Corrosion Resistance Of Carbide Grades: Testing Methods And Results

AUG 22, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbide Corrosion Resistance Background and Objectives

Carbide materials have been integral to industrial applications for over a century, with their development tracing back to the early 1900s when researchers first synthesized tungsten carbide. The evolution of carbide technology has been marked by continuous improvements in composition, manufacturing processes, and performance characteristics. Initially limited to cutting tools, carbides now serve critical functions across diverse industries including aerospace, automotive, mining, oil and gas, and electronics manufacturing.

The corrosion resistance of carbide grades has become increasingly important as these materials face more demanding operational environments. Traditional carbide applications focused primarily on wear resistance and hardness, with corrosion considerations often secondary. However, modern industrial requirements have shifted this paradigm, particularly as carbides encounter aggressive chemical environments, high temperatures, and varying pH conditions.

Recent technological trends show a growing emphasis on developing specialized carbide grades with enhanced corrosion resistance while maintaining their superior mechanical properties. This development trajectory has been driven by the expanding application scope of carbides in chemical processing equipment, marine environments, and medical implants where corrosion performance is paramount.

The standardization of testing methodologies for carbide corrosion resistance has not kept pace with material development, creating significant challenges in comparing performance across different manufacturers and applications. Current testing protocols vary widely, from simple immersion tests to sophisticated electrochemical evaluations, resulting in inconsistent data interpretation and application recommendations.

This technical research aims to comprehensively evaluate existing testing methods for carbide corrosion resistance, analyze their correlation with real-world performance, and establish more reliable predictive models. The objective is to develop a standardized framework for assessing corrosion behavior that accounts for the complex interplay between carbide composition, microstructure, and environmental factors.

Additionally, this research seeks to map the relationship between specific carbide grades and their corrosion performance in various industrial environments, providing engineers with more precise selection criteria. By identifying key performance indicators and failure mechanisms, we aim to enable more accurate prediction of service life and maintenance requirements for carbide components exposed to corrosive conditions.

The ultimate goal is to establish a comprehensive knowledge base that bridges the gap between laboratory testing and field performance, facilitating the development of next-generation carbide materials with optimized corrosion resistance for specific application requirements. This will support industries in making more informed decisions regarding material selection, potentially extending component lifespans and reducing maintenance costs in corrosive environments.

The corrosion resistance of carbide grades has become increasingly important as these materials face more demanding operational environments. Traditional carbide applications focused primarily on wear resistance and hardness, with corrosion considerations often secondary. However, modern industrial requirements have shifted this paradigm, particularly as carbides encounter aggressive chemical environments, high temperatures, and varying pH conditions.

Recent technological trends show a growing emphasis on developing specialized carbide grades with enhanced corrosion resistance while maintaining their superior mechanical properties. This development trajectory has been driven by the expanding application scope of carbides in chemical processing equipment, marine environments, and medical implants where corrosion performance is paramount.

The standardization of testing methodologies for carbide corrosion resistance has not kept pace with material development, creating significant challenges in comparing performance across different manufacturers and applications. Current testing protocols vary widely, from simple immersion tests to sophisticated electrochemical evaluations, resulting in inconsistent data interpretation and application recommendations.

This technical research aims to comprehensively evaluate existing testing methods for carbide corrosion resistance, analyze their correlation with real-world performance, and establish more reliable predictive models. The objective is to develop a standardized framework for assessing corrosion behavior that accounts for the complex interplay between carbide composition, microstructure, and environmental factors.

Additionally, this research seeks to map the relationship between specific carbide grades and their corrosion performance in various industrial environments, providing engineers with more precise selection criteria. By identifying key performance indicators and failure mechanisms, we aim to enable more accurate prediction of service life and maintenance requirements for carbide components exposed to corrosive conditions.

The ultimate goal is to establish a comprehensive knowledge base that bridges the gap between laboratory testing and field performance, facilitating the development of next-generation carbide materials with optimized corrosion resistance for specific application requirements. This will support industries in making more informed decisions regarding material selection, potentially extending component lifespans and reducing maintenance costs in corrosive environments.

Market Demand Analysis for Corrosion-Resistant Carbides

The global market for corrosion-resistant carbide materials has experienced significant growth in recent years, driven primarily by increasing demands in harsh operating environments across multiple industries. The oil and gas sector represents one of the largest market segments, where carbide components are extensively used in drilling equipment, valves, and pumps exposed to highly corrosive fluids and abrasive conditions. Market research indicates that this sector alone accounts for approximately 30% of the total demand for corrosion-resistant carbides.

The aerospace and automotive industries have also emerged as substantial consumers of corrosion-resistant carbide materials. In aerospace applications, these materials are critical for engine components, landing gear, and structural elements that must withstand extreme temperatures and corrosive environments. The automotive sector increasingly utilizes carbide components in fuel injection systems, turbochargers, and exhaust systems, where resistance to both corrosion and wear is essential for longevity and performance.

Manufacturing and processing industries represent another significant market segment, particularly in chemical processing, where equipment must withstand aggressive chemical environments. The demand in this sector has grown steadily at around 7% annually over the past five years, outpacing the overall industrial growth rate. This trend reflects the increasing recognition of the long-term cost benefits of corrosion-resistant carbides despite their higher initial investment.

Geographically, North America and Europe currently dominate the market for high-performance corrosion-resistant carbides, collectively accounting for over 60% of global consumption. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate, driven by rapid industrialization and increasing adoption of advanced materials in manufacturing processes.

Market analysis reveals a growing preference for customized carbide solutions tailored to specific corrosive environments rather than general-purpose grades. This shift has created new opportunities for manufacturers who can provide specialized testing and validation services alongside their products. The ability to accurately predict and demonstrate corrosion resistance in specific operating conditions has become a key competitive advantage in the market.

The economic impact of corrosion continues to drive market growth, with global corrosion costs estimated at 3-4% of GDP in industrialized nations. As industries seek to reduce these costs through more durable materials, the market for advanced corrosion-resistant carbides is projected to expand at a compound annual growth rate of 8.5% through 2028, reaching a market value that significantly exceeds current levels.

The aerospace and automotive industries have also emerged as substantial consumers of corrosion-resistant carbide materials. In aerospace applications, these materials are critical for engine components, landing gear, and structural elements that must withstand extreme temperatures and corrosive environments. The automotive sector increasingly utilizes carbide components in fuel injection systems, turbochargers, and exhaust systems, where resistance to both corrosion and wear is essential for longevity and performance.

Manufacturing and processing industries represent another significant market segment, particularly in chemical processing, where equipment must withstand aggressive chemical environments. The demand in this sector has grown steadily at around 7% annually over the past five years, outpacing the overall industrial growth rate. This trend reflects the increasing recognition of the long-term cost benefits of corrosion-resistant carbides despite their higher initial investment.

Geographically, North America and Europe currently dominate the market for high-performance corrosion-resistant carbides, collectively accounting for over 60% of global consumption. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate, driven by rapid industrialization and increasing adoption of advanced materials in manufacturing processes.

Market analysis reveals a growing preference for customized carbide solutions tailored to specific corrosive environments rather than general-purpose grades. This shift has created new opportunities for manufacturers who can provide specialized testing and validation services alongside their products. The ability to accurately predict and demonstrate corrosion resistance in specific operating conditions has become a key competitive advantage in the market.

The economic impact of corrosion continues to drive market growth, with global corrosion costs estimated at 3-4% of GDP in industrialized nations. As industries seek to reduce these costs through more durable materials, the market for advanced corrosion-resistant carbides is projected to expand at a compound annual growth rate of 8.5% through 2028, reaching a market value that significantly exceeds current levels.

Current Testing Methods and Technical Challenges

The evaluation of carbide grades' corrosion resistance requires standardized testing methodologies to ensure reliable and comparable results. Currently, the industry employs several established testing methods, each with specific applications and limitations. The most widely used approach is the immersion test, where carbide samples are submerged in corrosive media for predetermined periods, with weight loss and surface degradation measured afterward. This method provides realistic exposure conditions but requires extended testing periods, sometimes spanning weeks or months to generate meaningful data.

Electrochemical testing represents another significant methodology, including potentiodynamic polarization and electrochemical impedance spectroscopy (EIS). These techniques offer accelerated results and detailed insights into corrosion mechanisms but may not always correlate perfectly with real-world performance. The salt spray test (ASTM B117) remains popular for simulating marine or coastal environments, though its correlation with actual field performance has been questioned by recent research.

Advanced surface analysis techniques such as X-ray photoelectron spectroscopy (XPS) and scanning electron microscopy (SEM) are increasingly integrated into testing protocols to characterize corrosion products and mechanisms at the microstructural level. These methods provide valuable insights but require sophisticated equipment and specialized expertise for proper interpretation.

Despite these established methodologies, significant technical challenges persist in carbide corrosion testing. The primary challenge involves the difficulty in replicating real-world operating conditions, particularly when carbide components face multiple simultaneous stressors like mechanical loading, temperature fluctuations, and corrosive media. Current laboratory tests often isolate individual factors, potentially missing critical synergistic effects.

Standardization issues represent another major challenge, as different industries and regions employ varying testing protocols, making cross-comparison of results problematic. The time-acceleration correlation problem also remains unresolved – accelerated tests may induce different corrosion mechanisms than those occurring during normal service life, leading to potentially misleading conclusions about long-term performance.

The microstructural complexity of modern carbide grades further complicates testing efforts. Variations in grain size, binder content, and phase distribution significantly influence corrosion behavior, yet current testing methods often treat samples as homogeneous materials. Additionally, the boundary between mechanical wear and corrosive degradation becomes increasingly blurred in many applications, with current methods struggling to differentiate between these interrelated phenomena.

Emerging challenges include developing reliable methods for testing newer carbide grades with specialized coatings or compositional modifications specifically designed for corrosion resistance. The industry also faces difficulties in establishing predictive models that can accurately translate laboratory test results into reliable service life predictions across diverse operating environments.

Electrochemical testing represents another significant methodology, including potentiodynamic polarization and electrochemical impedance spectroscopy (EIS). These techniques offer accelerated results and detailed insights into corrosion mechanisms but may not always correlate perfectly with real-world performance. The salt spray test (ASTM B117) remains popular for simulating marine or coastal environments, though its correlation with actual field performance has been questioned by recent research.

Advanced surface analysis techniques such as X-ray photoelectron spectroscopy (XPS) and scanning electron microscopy (SEM) are increasingly integrated into testing protocols to characterize corrosion products and mechanisms at the microstructural level. These methods provide valuable insights but require sophisticated equipment and specialized expertise for proper interpretation.

Despite these established methodologies, significant technical challenges persist in carbide corrosion testing. The primary challenge involves the difficulty in replicating real-world operating conditions, particularly when carbide components face multiple simultaneous stressors like mechanical loading, temperature fluctuations, and corrosive media. Current laboratory tests often isolate individual factors, potentially missing critical synergistic effects.

Standardization issues represent another major challenge, as different industries and regions employ varying testing protocols, making cross-comparison of results problematic. The time-acceleration correlation problem also remains unresolved – accelerated tests may induce different corrosion mechanisms than those occurring during normal service life, leading to potentially misleading conclusions about long-term performance.

The microstructural complexity of modern carbide grades further complicates testing efforts. Variations in grain size, binder content, and phase distribution significantly influence corrosion behavior, yet current testing methods often treat samples as homogeneous materials. Additionally, the boundary between mechanical wear and corrosive degradation becomes increasingly blurred in many applications, with current methods struggling to differentiate between these interrelated phenomena.

Emerging challenges include developing reliable methods for testing newer carbide grades with specialized coatings or compositional modifications specifically designed for corrosion resistance. The industry also faces difficulties in establishing predictive models that can accurately translate laboratory test results into reliable service life predictions across diverse operating environments.

Standard Corrosion Testing Protocols and Results

01 Tungsten carbide compositions with enhanced corrosion resistance

Tungsten carbide-based materials can be formulated with specific binder compositions to enhance corrosion resistance. These formulations typically include cobalt, nickel, or chromium binders that create a protective layer against corrosive environments. The addition of certain alloying elements to the binder phase can significantly improve the material's resistance to acidic, alkaline, or saline conditions while maintaining the carbide's hardness and wear resistance properties.- Tungsten carbide compositions with enhanced corrosion resistance: Tungsten carbide-based materials can be formulated with specific binder compositions to enhance corrosion resistance. These formulations typically include cobalt, nickel, or chromium binders that create a protective layer against corrosive environments. The addition of certain alloying elements to the binder phase can significantly improve the material's resistance to acidic, alkaline, or saline conditions while maintaining the hardness and wear resistance properties of the carbide.

- Silicon carbide materials for corrosive applications: Silicon carbide materials offer exceptional corrosion resistance in harsh chemical environments. These materials can be processed through sintering with specific additives to enhance their resistance to oxidation and chemical attack. Silicon carbide ceramics maintain their structural integrity and performance characteristics even when exposed to strong acids, bases, and high-temperature corrosive gases, making them suitable for applications in chemical processing equipment, pump components, and valve parts.

- Surface treatment methods for improving carbide corrosion resistance: Various surface treatment techniques can be applied to carbide materials to enhance their corrosion resistance. These include physical vapor deposition (PVD), chemical vapor deposition (CVD), and plasma spray coating with corrosion-resistant materials. Surface nitriding, carburizing, or the application of specialized ceramic coatings can create a protective barrier that significantly improves the carbide's performance in corrosive environments while preserving the base material's mechanical properties.

- Composite carbide materials with gradient structures: Gradient-structured composite carbide materials combine different carbide compositions or phases to achieve optimal corrosion resistance. These materials feature a gradual transition between layers with varying compositions, creating a structure that resists corrosion while maintaining mechanical strength. The gradient design allows for customization of the surface properties to resist specific corrosive environments while the core maintains the required structural integrity and wear resistance for demanding applications.

- Nano-structured carbides with enhanced corrosion properties: Nano-structured carbide materials exhibit superior corrosion resistance due to their refined grain structure and increased grain boundary area. These materials can be synthesized through advanced powder metallurgy techniques, including mechanical alloying and spark plasma sintering. The nano-scale features create more uniform distribution of corrosion-inhibiting elements and reduce preferential corrosion pathways, resulting in materials that maintain their integrity in aggressive environments while offering improved mechanical properties compared to conventional carbide grades.

02 Silicon carbide materials for corrosive applications

Silicon carbide materials offer exceptional corrosion resistance in aggressive chemical environments. These materials can be processed through various sintering methods to create dense structures with minimal porosity, enhancing their resistance to chemical attack. Silicon carbide grades can be tailored with specific additives or processing techniques to optimize corrosion resistance for applications in chemical processing equipment, pump components, and mechanical seals exposed to corrosive media.Expand Specific Solutions03 Coated carbide grades for improved corrosion protection

Applying protective coatings to carbide substrates can significantly enhance their corrosion resistance. Various coating technologies including PVD, CVD, and thermal spray processes can deposit corrosion-resistant layers such as titanium nitride, chromium nitride, or aluminum oxide onto carbide surfaces. These coatings create a barrier that protects the underlying carbide material from corrosive attack while maintaining the mechanical properties of the base material.Expand Specific Solutions04 Carbide composites with corrosion-resistant matrices

Composite materials combining carbide particles within corrosion-resistant metal or ceramic matrices offer enhanced performance in aggressive environments. These composites leverage the hardness and wear resistance of carbide particles while the surrounding matrix provides corrosion protection. By carefully selecting matrix materials such as nickel-based alloys, stainless steels, or specialized ceramics, these composites can be tailored for specific corrosive conditions while maintaining structural integrity and mechanical properties.Expand Specific Solutions05 Nano-structured carbides with improved corrosion resistance

Nano-structured carbide materials exhibit superior corrosion resistance compared to their conventional counterparts due to their refined microstructure. These materials feature reduced grain size, more uniform distribution of constituents, and modified grain boundaries that limit corrosion propagation pathways. Advanced processing techniques such as spark plasma sintering, high-energy ball milling, and controlled precipitation methods can produce these nano-structured carbides with enhanced resistance to various corrosive media while maintaining or improving mechanical properties.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The corrosion resistance testing of carbide grades market is currently in a growth phase, with increasing demand driven by automotive, steel manufacturing, and energy sectors. The global market size is estimated to reach $2.5 billion by 2025, expanding at 5.7% CAGR. Technical maturity varies across testing methodologies, with established players leading innovation. NIPPON STEEL, JFE Steel, and Sandvik Intellectual Property demonstrate advanced capabilities in standardized testing protocols, while Hyperion Materials & Technologies and Robert Bosch are pioneering accelerated testing methods. ExxonMobil and ArianeGroup are developing specialized applications for extreme environments, creating a competitive landscape where traditional metallurgical expertise meets emerging digital analysis techniques.

NIPPON STEEL CORP.

Technical Solution: NIPPON STEEL has established a comprehensive carbide corrosion testing program that integrates laboratory testing with field validation in steel manufacturing environments. Their methodology includes specialized high-temperature corrosion testing that simulates conditions in blast furnaces and continuous casting operations. NIPPON STEEL's proprietary "CarbGuard" technology incorporates gradient structures in cemented carbides that provide superior resistance to both corrosion and thermal shock. Their testing protocol includes slurry erosion-corrosion testing that evaluates performance under combined mechanical and chemical attack conditions relevant to mineral processing applications. The company has developed specialized carbide grades with optimized chromium and vanadium additions that form stable protective oxide layers in oxidizing environments. NIPPON STEEL's research has pioneered the use of alternative binder phases to replace traditional cobalt in applications where superior corrosion resistance is required, resulting in grades that maintain structural integrity even after extended exposure to acidic environments.

Strengths: Extensive experience with high-temperature applications; strong integration of laboratory testing with industrial validation; ability to develop specialized grades for extreme environments in steel manufacturing. Weaknesses: Solutions may be optimized primarily for steel industry applications; some specialized grades may have limited availability outside Japan; testing methods may emphasize high-temperature performance over ambient corrosion resistance.

Hyperion Materials & Technologies (Sweden) AB

Technical Solution: Hyperion has established a sophisticated corrosion testing framework specifically designed for tungsten carbide (WC-Co) grades used in demanding industrial applications. Their methodology incorporates electrochemical impedance spectroscopy (EIS) to characterize corrosion mechanisms at the microstructural level. Hyperion's proprietary "CorroTest" protocol combines standardized immersion testing with application-specific chemical environments to predict service life in various industrial settings. Their research has led to the development of specialized binder phases that significantly improve corrosion resistance without compromising mechanical properties. Hyperion employs advanced surface characterization techniques including SEM-EDS and XPS to analyze corrosion products and failure mechanisms. Their corrosion-resistant carbide grades feature optimized cobalt content and grain size distribution, with some grades incorporating corrosion inhibitors directly into the binder phase.

Strengths: Advanced understanding of corrosion mechanisms in cemented carbides; ability to develop application-specific grades for highly corrosive environments; comprehensive testing capabilities that correlate well with field performance. Weaknesses: Premium pricing for specialized grades; longer lead times for custom formulations; some corrosion-resistant formulations may have reduced wear resistance in certain applications.

Key Innovations in Carbide Corrosion Resistance

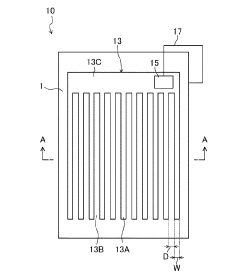

Cemented carbide for high demand applications

PatentWO2020128688A1

Innovation

- A cemented carbide composition with a binder phase content between 7 to 11 wt%, comprising 5.9-9 wt% Ni, 0.45-0.75 wt% Cr, 0.55-0.85 wt% Mo, and 85-95 wt% WC, with a WC grain size of 0.1 to 2 μm, providing enhanced corrosion, erosion, and cavitation resistance, along with high hardness and toughness.

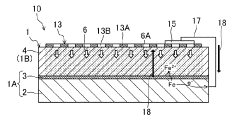

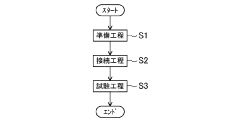

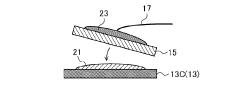

Corrosion resistance testing method for coated metal material and test piece

PatentActiveJP2022001834A

Innovation

- A corrosion resistance test method involving a conductive portion with a higher standard electrode potential than the metal substrate, connected via an external circuit, accelerates corrosion by generating a potential difference that promotes the penetration of corrosive factors into the surface treatment film, allowing for rapid evaluation of corrosion resistance.

Industry Standards and Certification Requirements

The carbide industry operates under a comprehensive framework of standards and certifications that ensure product quality, safety, and performance consistency. ISO 3738 serves as the cornerstone standard for determining the hardness of cemented carbide grades, providing manufacturers and end-users with reliable metrics for material comparison. Complementing this, ASTM B611 establishes standardized procedures for evaluating the abrasion resistance of cemented carbides, which directly correlates with their durability in corrosive environments.

For corrosion resistance specifically, ISO 11782-1 and ISO 11782-2 outline the methodologies for testing carbide materials against chemical degradation. These standards prescribe precise testing conditions, including temperature ranges, exposure durations, and chemical concentrations, ensuring reproducible results across different laboratories and manufacturing facilities.

The International Carbide Association (ICA) has developed certification programs that validate manufacturers' adherence to these testing protocols. Companies seeking ICA certification must demonstrate consistent quality control processes and regular third-party verification of their corrosion resistance claims. This certification has become increasingly important for suppliers serving industries with critical applications such as chemical processing, offshore drilling, and medical implants.

Regional variations in certification requirements present challenges for global manufacturers. European markets typically follow the EN 13231 standard, which imposes stricter requirements for environmental impact assessment of carbide production processes. Meanwhile, North American markets emphasize ANSI/AWS C2.25 standards, which focus on performance under extreme temperature fluctuations.

Emerging economies have begun developing their own certification frameworks, with China's GB/T 20975 standard gaining prominence in Asian markets. This standard incorporates elements from both ISO and ASTM methodologies but adds specific requirements for testing in highly acidic environments common in regional manufacturing processes.

Industry certification is increasingly moving toward lifecycle assessment approaches, requiring manufacturers to document corrosion resistance throughout the expected service life of carbide components. The recently introduced ISO 14025 Environmental Product Declaration (EPD) requirements have begun to influence how corrosion resistance is evaluated, emphasizing long-term performance under actual operating conditions rather than accelerated laboratory testing alone.

Compliance with these standards and certifications represents a significant investment for manufacturers but provides essential market differentiation and customer assurance in applications where material failure could result in catastrophic consequences.

For corrosion resistance specifically, ISO 11782-1 and ISO 11782-2 outline the methodologies for testing carbide materials against chemical degradation. These standards prescribe precise testing conditions, including temperature ranges, exposure durations, and chemical concentrations, ensuring reproducible results across different laboratories and manufacturing facilities.

The International Carbide Association (ICA) has developed certification programs that validate manufacturers' adherence to these testing protocols. Companies seeking ICA certification must demonstrate consistent quality control processes and regular third-party verification of their corrosion resistance claims. This certification has become increasingly important for suppliers serving industries with critical applications such as chemical processing, offshore drilling, and medical implants.

Regional variations in certification requirements present challenges for global manufacturers. European markets typically follow the EN 13231 standard, which imposes stricter requirements for environmental impact assessment of carbide production processes. Meanwhile, North American markets emphasize ANSI/AWS C2.25 standards, which focus on performance under extreme temperature fluctuations.

Emerging economies have begun developing their own certification frameworks, with China's GB/T 20975 standard gaining prominence in Asian markets. This standard incorporates elements from both ISO and ASTM methodologies but adds specific requirements for testing in highly acidic environments common in regional manufacturing processes.

Industry certification is increasingly moving toward lifecycle assessment approaches, requiring manufacturers to document corrosion resistance throughout the expected service life of carbide components. The recently introduced ISO 14025 Environmental Product Declaration (EPD) requirements have begun to influence how corrosion resistance is evaluated, emphasizing long-term performance under actual operating conditions rather than accelerated laboratory testing alone.

Compliance with these standards and certifications represents a significant investment for manufacturers but provides essential market differentiation and customer assurance in applications where material failure could result in catastrophic consequences.

Environmental Impact of Carbide Corrosion Protection Methods

The environmental implications of carbide corrosion protection methods have become increasingly significant as industries face stricter regulations and growing sustainability concerns. Traditional corrosion protection techniques for carbide materials often involve chemical treatments and coatings that may contain heavy metals, volatile organic compounds (VOCs), and other potentially harmful substances that can adversely affect ecosystems when released into the environment.

Chromium-based protective coatings, commonly used for enhancing carbide corrosion resistance, present particular environmental challenges. Hexavalent chromium (Cr VI), a component in many conventional treatments, is classified as carcinogenic and poses serious risks to aquatic life and soil health. Recent environmental impact assessments have documented bioaccumulation of these compounds in food chains, with detectable levels appearing in organisms far from industrial sources.

Water pollution represents another critical concern, as waste streams from carbide treatment facilities may contain dissolved metal ions, treatment chemicals, and particulate matter. Studies indicate that even at low concentrations, these contaminants can disrupt aquatic ecosystems and potentially contaminate groundwater resources. The treatment of such effluents requires sophisticated filtration and precipitation systems, adding to the overall environmental footprint of corrosion protection processes.

Air quality impacts also merit consideration, particularly with spray application methods for protective coatings. Aerosol emissions can contain fine particulates and volatile compounds that contribute to atmospheric pollution and potential respiratory health issues in surrounding communities. Modern ventilation and filtration systems have reduced these emissions significantly, though complete elimination remains challenging.

Energy consumption constitutes a substantial environmental factor in corrosion protection processes. Thermal spray techniques and heat treatment methods used for applying protective layers to carbide components require considerable energy inputs, contributing to carbon emissions when fossil fuel energy sources are utilized. Life cycle assessments reveal that the energy demands of some advanced protection methods may partially offset their environmental benefits from extended product lifespans.

Emerging environmentally friendly alternatives show promising developments. These include water-based coating systems, thermal diffusion processes with reduced emissions, and novel surface modification techniques utilizing plasma technology. Research indicates these methods can achieve comparable corrosion resistance while significantly reducing environmental impact, with some studies reporting up to 70% reduction in hazardous waste generation compared to conventional methods.

Regulatory frameworks worldwide are increasingly emphasizing the need for greener corrosion protection approaches, with the European Union's REACH regulations and similar initiatives in North America and Asia driving innovation toward more sustainable practices in carbide protection technologies.

Chromium-based protective coatings, commonly used for enhancing carbide corrosion resistance, present particular environmental challenges. Hexavalent chromium (Cr VI), a component in many conventional treatments, is classified as carcinogenic and poses serious risks to aquatic life and soil health. Recent environmental impact assessments have documented bioaccumulation of these compounds in food chains, with detectable levels appearing in organisms far from industrial sources.

Water pollution represents another critical concern, as waste streams from carbide treatment facilities may contain dissolved metal ions, treatment chemicals, and particulate matter. Studies indicate that even at low concentrations, these contaminants can disrupt aquatic ecosystems and potentially contaminate groundwater resources. The treatment of such effluents requires sophisticated filtration and precipitation systems, adding to the overall environmental footprint of corrosion protection processes.

Air quality impacts also merit consideration, particularly with spray application methods for protective coatings. Aerosol emissions can contain fine particulates and volatile compounds that contribute to atmospheric pollution and potential respiratory health issues in surrounding communities. Modern ventilation and filtration systems have reduced these emissions significantly, though complete elimination remains challenging.

Energy consumption constitutes a substantial environmental factor in corrosion protection processes. Thermal spray techniques and heat treatment methods used for applying protective layers to carbide components require considerable energy inputs, contributing to carbon emissions when fossil fuel energy sources are utilized. Life cycle assessments reveal that the energy demands of some advanced protection methods may partially offset their environmental benefits from extended product lifespans.

Emerging environmentally friendly alternatives show promising developments. These include water-based coating systems, thermal diffusion processes with reduced emissions, and novel surface modification techniques utilizing plasma technology. Research indicates these methods can achieve comparable corrosion resistance while significantly reducing environmental impact, with some studies reporting up to 70% reduction in hazardous waste generation compared to conventional methods.

Regulatory frameworks worldwide are increasingly emphasizing the need for greener corrosion protection approaches, with the European Union's REACH regulations and similar initiatives in North America and Asia driving innovation toward more sustainable practices in carbide protection technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!