Carbide Brazing: Procedures, Fluxes, And Joint Reliability

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbide Brazing Technology Background and Objectives

Carbide brazing technology has evolved significantly over the past century, with its roots dating back to the early 1900s when tungsten carbide was first developed as a cutting tool material. The fundamental concept involves joining carbide components to steel or other metal substrates using a filler metal that melts and flows between the joint surfaces, creating a strong metallurgical bond upon solidification. This joining technique has become increasingly critical in manufacturing industries where tool durability and performance are paramount.

The evolution of carbide brazing has been characterized by continuous improvements in filler metals, fluxes, and process parameters. Early brazing techniques relied on simple copper-based alloys, but the industry has progressively shifted toward silver-based, nickel-based, and specialized active brazing alloys to meet more demanding applications. This technological progression has been driven by the need for joints that can withstand higher temperatures, resist corrosion, and maintain structural integrity under extreme mechanical stresses.

Current market trends indicate a growing demand for carbide-brazed components in aerospace, automotive, mining, and precision machining industries. The global carbide tools market, heavily dependent on brazing technology, is projected to reach $18.8 billion by 2027, with a compound annual growth rate of approximately 6.2%. This growth underscores the strategic importance of advancing carbide brazing technologies to meet evolving industrial requirements.

The primary technical objectives in carbide brazing research focus on several key areas. First, enhancing joint reliability through improved understanding of interfacial reactions between the carbide, filler metal, and substrate. Second, developing environmentally friendly flux systems that eliminate hazardous components while maintaining or improving performance. Third, optimizing brazing procedures to minimize residual stresses and prevent crack formation in the heat-affected zone.

Another significant objective is the standardization of brazing procedures across industries to ensure consistent quality and performance. This includes establishing reliable testing methodologies for joint evaluation and developing predictive models for joint behavior under various service conditions. The integration of automation and precise temperature control systems represents another frontier, aimed at reducing process variability and enhancing reproducibility.

Looking forward, the field is moving toward more sophisticated multi-material joining solutions, where carbide components are brazed alongside other advanced materials in complex assemblies. This trend necessitates innovative approaches to address thermal expansion mismatches and chemical compatibility challenges, driving research into new filler metal compositions and surface preparation techniques.

The evolution of carbide brazing has been characterized by continuous improvements in filler metals, fluxes, and process parameters. Early brazing techniques relied on simple copper-based alloys, but the industry has progressively shifted toward silver-based, nickel-based, and specialized active brazing alloys to meet more demanding applications. This technological progression has been driven by the need for joints that can withstand higher temperatures, resist corrosion, and maintain structural integrity under extreme mechanical stresses.

Current market trends indicate a growing demand for carbide-brazed components in aerospace, automotive, mining, and precision machining industries. The global carbide tools market, heavily dependent on brazing technology, is projected to reach $18.8 billion by 2027, with a compound annual growth rate of approximately 6.2%. This growth underscores the strategic importance of advancing carbide brazing technologies to meet evolving industrial requirements.

The primary technical objectives in carbide brazing research focus on several key areas. First, enhancing joint reliability through improved understanding of interfacial reactions between the carbide, filler metal, and substrate. Second, developing environmentally friendly flux systems that eliminate hazardous components while maintaining or improving performance. Third, optimizing brazing procedures to minimize residual stresses and prevent crack formation in the heat-affected zone.

Another significant objective is the standardization of brazing procedures across industries to ensure consistent quality and performance. This includes establishing reliable testing methodologies for joint evaluation and developing predictive models for joint behavior under various service conditions. The integration of automation and precise temperature control systems represents another frontier, aimed at reducing process variability and enhancing reproducibility.

Looking forward, the field is moving toward more sophisticated multi-material joining solutions, where carbide components are brazed alongside other advanced materials in complex assemblies. This trend necessitates innovative approaches to address thermal expansion mismatches and chemical compatibility challenges, driving research into new filler metal compositions and surface preparation techniques.

Market Analysis for Carbide Brazed Products

The global market for carbide brazed products has experienced consistent growth over the past decade, primarily driven by increasing demand in manufacturing, automotive, aerospace, and construction industries. The market size for carbide brazed tools and components is currently valued at approximately 3.2 billion USD, with projections indicating a compound annual growth rate of 5.7% through 2028.

The manufacturing sector remains the largest consumer of carbide brazed products, accounting for roughly 42% of the total market share. This dominance stems from the critical need for high-performance cutting tools, wear-resistant components, and precision instruments in modern manufacturing processes. The automotive industry follows closely, representing about 27% of market demand, particularly for engine components, transmission parts, and specialized tooling for vehicle production.

Regional analysis reveals that Asia-Pacific dominates the global market with approximately 38% share, led by China, Japan, and South Korea's robust manufacturing bases. North America and Europe collectively account for about 45% of the market, with particularly strong demand in aerospace, defense, and premium automotive manufacturing sectors.

Customer requirements are increasingly focused on joint reliability and longevity, with end-users willing to pay premium prices for brazed carbide products that demonstrate superior performance under extreme conditions. Market research indicates that products offering documented reliability improvements of 15-20% command price premiums of up to 35% compared to standard offerings.

The competitive landscape features both established multinational corporations and specialized regional manufacturers. Major players include Kennametal, Sandvik Coromant, and Mitsubishi Materials, who collectively hold approximately 42% of the global market share. These industry leaders have invested heavily in advanced brazing technologies and proprietary flux formulations to maintain their competitive edge.

Emerging market trends include growing demand for customized brazing solutions for specific applications, increased focus on environmentally friendly flux compositions with reduced toxic components, and rising interest in automated brazing processes that ensure consistent joint quality. Additionally, there is expanding demand for carbide brazed products in renewable energy infrastructure, particularly wind turbine manufacturing and maintenance.

Price sensitivity varies significantly across market segments, with aerospace and medical industries demonstrating low price elasticity due to stringent performance requirements, while general manufacturing and construction sectors show greater price sensitivity. This market stratification has led to diversified product offerings, with premium lines featuring advanced flux technologies and standard lines focusing on cost-effectiveness for less demanding applications.

The manufacturing sector remains the largest consumer of carbide brazed products, accounting for roughly 42% of the total market share. This dominance stems from the critical need for high-performance cutting tools, wear-resistant components, and precision instruments in modern manufacturing processes. The automotive industry follows closely, representing about 27% of market demand, particularly for engine components, transmission parts, and specialized tooling for vehicle production.

Regional analysis reveals that Asia-Pacific dominates the global market with approximately 38% share, led by China, Japan, and South Korea's robust manufacturing bases. North America and Europe collectively account for about 45% of the market, with particularly strong demand in aerospace, defense, and premium automotive manufacturing sectors.

Customer requirements are increasingly focused on joint reliability and longevity, with end-users willing to pay premium prices for brazed carbide products that demonstrate superior performance under extreme conditions. Market research indicates that products offering documented reliability improvements of 15-20% command price premiums of up to 35% compared to standard offerings.

The competitive landscape features both established multinational corporations and specialized regional manufacturers. Major players include Kennametal, Sandvik Coromant, and Mitsubishi Materials, who collectively hold approximately 42% of the global market share. These industry leaders have invested heavily in advanced brazing technologies and proprietary flux formulations to maintain their competitive edge.

Emerging market trends include growing demand for customized brazing solutions for specific applications, increased focus on environmentally friendly flux compositions with reduced toxic components, and rising interest in automated brazing processes that ensure consistent joint quality. Additionally, there is expanding demand for carbide brazed products in renewable energy infrastructure, particularly wind turbine manufacturing and maintenance.

Price sensitivity varies significantly across market segments, with aerospace and medical industries demonstrating low price elasticity due to stringent performance requirements, while general manufacturing and construction sectors show greater price sensitivity. This market stratification has led to diversified product offerings, with premium lines featuring advanced flux technologies and standard lines focusing on cost-effectiveness for less demanding applications.

Current Challenges in Carbide Brazing Techniques

Despite significant advancements in carbide brazing technology, several persistent challenges continue to impede optimal performance and reliability in industrial applications. One of the most critical issues involves flux formulation and application. Current fluxes often fail to adequately protect the joint area from oxidation at elevated temperatures, particularly when brazing tungsten carbide to steel substrates. The chemical stability of these fluxes deteriorates rapidly above 800°C, leading to incomplete wetting and compromised joint integrity.

Joint reliability remains problematic due to residual stress formation during the cooling phase. The substantial difference in thermal expansion coefficients between carbide materials (typically 4-6 × 10^-6/K) and steel substrates (12-14 × 10^-6/K) creates significant internal stresses that can lead to immediate cracking or premature failure during service. Current techniques have not fully resolved this fundamental mismatch issue.

Temperature control during the brazing process presents another significant challenge. The narrow processing window between the melting point of the filler metal and the degradation temperature of the carbide material requires precise heating protocols. Conventional heating methods often produce temperature gradients across complex geometries, resulting in inconsistent joint quality. This is particularly problematic in mass production environments where process repeatability is essential.

The environmental and health concerns associated with traditional brazing fluxes containing boron, fluoride compounds, and cadmium-bearing fillers have prompted regulatory restrictions in many regions. However, environmentally friendly alternatives currently available typically demonstrate inferior performance in terms of wetting ability and joint strength, creating a significant technical barrier for manufacturers seeking to comply with evolving regulations.

Automation challenges persist in the carbide brazing process. The precise positioning requirements and the need for controlled atmosphere conditions make full automation difficult to implement cost-effectively. Manual intervention remains necessary at critical stages, introducing variability in joint quality and limiting production throughput.

Quality assessment of completed brazed joints presents additional challenges. Non-destructive testing methods often fail to reliably detect subsurface defects at the carbide-braze interface. The opacity of carbide materials to conventional inspection techniques such as ultrasonic testing necessitates destructive testing of sample pieces, which increases production costs and cannot guarantee the integrity of all production components.

Joint reliability remains problematic due to residual stress formation during the cooling phase. The substantial difference in thermal expansion coefficients between carbide materials (typically 4-6 × 10^-6/K) and steel substrates (12-14 × 10^-6/K) creates significant internal stresses that can lead to immediate cracking or premature failure during service. Current techniques have not fully resolved this fundamental mismatch issue.

Temperature control during the brazing process presents another significant challenge. The narrow processing window between the melting point of the filler metal and the degradation temperature of the carbide material requires precise heating protocols. Conventional heating methods often produce temperature gradients across complex geometries, resulting in inconsistent joint quality. This is particularly problematic in mass production environments where process repeatability is essential.

The environmental and health concerns associated with traditional brazing fluxes containing boron, fluoride compounds, and cadmium-bearing fillers have prompted regulatory restrictions in many regions. However, environmentally friendly alternatives currently available typically demonstrate inferior performance in terms of wetting ability and joint strength, creating a significant technical barrier for manufacturers seeking to comply with evolving regulations.

Automation challenges persist in the carbide brazing process. The precise positioning requirements and the need for controlled atmosphere conditions make full automation difficult to implement cost-effectively. Manual intervention remains necessary at critical stages, introducing variability in joint quality and limiting production throughput.

Quality assessment of completed brazed joints presents additional challenges. Non-destructive testing methods often fail to reliably detect subsurface defects at the carbide-braze interface. The opacity of carbide materials to conventional inspection techniques such as ultrasonic testing necessitates destructive testing of sample pieces, which increases production costs and cannot guarantee the integrity of all production components.

Contemporary Carbide Brazing Procedures and Flux Solutions

01 Brazing materials and compositions for carbide joints

Specific brazing materials and compositions are crucial for creating reliable carbide joints. These include specialized alloys containing elements such as silver, copper, zinc, and nickel that provide optimal wetting properties and bond strength with carbide materials. The composition of these brazing materials affects the joint's mechanical properties, thermal resistance, and overall reliability. Proper selection of brazing materials based on the specific carbide type and application requirements is essential for achieving durable and reliable brazed joints.- Brazing materials and compositions for carbide joints: Specific brazing materials and compositions are crucial for creating reliable carbide joints. These include specialized alloys containing elements such as silver, copper, zinc, and nickel that provide optimal wetting and bonding to carbide surfaces. The composition of these brazing materials affects the joint's mechanical properties, thermal resistance, and overall reliability. Proper selection of brazing alloys based on the specific carbide material and application requirements ensures enhanced joint strength and durability.

- Brazing process parameters for carbide joint reliability: The reliability of carbide brazed joints is significantly influenced by process parameters such as temperature profiles, heating rates, cooling methods, and dwell times. Controlled heating and cooling cycles prevent thermal shock and residual stress formation in the carbide material. Vacuum or controlled atmosphere brazing environments minimize oxidation and contamination at the joint interface. Precise control of these parameters ensures consistent joint quality and prevents defects such as voids, cracks, or incomplete bonding that would compromise reliability.

- Joint design considerations for carbide brazing reliability: The geometric design of carbide brazed joints significantly impacts their reliability. Factors such as joint clearance, overlap length, and surface preparation affect the capillary flow of brazing material and resulting bond strength. Proper joint design accommodates differences in thermal expansion between carbide and base materials, reducing stress concentrations during thermal cycling. Specialized joint configurations can enhance stress distribution and improve fatigue resistance in applications subjected to cyclic loading or extreme operating conditions.

- Surface preparation techniques for carbide brazing: Effective surface preparation is essential for reliable carbide brazed joints. Techniques include mechanical cleaning, chemical etching, and specialized treatments to remove contaminants and create optimal surface conditions for brazing material adhesion. Surface activation methods enhance wettability of the carbide surface, promoting complete filling of the joint gap and strong metallurgical bonding. Proper surface roughness profiles improve mechanical interlocking between the brazing material and carbide substrate, contributing to enhanced joint reliability and performance under stress.

- Testing and quality control methods for carbide brazed joints: Various testing and quality control methods are employed to ensure carbide brazed joint reliability. Non-destructive techniques such as ultrasonic testing, X-ray inspection, and thermal imaging can detect internal defects without damaging the joint. Destructive testing methods including shear testing, tensile testing, and metallographic examination provide quantitative data on joint strength and quality. Accelerated aging tests and thermal cycling evaluations help predict long-term reliability under actual service conditions. Implementation of comprehensive quality control protocols throughout the brazing process ensures consistent joint performance and reliability.

02 Brazing techniques and process parameters

Various brazing techniques and process parameters significantly impact carbide joint reliability. These include temperature control, heating rate, cooling rate, dwell time, and atmosphere conditions during the brazing process. Vacuum brazing, induction brazing, and furnace brazing are common methods used for carbide joints. Precise control of these parameters helps prevent thermal stress, cracking, and ensures proper flow and wetting of the brazing material, resulting in stronger and more reliable joints between carbide components and other materials.Expand Specific Solutions03 Joint design and surface preparation

The design of the joint interface and proper surface preparation are critical factors affecting carbide brazing reliability. This includes considerations for joint clearance, overlap length, surface roughness, and cleanliness. Proper surface preparation techniques such as degreasing, etching, and activation treatments improve wettability and bonding strength. Strategic joint designs that account for thermal expansion differences between carbide and other materials help minimize residual stresses and prevent joint failure under operational conditions.Expand Specific Solutions04 Testing and quality assessment methods

Various testing and quality assessment methods are employed to evaluate the reliability of carbide brazed joints. These include non-destructive testing techniques such as ultrasonic inspection, X-ray analysis, and thermal imaging to detect defects without damaging the joint. Destructive testing methods like shear strength tests, tensile tests, and fatigue tests provide quantitative data on joint performance. Microstructural analysis through scanning electron microscopy and energy-dispersive X-ray spectroscopy helps evaluate the integrity of the brazed interface and identify potential failure mechanisms.Expand Specific Solutions05 Application-specific reliability enhancements

Specialized approaches for enhancing carbide brazing joint reliability in specific applications have been developed. These include reinforcement techniques for high-stress applications, protective coatings for corrosive environments, and multi-layer brazing approaches for complex thermal conditions. For cutting tools, drilling equipment, and wear-resistant components, specific joint designs and material combinations are employed to withstand the unique operational stresses. These application-specific enhancements consider factors such as thermal cycling, mechanical shock, and environmental exposure to optimize joint performance and longevity.Expand Specific Solutions

Leading Manufacturers and Suppliers in Carbide Brazing Industry

Carbide brazing technology is currently in a mature development stage, with a global market size estimated to exceed $2 billion annually and growing steadily at 5-7%. The competitive landscape features established industrial leaders like Lucas-Milhaupt and Diamond Innovations dominating with advanced flux formulations and proprietary joining techniques, while research institutions such as Zhengzhou Research Institute and Beijing Institute of Aeronautical Materials drive innovation in joint reliability. Major manufacturers including GE, Hitachi, and Sandvik Coromant have integrated specialized carbide brazing processes into their production systems, focusing on high-performance applications. The technology has reached significant maturity with standardized procedures, though ongoing research by companies like 3M and Solvay continues to enhance flux compositions and joint durability for extreme operating conditions.

Zhengzhou Research Institute of Mechanical Engineering

Technical Solution: The Zhengzhou Research Institute of Mechanical Engineering has developed comprehensive carbide brazing solutions focused on heavy industrial applications. Their research has yielded innovative high-temperature brazing procedures using custom-formulated nickel-chromium-boron filler metals that maintain joint integrity at operating temperatures up to 900°C. The institute's proprietary flux systems incorporate rare earth elements that significantly improve wetting characteristics on difficult-to-braze carbide grades while minimizing interfacial reactions that could compromise joint strength. Their process optimization studies have established precise correlations between brazing parameters and joint reliability, with particular emphasis on controlling the formation of brittle intermetallic phases at the carbide-braze interface. The institute employs advanced non-destructive testing methods including acoustic microscopy and thermal imaging to validate joint quality. Their research has demonstrated that controlled cooling rates below 10°C/minute during the post-braze phase can increase joint fatigue resistance by up to 40% in cyclically loaded components. For large carbide inserts, they've pioneered stress-relief techniques that maintain dimensional stability while preventing microcrack formation in the heat-affected zone.

Strengths: Extensive experience with large-scale industrial carbide components; innovative flux formulations that work effectively with a wide range of carbide compositions. Weaknesses: Some of their advanced processes have limited scalability for mass production; their specialized brazing techniques often require longer cycle times than conventional methods.

Beijing Institute of Aeronautical Materials

Technical Solution: The Beijing Institute of Aeronautical Materials has developed sophisticated carbide brazing technologies specifically for aerospace applications. Their approach centers on ultra-high vacuum brazing procedures (10^-6 torr) combined with active metal filler alloys containing titanium and zirconium additives that promote direct chemical bonding with carbide surfaces without conventional fluxes. The institute's research has established optimal brazing parameters for joining complex carbide-superalloy assemblies, achieving shear strengths exceeding 400 MPa while maintaining dimensional tolerances within ±0.01mm. Their proprietary gradient heating technology utilizes focused infrared radiation to create precisely controlled temperature distributions that minimize thermal stresses in dissimilar material joints. For critical aerospace components, they've developed specialized post-braze heat treatment protocols that optimize the microstructure of the braze layer while relieving residual stresses. The institute's testing protocols include thermal cycling between -60°C and 800°C to validate joint reliability under extreme operating conditions. Their research has demonstrated that controlled cooling rates and specialized fixture designs can reduce joint failure rates by over 70% compared to conventional brazing approaches for carbide components subjected to high thermal and mechanical stresses.

Strengths: Exceptional expertise in high-precision aerospace applications; advanced vacuum brazing capabilities that eliminate flux-related contamination issues. Weaknesses: Their highly specialized processes require sophisticated equipment with significant capital costs; some of their techniques have limited transferability to high-volume industrial applications.

Critical Patents and Research in Joint Reliability Enhancement

Method of brazing carbide using copper-zinc-manganese-nickel alloys

PatentInactiveUS4684052A

Innovation

- Copper-zinc-manganese-nickel alloys with specific compositions (30-70% Cu, 15-45% Zn, 5-20% Mn, 1-20% Ni, and 0.05-2% Si) are developed, providing compatibility with carbide compounds and substrates, comparable strength, and reduced brazing temperatures, along with a cost-effective alternative to silver-based alloys.

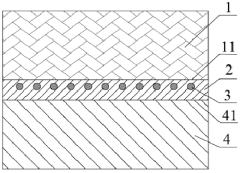

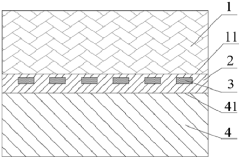

Carbide brazed joint, manufacturing method therefor, and carbide tool

PatentActiveBE1027778A1

Innovation

- A brazing method using a specific composition of brazing filler metal and a carbide tool blank, involving a controlled atmosphere brazing process to enhance bonding strength and reliability.

Material Compatibility and Selection Criteria

Material compatibility is a critical factor in the success of carbide brazing operations. When selecting materials for carbide brazing, engineers must consider the thermal expansion coefficients of both the carbide and the base metal. Tungsten carbide, for instance, has a coefficient of thermal expansion (CTE) of approximately 4.5-7.0 × 10^-6/°C, while most steels have CTEs ranging from 11-13 × 10^-6/°C. This mismatch can lead to residual stresses during cooling, potentially causing joint failure if not properly managed.

The selection of appropriate filler metals is equally important for ensuring joint reliability. Silver-based alloys (Ag-Cu-Zn) are commonly used for lower temperature applications (620-710°C), offering good wettability and ductility to accommodate stress. For higher temperature applications, copper-based alloys and nickel-based alloys are preferred, with working temperatures of 700-1100°C and above 950°C respectively. The filler metal must be compatible with both the carbide and the base metal to form strong metallurgical bonds.

Surface preparation significantly impacts material compatibility. Carbide surfaces require thorough cleaning to remove manufacturing residues and oxides. For optimal results, light grinding or etching may be necessary to expose fresh material surfaces. Base metals should undergo similar preparation processes, with particular attention to removing any surface contaminants that might inhibit proper wetting by the brazing alloy.

The geometry of the joint design must account for the physical properties of the materials involved. Optimal joint clearances typically range from 0.025 to 0.125 mm, depending on the specific filler metal and application requirements. Tighter clearances are generally preferred for higher strength joints, while allowing for sufficient capillary action of the molten filler metal.

Environmental considerations also influence material selection. For applications exposed to corrosive environments, nickel-based filler metals offer superior corrosion resistance compared to silver or copper-based alternatives. Similarly, for high-temperature applications, the oxidation resistance of both the carbide and the base metal must be evaluated to ensure long-term joint stability.

The mechanical properties of the joint interface must be compatible with the intended application. Shear strength is particularly important in carbide brazing, with properly executed joints capable of achieving strengths of 200-350 MPa. The hardness transition between the carbide (typically 1400-1800 HV) and the base metal must be managed through appropriate filler metal selection to prevent stress concentration and premature failure.

The selection of appropriate filler metals is equally important for ensuring joint reliability. Silver-based alloys (Ag-Cu-Zn) are commonly used for lower temperature applications (620-710°C), offering good wettability and ductility to accommodate stress. For higher temperature applications, copper-based alloys and nickel-based alloys are preferred, with working temperatures of 700-1100°C and above 950°C respectively. The filler metal must be compatible with both the carbide and the base metal to form strong metallurgical bonds.

Surface preparation significantly impacts material compatibility. Carbide surfaces require thorough cleaning to remove manufacturing residues and oxides. For optimal results, light grinding or etching may be necessary to expose fresh material surfaces. Base metals should undergo similar preparation processes, with particular attention to removing any surface contaminants that might inhibit proper wetting by the brazing alloy.

The geometry of the joint design must account for the physical properties of the materials involved. Optimal joint clearances typically range from 0.025 to 0.125 mm, depending on the specific filler metal and application requirements. Tighter clearances are generally preferred for higher strength joints, while allowing for sufficient capillary action of the molten filler metal.

Environmental considerations also influence material selection. For applications exposed to corrosive environments, nickel-based filler metals offer superior corrosion resistance compared to silver or copper-based alternatives. Similarly, for high-temperature applications, the oxidation resistance of both the carbide and the base metal must be evaluated to ensure long-term joint stability.

The mechanical properties of the joint interface must be compatible with the intended application. Shear strength is particularly important in carbide brazing, with properly executed joints capable of achieving strengths of 200-350 MPa. The hardness transition between the carbide (typically 1400-1800 HV) and the base metal must be managed through appropriate filler metal selection to prevent stress concentration and premature failure.

Quality Control Standards for Brazed Carbide Joints

Quality control standards for brazed carbide joints are essential to ensure the reliability, durability, and performance of these critical industrial components. Effective quality control begins with comprehensive material inspection protocols that verify the composition, dimensions, and surface conditions of both the carbide inserts and the steel bodies before the brazing process commences. These inspections typically include spectrographic analysis, hardness testing, and microscopic examination to detect any potential defects that could compromise joint integrity.

The brazing process itself requires stringent parameter monitoring, including temperature profiles, heating rates, and cooling cycles. Industry standards such as AWS C3.2 and ISO 17672 provide specific guidelines for these parameters, with temperature tolerances typically maintained within ±10°C of the specified brazing temperature. Automated systems with digital recording capabilities are increasingly becoming the norm for ensuring process consistency and traceability.

Non-destructive testing (NDT) methods play a crucial role in post-brazing quality assessment. Ultrasonic testing can detect subsurface voids or lack of fusion, while radiographic inspection identifies internal defects that might compromise joint strength. Dye penetrant testing is commonly employed to reveal surface discontinuities that could serve as stress concentration points. These NDT methods are complemented by standardized destructive testing protocols on sample pieces from each production batch.

Statistical process control (SPC) methodologies are implemented to monitor trends in joint quality over time. Key performance indicators such as shear strength, thermal cycling resistance, and dimensional stability are tracked using control charts to identify process drift before it results in defective products. Industry standards typically require minimum shear strength values ranging from 200-350 MPa depending on the specific carbide-steel combination and application requirements.

Documentation and traceability systems form another critical component of quality control standards. Each brazed assembly should be accompanied by records detailing material certifications, process parameters, inspection results, and operator qualifications. This documentation chain enables root cause analysis in the event of field failures and facilitates continuous improvement initiatives.

Acceptance criteria for brazed carbide joints are typically defined in terms of both visual and mechanical standards. Visually, joints must show complete filler metal flow with minimal porosity and no evidence of flux entrapment. Mechanically, they must withstand application-specific load testing that simulates actual service conditions, including thermal cycling, impact loading, or vibration resistance as appropriate for the intended use environment.

The brazing process itself requires stringent parameter monitoring, including temperature profiles, heating rates, and cooling cycles. Industry standards such as AWS C3.2 and ISO 17672 provide specific guidelines for these parameters, with temperature tolerances typically maintained within ±10°C of the specified brazing temperature. Automated systems with digital recording capabilities are increasingly becoming the norm for ensuring process consistency and traceability.

Non-destructive testing (NDT) methods play a crucial role in post-brazing quality assessment. Ultrasonic testing can detect subsurface voids or lack of fusion, while radiographic inspection identifies internal defects that might compromise joint strength. Dye penetrant testing is commonly employed to reveal surface discontinuities that could serve as stress concentration points. These NDT methods are complemented by standardized destructive testing protocols on sample pieces from each production batch.

Statistical process control (SPC) methodologies are implemented to monitor trends in joint quality over time. Key performance indicators such as shear strength, thermal cycling resistance, and dimensional stability are tracked using control charts to identify process drift before it results in defective products. Industry standards typically require minimum shear strength values ranging from 200-350 MPa depending on the specific carbide-steel combination and application requirements.

Documentation and traceability systems form another critical component of quality control standards. Each brazed assembly should be accompanied by records detailing material certifications, process parameters, inspection results, and operator qualifications. This documentation chain enables root cause analysis in the event of field failures and facilitates continuous improvement initiatives.

Acceptance criteria for brazed carbide joints are typically defined in terms of both visual and mechanical standards. Visually, joints must show complete filler metal flow with minimal porosity and no evidence of flux entrapment. Mechanically, they must withstand application-specific load testing that simulates actual service conditions, including thermal cycling, impact loading, or vibration resistance as appropriate for the intended use environment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!