Carbide Quality Control Protocols: Microstructure, Porosity, And Hardness Tests

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbide Manufacturing Background and Objectives

Carbide materials have been integral to industrial applications for over a century, with significant advancements occurring during the early 20th century when tungsten carbide was first commercially produced. These materials are valued for their exceptional hardness, wear resistance, and thermal stability, making them indispensable in cutting tools, mining equipment, and various high-wear applications. The evolution of carbide manufacturing has been characterized by continuous refinement of powder metallurgy techniques, with particular emphasis on particle size control and sintering processes.

The current landscape of carbide manufacturing encompasses a diverse range of materials including tungsten carbide (WC), titanium carbide (TiC), tantalum carbide (TaC), and various mixed carbides, each offering specific performance characteristics suited to different industrial needs. The manufacturing process typically involves powder preparation, mixing with binder metals (commonly cobalt), pressing, and sintering under controlled conditions. This complex process chain presents numerous opportunities for quality variations that must be rigorously controlled.

Quality control in carbide production has historically focused on macroscopic properties such as dimensional accuracy and surface finish. However, as applications have become more demanding, particularly in aerospace, automotive, and precision machining industries, there has been a shift toward more sophisticated quality assessment methodologies that examine microstructural characteristics, porosity levels, and hardness distributions. This evolution reflects the growing understanding of how these microscopic features directly influence performance and longevity in service conditions.

The primary objective of modern carbide quality control protocols is to establish standardized, reliable, and reproducible testing methodologies that can accurately predict in-service performance. This includes developing non-destructive testing techniques that can be integrated into production lines, enabling real-time quality assessment and reducing waste. Additionally, there is a growing emphasis on correlating microstructural features with mechanical properties to enable more precise tailoring of carbide compositions for specific applications.

Another critical objective is the development of quantitative metrics for porosity assessment, as even microscopic voids can significantly impact carbide performance under high-stress conditions. Similarly, hardness testing protocols are being refined to account for the inherent heterogeneity of carbide microstructures, particularly at the interface between carbide particles and binder phases. These advancements aim to move beyond simple pass/fail criteria toward a more nuanced understanding of quality that can inform continuous improvement in manufacturing processes.

The technological trajectory in this field is moving toward automated inspection systems incorporating machine learning algorithms capable of detecting subtle patterns in microstructural data that may escape human analysis. This represents a paradigm shift from reactive quality control to predictive quality assurance, potentially revolutionizing how carbide materials are manufactured and certified for critical applications.

The current landscape of carbide manufacturing encompasses a diverse range of materials including tungsten carbide (WC), titanium carbide (TiC), tantalum carbide (TaC), and various mixed carbides, each offering specific performance characteristics suited to different industrial needs. The manufacturing process typically involves powder preparation, mixing with binder metals (commonly cobalt), pressing, and sintering under controlled conditions. This complex process chain presents numerous opportunities for quality variations that must be rigorously controlled.

Quality control in carbide production has historically focused on macroscopic properties such as dimensional accuracy and surface finish. However, as applications have become more demanding, particularly in aerospace, automotive, and precision machining industries, there has been a shift toward more sophisticated quality assessment methodologies that examine microstructural characteristics, porosity levels, and hardness distributions. This evolution reflects the growing understanding of how these microscopic features directly influence performance and longevity in service conditions.

The primary objective of modern carbide quality control protocols is to establish standardized, reliable, and reproducible testing methodologies that can accurately predict in-service performance. This includes developing non-destructive testing techniques that can be integrated into production lines, enabling real-time quality assessment and reducing waste. Additionally, there is a growing emphasis on correlating microstructural features with mechanical properties to enable more precise tailoring of carbide compositions for specific applications.

Another critical objective is the development of quantitative metrics for porosity assessment, as even microscopic voids can significantly impact carbide performance under high-stress conditions. Similarly, hardness testing protocols are being refined to account for the inherent heterogeneity of carbide microstructures, particularly at the interface between carbide particles and binder phases. These advancements aim to move beyond simple pass/fail criteria toward a more nuanced understanding of quality that can inform continuous improvement in manufacturing processes.

The technological trajectory in this field is moving toward automated inspection systems incorporating machine learning algorithms capable of detecting subtle patterns in microstructural data that may escape human analysis. This represents a paradigm shift from reactive quality control to predictive quality assurance, potentially revolutionizing how carbide materials are manufactured and certified for critical applications.

Market Requirements for High-Quality Carbide Products

The global market for high-quality carbide products continues to expand, driven by increasing demands across multiple industries including aerospace, automotive, mining, and precision manufacturing. These sectors require carbide components with exceptional performance characteristics, particularly in terms of wear resistance, thermal stability, and mechanical strength under extreme conditions.

Manufacturing companies are increasingly specifying stringent quality requirements for carbide materials, with microstructure uniformity emerging as a primary concern. End users demand products with consistent grain size distribution and minimal structural defects, as these directly impact tool life and performance predictability. Market research indicates that manufacturers are willing to pay premium prices for carbides with certified microstructural quality, as this translates to longer service intervals and reduced downtime costs.

Porosity control has become a critical market requirement, particularly in high-stress applications. The presence of pores in carbide materials can lead to catastrophic failure under load, making porosity testing essential for safety-critical components. Industries such as aerospace and defense specify maximum acceptable porosity levels below 0.02% by volume, while automotive applications typically accept levels up to 0.05%. This differentiation in requirements has created market segments with varying price points based on porosity certification.

Hardness consistency across batches represents another key market demand. Customers increasingly require tight Rockwell hardness tolerances, typically within ±0.5 HRA for premium applications. This consistency ensures predictable wear rates and machining performance. The market has responded with tiered pricing models based on hardness variation guarantees, with top-tier products commanding up to 40% price premiums.

Traceability and documentation of quality control processes have evolved from optional features to market necessities. Customers now routinely demand comprehensive test reports detailing microstructure analysis, porosity measurements, and hardness testing results for each production batch. This trend is particularly pronounced in regulated industries where material certification is mandatory.

Emerging market requirements include non-destructive testing capabilities that allow for 100% inspection rather than statistical sampling. Technologies enabling real-time monitoring of carbide quality during production are gaining significant market traction, with manufacturers willing to invest in advanced quality control systems that reduce rejection rates and improve consistency.

The geographical distribution of demand for high-quality carbide products shows concentration in regions with advanced manufacturing capabilities, particularly Germany, Japan, the United States, and increasingly China, where precision engineering industries are rapidly developing quality standards comparable to traditional market leaders.

Manufacturing companies are increasingly specifying stringent quality requirements for carbide materials, with microstructure uniformity emerging as a primary concern. End users demand products with consistent grain size distribution and minimal structural defects, as these directly impact tool life and performance predictability. Market research indicates that manufacturers are willing to pay premium prices for carbides with certified microstructural quality, as this translates to longer service intervals and reduced downtime costs.

Porosity control has become a critical market requirement, particularly in high-stress applications. The presence of pores in carbide materials can lead to catastrophic failure under load, making porosity testing essential for safety-critical components. Industries such as aerospace and defense specify maximum acceptable porosity levels below 0.02% by volume, while automotive applications typically accept levels up to 0.05%. This differentiation in requirements has created market segments with varying price points based on porosity certification.

Hardness consistency across batches represents another key market demand. Customers increasingly require tight Rockwell hardness tolerances, typically within ±0.5 HRA for premium applications. This consistency ensures predictable wear rates and machining performance. The market has responded with tiered pricing models based on hardness variation guarantees, with top-tier products commanding up to 40% price premiums.

Traceability and documentation of quality control processes have evolved from optional features to market necessities. Customers now routinely demand comprehensive test reports detailing microstructure analysis, porosity measurements, and hardness testing results for each production batch. This trend is particularly pronounced in regulated industries where material certification is mandatory.

Emerging market requirements include non-destructive testing capabilities that allow for 100% inspection rather than statistical sampling. Technologies enabling real-time monitoring of carbide quality during production are gaining significant market traction, with manufacturers willing to invest in advanced quality control systems that reduce rejection rates and improve consistency.

The geographical distribution of demand for high-quality carbide products shows concentration in regions with advanced manufacturing capabilities, particularly Germany, Japan, the United States, and increasingly China, where precision engineering industries are rapidly developing quality standards comparable to traditional market leaders.

Current QC Challenges in Carbide Production

The carbide manufacturing industry faces significant quality control challenges that impact product performance and reliability. Traditional QC methods often struggle to detect subtle microstructural variations that can dramatically affect carbide performance in demanding applications. Current inspection techniques frequently rely on sampling methodologies that may miss critical defects, creating inconsistencies in final product quality.

Microstructure analysis presents particular difficulties as conventional optical microscopy has resolution limitations that prevent accurate assessment of grain size distribution and phase homogeneity in advanced carbide formulations. The industry lacks standardized protocols for quantitative microstructural evaluation, resulting in subjective interpretations and inconsistent quality benchmarks across manufacturers.

Porosity detection remains problematic despite its critical importance to structural integrity. Current methods such as Archimedes density testing provide bulk measurements but fail to characterize pore size distribution, morphology, and spatial arrangement. This limitation is especially concerning for complex-shaped components where localized porosity can create failure points under operational stress.

Hardness testing protocols face challenges in correlation with actual performance metrics. The industry standard Vickers or Rockwell tests may not accurately predict wear resistance or fracture toughness in real-world applications. Furthermore, surface preparation inconsistencies often introduce variability in hardness measurements, complicating quality assurance efforts.

Non-destructive testing (NDT) implementation remains limited in carbide production. While ultrasonic and X-ray techniques show promise, their integration into production lines is hampered by high equipment costs, specialized operator requirements, and interpretation complexities. This creates a significant barrier to comprehensive quality control, particularly for small to medium manufacturers.

Real-time monitoring capabilities are largely absent in current production environments. Most quality assessments occur post-production, preventing proactive process adjustments that could reduce defect rates. The lack of in-line sensing technologies creates inefficiencies through increased scrap rates and production delays when quality issues are discovered late in the manufacturing cycle.

Data integration across different quality parameters represents another significant challenge. Current systems typically evaluate microstructure, porosity, and hardness as isolated characteristics rather than interconnected properties. This siloed approach prevents manufacturers from developing comprehensive quality models that could predict performance based on multiple correlated parameters.

Microstructure analysis presents particular difficulties as conventional optical microscopy has resolution limitations that prevent accurate assessment of grain size distribution and phase homogeneity in advanced carbide formulations. The industry lacks standardized protocols for quantitative microstructural evaluation, resulting in subjective interpretations and inconsistent quality benchmarks across manufacturers.

Porosity detection remains problematic despite its critical importance to structural integrity. Current methods such as Archimedes density testing provide bulk measurements but fail to characterize pore size distribution, morphology, and spatial arrangement. This limitation is especially concerning for complex-shaped components where localized porosity can create failure points under operational stress.

Hardness testing protocols face challenges in correlation with actual performance metrics. The industry standard Vickers or Rockwell tests may not accurately predict wear resistance or fracture toughness in real-world applications. Furthermore, surface preparation inconsistencies often introduce variability in hardness measurements, complicating quality assurance efforts.

Non-destructive testing (NDT) implementation remains limited in carbide production. While ultrasonic and X-ray techniques show promise, their integration into production lines is hampered by high equipment costs, specialized operator requirements, and interpretation complexities. This creates a significant barrier to comprehensive quality control, particularly for small to medium manufacturers.

Real-time monitoring capabilities are largely absent in current production environments. Most quality assessments occur post-production, preventing proactive process adjustments that could reduce defect rates. The lack of in-line sensing technologies creates inefficiencies through increased scrap rates and production delays when quality issues are discovered late in the manufacturing cycle.

Data integration across different quality parameters represents another significant challenge. Current systems typically evaluate microstructure, porosity, and hardness as isolated characteristics rather than interconnected properties. This siloed approach prevents manufacturers from developing comprehensive quality models that could predict performance based on multiple correlated parameters.

Standard Protocols for Carbide Microstructure Analysis

01 Carbide microstructure control for improved hardness

Controlling the carbide microstructure in materials can significantly enhance hardness properties. This involves optimizing the size, distribution, and morphology of carbide particles within the material matrix. Fine, uniformly distributed carbides typically yield higher hardness values compared to coarse, irregularly distributed ones. Heat treatment processes, such as quenching and tempering, can be employed to achieve desired carbide precipitation patterns that maximize hardness while maintaining structural integrity.- Carbide microstructure control for enhanced hardness: Controlling the carbide microstructure in materials can significantly enhance hardness properties. This involves optimizing the size, distribution, and morphology of carbide particles within the material matrix. Fine, uniformly distributed carbides typically result in higher hardness values compared to coarse, irregularly distributed ones. Heat treatment processes such as quenching and tempering can be employed to achieve desired carbide precipitation patterns, which directly influence the material's resistance to deformation and wear.

- Porosity reduction techniques in carbide materials: Various techniques can be employed to reduce porosity in carbide materials, which is crucial for improving mechanical properties including hardness. These methods include hot isostatic pressing, vacuum sintering, and the addition of specific binding agents. Reducing porosity enhances the material density and structural integrity, leading to improved hardness and strength. The relationship between porosity level and mechanical properties is often inversely proportional, with lower porosity generally resulting in higher hardness values.

- Correlation between carbide composition and hardness: The chemical composition of carbides plays a crucial role in determining the hardness of the material. Different types of carbides (tungsten carbide, titanium carbide, chromium carbide, etc.) exhibit varying hardness levels. The stoichiometric ratio of carbon to metal atoms in the carbide structure significantly influences the material's hardness. Additionally, the incorporation of secondary elements or dopants can modify the carbide structure and consequently alter the hardness properties, allowing for customization based on specific application requirements.

- Advanced characterization methods for carbide microstructure and porosity: Advanced characterization techniques are essential for analyzing carbide microstructure and porosity in materials. Methods such as scanning electron microscopy (SEM), X-ray diffraction (XRD), and computed tomography (CT) provide detailed information about carbide size, distribution, and morphology. Porosity can be quantified using techniques like mercury intrusion porosimetry and gas adsorption. These analytical approaches enable researchers to establish correlations between processing parameters, resulting microstructures, and mechanical properties including hardness.

- Novel processing techniques for optimizing carbide-hardness relationships: Innovative processing techniques have been developed to optimize the relationship between carbide structures and hardness properties. These include spark plasma sintering, ultrasonic-assisted manufacturing, and controlled atmosphere heat treatments. Such advanced methods allow for precise control over carbide nucleation and growth, enabling the development of materials with tailored microstructures. By manipulating processing parameters such as temperature, pressure, and cooling rates, manufacturers can achieve specific combinations of carbide characteristics and hardness values suited for particular applications.

02 Porosity reduction techniques in carbide materials

Various methods can be employed to reduce porosity in carbide materials, which directly impacts hardness and mechanical properties. These techniques include optimized sintering parameters, hot isostatic pressing, and the addition of specific binding agents. Reducing porosity enhances density, which typically correlates with improved hardness and wear resistance. Controlled cooling rates during manufacturing also help minimize void formation and ensure more consistent material properties throughout the component.Expand Specific Solutions03 Relationship between carbide composition and hardness

The chemical composition of carbides significantly influences material hardness. Different types of carbides (tungsten carbide, titanium carbide, chromium carbide, etc.) exhibit varying hardness levels. The ratio of carbide to binder material also affects the overall hardness, with higher carbide content generally resulting in harder but potentially more brittle materials. Alloying elements can be added to modify carbide formation and enhance specific properties such as hardness, wear resistance, or toughness.Expand Specific Solutions04 Advanced testing methods for carbide microstructure and hardness

Modern analytical techniques enable precise characterization of carbide microstructure and hardness properties. These include scanning electron microscopy (SEM), X-ray diffraction (XRD), nanoindentation, and advanced hardness testing methods. Correlating microstructural features with hardness measurements allows for better understanding of structure-property relationships. Non-destructive testing approaches can also be employed to evaluate porosity levels and their impact on mechanical properties without damaging the sample.Expand Specific Solutions05 Novel processing techniques for optimizing carbide properties

Innovative manufacturing and processing methods can be employed to simultaneously control carbide microstructure, reduce porosity, and enhance hardness. These include powder metallurgy techniques, spark plasma sintering, additive manufacturing, and surface treatment processes. By carefully controlling processing parameters such as temperature, pressure, and cooling rates, materials with tailored carbide distributions and minimal porosity can be produced. Post-processing treatments may also be applied to further refine microstructure and enhance hardness properties.Expand Specific Solutions

Leading Manufacturers and Testing Equipment Providers

The carbide quality control market is currently in a growth phase, with increasing demand driven by industrial applications requiring high-performance materials. The global market size is expanding steadily, particularly in automotive, steel manufacturing, and energy sectors. Technologically, the field shows varying maturity levels across testing protocols. Leading players like NIPPON STEEL, Sandvik Intellectual Property, and Hyperion Materials & Technologies demonstrate advanced capabilities in microstructure analysis, while companies such as VBN Components and Lyten are pioneering innovative approaches to porosity control. Research institutions including Nanjing University and KIST Corp. are contributing significant advancements in hardness testing methodologies. The competitive landscape features traditional steel manufacturers expanding their quality control capabilities alongside specialized materials technology firms developing proprietary testing protocols.

NIPPON STEEL CORP.

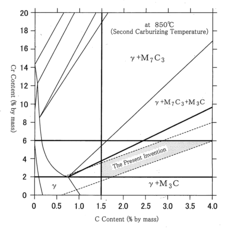

Technical Solution: Nippon Steel has pioneered an integrated carbide quality control protocol focusing on the precise control of carbide precipitation in high-performance steels. Their system employs advanced characterization techniques including field emission scanning electron microscopy (FE-SEM) and transmission electron microscopy (TEM) to analyze carbide morphology, size distribution, and spatial arrangement at nanometer resolution. The company has developed proprietary etching techniques that selectively reveal different carbide types (M23C6, M7C3, MC, etc.) for quantitative analysis. Their protocol incorporates automated image analysis software that quantifies carbide volume fraction, size distribution, and nearest-neighbor distances with high statistical reliability. For porosity assessment, Nippon Steel utilizes X-ray computed tomography with 3D reconstruction capabilities, allowing non-destructive evaluation of internal defects. Their hardness testing methodology combines traditional Rockwell and Vickers measurements with instrumented indentation testing to correlate hardness with other mechanical properties. The company has established a comprehensive database correlating microstructural parameters with processing conditions, enabling predictive modeling of carbide evolution during heat treatment.

Strengths: Exceptional precision in characterizing nanoscale carbide features; comprehensive correlation between processing parameters and microstructural outcomes; advanced non-destructive testing capabilities. Weaknesses: Time-intensive characterization procedures; requires highly specialized equipment; protocol optimization needed for each steel grade.

Daido Steel Co., Ltd.

Technical Solution: Daido Steel has established a comprehensive carbide quality control protocol specifically designed for high-alloy tool steels and powder metallurgy products. Their system employs a combination of optical microscopy, scanning electron microscopy (SEM), and electron backscatter diffraction (EBSD) to characterize carbide type, morphology, size distribution, and crystallographic orientation. The company has developed specialized etching techniques that selectively reveal different carbide types, enabling quantitative analysis of complex microstructures containing multiple carbide species. For porosity assessment, Daido utilizes both conventional metallographic methods and advanced X-ray computed tomography, achieving detection sensitivity for defects down to 5 μm. Their hardness testing methodology incorporates both macro and micro Vickers measurements with statistical process control to ensure consistency across production batches. Notably, Daido has implemented an integrated database system that correlates processing parameters, microstructural features, and mechanical properties, enabling continuous improvement of their manufacturing processes. The company has established specific acceptance criteria for different product categories based on extensive correlation studies between microstructural parameters and in-service performance.

Strengths: Exceptional expertise in characterizing complex carbide structures in high-alloy steels; comprehensive correlation between processing parameters and microstructural outcomes; robust statistical process control implementation. Weaknesses: Protocol optimization required for each steel grade; time-intensive characterization procedures; higher implementation costs for smaller production volumes.

Advanced Techniques for Porosity and Hardness Evaluation

Carburized component and manufacturing method thereof

PatentActiveUS20070246126A1

Innovation

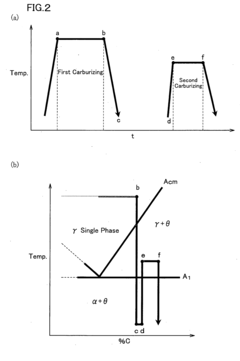

- A carburized component with a steel composition of C: 0.10% to 0.40%, Si: 0.05% to 0.8%, Mn: 0.35% to 1.2%, and Cr: 2.0% to 6.0% is developed, featuring a carburized layer with a grain boundary oxidized layer depth of 1 μm or less and a carbide area ratio of 15% to 60%, utilizing a two-stage carburizing process to produce a high concentration of fine M3C-type carbides, which enhances surface fatigue resistance.

Industry Standards and Certification Requirements

Carbide materials are subject to rigorous industry standards and certification requirements that ensure their quality, reliability, and performance across various applications. The American Society for Testing and Materials (ASTM) has established several key standards specifically for carbide testing, including ASTM B311 for density determination, ASTM B406 for grain size measurement, and ASTM B390 for hardness testing of cemented carbides. These standards provide detailed methodologies and acceptance criteria that manufacturers must adhere to during quality control processes.

The International Organization for Standardization (ISO) complements these with its own comprehensive framework, particularly ISO 4499 series which addresses the metallographic determination of microstructure in cemented carbides. ISO 3878 specifically focuses on hardness testing methods for these materials, establishing globally recognized procedures that facilitate international trade and quality assurance.

In aerospace and defense sectors, additional certification requirements are imposed through standards like AMS-T-21074 and MIL-STD-1916, which mandate statistical sampling plans and more stringent quality control measures for critical components. These sectors often require suppliers to maintain AS9100 certification, which extends ISO 9001 quality management systems with aerospace-specific requirements.

The automotive industry relies on the International Automotive Task Force's IATF 16949 standard, which includes specific provisions for material testing and validation of carbide components used in vehicle manufacturing. This standard emphasizes process capability, measurement system analysis, and continuous improvement methodologies that directly impact carbide quality control protocols.

For medical applications, FDA regulations in the United States and the Medical Device Regulation (MDR) in Europe impose additional requirements on carbide materials used in surgical instruments and implantable devices. These regulations necessitate biocompatibility testing, sterility validation, and comprehensive documentation of material properties.

Certification bodies like TÜV, SGS, and Bureau Veritas provide third-party verification services that validate compliance with these standards. Manufacturers seeking certification must demonstrate consistent adherence to prescribed testing methodologies, maintain calibrated testing equipment, and employ qualified personnel to conduct microstructure, porosity, and hardness tests.

The energy sector, particularly oil and gas exploration, follows NACE (National Association of Corrosion Engineers) standards for carbide components exposed to corrosive environments. These standards specify additional testing requirements for hydrogen embrittlement resistance and stress corrosion cracking susceptibility, which are critical for downhole tool applications.

The International Organization for Standardization (ISO) complements these with its own comprehensive framework, particularly ISO 4499 series which addresses the metallographic determination of microstructure in cemented carbides. ISO 3878 specifically focuses on hardness testing methods for these materials, establishing globally recognized procedures that facilitate international trade and quality assurance.

In aerospace and defense sectors, additional certification requirements are imposed through standards like AMS-T-21074 and MIL-STD-1916, which mandate statistical sampling plans and more stringent quality control measures for critical components. These sectors often require suppliers to maintain AS9100 certification, which extends ISO 9001 quality management systems with aerospace-specific requirements.

The automotive industry relies on the International Automotive Task Force's IATF 16949 standard, which includes specific provisions for material testing and validation of carbide components used in vehicle manufacturing. This standard emphasizes process capability, measurement system analysis, and continuous improvement methodologies that directly impact carbide quality control protocols.

For medical applications, FDA regulations in the United States and the Medical Device Regulation (MDR) in Europe impose additional requirements on carbide materials used in surgical instruments and implantable devices. These regulations necessitate biocompatibility testing, sterility validation, and comprehensive documentation of material properties.

Certification bodies like TÜV, SGS, and Bureau Veritas provide third-party verification services that validate compliance with these standards. Manufacturers seeking certification must demonstrate consistent adherence to prescribed testing methodologies, maintain calibrated testing equipment, and employ qualified personnel to conduct microstructure, porosity, and hardness tests.

The energy sector, particularly oil and gas exploration, follows NACE (National Association of Corrosion Engineers) standards for carbide components exposed to corrosive environments. These standards specify additional testing requirements for hydrogen embrittlement resistance and stress corrosion cracking susceptibility, which are critical for downhole tool applications.

Cost-Benefit Analysis of QC Implementation

Implementing quality control protocols for carbide materials requires significant investment in equipment, personnel training, and operational adjustments. This analysis examines the financial implications of implementing comprehensive QC systems focused on microstructure, porosity, and hardness testing against the potential benefits derived from such investments.

Initial implementation costs for a complete carbide QC system typically range from $150,000 to $500,000, depending on the sophistication of testing equipment selected. High-resolution scanning electron microscopes for microstructure analysis represent the largest capital expenditure, averaging $200,000-$300,000, while porosity measurement systems and hardness testers add approximately $50,000-$100,000 each. Additionally, facility modifications to accommodate sensitive equipment may require $25,000-$75,000.

Recurring operational expenses include calibration services ($5,000-$10,000 annually), consumable materials ($15,000-$30,000 annually), and specialized personnel ($80,000-$120,000 annually for qualified technicians). These ongoing costs typically represent 15-20% of the initial implementation investment on an annual basis.

Against these expenses, manufacturers must weigh tangible benefits. Defect reduction represents the most immediate financial return, with properly implemented QC protocols typically reducing scrap rates by 30-45%. For a medium-sized carbide component manufacturer producing $10 million in annual output, this translates to $300,000-$450,000 in annual savings from reduced material waste and rework requirements.

Customer retention and premium pricing opportunities provide additional value. Companies with documented QC protocols command price premiums of 5-15% in high-precision markets such as aerospace, medical devices, and defense applications. Furthermore, warranty claim reductions of 25-40% directly impact profitability, particularly for manufacturers of high-value carbide components where a single failure can trigger significant financial liability.

The return on investment timeline varies by implementation scale and industry application. Most manufacturers achieve break-even within 18-36 months, with aerospace and medical device suppliers experiencing faster returns (12-24 months) due to higher margins and more stringent customer requirements. Industrial tooling manufacturers typically require 24-48 months to fully recoup investments.

Sensitivity analysis indicates that the most favorable cost-benefit ratios occur when QC implementation coincides with new product introductions or significant production expansions, allowing integration costs to be absorbed into broader capital expenditure programs rather than as standalone investments.

Initial implementation costs for a complete carbide QC system typically range from $150,000 to $500,000, depending on the sophistication of testing equipment selected. High-resolution scanning electron microscopes for microstructure analysis represent the largest capital expenditure, averaging $200,000-$300,000, while porosity measurement systems and hardness testers add approximately $50,000-$100,000 each. Additionally, facility modifications to accommodate sensitive equipment may require $25,000-$75,000.

Recurring operational expenses include calibration services ($5,000-$10,000 annually), consumable materials ($15,000-$30,000 annually), and specialized personnel ($80,000-$120,000 annually for qualified technicians). These ongoing costs typically represent 15-20% of the initial implementation investment on an annual basis.

Against these expenses, manufacturers must weigh tangible benefits. Defect reduction represents the most immediate financial return, with properly implemented QC protocols typically reducing scrap rates by 30-45%. For a medium-sized carbide component manufacturer producing $10 million in annual output, this translates to $300,000-$450,000 in annual savings from reduced material waste and rework requirements.

Customer retention and premium pricing opportunities provide additional value. Companies with documented QC protocols command price premiums of 5-15% in high-precision markets such as aerospace, medical devices, and defense applications. Furthermore, warranty claim reductions of 25-40% directly impact profitability, particularly for manufacturers of high-value carbide components where a single failure can trigger significant financial liability.

The return on investment timeline varies by implementation scale and industry application. Most manufacturers achieve break-even within 18-36 months, with aerospace and medical device suppliers experiencing faster returns (12-24 months) due to higher margins and more stringent customer requirements. Industrial tooling manufacturers typically require 24-48 months to fully recoup investments.

Sensitivity analysis indicates that the most favorable cost-benefit ratios occur when QC implementation coincides with new product introductions or significant production expansions, allowing integration costs to be absorbed into broader capital expenditure programs rather than as standalone investments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!