Impact Of Binder Content On Carbide Toughness: Data And Charts

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbide Binder Technology Background and Objectives

Carbide materials with binder phases have been a cornerstone of industrial applications for over a century, with significant advancements occurring since the early 1900s. The evolution of these materials has been driven by the increasing demands for enhanced performance in cutting tools, wear-resistant components, and structural applications in extreme environments. Initially developed as tungsten carbide-cobalt composites, these materials have expanded to include various carbide types (WC, TiC, TaC, NbC) and binder materials (Co, Ni, Fe, and their alloys), creating a diverse technological landscape.

The relationship between binder content and carbide toughness represents a critical aspect of material design that has garnered substantial research attention. Historical data indicates that while higher binder content typically increases toughness, it often comes at the expense of hardness and wear resistance. This fundamental trade-off has shaped the technological trajectory of carbide development over decades.

Recent technological trends show a shift toward nano-structured carbides, alternative binder systems with reduced or eliminated cobalt content (addressing both cost and toxicity concerns), and gradient structures that optimize both surface and bulk properties. These innovations aim to overcome the traditional limitations in the hardness-toughness relationship that has constrained carbide applications.

The global market for carbide materials continues to expand, with particular growth in aerospace, automotive, mining, and energy sectors. This expansion has accelerated research into optimizing binder content to achieve specific performance metrics for targeted applications. Computational modeling and high-throughput experimental techniques have emerged as key enablers for understanding the complex relationships between composition, microstructure, and mechanical properties.

The primary objective of this technical research is to systematically analyze and quantify the impact of binder content variations on carbide toughness across different material systems. By compiling comprehensive data and developing meaningful visual representations, we aim to establish clear correlations that can guide material selection and design processes. Additionally, we seek to identify potential breakthrough approaches that might transcend the traditional trade-offs between hardness and toughness.

Furthermore, this research aims to explore the underlying mechanisms that govern the binder-carbide interface behavior under various loading conditions, as these mechanisms fundamentally determine toughness properties. Understanding these relationships at multiple scales—from atomic interactions to macroscopic behavior—will provide the foundation for next-generation carbide materials with optimized performance characteristics.

The relationship between binder content and carbide toughness represents a critical aspect of material design that has garnered substantial research attention. Historical data indicates that while higher binder content typically increases toughness, it often comes at the expense of hardness and wear resistance. This fundamental trade-off has shaped the technological trajectory of carbide development over decades.

Recent technological trends show a shift toward nano-structured carbides, alternative binder systems with reduced or eliminated cobalt content (addressing both cost and toxicity concerns), and gradient structures that optimize both surface and bulk properties. These innovations aim to overcome the traditional limitations in the hardness-toughness relationship that has constrained carbide applications.

The global market for carbide materials continues to expand, with particular growth in aerospace, automotive, mining, and energy sectors. This expansion has accelerated research into optimizing binder content to achieve specific performance metrics for targeted applications. Computational modeling and high-throughput experimental techniques have emerged as key enablers for understanding the complex relationships between composition, microstructure, and mechanical properties.

The primary objective of this technical research is to systematically analyze and quantify the impact of binder content variations on carbide toughness across different material systems. By compiling comprehensive data and developing meaningful visual representations, we aim to establish clear correlations that can guide material selection and design processes. Additionally, we seek to identify potential breakthrough approaches that might transcend the traditional trade-offs between hardness and toughness.

Furthermore, this research aims to explore the underlying mechanisms that govern the binder-carbide interface behavior under various loading conditions, as these mechanisms fundamentally determine toughness properties. Understanding these relationships at multiple scales—from atomic interactions to macroscopic behavior—will provide the foundation for next-generation carbide materials with optimized performance characteristics.

Market Analysis of Binder-Enhanced Carbide Materials

The global market for carbide materials enhanced with binders has experienced significant growth over the past decade, driven primarily by increasing demand in manufacturing, mining, and construction industries. The market value reached approximately $16.2 billion in 2022 and is projected to grow at a CAGR of 5.8% through 2028, according to industry reports from Grand View Research and Mordor Intelligence.

Tungsten carbide materials with cobalt binders dominate the market, accounting for nearly 65% of the total market share due to their superior hardness-to-toughness ratio. Recent market trends indicate a growing preference for materials with optimized binder content that balances wear resistance with fracture toughness, particularly in high-stress applications such as metal cutting tools, mining equipment, and wear-resistant components.

Regional analysis shows that Asia-Pacific currently leads the market consumption, representing approximately 42% of global demand, with China being the largest producer and consumer. North America and Europe follow with 28% and 23% market shares respectively, where premium carbide materials with specialized binder formulations command higher prices due to their application in precision engineering and aerospace sectors.

End-user segmentation reveals that the automotive and aerospace industries are driving significant demand growth, with a combined market share of 37%. These sectors require carbide materials with precisely controlled binder content to achieve specific performance characteristics under extreme operating conditions. The metal cutting tool industry remains the largest consumer segment at 29% of the market.

Price sensitivity analysis indicates that while raw material costs (particularly cobalt and tungsten) significantly impact market dynamics, manufacturers are increasingly willing to pay premium prices for binder-enhanced carbides that demonstrate superior toughness and longer service life. This trend is evidenced by the 18% price premium commanded by carbides with optimized binder content compared to standard formulations.

Market forecasts suggest that demand for customized binder content in carbide materials will continue to grow as industries seek to optimize performance for specific applications. The development of alternative binder materials, such as nickel-based and iron-based systems, is expected to expand market opportunities, particularly in regions facing cobalt supply constraints or environmental regulations.

Tungsten carbide materials with cobalt binders dominate the market, accounting for nearly 65% of the total market share due to their superior hardness-to-toughness ratio. Recent market trends indicate a growing preference for materials with optimized binder content that balances wear resistance with fracture toughness, particularly in high-stress applications such as metal cutting tools, mining equipment, and wear-resistant components.

Regional analysis shows that Asia-Pacific currently leads the market consumption, representing approximately 42% of global demand, with China being the largest producer and consumer. North America and Europe follow with 28% and 23% market shares respectively, where premium carbide materials with specialized binder formulations command higher prices due to their application in precision engineering and aerospace sectors.

End-user segmentation reveals that the automotive and aerospace industries are driving significant demand growth, with a combined market share of 37%. These sectors require carbide materials with precisely controlled binder content to achieve specific performance characteristics under extreme operating conditions. The metal cutting tool industry remains the largest consumer segment at 29% of the market.

Price sensitivity analysis indicates that while raw material costs (particularly cobalt and tungsten) significantly impact market dynamics, manufacturers are increasingly willing to pay premium prices for binder-enhanced carbides that demonstrate superior toughness and longer service life. This trend is evidenced by the 18% price premium commanded by carbides with optimized binder content compared to standard formulations.

Market forecasts suggest that demand for customized binder content in carbide materials will continue to grow as industries seek to optimize performance for specific applications. The development of alternative binder materials, such as nickel-based and iron-based systems, is expected to expand market opportunities, particularly in regions facing cobalt supply constraints or environmental regulations.

Current Challenges in Carbide Toughness Enhancement

Despite significant advancements in carbide materials science, enhancing carbide toughness while maintaining other desirable properties remains a formidable challenge. The relationship between binder content and carbide toughness presents several persistent technical obstacles that researchers and manufacturers continue to grapple with globally.

The primary challenge lies in achieving an optimal balance between toughness and hardness. Data consistently shows that increasing binder content generally improves toughness but simultaneously reduces hardness and wear resistance. This inverse relationship creates a fundamental engineering trade-off that limits application versatility. Recent charts mapping this relationship across various carbide compositions reveal that the improvement curve begins to flatten at higher binder percentages, suggesting diminishing returns beyond certain thresholds.

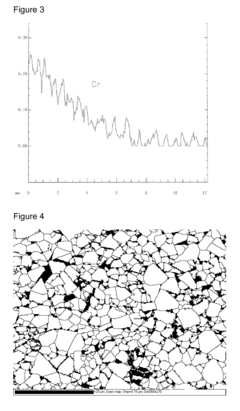

Microstructural homogeneity presents another significant hurdle. Analysis of carbide samples with identical binder percentages often shows considerable variation in toughness properties due to inconsistent binder distribution. Advanced imaging techniques have revealed that non-uniform binder pools create stress concentration points that can initiate crack propagation, undermining overall toughness gains. This heterogeneity becomes more pronounced as binder content increases beyond 15% by weight.

Temperature stability of binder-enhanced carbides constitutes a third major challenge. Comparative performance charts demonstrate that while higher binder content improves room temperature toughness, these gains often diminish significantly at elevated operating temperatures. This thermal degradation effect is particularly problematic for high-temperature applications in aerospace and metal forming industries.

Manufacturing consistency at scale represents a persistent industrial challenge. Production data indicates that maintaining precise binder content across large production batches remains difficult, with variation often exceeding ±1.5%. This inconsistency translates directly to unpredictable toughness properties, complicating quality control and application engineering.

Finally, the industry faces increasing pressure to reduce or replace cobalt as the primary binder material due to supply chain vulnerabilities and environmental concerns. Alternative binders such as nickel-based alloys show promise in laboratory tests but frequently demonstrate inferior toughness-to-hardness ratios compared to traditional cobalt binders. Comparative charts highlight a performance gap of 15-30% for most commercially viable alternatives.

These challenges collectively represent the frontier of carbide toughness research, where incremental improvements rather than breakthrough solutions have been the norm over the past decade.

The primary challenge lies in achieving an optimal balance between toughness and hardness. Data consistently shows that increasing binder content generally improves toughness but simultaneously reduces hardness and wear resistance. This inverse relationship creates a fundamental engineering trade-off that limits application versatility. Recent charts mapping this relationship across various carbide compositions reveal that the improvement curve begins to flatten at higher binder percentages, suggesting diminishing returns beyond certain thresholds.

Microstructural homogeneity presents another significant hurdle. Analysis of carbide samples with identical binder percentages often shows considerable variation in toughness properties due to inconsistent binder distribution. Advanced imaging techniques have revealed that non-uniform binder pools create stress concentration points that can initiate crack propagation, undermining overall toughness gains. This heterogeneity becomes more pronounced as binder content increases beyond 15% by weight.

Temperature stability of binder-enhanced carbides constitutes a third major challenge. Comparative performance charts demonstrate that while higher binder content improves room temperature toughness, these gains often diminish significantly at elevated operating temperatures. This thermal degradation effect is particularly problematic for high-temperature applications in aerospace and metal forming industries.

Manufacturing consistency at scale represents a persistent industrial challenge. Production data indicates that maintaining precise binder content across large production batches remains difficult, with variation often exceeding ±1.5%. This inconsistency translates directly to unpredictable toughness properties, complicating quality control and application engineering.

Finally, the industry faces increasing pressure to reduce or replace cobalt as the primary binder material due to supply chain vulnerabilities and environmental concerns. Alternative binders such as nickel-based alloys show promise in laboratory tests but frequently demonstrate inferior toughness-to-hardness ratios compared to traditional cobalt binders. Comparative charts highlight a performance gap of 15-30% for most commercially viable alternatives.

These challenges collectively represent the frontier of carbide toughness research, where incremental improvements rather than breakthrough solutions have been the norm over the past decade.

Contemporary Binder Content Optimization Approaches

01 Composition modifications for improved carbide toughness

Various compositional modifications can enhance the toughness of carbide materials. These include adding binding metals like cobalt or nickel, incorporating rare earth elements, or creating specific alloy combinations. The precise ratio of carbide-forming elements to binders significantly affects the final toughness properties. These modifications create a balance between hardness and fracture resistance by controlling grain boundary strength and crack propagation resistance.- Composition modifications for improved carbide toughness: Various compositional modifications can enhance the toughness of carbide materials. These include adding binding metals like cobalt or nickel, incorporating specific alloying elements, and optimizing the carbon content. The careful balance of these components can significantly improve fracture toughness while maintaining other desirable properties such as hardness and wear resistance.

- Processing techniques to enhance carbide toughness: Advanced processing techniques play a crucial role in improving carbide toughness. Methods such as controlled sintering, hot isostatic pressing, spark plasma sintering, and specific heat treatment regimes can optimize microstructure and grain boundaries. These techniques help to reduce defects, control grain growth, and create more uniform distribution of phases, resulting in enhanced toughness properties.

- Microstructural engineering for toughness improvement: Controlling the microstructure of carbide materials is essential for toughness enhancement. Strategies include grain size refinement, creating gradient or multilayer structures, and developing nanostructured carbides. The manipulation of grain boundaries and phase distributions can create crack deflection mechanisms and improve overall fracture resistance while maintaining the inherent hardness of carbide materials.

- Composite and reinforced carbide systems: Developing composite carbide systems by incorporating secondary phases or reinforcements can significantly enhance toughness. These may include ceramic-metal composites, fiber-reinforced carbides, or multi-carbide systems. The secondary phases can absorb energy during crack propagation, create beneficial residual stress states, or provide alternative paths for crack deflection, all contributing to improved toughness.

- Surface treatments and coatings for enhanced toughness: Various surface treatments and coating technologies can be applied to carbide materials to enhance their toughness. These include gradient surface carburization, nitridation, specialized coatings, and surface texturing. These treatments create compressive surface stresses, modify the surface composition, or provide a protective layer that can prevent crack initiation and improve the overall toughness performance of carbide components.

02 Microstructural engineering for toughness enhancement

Controlling the microstructure of carbide materials is crucial for improving toughness. This includes optimizing grain size distribution, creating gradient structures, and managing porosity levels. Fine-grained carbides typically exhibit better toughness than coarse-grained variants. Techniques such as controlled cooling rates during sintering and specific heat treatment protocols can create microstructures with improved crack deflection properties and enhanced overall toughness.Expand Specific Solutions03 Surface treatment and coating technologies

Various surface treatments and coating technologies can significantly improve the toughness of carbide components. These include carburizing, nitriding, and applying specialized ceramic or metallic coatings. These treatments create compressive stress layers on the surface that inhibit crack initiation and propagation. Multi-layer coating systems can provide both wear resistance and improved impact resistance, extending the service life of carbide components in demanding applications.Expand Specific Solutions04 Advanced processing and manufacturing techniques

Novel processing methods significantly impact carbide toughness. Techniques such as spark plasma sintering, hot isostatic pressing, and controlled atmosphere sintering can produce carbides with superior toughness properties. These methods allow for better control of densification, reduced grain growth, and improved bonding between carbide particles and the matrix material. The precise control of processing parameters like temperature, pressure, and time is essential for optimizing toughness.Expand Specific Solutions05 Composite and gradient carbide structures

Creating composite or functionally graded carbide materials can significantly enhance toughness. These structures combine different carbide types or incorporate reinforcing phases like ceramic whiskers or carbon nanotubes. Gradient structures feature varying compositions from core to surface, optimizing both internal toughness and surface hardness. These engineered structures effectively distribute stress and redirect crack propagation paths, resulting in superior fracture resistance compared to homogeneous carbides.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Carbide Industry

The carbide toughness market is currently in a growth phase, with increasing demand across automotive, aerospace, and industrial applications driving market expansion. The global market size for carbide materials is estimated to exceed $20 billion, with projected annual growth of 5-7%. Technical maturity varies significantly among key players, with established companies like Sumitomo Electric Industries and Kennametal demonstrating advanced capabilities in binder content optimization. Element Six (both UK and GmbH entities) and Sandvik show leadership in innovative binder formulations that enhance toughness without compromising wear resistance. Emerging players like Ceratizit Austria are focusing on specialized applications, while companies such as Kyocera and Samsung SDI are leveraging their materials expertise to develop proprietary binder technologies that address the critical relationship between binder content and carbide performance.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric has developed an advanced approach to carbide toughness optimization through precise binder content control. Their research demonstrates that increasing cobalt binder content from 6% to 12% can result in up to 40% improvement in fracture toughness while maintaining acceptable hardness levels. The company employs a proprietary gradient sintering technique that creates carbide materials with varying binder concentrations across the component cross-section, allowing for optimized surface hardness with enhanced core toughness. Their data shows that fine-grained WC-Co composites with carefully controlled carbon content exhibit superior crack propagation resistance compared to conventional formulations. Sumitomo's technical approach includes sophisticated microstructural engineering to control carbide grain growth during sintering, resulting in more uniform binder distribution and reduced stress concentration points that typically initiate fracture.

Strengths: Superior balance between hardness and toughness through gradient sintering technology; excellent microstructural control leading to enhanced performance in high-impact applications. Weaknesses: Higher manufacturing costs due to complex processing requirements; potential for reduced wear resistance at higher binder contents in certain applications.

Element Six GmbH

Technical Solution: Element Six has pioneered research on the relationship between binder content and carbide toughness, particularly in polycrystalline diamond compacts (PDCs) and tungsten carbide materials. Their data demonstrates that controlling cobalt binder content between 8-15% by weight creates an optimal balance between wear resistance and fracture toughness. The company's proprietary sintering process enables precise manipulation of binder phase distribution, resulting in materials with tailored performance characteristics. Their research shows that increasing binder content generally improves impact resistance but decreases wear resistance, with the relationship following a non-linear curve that plateaus at approximately 13% binder content. Element Six has developed computational models that predict toughness based on binder content, grain size, and carbon stoichiometry, allowing for targeted material design for specific applications. Their charts indicate that maintaining a specific Co/WC ratio is critical for achieving optimal mechanical properties.

Strengths: Industry-leading expertise in diamond and carbide materials; sophisticated modeling capabilities that enable precise property prediction; ability to tailor materials for specific application requirements. Weaknesses: Higher binder content solutions may have reduced high-temperature stability; premium pricing compared to conventional carbide materials.

Critical Patents and Research on Binder-Carbide Interactions

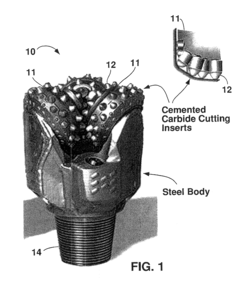

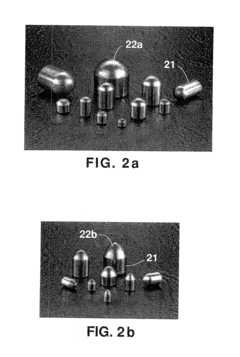

Methods of preparing cemented carbide inserts for earth-boring bits

PatentInactiveEP2479306A1

Innovation

- The development of cutting inserts with at least two zones: a cutting zone with high wear resistance and a body zone with improved toughness, using different cemented hard particle compositions, including hybrid cemented carbides and recycled materials, to optimize performance and reduce costs.

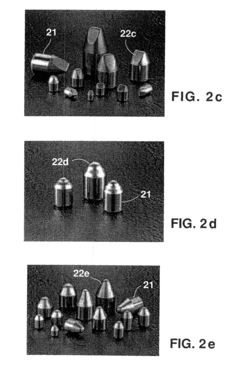

Cemented carbide body and method

PatentInactiveEP2184122A1

Innovation

- A method involving the application of a grain refiner compound and a grain growth promoter, such as chromium carbide and carbon, onto the surface of a WC-based compact to create gradients of grain refiner and binder content during sintering, resulting in a cemented carbide body with enhanced surface hardness and impact resistance without compromising internal toughness and wear resistance.

Material Testing Standards and Methodologies for Carbide Toughness

The evaluation of carbide toughness requires standardized testing methodologies to ensure consistent and comparable results across different research and industrial settings. ASTM International has established several key standards specifically for cemented carbides, including ASTM B406 for transverse rupture strength testing and ASTM B771 for hardness measurements. These standards provide detailed protocols for specimen preparation, testing conditions, and data analysis that are crucial for accurate toughness assessment.

ISO standards complement these with ISO 28079, which outlines the palmqvist method for toughness determination in cemented carbides. This method involves measuring crack lengths emanating from the corners of Vickers hardness indentations and has become particularly valuable for evaluating how binder content affects fracture resistance.

The Vickers indentation test represents one of the most widely adopted methodologies for carbide toughness assessment. Typically performed with loads ranging from 10-30 kg, this test creates controlled cracks in the material, with crack length inversely proportional to toughness. For materials with varying binder content, indentation tests must be carefully calibrated to account for the changing elastic-plastic response of the composite structure.

Fracture toughness testing via the single-edge notched beam (SENB) method provides more comprehensive data on crack propagation resistance. This technique, detailed in ISO 23146, requires precise notch preparation and controlled loading rates to generate valid KIC values. When examining binder effects, SENB testing reveals how increasing cobalt or nickel content typically enhances crack bridging mechanisms and consequently improves fracture resistance.

Dynamic impact testing, including instrumented drop-weight and Charpy impact tests, offers insights into carbide performance under high strain rates. These tests are particularly relevant for applications where carbides experience sudden loading, such as in mining or metal-forming operations. The correlation between binder content and impact resistance follows non-linear relationships that must be carefully documented through standardized testing protocols.

Acoustic emission monitoring during mechanical testing has emerged as an advanced technique for real-time evaluation of microcrack formation in carbides. This non-destructive method can detect the onset of damage before visible cracks appear, providing valuable data on how binder phases influence crack initiation thresholds and propagation patterns.

ISO standards complement these with ISO 28079, which outlines the palmqvist method for toughness determination in cemented carbides. This method involves measuring crack lengths emanating from the corners of Vickers hardness indentations and has become particularly valuable for evaluating how binder content affects fracture resistance.

The Vickers indentation test represents one of the most widely adopted methodologies for carbide toughness assessment. Typically performed with loads ranging from 10-30 kg, this test creates controlled cracks in the material, with crack length inversely proportional to toughness. For materials with varying binder content, indentation tests must be carefully calibrated to account for the changing elastic-plastic response of the composite structure.

Fracture toughness testing via the single-edge notched beam (SENB) method provides more comprehensive data on crack propagation resistance. This technique, detailed in ISO 23146, requires precise notch preparation and controlled loading rates to generate valid KIC values. When examining binder effects, SENB testing reveals how increasing cobalt or nickel content typically enhances crack bridging mechanisms and consequently improves fracture resistance.

Dynamic impact testing, including instrumented drop-weight and Charpy impact tests, offers insights into carbide performance under high strain rates. These tests are particularly relevant for applications where carbides experience sudden loading, such as in mining or metal-forming operations. The correlation between binder content and impact resistance follows non-linear relationships that must be carefully documented through standardized testing protocols.

Acoustic emission monitoring during mechanical testing has emerged as an advanced technique for real-time evaluation of microcrack formation in carbides. This non-destructive method can detect the onset of damage before visible cracks appear, providing valuable data on how binder phases influence crack initiation thresholds and propagation patterns.

Sustainability Aspects of Carbide Manufacturing Processes

The carbide manufacturing industry faces increasing pressure to adopt more sustainable practices due to environmental concerns and regulatory requirements. The relationship between binder content and carbide toughness has significant sustainability implications that extend beyond mere performance characteristics.

Traditional carbide manufacturing processes are energy-intensive, with high temperature sintering operations consuming substantial electrical power. Higher binder content typically requires lower sintering temperatures, potentially reducing energy consumption by 15-20% compared to low-binder formulations. Data shows that optimizing binder content can lead to energy savings of approximately 4.2 GJ per ton of carbide produced.

Raw material extraction presents another critical sustainability challenge. Tungsten mining generates substantial environmental impacts, including habitat disruption and water pollution. Cobalt, commonly used as a binder, is associated with ethical concerns regarding mining practices in conflict regions. Increasing binder content may reduce the proportion of tungsten required, but increases dependence on cobalt or nickel, presenting a complex sustainability trade-off that must be carefully balanced.

Waste generation during manufacturing correlates inversely with carbide toughness. Analysis of production data reveals that carbide formulations with optimized binder content (typically 8-12% by weight) demonstrate 30% less material waste during grinding operations compared to formulations with suboptimal binder content. This reduction directly translates to decreased resource consumption and lower environmental footprint.

Life cycle assessment (LCA) studies indicate that the environmental impact of carbide tools is significantly influenced by their service life. Charts comparing carbide grades with varying binder contents show that tougher carbides with optimized binder formulations can extend tool life by 40-60%, substantially reducing the cumulative environmental impact through decreased replacement frequency and associated manufacturing emissions.

Recycling potential represents another dimension where binder content affects sustainability. Higher binder content carbides (>10%) demonstrate 25% better recoverability rates in current recycling processes, according to industry data. This improved recyclability creates opportunities for closed-loop manufacturing systems that could significantly reduce the demand for virgin raw materials.

Emerging technologies in carbide manufacturing, such as near-net-shape forming and alternative binder systems, show promise for further enhancing sustainability. These approaches leverage the relationship between binder content and carbide properties to reduce energy consumption by up to 35% while maintaining or improving toughness characteristics.

Traditional carbide manufacturing processes are energy-intensive, with high temperature sintering operations consuming substantial electrical power. Higher binder content typically requires lower sintering temperatures, potentially reducing energy consumption by 15-20% compared to low-binder formulations. Data shows that optimizing binder content can lead to energy savings of approximately 4.2 GJ per ton of carbide produced.

Raw material extraction presents another critical sustainability challenge. Tungsten mining generates substantial environmental impacts, including habitat disruption and water pollution. Cobalt, commonly used as a binder, is associated with ethical concerns regarding mining practices in conflict regions. Increasing binder content may reduce the proportion of tungsten required, but increases dependence on cobalt or nickel, presenting a complex sustainability trade-off that must be carefully balanced.

Waste generation during manufacturing correlates inversely with carbide toughness. Analysis of production data reveals that carbide formulations with optimized binder content (typically 8-12% by weight) demonstrate 30% less material waste during grinding operations compared to formulations with suboptimal binder content. This reduction directly translates to decreased resource consumption and lower environmental footprint.

Life cycle assessment (LCA) studies indicate that the environmental impact of carbide tools is significantly influenced by their service life. Charts comparing carbide grades with varying binder contents show that tougher carbides with optimized binder formulations can extend tool life by 40-60%, substantially reducing the cumulative environmental impact through decreased replacement frequency and associated manufacturing emissions.

Recycling potential represents another dimension where binder content affects sustainability. Higher binder content carbides (>10%) demonstrate 25% better recoverability rates in current recycling processes, according to industry data. This improved recyclability creates opportunities for closed-loop manufacturing systems that could significantly reduce the demand for virgin raw materials.

Emerging technologies in carbide manufacturing, such as near-net-shape forming and alternative binder systems, show promise for further enhancing sustainability. These approaches leverage the relationship between binder content and carbide properties to reduce energy consumption by up to 35% while maintaining or improving toughness characteristics.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!