Failure Modes Of Tungsten Carbide Inserts: Causes And Remedies

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Tungsten Carbide Insert Technology Background and Objectives

Tungsten carbide inserts have revolutionized the machining industry since their introduction in the early 20th century. These cutting tools, composed primarily of tungsten carbide particles bonded with cobalt or other metals, offer exceptional hardness, wear resistance, and thermal stability compared to traditional high-speed steel tools. The evolution of tungsten carbide insert technology has been marked by continuous improvements in material composition, manufacturing processes, and coating technologies to enhance performance and longevity.

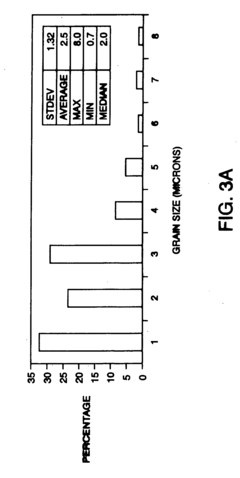

The development trajectory of tungsten carbide inserts has seen significant advancements in grain size refinement, from conventional micron-sized grains to modern nano-structured carbides. This progression has enabled superior hardness-toughness combinations, addressing the historical trade-off between these properties. Concurrently, innovations in binder materials and proportions have expanded the application range of these inserts across diverse machining environments.

Coating technologies represent another critical advancement path, evolving from single-layer TiN coatings to sophisticated multi-layer architectures incorporating materials such as TiAlN, TiCN, and diamond-like carbon. These coatings significantly enhance wear resistance, reduce friction, and improve thermal stability during high-speed machining operations.

Despite these advancements, tungsten carbide inserts continue to face failure challenges in industrial applications, including edge chipping, crater wear, thermal cracking, and catastrophic fracture. These failure modes result in reduced tool life, compromised workpiece quality, increased production costs, and manufacturing inefficiencies. Understanding the root causes and developing effective remediation strategies remains a primary focus for researchers and manufacturers alike.

The primary objective of this technical investigation is to comprehensively analyze the failure mechanisms of tungsten carbide inserts under various operational conditions. By identifying the fundamental causes of different failure modes, we aim to establish correlations between material properties, operational parameters, and failure patterns. This understanding will inform the development of more resilient tungsten carbide formulations, optimized coating systems, and improved application guidelines.

Additionally, this research seeks to evaluate emerging technologies and methodologies that could potentially extend insert lifespan, including advanced material compositions, novel manufacturing techniques, and innovative cooling strategies. The ultimate goal is to provide actionable insights for both manufacturers and end-users to minimize insert failures, optimize machining efficiency, and reduce overall production costs in industrial applications.

The development trajectory of tungsten carbide inserts has seen significant advancements in grain size refinement, from conventional micron-sized grains to modern nano-structured carbides. This progression has enabled superior hardness-toughness combinations, addressing the historical trade-off between these properties. Concurrently, innovations in binder materials and proportions have expanded the application range of these inserts across diverse machining environments.

Coating technologies represent another critical advancement path, evolving from single-layer TiN coatings to sophisticated multi-layer architectures incorporating materials such as TiAlN, TiCN, and diamond-like carbon. These coatings significantly enhance wear resistance, reduce friction, and improve thermal stability during high-speed machining operations.

Despite these advancements, tungsten carbide inserts continue to face failure challenges in industrial applications, including edge chipping, crater wear, thermal cracking, and catastrophic fracture. These failure modes result in reduced tool life, compromised workpiece quality, increased production costs, and manufacturing inefficiencies. Understanding the root causes and developing effective remediation strategies remains a primary focus for researchers and manufacturers alike.

The primary objective of this technical investigation is to comprehensively analyze the failure mechanisms of tungsten carbide inserts under various operational conditions. By identifying the fundamental causes of different failure modes, we aim to establish correlations between material properties, operational parameters, and failure patterns. This understanding will inform the development of more resilient tungsten carbide formulations, optimized coating systems, and improved application guidelines.

Additionally, this research seeks to evaluate emerging technologies and methodologies that could potentially extend insert lifespan, including advanced material compositions, novel manufacturing techniques, and innovative cooling strategies. The ultimate goal is to provide actionable insights for both manufacturers and end-users to minimize insert failures, optimize machining efficiency, and reduce overall production costs in industrial applications.

Market Demand Analysis for High-Performance Cutting Tools

The global market for high-performance cutting tools, particularly tungsten carbide inserts, has been experiencing robust growth driven by expanding manufacturing activities across automotive, aerospace, and general engineering sectors. Current market valuations indicate that the tungsten carbide tooling segment accounts for approximately 65% of the total cutting tool market, with annual growth rates consistently outpacing general industrial production indices.

Manufacturing industries worldwide are increasingly demanding cutting tools that can deliver higher productivity, extended tool life, and improved surface finish quality. This demand is particularly evident in precision machining operations where tungsten carbide inserts are preferred for their superior hardness, wear resistance, and thermal stability compared to traditional high-speed steel alternatives.

The automotive industry represents the largest end-user segment, consuming nearly 30% of all tungsten carbide inserts produced globally. This sector's push toward lightweight materials, including difficult-to-machine alloys and composites, has intensified the need for advanced cutting tools that can maintain dimensional accuracy while reducing machining cycle times. Similarly, the aerospace industry's requirements for machining heat-resistant superalloys has created premium market segments where tool performance supersedes cost considerations.

Regional analysis reveals that Asia-Pacific currently dominates the market consumption, led by China's massive manufacturing base, followed by North America and Europe. However, the highest growth rates are being observed in emerging economies of Southeast Asia and India, where rapid industrialization is driving double-digit annual increases in cutting tool consumption.

A significant market trend is the growing preference for customized tooling solutions rather than standard catalog items. End users are increasingly seeking application-specific inserts that address particular failure modes common in their operations. This shift has created new market opportunities for tool manufacturers who can provide technical consultation and tailored solutions that extend insert life and reduce failure incidents.

The aftermarket for tungsten carbide inserts also presents substantial revenue potential, with replacement and reconditioning services growing at approximately 8% annually. This segment is particularly important as manufacturers seek to optimize total tooling costs while maintaining production efficiency.

Price sensitivity varies significantly across market segments, with general machining operations being highly cost-conscious, while aerospace and medical device manufacturing prioritizing performance reliability over initial tool costs. This market stratification has led to diversified product offerings ranging from economy-grade to premium tungsten carbide inserts with specialized coatings and geometries designed to address specific failure modes.

Manufacturing industries worldwide are increasingly demanding cutting tools that can deliver higher productivity, extended tool life, and improved surface finish quality. This demand is particularly evident in precision machining operations where tungsten carbide inserts are preferred for their superior hardness, wear resistance, and thermal stability compared to traditional high-speed steel alternatives.

The automotive industry represents the largest end-user segment, consuming nearly 30% of all tungsten carbide inserts produced globally. This sector's push toward lightweight materials, including difficult-to-machine alloys and composites, has intensified the need for advanced cutting tools that can maintain dimensional accuracy while reducing machining cycle times. Similarly, the aerospace industry's requirements for machining heat-resistant superalloys has created premium market segments where tool performance supersedes cost considerations.

Regional analysis reveals that Asia-Pacific currently dominates the market consumption, led by China's massive manufacturing base, followed by North America and Europe. However, the highest growth rates are being observed in emerging economies of Southeast Asia and India, where rapid industrialization is driving double-digit annual increases in cutting tool consumption.

A significant market trend is the growing preference for customized tooling solutions rather than standard catalog items. End users are increasingly seeking application-specific inserts that address particular failure modes common in their operations. This shift has created new market opportunities for tool manufacturers who can provide technical consultation and tailored solutions that extend insert life and reduce failure incidents.

The aftermarket for tungsten carbide inserts also presents substantial revenue potential, with replacement and reconditioning services growing at approximately 8% annually. This segment is particularly important as manufacturers seek to optimize total tooling costs while maintaining production efficiency.

Price sensitivity varies significantly across market segments, with general machining operations being highly cost-conscious, while aerospace and medical device manufacturing prioritizing performance reliability over initial tool costs. This market stratification has led to diversified product offerings ranging from economy-grade to premium tungsten carbide inserts with specialized coatings and geometries designed to address specific failure modes.

Current Challenges in Tungsten Carbide Insert Technology

Despite significant advancements in tungsten carbide insert technology, several critical challenges continue to impede optimal performance and longevity in industrial applications. The primary challenge remains premature failure due to complex wear mechanisms that occur simultaneously during machining operations. These mechanisms include abrasive wear, adhesive wear, diffusion wear, and chemical wear, which often interact synergistically, making prediction and prevention difficult.

Thermal management presents another significant hurdle. During high-speed machining operations, inserts experience extreme temperature gradients that can exceed 1000°C within milliseconds. These thermal shocks create internal stresses that lead to microcracking and eventual catastrophic failure. Current cooling technologies struggle to effectively dissipate heat without introducing additional thermal shock risks.

Material inconsistency in tungsten carbide production continues to challenge manufacturers. Variations in cobalt binder content, grain size distribution, and carbide phase homogeneity result in unpredictable performance across supposedly identical inserts. This inconsistency is particularly problematic in automated manufacturing environments where process stability is paramount.

Edge preparation techniques represent another area of concern. The balance between edge sharpness for cutting efficiency and edge strength for durability remains difficult to optimize across diverse workpiece materials. Current edge preparation methods often produce inconsistent results, leading to variable tool life even within the same batch of inserts.

Coating adhesion failures constitute a persistent challenge, particularly in interrupted cutting applications. Despite advances in coating technologies, the interface between substrate and coating remains vulnerable to delamination under cyclic thermal and mechanical loading. This is exacerbated by the inherent mismatch in thermal expansion coefficients between tungsten carbide substrates and modern multi-layer coatings.

Tool-workpiece material compatibility issues have become more pronounced as new workpiece materials enter industrial use. Advanced alloys, composites, and additively manufactured components often exhibit unpredictable machining behavior, leading to accelerated and unpredictable insert failure modes that current predictive models cannot accurately forecast.

Economic and environmental considerations add further complexity. The rising costs of raw materials, particularly cobalt and other strategic metals, drive the need for more efficient use of these resources. Meanwhile, increasing environmental regulations regarding the mining, processing, and disposal of tungsten carbide materials necessitate new approaches to insert design and recycling that do not compromise performance.

Thermal management presents another significant hurdle. During high-speed machining operations, inserts experience extreme temperature gradients that can exceed 1000°C within milliseconds. These thermal shocks create internal stresses that lead to microcracking and eventual catastrophic failure. Current cooling technologies struggle to effectively dissipate heat without introducing additional thermal shock risks.

Material inconsistency in tungsten carbide production continues to challenge manufacturers. Variations in cobalt binder content, grain size distribution, and carbide phase homogeneity result in unpredictable performance across supposedly identical inserts. This inconsistency is particularly problematic in automated manufacturing environments where process stability is paramount.

Edge preparation techniques represent another area of concern. The balance between edge sharpness for cutting efficiency and edge strength for durability remains difficult to optimize across diverse workpiece materials. Current edge preparation methods often produce inconsistent results, leading to variable tool life even within the same batch of inserts.

Coating adhesion failures constitute a persistent challenge, particularly in interrupted cutting applications. Despite advances in coating technologies, the interface between substrate and coating remains vulnerable to delamination under cyclic thermal and mechanical loading. This is exacerbated by the inherent mismatch in thermal expansion coefficients between tungsten carbide substrates and modern multi-layer coatings.

Tool-workpiece material compatibility issues have become more pronounced as new workpiece materials enter industrial use. Advanced alloys, composites, and additively manufactured components often exhibit unpredictable machining behavior, leading to accelerated and unpredictable insert failure modes that current predictive models cannot accurately forecast.

Economic and environmental considerations add further complexity. The rising costs of raw materials, particularly cobalt and other strategic metals, drive the need for more efficient use of these resources. Meanwhile, increasing environmental regulations regarding the mining, processing, and disposal of tungsten carbide materials necessitate new approaches to insert design and recycling that do not compromise performance.

Current Failure Mode Identification and Solution Approaches

01 Thermal cracking and fracture failure modes

Tungsten carbide inserts can fail due to thermal cracking and fracture when exposed to extreme temperature fluctuations during drilling operations. The difference in thermal expansion between the tungsten carbide and cobalt binder can create internal stresses, leading to crack initiation and propagation. These cracks typically form perpendicular to the cutting edge and can result in catastrophic failure of the insert during operation.- Thermal cracking and fracture failure: Tungsten carbide inserts can fail due to thermal cracking and fracture when exposed to extreme temperature fluctuations during drilling or cutting operations. The difference in thermal expansion coefficients between the carbide and binder materials creates internal stresses that lead to crack initiation and propagation. These cracks typically appear as radial or concentric patterns on the insert surface and can ultimately result in catastrophic failure, especially in high-temperature applications or when cooling is insufficient.

- Wear and erosion mechanisms: Progressive wear and erosion represent common failure modes for tungsten carbide inserts in abrasive environments. This includes abrasive wear from contact with hard materials, erosive wear from particle impingement, and chemical wear from corrosive environments. The wear typically manifests as gradual material loss, rounding of cutting edges, or formation of wear flats. Factors affecting wear resistance include carbide grain size, binder content, and the presence of protective coatings or surface treatments.

- Binder phase depletion and cobalt leaching: Failure can occur due to the depletion of the binder phase (typically cobalt) that holds the tungsten carbide particles together. In corrosive environments or under high temperatures, the cobalt binder can leach out, leaving a porous structure with reduced strength and toughness. This phenomenon weakens the overall insert structure, making it susceptible to premature failure. The rate of binder depletion depends on operating conditions, binder content, and the presence of corrosion inhibitors or protective coatings.

- Impact and shock failure: Tungsten carbide inserts are vulnerable to impact and shock failure, particularly in intermittent cutting operations or when encountering unexpected hard inclusions. The brittle nature of tungsten carbide makes it susceptible to chipping, spalling, and catastrophic fracture under sudden impact loads. These failures typically originate at stress concentration points such as sharp corners or pre-existing defects. Factors affecting impact resistance include carbide grade, binder content, insert geometry, and the presence of toughening agents or gradient structures.

- Manufacturing defects and material inconsistencies: Failure of tungsten carbide inserts can be attributed to manufacturing defects and material inconsistencies that act as stress concentrators. These include porosity, inclusions, non-uniform grain size distribution, improper sintering, and inconsistent binder distribution. Such defects create weak points in the insert structure that can initiate cracks under operational stresses. Quality control measures, advanced powder metallurgy techniques, and post-processing treatments are essential to minimize these defects and enhance the reliability of tungsten carbide inserts.

02 Wear and abrasion failure mechanisms

Progressive wear and abrasion represent common failure modes for tungsten carbide inserts, particularly in high-abrasion drilling environments. The wear process typically begins with gradual erosion of the binder phase, followed by grain pullout of the tungsten carbide particles. This type of failure is characterized by rounded cutting edges, reduced insert diameter, and diminished cutting efficiency over time.Expand Specific Solutions03 Impact and shock damage failure

Tungsten carbide inserts can fail due to impact and shock damage when subjected to sudden loads or impacts during drilling operations. This failure mode is characterized by chipping, spalling, or complete fracture of the insert. The brittleness of tungsten carbide makes it particularly susceptible to impact damage, especially when the insert geometry features sharp edges or corners that concentrate stress.Expand Specific Solutions04 Chemical degradation and corrosion failure

Chemical degradation and corrosion represent significant failure modes for tungsten carbide inserts, particularly in environments with aggressive chemicals or high temperatures. The cobalt binder phase is especially susceptible to chemical attack, which can lead to weakening of the insert structure. This failure mechanism is characterized by surface pitting, selective leaching of the binder phase, and reduced mechanical integrity of the insert.Expand Specific Solutions05 Manufacturing defects and material composition issues

Failure of tungsten carbide inserts can originate from manufacturing defects and material composition issues. These include non-uniform distribution of the binder phase, presence of porosity, improper grain size distribution, and inadequate sintering. Such defects create stress concentration points that can initiate cracks under loading conditions. Improper carbide-to-binder ratios can also lead to either excessive brittleness or insufficient hardness, both contributing to premature failure.Expand Specific Solutions

Major Manufacturers and Industry Competition Landscape

The tungsten carbide insert failure market is currently in a mature growth phase, with an estimated global market size exceeding $5 billion. Key failure modes include thermal cracking, mechanical breakage, and chemical degradation, which major players are addressing through advanced material science and manufacturing innovations. Companies like Kennametal, Sandvik, and Sumitomo Electric lead with comprehensive solutions, while specialized players such as Seco Tools and Element Six focus on niche applications. Chinese manufacturers including Zhuzhou Cemented Carbides Group and Beijing Bei Ying Hard Alloy are rapidly gaining market share through cost-effective solutions. Research collaborations between industry leaders and institutions like University of Science & Technology Beijing are accelerating technological advancements in wear resistance, thermal stability, and recycling capabilities.

Seco Tools AB

Technical Solution: Seco Tools has developed the Duratomic® technology platform specifically addressing tungsten carbide insert failure modes. This technology manipulates the atomic structure of the coating at the microscopic level, creating an aluminum oxide coating with a unique crystalline structure that provides both increased wear resistance and toughness. Their approach includes a controlled oxygen vacancy distribution within the coating that enhances performance under thermal stress. Seco's substrate engineering incorporates gradient technology with optimized cobalt distribution from core to surface, providing a balance of toughness and wear resistance. Their Jetstream Tooling® technology addresses thermal cracking failures by directing high-pressure coolant precisely at the cutting zone, significantly reducing temperatures at the cutting edge. Seco has also developed specialized edge preparation techniques including their proprietary Edge Preparation System (EPS) that creates micro-geometries on cutting edges to reduce chipping and breakage. Their Duratomic MT technology specifically addresses built-up edge formation by incorporating a chrome-based top layer that reduces friction and material adhesion.

Strengths: Duratomic® technology provides exceptional balance between wear resistance and toughness; Jetstream Tooling® effectively manages heat generation; advanced edge preparation techniques minimize edge failures. Weaknesses: High-pressure coolant solutions require specialized machine tool capabilities; premium coating technologies come at higher cost; some specialized grades have narrower application windows than general-purpose alternatives.

Kennametal, Inc.

Technical Solution: Kennametal has developed comprehensive solutions addressing tungsten carbide insert failure modes through their Beyond™ and KenTIP™ technology platforms. Their approach focuses on advanced coating technologies including PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) multi-layer coatings that significantly enhance wear resistance while maintaining toughness. Kennametal's proprietary gradient substrate technology creates optimized carbide microstructures with controlled cobalt distribution, resulting in inserts with both high hardness at the cutting edge and increased toughness in the core. Their KenTIP FS™ modular drill system specifically addresses common failure modes by incorporating a replaceable carbide tip design that maintains precision while reducing material waste. Additionally, Kennametal has pioneered specialized post-treatment processes that reduce residual stresses in coated inserts, minimizing delamination failures that commonly occur at high cutting temperatures.

Strengths: Superior coating adhesion technology minimizes delamination failures; gradient substrate technology provides optimal balance between wear resistance and fracture toughness; modular designs reduce material waste while maintaining performance. Weaknesses: Premium solutions come at higher initial cost; some specialized coatings require specific cutting parameters that limit application flexibility; complex multi-layer coatings may require more controlled machining environments.

Critical Metallurgical and Material Science Innovations

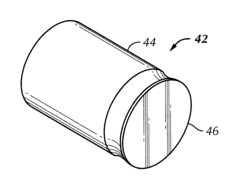

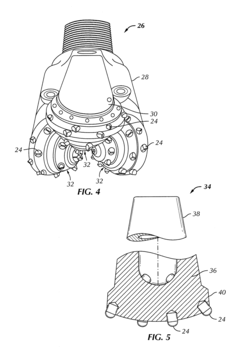

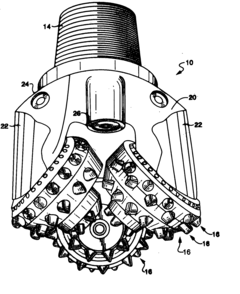

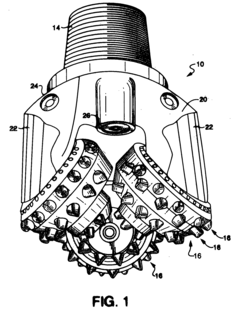

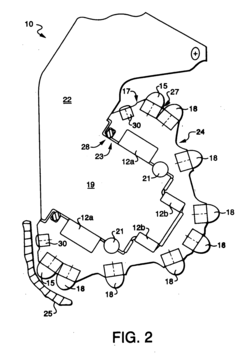

Novel hardmetal for use in oil and gas drilling applications

PatentInactiveUS20110168454A1

Innovation

- Incorporating nanoparticles into a binder matrix phase of coarse grained carbides, with ultra-thin conformal coatings, to enhance both wear resistance and fracture toughness, thereby shifting the material properties beyond the conventional inverse relationship.

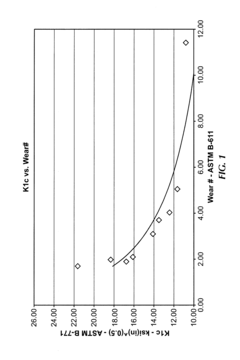

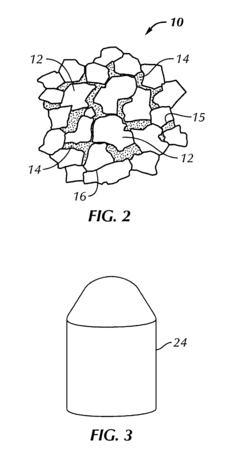

Fracture and wear resistant compounds and rock bits

PatentInactiveUS20060254828A1

Innovation

- The use of tungsten carbide inserts with a cobalt binder, featuring a coarse grain size and selected cobalt content to achieve a fracture toughness of at least 18 ksi (in)0.5 and a wear number of at least 2.0, balancing toughness and wear resistance for improved performance in drilling.

Environmental Impact and Sustainability Considerations

The environmental impact of tungsten carbide insert production and disposal represents a significant concern in the metalworking industry. The mining and processing of tungsten ore involves substantial energy consumption, water usage, and potential release of heavy metals into the environment. Traditional extraction methods can lead to habitat destruction, soil erosion, and water pollution if not properly managed. Additionally, the cobalt binder commonly used in tungsten carbide inserts presents particular environmental challenges due to its toxicity and the controversial mining practices often associated with its extraction, especially in regions like the Democratic Republic of Congo.

Manufacturing processes for tungsten carbide inserts require high temperatures and pressures, resulting in considerable carbon emissions. The sintering process alone typically operates at temperatures between 1350-1500°C, consuming significant energy resources. Studies indicate that the production of one kilogram of tungsten carbide can generate approximately 12-15 kg of CO2 equivalent emissions, highlighting the carbon-intensive nature of this material.

Waste management presents another critical environmental consideration. Failed or worn tungsten carbide inserts often end up in landfills, where the slow degradation of tungsten and cobalt can potentially contaminate soil and groundwater. The leaching of heavy metals from improperly disposed inserts poses long-term environmental risks that extend beyond the product's useful life.

Recycling offers a promising pathway toward sustainability in this sector. Advanced recycling technologies can recover up to 95% of tungsten from used inserts, significantly reducing the need for virgin material extraction. The "zinc process" has emerged as an environmentally preferable recycling method, using zinc to dissolve the cobalt binder at relatively low temperatures (around 900°C), allowing for efficient separation and recovery of tungsten carbide particles.

Several manufacturers have begun implementing closed-loop systems for insert collection and recycling, reducing waste while creating economic benefits. These programs typically offer incentives for customers to return used inserts, which are then processed to recover valuable materials for reuse in new products.

Future sustainability improvements may include the development of alternative binder materials to replace cobalt, optimization of manufacturing processes to reduce energy consumption, and implementation of more efficient cooling systems during machining to extend insert lifespan. Some research indicates that nano-structured tungsten carbide composites may offer improved performance with reduced material requirements, potentially decreasing the overall environmental footprint of these essential machining components.

Manufacturing processes for tungsten carbide inserts require high temperatures and pressures, resulting in considerable carbon emissions. The sintering process alone typically operates at temperatures between 1350-1500°C, consuming significant energy resources. Studies indicate that the production of one kilogram of tungsten carbide can generate approximately 12-15 kg of CO2 equivalent emissions, highlighting the carbon-intensive nature of this material.

Waste management presents another critical environmental consideration. Failed or worn tungsten carbide inserts often end up in landfills, where the slow degradation of tungsten and cobalt can potentially contaminate soil and groundwater. The leaching of heavy metals from improperly disposed inserts poses long-term environmental risks that extend beyond the product's useful life.

Recycling offers a promising pathway toward sustainability in this sector. Advanced recycling technologies can recover up to 95% of tungsten from used inserts, significantly reducing the need for virgin material extraction. The "zinc process" has emerged as an environmentally preferable recycling method, using zinc to dissolve the cobalt binder at relatively low temperatures (around 900°C), allowing for efficient separation and recovery of tungsten carbide particles.

Several manufacturers have begun implementing closed-loop systems for insert collection and recycling, reducing waste while creating economic benefits. These programs typically offer incentives for customers to return used inserts, which are then processed to recover valuable materials for reuse in new products.

Future sustainability improvements may include the development of alternative binder materials to replace cobalt, optimization of manufacturing processes to reduce energy consumption, and implementation of more efficient cooling systems during machining to extend insert lifespan. Some research indicates that nano-structured tungsten carbide composites may offer improved performance with reduced material requirements, potentially decreasing the overall environmental footprint of these essential machining components.

Quality Control and Testing Methodologies for Insert Performance

Quality control and testing methodologies play a crucial role in ensuring the reliability and performance of tungsten carbide inserts in industrial applications. Comprehensive testing protocols have been developed to evaluate insert quality before deployment, significantly reducing failure rates in production environments.

Standard quality control procedures typically begin with dimensional verification using precision measuring instruments such as coordinate measuring machines (CMMs) and optical comparators. These measurements ensure that inserts meet specified tolerances, which is essential for proper fit and function in tooling systems. Deviations as small as 0.001 mm can impact performance, particularly in high-precision machining operations.

Hardness testing represents another fundamental quality control measure, with Rockwell and Vickers hardness tests being the most commonly employed methods. For tungsten carbide inserts, the acceptable hardness range typically falls between 89-93 HRA (Rockwell A scale), depending on the specific grade and application. Regular calibration of testing equipment is essential to maintain measurement accuracy.

Microstructural analysis through scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS) enables manufacturers to detect internal defects such as porosity, non-uniform grain distribution, or cobalt pooling that could lead to premature failure. These techniques can identify potential failure modes before inserts enter service, allowing for process adjustments in manufacturing.

Performance testing under simulated working conditions has emerged as a critical evaluation method. Accelerated wear testing, using specialized equipment that replicates actual cutting conditions, provides valuable data on insert lifespan and failure patterns. These tests typically measure parameters such as flank wear progression, crater formation rate, and edge chipping resistance under controlled conditions.

Impact resistance testing has gained prominence, particularly for applications involving interrupted cutting. Drop tests and pendulum impact tests quantify an insert's ability to withstand sudden forces without catastrophic failure. The results inform appropriate application recommendations and help users select optimal insert grades for specific operations.

Non-destructive testing methods, including ultrasonic inspection and X-ray computed tomography, have revolutionized quality control by enabling 100% inspection of critical components without compromising their integrity. These techniques can detect subsurface defects that might otherwise go unnoticed until failure occurs during operation.

Statistical process control (SPC) methodologies have been integrated into manufacturing workflows, establishing control limits for critical parameters and enabling real-time monitoring of production quality. This approach facilitates early intervention when process drift is detected, maintaining consistent insert quality and reducing variation between production batches.

Standard quality control procedures typically begin with dimensional verification using precision measuring instruments such as coordinate measuring machines (CMMs) and optical comparators. These measurements ensure that inserts meet specified tolerances, which is essential for proper fit and function in tooling systems. Deviations as small as 0.001 mm can impact performance, particularly in high-precision machining operations.

Hardness testing represents another fundamental quality control measure, with Rockwell and Vickers hardness tests being the most commonly employed methods. For tungsten carbide inserts, the acceptable hardness range typically falls between 89-93 HRA (Rockwell A scale), depending on the specific grade and application. Regular calibration of testing equipment is essential to maintain measurement accuracy.

Microstructural analysis through scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS) enables manufacturers to detect internal defects such as porosity, non-uniform grain distribution, or cobalt pooling that could lead to premature failure. These techniques can identify potential failure modes before inserts enter service, allowing for process adjustments in manufacturing.

Performance testing under simulated working conditions has emerged as a critical evaluation method. Accelerated wear testing, using specialized equipment that replicates actual cutting conditions, provides valuable data on insert lifespan and failure patterns. These tests typically measure parameters such as flank wear progression, crater formation rate, and edge chipping resistance under controlled conditions.

Impact resistance testing has gained prominence, particularly for applications involving interrupted cutting. Drop tests and pendulum impact tests quantify an insert's ability to withstand sudden forces without catastrophic failure. The results inform appropriate application recommendations and help users select optimal insert grades for specific operations.

Non-destructive testing methods, including ultrasonic inspection and X-ray computed tomography, have revolutionized quality control by enabling 100% inspection of critical components without compromising their integrity. These techniques can detect subsurface defects that might otherwise go unnoticed until failure occurs during operation.

Statistical process control (SPC) methodologies have been integrated into manufacturing workflows, establishing control limits for critical parameters and enabling real-time monitoring of production quality. This approach facilitates early intervention when process drift is detected, maintaining consistent insert quality and reducing variation between production batches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!