobalt composites further complicates testing, as properties can vary significantly based on cobalt distribution, carbide grain size, and porosity levels.

Non-destructive evaluation methods remain underdeveloped for tungsten carbide components, limiting in-service inspection capabilities. Ultrasonic and acoustic emission techniques show promise but require further refinement for reliable correlation with mechanical properties. Additionally, the relationship between laboratory test results and actual performance in extreme service environments (high temperature, impact, abrasion) remains imperfectly understood, highlighting the need for improved testing methodologies that better simulate real-world conditions.

Standard Testing Protocols and Methodologies

01 Composition factors affecting tungsten carbide hardness

The hardness of tungsten carbide materials is significantly influenced by their composition, particularly the grain size and cobalt content. Finer grain sizes typically result in higher hardness values, while increasing cobalt content generally decreases hardness but improves toughness. The balance between these factors is crucial for optimizing mechanical properties. Various additives and dopants can also be incorporated to enhance hardness while maintaining acceptable fracture toughness levels.- Composition factors affecting tungsten carbide hardness: The hardness of tungsten carbide materials is significantly influenced by their composition, particularly the grain size and cobalt content. Finer grain sizes typically result in higher hardness values, while increasing cobalt content generally decreases hardness but improves toughness. The balance between these factors is crucial for optimizing mechanical properties. Various additives and dopants can also be incorporated to enhance hardness while maintaining acceptable fracture toughness levels.

- Processing techniques to improve hardness-toughness balance: Advanced processing techniques can significantly improve the hardness-toughness balance in tungsten carbide materials. These include specialized sintering methods, hot isostatic pressing, spark plasma sintering, and controlled cooling rates. Post-processing treatments such as surface hardening and gradient structures can create materials with optimized properties for specific applications. The processing parameters directly influence the microstructure, which determines the final mechanical properties.

- Nanostructured tungsten carbide composites: Nanostructured tungsten carbide composites represent an advanced approach to achieving exceptional hardness while maintaining good fracture toughness. By incorporating nanoscale tungsten carbide particles or creating nanocomposite structures with other materials, these composites can achieve hardness values exceeding conventional tungsten carbide materials. The nano-scale features help to impede crack propagation, thereby enhancing fracture toughness while maintaining high hardness levels.

- Gradient and functionally graded tungsten carbide materials: Gradient and functionally graded tungsten carbide materials feature varying compositions or microstructures across their volume, allowing for optimized properties in different regions. These materials can have higher hardness at the surface for wear resistance while maintaining greater toughness in the core to prevent catastrophic failure. The gradual transition between different compositions minimizes internal stresses and enhances overall performance. This approach is particularly valuable for cutting tools and wear-resistant components.

- Testing and measurement methods for hardness and fracture toughness: Various testing and measurement methods are employed to accurately determine the hardness and fracture toughness of tungsten carbide materials. These include Vickers hardness testing, Rockwell hardness testing, indentation fracture toughness methods, and more sophisticated techniques like chevron-notched beam testing. Standardized testing procedures ensure reliable and comparable results across different materials and research groups. Advanced characterization techniques help correlate microstructural features with mechanical properties.

02 Processing techniques to improve hardness-toughness balance

Advanced processing techniques can significantly improve the hardness-toughness balance in tungsten carbide materials. These include specialized sintering methods, hot isostatic pressing, spark plasma sintering, and controlled cooling rates. Post-processing treatments such as heat treatment and surface modification can further enhance mechanical properties. The processing parameters directly affect grain growth, densification, and phase distribution, which in turn determine the final hardness and fracture toughness values.Expand Specific Solutions03 Gradient and composite tungsten carbide structures

Gradient and composite structures offer a promising approach to achieving both high hardness and fracture toughness in tungsten carbide materials. These structures feature varying compositions or microstructures across the material, with harder regions where wear resistance is critical and tougher regions where impact resistance is needed. Functionally graded materials (FGMs) with gradual transitions between different compositions can provide optimal performance in applications requiring both properties. Multilayer composites and core-shell structures are also effective design strategies.Expand Specific Solutions04 Nano-structured tungsten carbide for enhanced properties

Nano-structured tungsten carbide materials exhibit exceptional combinations of hardness and fracture toughness. By reducing grain size to the nanoscale, these materials can achieve hardness values significantly higher than conventional tungsten carbide while maintaining good fracture toughness. Various techniques including mechanical alloying, chemical vapor deposition, and solution-based methods are used to produce nano-structured tungsten carbide. The nano-scale features inhibit crack propagation and enhance mechanical properties through mechanisms such as grain boundary strengthening.Expand Specific Solutions05 Testing and measurement methods for hardness and fracture toughness

Accurate testing and measurement methods are essential for characterizing the hardness and fracture toughness of tungsten carbide materials. Vickers and Knoop indentation techniques are commonly used for hardness testing, while fracture toughness is often measured using indentation fracture, single-edge notched beam, or chevron notch methods. Advanced characterization techniques including nanoindentation, acoustic emission monitoring, and in-situ testing provide deeper insights into mechanical behavior. Standardized testing protocols ensure reliable and comparable results across different materials and research groups.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The tungsten carbide hardness and fracture toughness testing market is in a mature growth phase, with an estimated global market size of $1.2-1.5 billion. The competitive landscape features established players from both oil/gas and materials manufacturing sectors. Companies like Kennametal, Ceratizit, and Seco Tools dominate the Western markets, while Chinese firms including Zhuzhou Cemented Carbides Group and Xiamen Tungsten Co. are rapidly expanding their global presence. The technology has reached high maturity in traditional testing methods, but innovation continues in non-destructive and in-situ testing approaches. Research institutions like Hefei Institutes of Physical Science and Yanshan University are collaborating with industry leaders such as Sumitomo Electric and Baker Hughes to develop advanced testing methodologies that combine precision, efficiency, and reliability.

Zhuzhou Cemented Carbides Group Corp. Ltd.

Technical Solution: Zhuzhou Cemented Carbides Group has developed a comprehensive testing methodology for tungsten carbide hardness and fracture toughness that combines multiple testing approaches. Their primary method utilizes Vickers hardness testing with diamond pyramid indenters under controlled loads (typically 10-30 kgf), which creates measurable indentations on polished tungsten carbide surfaces. For fracture toughness assessment, they employ the indentation fracture method where crack propagation from Vickers indentations is measured and analyzed using specialized equations that correlate crack length to fracture toughness values. The company has also pioneered automated optical measurement systems that digitally analyze indentation dimensions and crack patterns with high precision, reducing human error. Their testing protocols include standardized sample preparation procedures involving precise grinding and polishing to achieve mirror-like surfaces with minimal subsurface damage, which is critical for accurate measurements. Additionally, they've developed proprietary calibration standards specifically for tungsten carbide materials with varying cobalt contents to ensure measurement consistency across different material grades.

Strengths: Their integrated testing system provides exceptional measurement repeatability with reported variation under 1% for hardness values. Their automated optical analysis reduces operator bias and increases throughput. Weaknesses: Their indentation fracture method, while practical, provides indirect toughness measurements that may not fully correlate with actual component performance under complex loading conditions. The system requires highly trained operators despite automation.

Seco Tools AB

Technical Solution: Seco Tools has engineered a sophisticated testing methodology for tungsten carbide hardness and fracture toughness that emphasizes application-specific evaluation. Their approach begins with conventional Vickers hardness testing using carefully calibrated equipment with loads ranging from 5-50 kgf depending on the carbide grade being tested. For fracture toughness determination, they employ both the indentation crack length method (using the Palmqvist crack model) and the more rigorous Chevron Notched Beam (CNB) testing for critical applications. Seco's innovation lies in their development of a thermal cycling protocol that tests material properties at both ambient and elevated temperatures (up to 800°C), simulating actual cutting conditions where tungsten carbide tools experience significant temperature fluctuations. Their testing system incorporates high-resolution scanning electron microscopy to analyze fracture surfaces post-testing, providing insights into failure mechanisms and microstructural influences on mechanical properties. Seco has also developed specialized fixtures that allow for in-situ testing of actual tool geometries rather than just standard test specimens, enabling direct correlation between material properties and tool performance. Their quality control system includes regular verification using certified reference materials traceable to national standards institutes, ensuring measurement consistency across global manufacturing facilities.

Strengths: Their thermal cycling protocol provides more realistic assessment of material performance under actual application conditions. The combination of multiple testing methods offers comprehensive material characterization beyond simple hardness numbers. Weaknesses: The sophisticated testing approach requires significant investment in equipment and trained personnel. The thermal cycling tests are time-consuming, limiting throughput for routine quality control applications.

Key Technologies in Tungsten Carbide Property Measurement

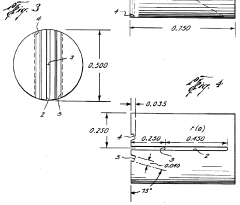

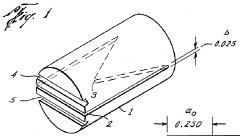

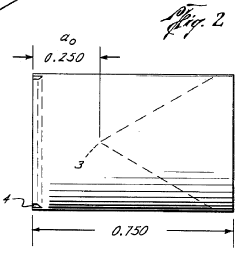

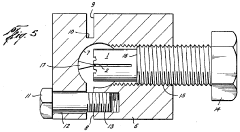

Fracture toughness test method

PatentInactiveUS4090489A

Innovation

- A method involving the preparation of small specimens with thin intersecting slots in a V configuration, where a crack is initiated and arrested, and the peak force required for crack propagation is measured to determine the critical stress intensity factor, using a specialized fixture to minimize uncontrolled crack growth and employing correction factors for machining tolerances.

Cemented carbide containing tungsten carbide and iron alloy binder

PatentInactiveUS20200024702A1

Innovation

- A sintered cemented carbide body is developed using a substantially cobalt-free binder composed of an iron-based alloy, which is uniformly distributed around tungsten carbide particles, achieving a hardness of at least 15 GPa and fracture toughness of at least 11 MPa√m through processes like uniaxial hot pressing, field-assisted sintering technology, and pressureless sintering, utilizing an iron-nickel-zirconium alloy to replace cobalt and enhance mechanical properties.

Quality Control Standards and Certification Requirements

Quality control standards for tungsten carbide hardness and fracture toughness testing are governed by several international organizations, with ASTM International and ISO leading the development of standardized testing methodologies. The primary standards include ASTM B294 for hardness testing of cemented carbides and ISO 28079 for fracture toughness determination. These standards establish precise testing procedures, equipment specifications, and reporting requirements to ensure consistency across the industry.

For hardness testing, the Vickers hardness test (ASTM E92, ISO 6507) is widely accepted, requiring specific indenter geometry, applied loads, and dwell times. The Rockwell hardness test (ASTM E18, ISO 6508) provides an alternative method with its own certification requirements. Both methods mandate regular calibration of testing equipment using certified reference blocks traceable to national standards.

Fracture toughness testing follows standards such as ISO 28079 and ASTM C1421, which detail specimen preparation, testing conditions, and calculation methods. These standards require precise control of loading rates, specimen dimensions, and environmental conditions during testing. The Palmqvist method and the SEPB (Single Edge Precracked Beam) method are commonly specified approaches, each with distinct certification requirements.

Certification bodies like NADCAP (National Aerospace and Defense Contractors Accreditation Program) and A2LA (American Association for Laboratory Accreditation) provide laboratory accreditation for tungsten carbide testing. These certifications verify that testing facilities maintain appropriate quality management systems, employ qualified personnel, and utilize properly calibrated equipment. For aerospace and defense applications, NADCAP certification is often mandatory, while ISO/IEC 17025 accreditation demonstrates technical competence for testing laboratories across various industries.

Material manufacturers must also comply with industry-specific standards such as ISO 9001 for quality management systems and, in some cases, ISO/TS 16949 for automotive applications. These standards require documented procedures for material testing, statistical process control, and continuous improvement of quality processes.

Documentation requirements include detailed test reports with specific information: test method references, equipment details, environmental conditions, sample preparation methods, and measurement uncertainties. Traceability documentation must establish an unbroken chain from the test results to national or international measurement standards, particularly important for critical applications in aerospace, medical devices, and defense sectors.

For hardness testing, the Vickers hardness test (ASTM E92, ISO 6507) is widely accepted, requiring specific indenter geometry, applied loads, and dwell times. The Rockwell hardness test (ASTM E18, ISO 6508) provides an alternative method with its own certification requirements. Both methods mandate regular calibration of testing equipment using certified reference blocks traceable to national standards.

Fracture toughness testing follows standards such as ISO 28079 and ASTM C1421, which detail specimen preparation, testing conditions, and calculation methods. These standards require precise control of loading rates, specimen dimensions, and environmental conditions during testing. The Palmqvist method and the SEPB (Single Edge Precracked Beam) method are commonly specified approaches, each with distinct certification requirements.

Certification bodies like NADCAP (National Aerospace and Defense Contractors Accreditation Program) and A2LA (American Association for Laboratory Accreditation) provide laboratory accreditation for tungsten carbide testing. These certifications verify that testing facilities maintain appropriate quality management systems, employ qualified personnel, and utilize properly calibrated equipment. For aerospace and defense applications, NADCAP certification is often mandatory, while ISO/IEC 17025 accreditation demonstrates technical competence for testing laboratories across various industries.

Material manufacturers must also comply with industry-specific standards such as ISO 9001 for quality management systems and, in some cases, ISO/TS 16949 for automotive applications. These standards require documented procedures for material testing, statistical process control, and continuous improvement of quality processes.

Documentation requirements include detailed test reports with specific information: test method references, equipment details, environmental conditions, sample preparation methods, and measurement uncertainties. Traceability documentation must establish an unbroken chain from the test results to national or international measurement standards, particularly important for critical applications in aerospace, medical devices, and defense sectors.

Industrial Applications and Performance Correlations

Tungsten carbide hardness and fracture toughness measurements have direct implications across numerous industrial applications, with performance correlations that significantly impact product design and material selection decisions. In the mining and drilling industries, tungsten carbide tools with higher hardness values consistently demonstrate superior wear resistance when exposed to abrasive rock formations, extending operational lifespans by up to 40% compared to lower-grade alternatives. However, these applications also reveal that excessive hardness without adequate fracture toughness can lead to catastrophic tool failure under impact loading conditions.

The metal forming industry has established clear correlations between tungsten carbide hardness measurements and die longevity. Manufacturing facilities utilizing dies with hardness values exceeding 1500 HV report tool life improvements of 25-35% when processing high-strength alloys. These performance benefits translate directly to reduced downtime and lower production costs, creating a compelling economic case for precise hardness testing during material selection phases.

Aerospace and automotive sectors leverage tungsten carbide's unique property combinations in critical components where both wear resistance and structural integrity are essential. Engineering teams in these industries have developed proprietary performance matrices that correlate specific hardness-to-toughness ratios with optimal application environments. Components with balanced properties (typically 1400-1600 HV hardness with fracture toughness values of 10-15 MPa·m½) demonstrate optimal performance in high-stress mechanical systems.

The electronics manufacturing industry presents a distinctive application case where micro-hardness testing of tungsten carbide components used in precision assembly equipment shows direct correlation with positioning accuracy and repeatability. Testing data indicates that maintaining hardness variations below 3% across components results in 99.7% assembly precision, a critical factor in advanced semiconductor fabrication.

Medical device manufacturers have established rigorous testing protocols correlating tungsten carbide hardness with biocompatibility and functional longevity in surgical instruments and implantable devices. Research demonstrates that properly characterized tungsten carbide components maintain functional edges approximately 4-6 times longer than stainless steel alternatives in surgical applications, with predictable performance directly linked to verified hardness values.

Cutting tool manufacturers have developed comprehensive performance prediction models based on hardness and fracture toughness measurements. These models enable application-specific grade recommendations that optimize tool life and machining efficiency across diverse workpiece materials. Industry data shows that properly matched tungsten carbide grades can improve productivity by 15-30% while reducing overall tooling costs by up to 25% in high-volume manufacturing operations.

The metal forming industry has established clear correlations between tungsten carbide hardness measurements and die longevity. Manufacturing facilities utilizing dies with hardness values exceeding 1500 HV report tool life improvements of 25-35% when processing high-strength alloys. These performance benefits translate directly to reduced downtime and lower production costs, creating a compelling economic case for precise hardness testing during material selection phases.

Aerospace and automotive sectors leverage tungsten carbide's unique property combinations in critical components where both wear resistance and structural integrity are essential. Engineering teams in these industries have developed proprietary performance matrices that correlate specific hardness-to-toughness ratios with optimal application environments. Components with balanced properties (typically 1400-1600 HV hardness with fracture toughness values of 10-15 MPa·m½) demonstrate optimal performance in high-stress mechanical systems.

The electronics manufacturing industry presents a distinctive application case where micro-hardness testing of tungsten carbide components used in precision assembly equipment shows direct correlation with positioning accuracy and repeatability. Testing data indicates that maintaining hardness variations below 3% across components results in 99.7% assembly precision, a critical factor in advanced semiconductor fabrication.

Medical device manufacturers have established rigorous testing protocols correlating tungsten carbide hardness with biocompatibility and functional longevity in surgical instruments and implantable devices. Research demonstrates that properly characterized tungsten carbide components maintain functional edges approximately 4-6 times longer than stainless steel alternatives in surgical applications, with predictable performance directly linked to verified hardness values.

Cutting tool manufacturers have developed comprehensive performance prediction models based on hardness and fracture toughness measurements. These models enable application-specific grade recommendations that optimize tool life and machining efficiency across diverse workpiece materials. Industry data shows that properly matched tungsten carbide grades can improve productivity by 15-30% while reducing overall tooling costs by up to 25% in high-volume manufacturing operations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!