Tungsten Carbide Grades Explained: Selection For Cutting Tools

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tungsten Carbide Evolution and Performance Objectives

Tungsten carbide has evolved significantly since its initial development in the early 20th century, transforming from a novel material to an essential component in modern cutting tools. The evolution began in 1923 when Karl Schröter patented the process for creating tungsten carbide by combining tungsten and carbon powder through powder metallurgy techniques. This breakthrough laid the foundation for what would become a revolutionary material in manufacturing industries.

The 1930s marked the commercial introduction of tungsten carbide cutting tools, primarily in simple geometries with limited grade options. These early implementations demonstrated superior hardness and wear resistance compared to high-speed steel, though they lacked the toughness and thermal stability required for diverse machining applications.

By the 1950s and 1960s, significant advancements emerged with the introduction of multi-carbide grades incorporating titanium, tantalum, and niobium carbides. These additions enhanced high-temperature performance and chemical stability, expanding tungsten carbide's application range. The development of cobalt as a binding matrix further improved toughness while maintaining hardness.

The 1970s and 1980s witnessed the introduction of coating technologies, particularly chemical vapor deposition (CVD) and physical vapor deposition (PVD) methods. These innovations allowed manufacturers to apply thin layers of titanium nitride, titanium carbonitride, and aluminum oxide to carbide substrates, dramatically improving wear resistance and extending tool life.

Recent decades have seen the refinement of nano-grain carbides, offering an optimal balance of hardness and toughness through precise control of grain size at the nanometer scale. Gradient structures with varying cobalt content from core to surface have also emerged, providing both toughness and wear resistance in a single tool.

The performance objectives for modern tungsten carbide cutting tools focus on several key parameters. Extended tool life remains paramount, with manufacturers seeking grades that maintain cutting edge integrity through thousands of machining cycles. Increased cutting speeds and feeds are essential for productivity improvements, requiring carbide grades that maintain stability under higher thermal and mechanical stresses.

Versatility across workpiece materials represents another critical objective, as manufacturers seek to reduce tooling inventory by developing grades capable of effectively machining multiple material types. Sustainability considerations have also gained prominence, with research directed toward reducing cobalt content while maintaining performance, and developing recycling processes to recover valuable elements from spent tools.

The future trajectory aims toward "smart" carbide tools with integrated sensors for real-time performance monitoring, and further refinement of multi-layer coating architectures to address specific machining challenges. These evolutionary paths reflect the ongoing pursuit of optimizing the balance between hardness, toughness, and thermal stability in tungsten carbide cutting tools.

The 1930s marked the commercial introduction of tungsten carbide cutting tools, primarily in simple geometries with limited grade options. These early implementations demonstrated superior hardness and wear resistance compared to high-speed steel, though they lacked the toughness and thermal stability required for diverse machining applications.

By the 1950s and 1960s, significant advancements emerged with the introduction of multi-carbide grades incorporating titanium, tantalum, and niobium carbides. These additions enhanced high-temperature performance and chemical stability, expanding tungsten carbide's application range. The development of cobalt as a binding matrix further improved toughness while maintaining hardness.

The 1970s and 1980s witnessed the introduction of coating technologies, particularly chemical vapor deposition (CVD) and physical vapor deposition (PVD) methods. These innovations allowed manufacturers to apply thin layers of titanium nitride, titanium carbonitride, and aluminum oxide to carbide substrates, dramatically improving wear resistance and extending tool life.

Recent decades have seen the refinement of nano-grain carbides, offering an optimal balance of hardness and toughness through precise control of grain size at the nanometer scale. Gradient structures with varying cobalt content from core to surface have also emerged, providing both toughness and wear resistance in a single tool.

The performance objectives for modern tungsten carbide cutting tools focus on several key parameters. Extended tool life remains paramount, with manufacturers seeking grades that maintain cutting edge integrity through thousands of machining cycles. Increased cutting speeds and feeds are essential for productivity improvements, requiring carbide grades that maintain stability under higher thermal and mechanical stresses.

Versatility across workpiece materials represents another critical objective, as manufacturers seek to reduce tooling inventory by developing grades capable of effectively machining multiple material types. Sustainability considerations have also gained prominence, with research directed toward reducing cobalt content while maintaining performance, and developing recycling processes to recover valuable elements from spent tools.

The future trajectory aims toward "smart" carbide tools with integrated sensors for real-time performance monitoring, and further refinement of multi-layer coating architectures to address specific machining challenges. These evolutionary paths reflect the ongoing pursuit of optimizing the balance between hardness, toughness, and thermal stability in tungsten carbide cutting tools.

Market Analysis of Carbide Cutting Tool Applications

The global carbide cutting tool market has demonstrated robust growth, reaching approximately $7.5 billion in 2022 and projected to expand at a CAGR of 6.8% through 2028. This growth is primarily driven by increasing demand across automotive, aerospace, and general manufacturing sectors, where precision machining requirements continue to rise with the advancement of complex component designs.

Tungsten carbide tools dominate the market with over 70% share due to their superior hardness, wear resistance, and thermal stability compared to high-speed steel alternatives. Within the carbide tool segment, coated carbide tools represent the fastest-growing category, expanding at nearly 8% annually as manufacturers seek enhanced performance and tool life.

Regionally, Asia-Pacific leads market consumption, accounting for approximately 42% of global demand, with China and India serving as primary growth engines due to rapid industrialization and manufacturing expansion. North America and Europe follow with 25% and 22% market shares respectively, where demand is primarily driven by high-precision industries including medical devices, aerospace, and automotive components manufacturing.

Application-wise, turning operations constitute the largest segment at 32% of the market, followed by milling (28%), drilling (22%), and other specialized applications. The automotive sector remains the largest end-user, consuming nearly 35% of all carbide cutting tools, followed by aerospace (18%) and general engineering (15%).

Market trends indicate increasing adoption of micro-grain carbide grades for high-precision applications, with grades containing cobalt percentages between 6-12% showing the strongest growth trajectory. Additionally, there is rising demand for specialized grades optimized for difficult-to-machine materials such as titanium alloys, Inconel, and hardened steels above 45 HRC.

Price sensitivity varies significantly by region and application, with high-performance grades commanding premiums of 30-50% over standard grades. However, total cost of ownership calculations increasingly favor premium grades due to their extended tool life and reduced machine downtime, particularly in high-volume production environments.

The market exhibits moderate fragmentation with the top five manufacturers controlling approximately 45% of global market share. Strategic partnerships between cutting tool manufacturers and machine tool producers are becoming increasingly common, creating integrated machining solutions optimized for specific materials and applications.

Tungsten carbide tools dominate the market with over 70% share due to their superior hardness, wear resistance, and thermal stability compared to high-speed steel alternatives. Within the carbide tool segment, coated carbide tools represent the fastest-growing category, expanding at nearly 8% annually as manufacturers seek enhanced performance and tool life.

Regionally, Asia-Pacific leads market consumption, accounting for approximately 42% of global demand, with China and India serving as primary growth engines due to rapid industrialization and manufacturing expansion. North America and Europe follow with 25% and 22% market shares respectively, where demand is primarily driven by high-precision industries including medical devices, aerospace, and automotive components manufacturing.

Application-wise, turning operations constitute the largest segment at 32% of the market, followed by milling (28%), drilling (22%), and other specialized applications. The automotive sector remains the largest end-user, consuming nearly 35% of all carbide cutting tools, followed by aerospace (18%) and general engineering (15%).

Market trends indicate increasing adoption of micro-grain carbide grades for high-precision applications, with grades containing cobalt percentages between 6-12% showing the strongest growth trajectory. Additionally, there is rising demand for specialized grades optimized for difficult-to-machine materials such as titanium alloys, Inconel, and hardened steels above 45 HRC.

Price sensitivity varies significantly by region and application, with high-performance grades commanding premiums of 30-50% over standard grades. However, total cost of ownership calculations increasingly favor premium grades due to their extended tool life and reduced machine downtime, particularly in high-volume production environments.

The market exhibits moderate fragmentation with the top five manufacturers controlling approximately 45% of global market share. Strategic partnerships between cutting tool manufacturers and machine tool producers are becoming increasingly common, creating integrated machining solutions optimized for specific materials and applications.

Current Tungsten Carbide Grade Landscape and Limitations

The global tungsten carbide grade landscape is characterized by a diverse array of formulations tailored to specific cutting applications. Currently, the ISO classification system divides carbide grades into P, M, K, N, S, and H categories, each optimized for different workpiece materials. Within these categories, manufacturers have developed hundreds of proprietary grades with varying cobalt binder percentages (typically 3-12%) and grain sizes (nano, submicron, fine, medium, and coarse).

The market is dominated by established players like Sandvik Coromant, Kennametal, Mitsubishi Materials, and Iscar, who continuously refine their grade offerings. Recent advancements have focused on developing grades with enhanced wear resistance through nano-grain structures and specialized coatings, particularly TiAlN, AlCrN, and diamond coatings for demanding applications.

Despite significant progress, current tungsten carbide grades face several limitations. The fundamental trade-off between hardness and toughness remains a persistent challenge. Grades optimized for wear resistance typically sacrifice fracture toughness, making them susceptible to chipping and catastrophic failure under interrupted cutting conditions. Conversely, tougher grades with higher cobalt content demonstrate reduced wear resistance and tool life in continuous cutting operations.

Thermal stability presents another significant limitation. Most conventional grades experience rapid performance degradation at temperatures exceeding 800°C, restricting their application in high-speed machining of difficult-to-cut materials like titanium alloys and nickel-based superalloys. This limitation necessitates reduced cutting speeds and productivity when machining these increasingly important aerospace and medical materials.

The environmental and supply chain concerns surrounding tungsten carbide production constitute growing limitations. Tungsten is classified as a conflict mineral with concentrated supply chains primarily in China, creating geopolitical vulnerabilities. Additionally, the energy-intensive production process and use of cobalt (another critical material) raise sustainability questions as industries face increasing pressure to reduce environmental footprints.

Cost factors also limit widespread adoption of premium carbide grades. Advanced grades with specialized coatings and optimized microstructures command significant price premiums, creating barriers for small and medium manufacturers. This cost differential drives continued use of suboptimal grades in many applications, resulting in reduced productivity and higher overall machining costs.

The market is dominated by established players like Sandvik Coromant, Kennametal, Mitsubishi Materials, and Iscar, who continuously refine their grade offerings. Recent advancements have focused on developing grades with enhanced wear resistance through nano-grain structures and specialized coatings, particularly TiAlN, AlCrN, and diamond coatings for demanding applications.

Despite significant progress, current tungsten carbide grades face several limitations. The fundamental trade-off between hardness and toughness remains a persistent challenge. Grades optimized for wear resistance typically sacrifice fracture toughness, making them susceptible to chipping and catastrophic failure under interrupted cutting conditions. Conversely, tougher grades with higher cobalt content demonstrate reduced wear resistance and tool life in continuous cutting operations.

Thermal stability presents another significant limitation. Most conventional grades experience rapid performance degradation at temperatures exceeding 800°C, restricting their application in high-speed machining of difficult-to-cut materials like titanium alloys and nickel-based superalloys. This limitation necessitates reduced cutting speeds and productivity when machining these increasingly important aerospace and medical materials.

The environmental and supply chain concerns surrounding tungsten carbide production constitute growing limitations. Tungsten is classified as a conflict mineral with concentrated supply chains primarily in China, creating geopolitical vulnerabilities. Additionally, the energy-intensive production process and use of cobalt (another critical material) raise sustainability questions as industries face increasing pressure to reduce environmental footprints.

Cost factors also limit widespread adoption of premium carbide grades. Advanced grades with specialized coatings and optimized microstructures command significant price premiums, creating barriers for small and medium manufacturers. This cost differential drives continued use of suboptimal grades in many applications, resulting in reduced productivity and higher overall machining costs.

Grade Classification Systems and Selection Criteria

01 Composition and manufacturing of tungsten carbide grades

Various tungsten carbide grades can be manufactured with different compositions to achieve specific properties. The manufacturing process typically involves mixing tungsten carbide powder with a binder material, such as cobalt, and then sintering the mixture at high temperatures. The ratio of tungsten carbide to binder, as well as the grain size of the tungsten carbide particles, can be adjusted to create different grades with varying hardness, toughness, and wear resistance.- Composition and manufacturing of tungsten carbide grades: Different tungsten carbide grades are created through variations in composition and manufacturing processes. These grades typically consist of tungsten carbide particles in a cobalt binder matrix. The manufacturing process involves powder metallurgy techniques including mixing, pressing, and sintering. The ratio of tungsten carbide to cobalt, particle size distribution, and sintering conditions significantly affect the final properties of the material, allowing for customization of hardness, toughness, and wear resistance for specific applications.

- Specialized tungsten carbide grades for cutting tools: Specialized tungsten carbide grades have been developed specifically for cutting tool applications. These grades often incorporate additional elements such as titanium, tantalum, or niobium carbides to enhance performance characteristics. Fine-grained carbide structures provide improved edge retention and wear resistance in high-speed machining operations. Some cutting tool grades feature gradient structures or specialized coatings to optimize the balance between toughness at the core and wear resistance at the surface, extending tool life in demanding cutting applications.

- Wear-resistant tungsten carbide grades for mining and drilling: Tungsten carbide grades for mining and drilling applications are formulated to withstand extreme abrasion, impact, and corrosive environments. These grades typically feature higher cobalt content (8-15%) to provide enhanced toughness needed for impact resistance. The tungsten carbide grain size is carefully controlled to optimize wear resistance while maintaining sufficient fracture toughness. Some specialized mining grades incorporate corrosion-resistant binders or surface treatments to withstand exposure to aggressive chemicals and moisture encountered in mining operations.

- Nano-structured and ultra-fine tungsten carbide grades: Advanced nano-structured and ultra-fine tungsten carbide grades represent cutting-edge developments in carbide technology. These grades feature extremely fine tungsten carbide grain sizes (below 0.5 microns) that provide exceptional hardness while maintaining adequate toughness. The manufacturing of these grades requires specialized processing techniques to control grain growth during sintering. Nano-structured grades offer superior wear resistance, improved thermal shock resistance, and enhanced performance in high-precision applications such as micro-drilling and fine finishing operations.

- Tungsten carbide grades with alternative binders: Research has focused on developing tungsten carbide grades with alternative binders beyond traditional cobalt. These alternative binders include nickel, iron, chromium, or combinations thereof, which can provide specific advantages such as improved corrosion resistance or reduced cost. Some specialized grades utilize ceramic binders or create cermet structures to achieve unique property combinations. These alternative binder systems allow for tungsten carbide grades that can operate in environments where traditional cobalt-bonded grades would deteriorate, such as in highly acidic conditions or extreme temperatures.

02 Wear-resistant tungsten carbide grades for cutting tools

Specialized tungsten carbide grades have been developed specifically for cutting tools that require exceptional wear resistance. These grades typically contain higher percentages of tungsten carbide and may include additional elements such as titanium, tantalum, or niobium carbides to enhance their performance. The microstructure of these grades is carefully controlled to provide the optimal balance between hardness and toughness needed for cutting applications in various materials including metals, wood, and composites.Expand Specific Solutions03 Corrosion-resistant tungsten carbide grades

Certain tungsten carbide grades are formulated to provide enhanced corrosion resistance for applications in aggressive environments. These grades may incorporate specific binder compositions or protective coatings to prevent degradation when exposed to acids, bases, or other corrosive substances. The corrosion resistance can be achieved by modifying the binder phase or by adding elements that form protective oxide layers on the surface of the material.Expand Specific Solutions04 Fine-grained tungsten carbide grades for precision applications

Fine-grained tungsten carbide grades feature smaller carbide particles, typically less than 1 micron in size, which provide enhanced surface finish and edge retention in precision applications. These grades offer superior hardness while maintaining adequate toughness for applications requiring dimensional accuracy and fine detail. The manufacturing process for these grades requires careful control of grain growth during sintering to maintain the fine microstructure that gives these materials their unique properties.Expand Specific Solutions05 Gradient and composite tungsten carbide grades

Advanced tungsten carbide grades with gradient or composite structures combine different compositions or microstructures within a single component to optimize performance. These grades may feature a harder outer layer for wear resistance with a tougher core for impact resistance, or they may incorporate zones with different carbide grain sizes or binder contents. The gradient structure can be achieved through various manufacturing techniques including functionally graded sintering, dual-property sintering, or post-treatment processes that modify the surface properties.Expand Specific Solutions

Leading Manufacturers in Carbide Cutting Tool Industry

The tungsten carbide cutting tools market is in a mature growth phase, characterized by established technologies and steady demand across manufacturing sectors. The global market size is estimated at approximately $5-6 billion, with projected annual growth of 5-7% driven by industrial automation and precision machining requirements. Leading players include established multinational corporations like Mitsubishi Materials, Kennametal, and Sandvik, who dominate through extensive R&D capabilities and global distribution networks. Asian manufacturers, particularly Japanese firms such as Sumitomo Electric and Kyocera, have achieved technological parity with Western counterparts. The technology has reached high maturity with innovations now focused on specialized coatings, micro-grain structures, and application-specific grades rather than fundamental material breakthroughs.

Kennametal, Inc.

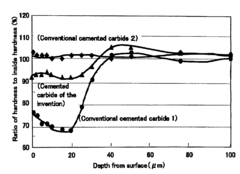

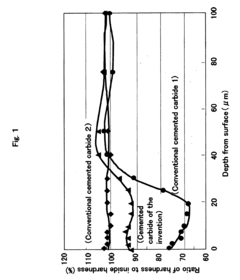

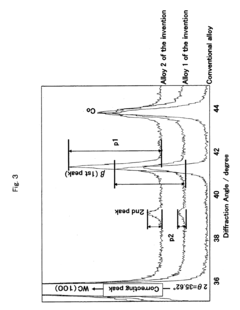

Technical Solution: Kennametal has pioneered the KenTIP FS modular drill system utilizing their proprietary KCP40 tungsten carbide grade, which features a 10% cobalt binder with specialized grain growth inhibitors to maintain submicron grain structure (average 0.5-0.7 μm). Their Beyond series of carbide grades incorporates post-sintering treatments that create a cobalt-enriched surface layer approximately 5-10 μm deep, enhancing edge toughness while maintaining core hardness. Kennametal's KCPK30 grade employs a multi-modal grain size distribution with both fine (0.3-0.5 μm) and ultra-fine (0.1-0.3 μm) WC particles, optimizing both abrasion resistance and impact strength. Their PVD coating technology utilizes ALPHATEK surface treatment prior to coating deposition, which removes surface defects and creates an optimal interface for coating adhesion, reducing delamination by up to 40% in interrupted cutting applications[2][5].

Strengths: Extensive application-specific grade development; strong performance in difficult-to-machine materials; innovative substrate treatments enhancing both wear resistance and toughness. Weaknesses: Complex grade naming system can be confusing for users; some specialized grades have limited cross-platform compatibility; higher cost compared to standard carbide offerings.

Kyocera Corp.

Technical Solution: Kyocera has developed the MEG series of tungsten carbide grades utilizing their proprietary "Micro-Grain Control" technology, which maintains an ultra-fine grain structure (0.3-0.5 μm) through specialized sintering additives that inhibit grain growth during consolidation. Their CA5 coating technology applies a unique Al-rich outer layer approximately 1-2 μm thick over a conventional TiCN base layer, creating a thermal barrier that reduces heat transfer to the substrate by up to 30%. Kyocera's PR1535 grade incorporates their "Tough-Edge Technology" which creates a gradient structure in the peripheral 15-20 μm of the cutting edge, with slightly higher cobalt content (8-10%) compared to the core (6-8%), enhancing edge strength without compromising wear resistance. Their latest innovation includes the MFH series with specialized ruthenium additions (0.3-0.5% by weight) to the cobalt binder, significantly improving high-temperature stability and resistance to plastic deformation under extreme cutting conditions[7][9].

Strengths: Excellent thermal stability in high-speed applications; superior edge retention in interrupted cutting; advanced microstructure control for optimized performance. Weaknesses: More limited grade selection compared to some competitors; higher cost for specialized grades; less market presence in some regions compared to larger competitors.

Key Innovations in Tungsten Carbide Composition

Cutting elements with increased toughness and thermal fatigue resistance for drilling applications

PatentInactiveUS20080245576A1

Innovation

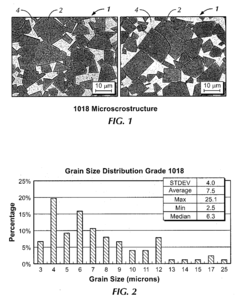

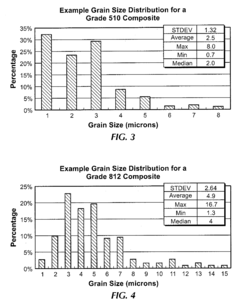

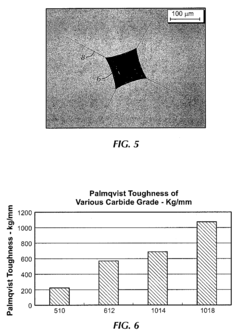

- Development of composite materials with coarse grains and higher binder content (at least 18% by weight) for cutting elements, providing increased fracture toughness and thermal fatigue resistance, such as tungsten carbide/cobalt (WC/Co) systems with specific grain sizes and binder compositions, like Grade 1018, which exhibit enhanced Rockwell A hardness, Palmqvist toughness, and wear resistance.

Cemented carbide and cutting tool

PatentInactiveUS6797369B2

Innovation

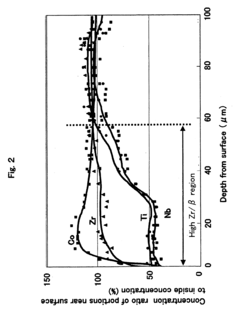

- A cemented carbide composition with controlled iron and chromium content, a surface region optimized with Zr and Nb solid solution phases, and a binder phase ratio, along with a hard coating, to enhance toughness, fracture resistance, and wear resistance, while maintaining high hardness and thermal conductivity.

Sustainability Challenges in Tungsten Carbide Production

The production of tungsten carbide faces significant sustainability challenges that demand industry-wide attention. The extraction of tungsten, primarily from wolframite and scheelite ores, involves energy-intensive mining operations that contribute substantially to environmental degradation. These processes generate considerable waste material, requiring extensive land use and often resulting in habitat destruction. Additionally, the chemical processes used to extract tungsten from its ores frequently involve hazardous substances that pose risks to both environmental and human health.

Water consumption represents another critical sustainability concern in tungsten carbide production. The manufacturing process requires substantial volumes of water for cooling, cleaning, and processing operations. In regions where water scarcity is prevalent, this intensive usage creates competition with agricultural and community needs, potentially exacerbating local resource tensions.

Carbon emissions present perhaps the most pressing sustainability challenge. The high-temperature sintering processes necessary for tungsten carbide production demand enormous energy inputs, typically derived from fossil fuel sources. These processes operate at temperatures exceeding 1400°C, resulting in substantial carbon footprints that contribute to global climate change concerns.

The cobalt binder commonly used in tungsten carbide cutting tools introduces additional sustainability complications. Cobalt mining is associated with severe human rights concerns, particularly in the Democratic Republic of Congo, where child labor and unsafe working conditions have been documented. Furthermore, cobalt presents toxicity risks throughout the production lifecycle and during disposal phases.

Waste management challenges extend throughout the tungsten carbide lifecycle. The production process generates various waste streams containing heavy metals and other contaminants that require specialized disposal procedures. End-of-life management for tungsten carbide tools remains problematic, as recycling technologies, while improving, still face efficiency limitations and economic barriers.

Regulatory pressures are intensifying globally, with legislation like the EU's REACH regulations and conflict mineral reporting requirements imposing stricter controls on tungsten carbide production. These regulations aim to address both environmental impacts and social concerns associated with raw material sourcing, compelling manufacturers to develop more sustainable practices.

Industry responses include developing alternative binder materials to reduce cobalt dependence, implementing closed-loop recycling systems, and exploring energy efficiency improvements. Some manufacturers are pioneering near-net-shape manufacturing techniques that minimize material waste and reduce energy requirements during production.

Water consumption represents another critical sustainability concern in tungsten carbide production. The manufacturing process requires substantial volumes of water for cooling, cleaning, and processing operations. In regions where water scarcity is prevalent, this intensive usage creates competition with agricultural and community needs, potentially exacerbating local resource tensions.

Carbon emissions present perhaps the most pressing sustainability challenge. The high-temperature sintering processes necessary for tungsten carbide production demand enormous energy inputs, typically derived from fossil fuel sources. These processes operate at temperatures exceeding 1400°C, resulting in substantial carbon footprints that contribute to global climate change concerns.

The cobalt binder commonly used in tungsten carbide cutting tools introduces additional sustainability complications. Cobalt mining is associated with severe human rights concerns, particularly in the Democratic Republic of Congo, where child labor and unsafe working conditions have been documented. Furthermore, cobalt presents toxicity risks throughout the production lifecycle and during disposal phases.

Waste management challenges extend throughout the tungsten carbide lifecycle. The production process generates various waste streams containing heavy metals and other contaminants that require specialized disposal procedures. End-of-life management for tungsten carbide tools remains problematic, as recycling technologies, while improving, still face efficiency limitations and economic barriers.

Regulatory pressures are intensifying globally, with legislation like the EU's REACH regulations and conflict mineral reporting requirements imposing stricter controls on tungsten carbide production. These regulations aim to address both environmental impacts and social concerns associated with raw material sourcing, compelling manufacturers to develop more sustainable practices.

Industry responses include developing alternative binder materials to reduce cobalt dependence, implementing closed-loop recycling systems, and exploring energy efficiency improvements. Some manufacturers are pioneering near-net-shape manufacturing techniques that minimize material waste and reduce energy requirements during production.

Application-Specific Grade Optimization Strategies

Optimizing tungsten carbide grade selection requires a strategic approach tailored to specific applications. In cutting tool applications, the optimization process begins with a thorough analysis of the workpiece material properties, including hardness, abrasiveness, and thermal conductivity. These characteristics directly influence the required balance between wear resistance and toughness in the selected carbide grade.

For high-speed machining of steel components, grades with moderate cobalt content (6-10%) and fine grain structure provide an optimal balance of heat resistance and edge stability. The addition of titanium, tantalum, and niobium carbides enhances performance by forming a stable thermal barrier coating during high-temperature operations, preventing premature tool failure.

When machining cast iron, optimization strategies shift toward grades with higher tungsten content and reduced cobalt percentage (typically 5-8%), as these materials require enhanced wear resistance rather than shock absorption. The incorporation of chromium carbide in these specialized grades provides additional resistance against the abrasive particles commonly found in cast iron materials.

For non-ferrous material machining, particularly aluminum and copper alloys, grade optimization focuses on reducing built-up edge formation. This is achieved by selecting grades with polished surfaces and specialized coatings such as diamond-like carbon (DLC) or titanium diboride. The underlying carbide substrate typically features medium grain size with moderate cobalt content (8-12%) to maintain edge sharpness.

Aerospace applications present unique challenges requiring grades optimized for heat-resistant superalloys. These specialized grades incorporate ruthenium and rhenium additives to stabilize the carbide structure at extreme temperatures. The cobalt binder phase is often modified with nickel and chromium to enhance oxidation resistance during high-temperature cutting operations.

Micro-machining applications demand ultra-fine grained carbide grades (grain size <0.5μm) with precisely controlled cobalt distribution. The optimization strategy focuses on maintaining consistent grain structure throughout the tool to prevent preferential wear patterns and ensure dimensional accuracy in microscale features.

Multi-material machining environments benefit from gradient carbide structures, where the composition transitions from a tough core to a wear-resistant surface. This optimization approach allows a single tool to effectively process varying materials without compromising performance or requiring frequent tool changes.

For high-speed machining of steel components, grades with moderate cobalt content (6-10%) and fine grain structure provide an optimal balance of heat resistance and edge stability. The addition of titanium, tantalum, and niobium carbides enhances performance by forming a stable thermal barrier coating during high-temperature operations, preventing premature tool failure.

When machining cast iron, optimization strategies shift toward grades with higher tungsten content and reduced cobalt percentage (typically 5-8%), as these materials require enhanced wear resistance rather than shock absorption. The incorporation of chromium carbide in these specialized grades provides additional resistance against the abrasive particles commonly found in cast iron materials.

For non-ferrous material machining, particularly aluminum and copper alloys, grade optimization focuses on reducing built-up edge formation. This is achieved by selecting grades with polished surfaces and specialized coatings such as diamond-like carbon (DLC) or titanium diboride. The underlying carbide substrate typically features medium grain size with moderate cobalt content (8-12%) to maintain edge sharpness.

Aerospace applications present unique challenges requiring grades optimized for heat-resistant superalloys. These specialized grades incorporate ruthenium and rhenium additives to stabilize the carbide structure at extreme temperatures. The cobalt binder phase is often modified with nickel and chromium to enhance oxidation resistance during high-temperature cutting operations.

Micro-machining applications demand ultra-fine grained carbide grades (grain size <0.5μm) with precisely controlled cobalt distribution. The optimization strategy focuses on maintaining consistent grain structure throughout the tool to prevent preferential wear patterns and ensure dimensional accuracy in microscale features.

Multi-material machining environments benefit from gradient carbide structures, where the composition transitions from a tough core to a wear-resistant surface. This optimization approach allows a single tool to effectively process varying materials without compromising performance or requiring frequent tool changes.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!