Tungsten Carbide Coating Options: TiN, AlTiN, And DLC Compared

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tungsten Carbide Coating Evolution and Objectives

Tungsten carbide coatings have evolved significantly over the past five decades, transforming from basic single-layer applications to sophisticated multi-layered systems with enhanced performance characteristics. The journey began in the 1970s with simple TiN (Titanium Nitride) coatings applied to tungsten carbide substrates, primarily for cutting tools. These early coatings offered modest improvements in wear resistance and tool life but suffered from limited temperature stability and oxidation resistance.

The 1980s witnessed the emergence of TiCN (Titanium Carbonitride) coatings, which combined the hardness of TiC with the toughness of TiN. This period marked the beginning of understanding how coating composition directly influences performance characteristics in various industrial applications. By the 1990s, AlTiN (Aluminum Titanium Nitride) coatings emerged as a significant advancement, offering superior oxidation resistance at elevated temperatures compared to their predecessors.

The early 2000s brought about a revolution with the commercial viability of DLC (Diamond-Like Carbon) coatings for tungsten carbide substrates. These coatings provided unprecedented hardness values while maintaining low friction coefficients, opening new possibilities for applications in demanding environments. Simultaneously, researchers began developing nano-composite coatings that combined different materials at the nanoscale to achieve properties unattainable with single-material coatings.

Current technological objectives in tungsten carbide coating development focus on several key areas. First, enhancing coating adhesion to tungsten carbide substrates remains crucial, as delamination continues to be a primary failure mode in many applications. Second, improving coating toughness without sacrificing hardness represents a significant challenge that researchers are addressing through gradient compositions and multi-layered architectures.

Another critical objective involves developing coatings with self-lubricating properties to reduce friction in dry machining operations, thereby extending tool life and improving surface finish quality. Additionally, researchers aim to create environmentally friendly coating processes that eliminate toxic chemicals while maintaining or improving coating performance characteristics.

The ultimate goal in this technological evolution is to develop "smart" coatings for tungsten carbide that can adapt to changing operational conditions. These adaptive coatings would ideally respond to temperature fluctuations, varying loads, and different work materials by altering their properties in real-time. Such advancement would represent a paradigm shift from passive protection to active performance enhancement, potentially revolutionizing industries ranging from aerospace manufacturing to energy production.

The 1980s witnessed the emergence of TiCN (Titanium Carbonitride) coatings, which combined the hardness of TiC with the toughness of TiN. This period marked the beginning of understanding how coating composition directly influences performance characteristics in various industrial applications. By the 1990s, AlTiN (Aluminum Titanium Nitride) coatings emerged as a significant advancement, offering superior oxidation resistance at elevated temperatures compared to their predecessors.

The early 2000s brought about a revolution with the commercial viability of DLC (Diamond-Like Carbon) coatings for tungsten carbide substrates. These coatings provided unprecedented hardness values while maintaining low friction coefficients, opening new possibilities for applications in demanding environments. Simultaneously, researchers began developing nano-composite coatings that combined different materials at the nanoscale to achieve properties unattainable with single-material coatings.

Current technological objectives in tungsten carbide coating development focus on several key areas. First, enhancing coating adhesion to tungsten carbide substrates remains crucial, as delamination continues to be a primary failure mode in many applications. Second, improving coating toughness without sacrificing hardness represents a significant challenge that researchers are addressing through gradient compositions and multi-layered architectures.

Another critical objective involves developing coatings with self-lubricating properties to reduce friction in dry machining operations, thereby extending tool life and improving surface finish quality. Additionally, researchers aim to create environmentally friendly coating processes that eliminate toxic chemicals while maintaining or improving coating performance characteristics.

The ultimate goal in this technological evolution is to develop "smart" coatings for tungsten carbide that can adapt to changing operational conditions. These adaptive coatings would ideally respond to temperature fluctuations, varying loads, and different work materials by altering their properties in real-time. Such advancement would represent a paradigm shift from passive protection to active performance enhancement, potentially revolutionizing industries ranging from aerospace manufacturing to energy production.

Market Applications and Demand Analysis for Advanced Coatings

The global market for advanced coatings has experienced significant growth in recent years, driven by increasing demands across multiple industries for enhanced material performance. Tungsten carbide coatings, particularly TiN (Titanium Nitride), AlTiN (Aluminum Titanium Nitride), and DLC (Diamond-Like Carbon), have emerged as critical solutions for applications requiring superior wear resistance, hardness, and thermal stability.

The cutting tool industry represents the largest market segment for these advanced coatings, accounting for approximately 35% of the total market share. Within this sector, the demand for AlTiN coatings has grown substantially due to their exceptional performance in high-speed machining operations and dry cutting applications. The automotive manufacturing sector has increasingly adopted these coatings to improve tool life by up to 300% when machining hardened steels and titanium alloys.

Aerospace and defense industries constitute another significant market segment, where the extreme operating conditions necessitate materials with superior thermal stability and wear resistance. TiN coatings have established a strong presence in this sector, particularly for components subjected to moderate temperatures and wear conditions. However, AlTiN is gaining market share due to its superior oxidation resistance at elevated temperatures up to 900°C.

The medical device manufacturing sector has shown remarkable growth in demand for DLC coatings, driven by their biocompatibility, low friction coefficient, and excellent wear resistance. Surgical instruments, orthopedic implants, and dental tools increasingly utilize DLC coatings to extend service life and reduce biological reactions. This segment has grown at a compound annual growth rate of 8.7% over the past five years.

Regional analysis reveals that North America and Europe currently dominate the advanced coating market, collectively accounting for over 60% of global consumption. However, the Asia-Pacific region, particularly China and India, demonstrates the highest growth rate due to rapid industrialization and increasing manufacturing activities in aerospace, automotive, and medical device sectors.

The electronics industry represents an emerging market for these advanced coatings, particularly DLC, which provides excellent electrical insulation properties combined with thermal conductivity. Microelectronics manufacturers are increasingly adopting DLC coatings for semiconductor processing equipment and components exposed to plasma environments.

Market forecasts indicate that the global advanced coating market will continue to expand, with particular growth in applications requiring combinations of properties such as low friction, high hardness, chemical inertness, and thermal stability. The trend toward environmentally friendly manufacturing processes has also boosted demand for coatings that enable dry machining, reducing the need for cooling lubricants.

The cutting tool industry represents the largest market segment for these advanced coatings, accounting for approximately 35% of the total market share. Within this sector, the demand for AlTiN coatings has grown substantially due to their exceptional performance in high-speed machining operations and dry cutting applications. The automotive manufacturing sector has increasingly adopted these coatings to improve tool life by up to 300% when machining hardened steels and titanium alloys.

Aerospace and defense industries constitute another significant market segment, where the extreme operating conditions necessitate materials with superior thermal stability and wear resistance. TiN coatings have established a strong presence in this sector, particularly for components subjected to moderate temperatures and wear conditions. However, AlTiN is gaining market share due to its superior oxidation resistance at elevated temperatures up to 900°C.

The medical device manufacturing sector has shown remarkable growth in demand for DLC coatings, driven by their biocompatibility, low friction coefficient, and excellent wear resistance. Surgical instruments, orthopedic implants, and dental tools increasingly utilize DLC coatings to extend service life and reduce biological reactions. This segment has grown at a compound annual growth rate of 8.7% over the past five years.

Regional analysis reveals that North America and Europe currently dominate the advanced coating market, collectively accounting for over 60% of global consumption. However, the Asia-Pacific region, particularly China and India, demonstrates the highest growth rate due to rapid industrialization and increasing manufacturing activities in aerospace, automotive, and medical device sectors.

The electronics industry represents an emerging market for these advanced coatings, particularly DLC, which provides excellent electrical insulation properties combined with thermal conductivity. Microelectronics manufacturers are increasingly adopting DLC coatings for semiconductor processing equipment and components exposed to plasma environments.

Market forecasts indicate that the global advanced coating market will continue to expand, with particular growth in applications requiring combinations of properties such as low friction, high hardness, chemical inertness, and thermal stability. The trend toward environmentally friendly manufacturing processes has also boosted demand for coatings that enable dry machining, reducing the need for cooling lubricants.

Current Technologies and Challenges in Hard Coatings

The hard coating industry has witnessed significant technological advancements in recent years, with tungsten carbide coatings emerging as a cornerstone technology for wear-resistant applications. Currently, three primary coating technologies dominate the market: Titanium Nitride (TiN), Aluminum Titanium Nitride (AlTiN), and Diamond-Like Carbon (DLC) coatings. Each offers distinct performance characteristics when applied to tungsten carbide substrates.

TiN coatings represent the most established technology, characterized by their distinctive gold color and hardness values typically ranging from 2300-2500 HV. These coatings provide excellent wear resistance and are applied through Physical Vapor Deposition (PVD) at temperatures between 400-500°C. While TiN offers good performance in general machining applications, it begins to oxidize at temperatures exceeding 500°C, limiting its effectiveness in high-temperature operations.

AlTiN coatings have gained prominence as an advancement over traditional TiN, offering superior hardness (3300-3500 HV) and oxidation resistance up to 900°C. The aluminum content forms a protective aluminum oxide layer during operation, enhancing thermal stability. This makes AlTiN particularly valuable for high-speed dry machining applications where significant heat generation occurs. However, these coatings typically require more sophisticated deposition equipment and higher process temperatures.

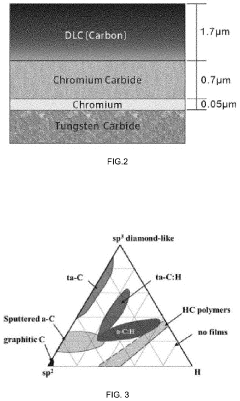

DLC coatings represent the cutting edge in hard coating technology, delivering exceptional hardness (up to 5000 HV) combined with an extremely low coefficient of friction (0.1-0.2). Applied through various methods including PECVD (Plasma-Enhanced Chemical Vapor Deposition), these amorphous carbon coatings excel in applications requiring minimal friction and wear. Their lower deposition temperatures (150-300°C) make them suitable for temperature-sensitive substrates.

Despite these advancements, significant challenges persist in the hard coating industry. Adhesion remains a critical issue, particularly for DLC coatings on tungsten carbide, often requiring intermediate layers to achieve acceptable bonding. Coating thickness uniformity presents another challenge, especially for components with complex geometries where edge build-up or shadowing effects can occur during deposition.

Coating durability under extreme conditions continues to challenge manufacturers, with thermal cycling and impact resistance representing areas requiring improvement. Additionally, the industry faces increasing pressure to develop environmentally friendly coating processes that reduce or eliminate hazardous materials while maintaining performance characteristics.

Cost-effectiveness remains a significant barrier to widespread adoption, particularly for newer technologies like DLC coatings, which typically command a premium of 30-50% over traditional TiN coatings. This economic factor often influences coating selection decisions, especially in price-sensitive market segments.

TiN coatings represent the most established technology, characterized by their distinctive gold color and hardness values typically ranging from 2300-2500 HV. These coatings provide excellent wear resistance and are applied through Physical Vapor Deposition (PVD) at temperatures between 400-500°C. While TiN offers good performance in general machining applications, it begins to oxidize at temperatures exceeding 500°C, limiting its effectiveness in high-temperature operations.

AlTiN coatings have gained prominence as an advancement over traditional TiN, offering superior hardness (3300-3500 HV) and oxidation resistance up to 900°C. The aluminum content forms a protective aluminum oxide layer during operation, enhancing thermal stability. This makes AlTiN particularly valuable for high-speed dry machining applications where significant heat generation occurs. However, these coatings typically require more sophisticated deposition equipment and higher process temperatures.

DLC coatings represent the cutting edge in hard coating technology, delivering exceptional hardness (up to 5000 HV) combined with an extremely low coefficient of friction (0.1-0.2). Applied through various methods including PECVD (Plasma-Enhanced Chemical Vapor Deposition), these amorphous carbon coatings excel in applications requiring minimal friction and wear. Their lower deposition temperatures (150-300°C) make them suitable for temperature-sensitive substrates.

Despite these advancements, significant challenges persist in the hard coating industry. Adhesion remains a critical issue, particularly for DLC coatings on tungsten carbide, often requiring intermediate layers to achieve acceptable bonding. Coating thickness uniformity presents another challenge, especially for components with complex geometries where edge build-up or shadowing effects can occur during deposition.

Coating durability under extreme conditions continues to challenge manufacturers, with thermal cycling and impact resistance representing areas requiring improvement. Additionally, the industry faces increasing pressure to develop environmentally friendly coating processes that reduce or eliminate hazardous materials while maintaining performance characteristics.

Cost-effectiveness remains a significant barrier to widespread adoption, particularly for newer technologies like DLC coatings, which typically command a premium of 30-50% over traditional TiN coatings. This economic factor often influences coating selection decisions, especially in price-sensitive market segments.

Comparative Analysis of TiN, AlTiN, and DLC Properties

01 Comparative performance of TiN, AlTiN, and DLC coatings

Different coating materials exhibit varying performance characteristics. Titanium Nitride (TiN) provides good wear resistance and hardness. Aluminum Titanium Nitride (AlTiN) offers superior oxidation resistance and hardness at elevated temperatures compared to TiN. Diamond-Like Carbon (DLC) coatings provide excellent tribological properties with low friction coefficients and high wear resistance. The selection between these coatings depends on specific application requirements such as operating temperature, wear conditions, and substrate material.- Comparative performance of TiN, AlTiN, and DLC coatings: Different coating materials exhibit varying performance characteristics for specific applications. Titanium Nitride (TiN) provides good wear resistance and reduced friction. Aluminum Titanium Nitride (AlTiN) offers superior oxidation resistance at high temperatures compared to TiN. Diamond-Like Carbon (DLC) coatings provide exceptional hardness and low friction coefficients. The selection between these coatings depends on the specific application requirements, operating conditions, and substrate material.

- Deposition methods for tungsten carbide and related coatings: Various deposition techniques are employed to apply tungsten carbide and other hard coatings to substrates. Physical Vapor Deposition (PVD) methods, including magnetron sputtering, provide excellent adhesion and coating uniformity. Chemical Vapor Deposition (CVD) allows for more complex geometries and thicker coatings. Plasma-enhanced deposition techniques improve coating density and adhesion at lower processing temperatures. The choice of deposition method significantly impacts the microstructure, adhesion, and overall performance of the coating.

- Wear resistance and tribological properties: Tungsten carbide coatings and related materials like TiN, AlTiN, and DLC exhibit exceptional wear resistance properties. These coatings significantly reduce friction coefficients in sliding contact applications, extending tool life and component durability. The tribological performance varies with coating thickness, composition, and microstructure. Multi-layer coating systems can provide optimized wear resistance by combining the beneficial properties of different materials. Surface preparation and coating adhesion are critical factors affecting long-term wear performance.

- Thermal stability and high-temperature performance: The thermal stability of coatings is crucial for applications involving high temperatures. AlTiN coatings typically outperform TiN in high-temperature environments due to the formation of a protective aluminum oxide layer. Tungsten carbide coatings maintain their hardness at elevated temperatures but may oxidize without protective top layers. DLC coatings, while offering excellent room temperature properties, may experience graphitization at higher temperatures. Thermal cycling can induce stress and potential delamination in coatings, requiring careful material selection and design for high-temperature applications.

- Coating adhesion and substrate compatibility: The performance of tungsten carbide and related coatings is highly dependent on their adhesion to the substrate. Proper surface preparation, including cleaning and roughening, is essential for optimal coating adhesion. Intermediate layers or gradient compositions can improve adhesion by reducing stress at the coating-substrate interface. Different substrate materials require specific coating parameters to ensure compatibility and prevent delamination. Post-deposition treatments, such as heat treatment or polishing, can enhance the bond strength and overall coating performance.

02 Tungsten carbide coating deposition methods and their impact on performance

Various deposition techniques significantly affect the performance of tungsten carbide coatings. Physical Vapor Deposition (PVD) produces dense, uniform coatings with excellent adhesion. Chemical Vapor Deposition (CVD) creates coatings with superior hardness and wear resistance at high temperatures. Plasma-enhanced methods improve coating density and adhesion while allowing for lower deposition temperatures. The deposition parameters, including temperature, pressure, and gas composition, directly influence the microstructure, hardness, and wear resistance of the resulting coating.Expand Specific Solutions03 Multi-layer and composite coating systems

Multi-layer coating systems combining different materials offer enhanced performance characteristics. Gradient layers between tungsten carbide and other coating materials improve adhesion and reduce internal stresses. Alternating layers of hard and tough materials provide a balance between wear resistance and impact strength. Composite coatings incorporating tungsten carbide with TiN, AlTiN, or DLC create synergistic effects that enhance overall coating performance, including improved hardness, wear resistance, and thermal stability.Expand Specific Solutions04 Coating performance in extreme environments

Specialized coatings are designed to perform in extreme operating conditions. High-temperature applications benefit from AlTiN coatings that maintain hardness and oxidation resistance at elevated temperatures. Corrosion-resistant formulations incorporate additional elements to protect against chemical attack. Impact-resistant coatings balance hardness with toughness to prevent chipping and cracking under high loads. Coatings for cutting tools and drilling applications are optimized to withstand the combined effects of heat, pressure, and abrasion.Expand Specific Solutions05 Surface preparation and post-treatment effects on coating performance

Surface preparation and post-treatment processes significantly impact coating performance. Proper substrate cleaning and surface activation enhance coating adhesion. Pre-treatments such as nitriding or carburizing can improve the load-bearing capacity of the substrate. Post-deposition treatments including annealing and polishing reduce residual stresses and improve surface finish. The interface between the substrate and coating is critical for overall performance, with properly prepared surfaces showing significantly improved coating durability and reduced failure rates.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The tungsten carbide coating market is currently in a growth phase, with TiN, AlTiN, and DLC coatings representing key technologies at different maturity levels. The global market is estimated at $4-5 billion annually, expanding at 5-7% CAGR driven by automotive, aerospace, and manufacturing applications. Leading players include established multinational corporations like Oerlikon Surface Solutions, Sandvik, and Kennametal, who possess advanced R&D capabilities and comprehensive coating portfolios. Asian manufacturers such as Zhuzhou Cemented Carbide Cutting Tools and Korloy are rapidly gaining market share through cost-effective solutions. Technical differentiation is increasingly important as companies like Mitsubishi Materials and Walter AG focus on specialized coatings for extreme applications, while research partnerships with institutions like Guangdong University of Technology drive continued innovation in coating performance and sustainability.

Oerlikon Surface Solutions AG

Technical Solution: Oerlikon Surface Solutions has developed advanced PVD (Physical Vapor Deposition) coating technologies for tungsten carbide tools, offering all three coating options with distinct applications. Their BALIQ® TISINOS coating combines TiN and TiSiN properties, providing gold-colored coatings with hardness up to 3,300 HV and operating temperatures of 600°C. For AlTiN, they've engineered the BALINIT® ALCRONA PRO coating with nano-crystalline structure, delivering hardness exceeding 3,400 HV and oxidation resistance up to 1,100°C. Their DLC solutions include BALINIT® DIAMOND NANO and DIAMOND MICRO coatings with extremely low friction coefficients (0.1-0.2) and hardness values reaching 5,000 HV. Oerlikon's proprietary S3p® technology (Scalable Pulsed Power Plasma) enables precise control of coating microstructure, resulting in smoother surfaces and better adhesion compared to conventional coating methods.

Strengths: Industry-leading coating uniformity and adhesion through proprietary S3p® technology; comprehensive portfolio covering all three coating types; exceptional hardness-to-toughness ratios. Weaknesses: Premium pricing structure compared to standard coatings; requires specialized equipment for application; some coatings may have longer processing times due to complex deposition requirements.

Seco Tools AB

Technical Solution: Seco Tools has developed the Duratomic® coating technology, a patented process that arranges aluminum and titanium atoms in the coating structure to optimize performance for specific applications. Their TiN coatings utilize a controlled reactive magnetron sputtering process, creating uniform layers with hardness values of 2,300-2,500 HV and thermal stability up to 500°C. For more demanding applications, Seco's AlTiN solutions employ their proprietary Alpha-Phase Stabilization™ technology, which maintains the hexagonal crystal structure of the coating even under extreme cutting temperatures, resulting in hardness values exceeding 3,300 HV and oxidation resistance up to 900°C. Their DLC portfolio includes the Seco-Deco™ series, featuring multi-layered structures with silicon and tungsten doping to enhance adhesion to carbide substrates. These coatings achieve friction coefficients below 0.1 and hardness values up to 4,500 HV. Seco's Edge Intelligence™ system allows for coating thickness optimization at cutting edges, providing up to 30% longer tool life compared to conventionally coated tools.

Strengths: Duratomic® technology provides excellent balance between hardness and toughness; Edge Intelligence™ system optimizes coating performance at critical cutting edges; comprehensive application-specific coating solutions. Weaknesses: Some specialized coatings have limited substrate compatibility; higher cost compared to standard coatings; certain advanced coatings require specific pre-treatment protocols that may not be available at all facilities.

Key Patents and Breakthroughs in Coating Technologies

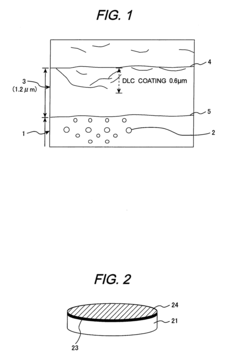

Article with high-hardness carbon coating

PatentInactiveUS20080063894A1

Innovation

- A substrate with an intermediate layer containing aluminum and carbon, where the aluminum concentration decreases and carbon concentration increases towards the high-hardness carbon coating, forming Al4C3 at the substrate side, and the high-hardness carbon coating contains 0.5 to 4.5% aluminum, enhancing adhesion and abrasion resistance.

Black diamond like carbon (DLC) coated articles and methods of making the same

PatentPendingUS20230038194A1

Innovation

- A multi-layer coating system comprising a thin first layer of elemental metals like chromium, an intermediate coating of carbides or nitrides, and an outermost layer of diamond-like carbon (DLC) is applied to the substrate, which enhances adhesive properties and provides a hard, wear-resistant surface.

Cost-Benefit Analysis of Different Coating Technologies

When evaluating tungsten carbide coating options such as TiN, AlTiN, and DLC, cost-benefit analysis reveals significant variations in initial investment, operational efficiency, and long-term value proposition.

TiN (Titanium Nitride) coatings represent the most economical initial investment, typically costing 30-40% less than AlTiN and 50-60% less than DLC coatings. The application process for TiN is well-established and widely available, contributing to its cost-effectiveness. However, TiN exhibits the shortest service life among the three options, requiring more frequent reapplication and potentially increasing long-term expenditure.

AlTiN (Aluminum Titanium Nitride) occupies the middle ground in the cost spectrum. While requiring a higher initial investment than TiN, it delivers superior performance at elevated temperatures and demonstrates approximately 40% longer tool life in high-speed machining applications. This extended durability translates to fewer tool changes and reduced downtime, offering compelling return on investment for medium to high-volume production environments.

DLC (Diamond-Like Carbon) coatings command premium pricing, with implementation costs typically 2-3 times higher than TiN. This substantial investment is justified by exceptional wear resistance and significantly reduced friction coefficients. Industry data indicates that DLC-coated components can achieve up to 300% longer service life compared to uncoated alternatives, particularly in applications involving non-ferrous materials.

Maintenance considerations further differentiate these coating technologies. TiN coatings can be stripped and reapplied relatively easily, making refurbishment economical. AlTiN presents moderate complexity for recoating, while DLC typically requires specialized processes that increase maintenance costs but deliver superior performance restoration.

Energy efficiency metrics favor DLC coatings, which reduce friction-related energy losses by up to 45% compared to uncoated surfaces. AlTiN demonstrates moderate energy efficiency improvements of approximately 25-30%, while TiN offers more modest gains around 15-20%. These efficiency differentials become particularly significant in high-volume, continuous operation scenarios.

Production environment compatibility also influences cost-benefit calculations. TiN performs adequately across diverse applications but loses effectiveness at temperatures exceeding 500°C. AlTiN maintains structural integrity up to approximately 900°C, making it suitable for high-temperature operations without requiring costly cooling systems. DLC, while offering superior performance in many aspects, degrades in oxygen-rich environments above 350°C, potentially necessitating additional protective measures.

The optimal coating selection ultimately depends on specific application requirements, production volumes, and operational conditions. Short-run, cost-sensitive applications may favor TiN despite higher long-term costs, while high-precision, high-volume operations often justify the premium investment in DLC technology.

TiN (Titanium Nitride) coatings represent the most economical initial investment, typically costing 30-40% less than AlTiN and 50-60% less than DLC coatings. The application process for TiN is well-established and widely available, contributing to its cost-effectiveness. However, TiN exhibits the shortest service life among the three options, requiring more frequent reapplication and potentially increasing long-term expenditure.

AlTiN (Aluminum Titanium Nitride) occupies the middle ground in the cost spectrum. While requiring a higher initial investment than TiN, it delivers superior performance at elevated temperatures and demonstrates approximately 40% longer tool life in high-speed machining applications. This extended durability translates to fewer tool changes and reduced downtime, offering compelling return on investment for medium to high-volume production environments.

DLC (Diamond-Like Carbon) coatings command premium pricing, with implementation costs typically 2-3 times higher than TiN. This substantial investment is justified by exceptional wear resistance and significantly reduced friction coefficients. Industry data indicates that DLC-coated components can achieve up to 300% longer service life compared to uncoated alternatives, particularly in applications involving non-ferrous materials.

Maintenance considerations further differentiate these coating technologies. TiN coatings can be stripped and reapplied relatively easily, making refurbishment economical. AlTiN presents moderate complexity for recoating, while DLC typically requires specialized processes that increase maintenance costs but deliver superior performance restoration.

Energy efficiency metrics favor DLC coatings, which reduce friction-related energy losses by up to 45% compared to uncoated surfaces. AlTiN demonstrates moderate energy efficiency improvements of approximately 25-30%, while TiN offers more modest gains around 15-20%. These efficiency differentials become particularly significant in high-volume, continuous operation scenarios.

Production environment compatibility also influences cost-benefit calculations. TiN performs adequately across diverse applications but loses effectiveness at temperatures exceeding 500°C. AlTiN maintains structural integrity up to approximately 900°C, making it suitable for high-temperature operations without requiring costly cooling systems. DLC, while offering superior performance in many aspects, degrades in oxygen-rich environments above 350°C, potentially necessitating additional protective measures.

The optimal coating selection ultimately depends on specific application requirements, production volumes, and operational conditions. Short-run, cost-sensitive applications may favor TiN despite higher long-term costs, while high-precision, high-volume operations often justify the premium investment in DLC technology.

Environmental Impact and Sustainability Considerations

The environmental impact of coating technologies has become increasingly significant in industrial applications, particularly for tungsten carbide coatings. When comparing TiN, AlTiN, and DLC coatings, several environmental factors must be considered throughout their lifecycle, from raw material extraction to disposal.

TiN (Titanium Nitride) coating processes typically involve Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD), which consume substantial energy. However, TiN coatings extend tool life significantly, reducing the frequency of replacement and consequently decreasing resource consumption. The production process generates minimal toxic byproducts compared to traditional coating methods, though nitrogen oxide emissions remain a concern.

AlTiN (Aluminum Titanium Nitride) coatings demonstrate superior environmental performance in high-temperature applications. Their exceptional durability reduces the frequency of tool replacement, minimizing waste generation. The manufacturing process for AlTiN requires approximately 15-20% more energy than TiN but delivers 30-40% longer tool life in demanding applications, representing a net positive environmental trade-off.

DLC (Diamond-Like Carbon) coatings stand out as the most environmentally friendly option among the three. The production process utilizes primarily carbon-based materials with minimal toxic elements. DLC coatings operate effectively without lubrication in many applications, reducing the need for environmentally harmful lubricants. Studies indicate that DLC-coated components can reduce friction-related energy losses by up to 45%, translating to significant energy savings in operational contexts.

Waste management considerations vary significantly across these coating technologies. TiN and AlTiN coating processes generate metal-containing waste that requires specialized disposal procedures. DLC, being carbon-based, presents fewer end-of-life disposal challenges but may require specialized recycling processes to recover substrate materials.

Recent sustainability initiatives in the coating industry have focused on reducing process temperatures and developing water-based rather than solvent-based solutions. Manufacturers implementing closed-loop systems for coating processes have reported 30-40% reductions in water consumption and up to 25% decreases in energy usage. These improvements significantly enhance the environmental profile of all three coating technologies.

Regulatory compliance is increasingly stringent, with RoHS and REACH regulations limiting hazardous substances in manufacturing processes. All three coating technologies generally comply with current regulations, though ongoing monitoring is essential as standards evolve, particularly regarding nanomaterial safety and disposal protocols.

TiN (Titanium Nitride) coating processes typically involve Physical Vapor Deposition (PVD) or Chemical Vapor Deposition (CVD), which consume substantial energy. However, TiN coatings extend tool life significantly, reducing the frequency of replacement and consequently decreasing resource consumption. The production process generates minimal toxic byproducts compared to traditional coating methods, though nitrogen oxide emissions remain a concern.

AlTiN (Aluminum Titanium Nitride) coatings demonstrate superior environmental performance in high-temperature applications. Their exceptional durability reduces the frequency of tool replacement, minimizing waste generation. The manufacturing process for AlTiN requires approximately 15-20% more energy than TiN but delivers 30-40% longer tool life in demanding applications, representing a net positive environmental trade-off.

DLC (Diamond-Like Carbon) coatings stand out as the most environmentally friendly option among the three. The production process utilizes primarily carbon-based materials with minimal toxic elements. DLC coatings operate effectively without lubrication in many applications, reducing the need for environmentally harmful lubricants. Studies indicate that DLC-coated components can reduce friction-related energy losses by up to 45%, translating to significant energy savings in operational contexts.

Waste management considerations vary significantly across these coating technologies. TiN and AlTiN coating processes generate metal-containing waste that requires specialized disposal procedures. DLC, being carbon-based, presents fewer end-of-life disposal challenges but may require specialized recycling processes to recover substrate materials.

Recent sustainability initiatives in the coating industry have focused on reducing process temperatures and developing water-based rather than solvent-based solutions. Manufacturers implementing closed-loop systems for coating processes have reported 30-40% reductions in water consumption and up to 25% decreases in energy usage. These improvements significantly enhance the environmental profile of all three coating technologies.

Regulatory compliance is increasingly stringent, with RoHS and REACH regulations limiting hazardous substances in manufacturing processes. All three coating technologies generally comply with current regulations, though ongoing monitoring is essential as standards evolve, particularly regarding nanomaterial safety and disposal protocols.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!