Carbide Tool Life Optimization: Coatings, Coolant, And Geometry Trade-Offs

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbide Tool Evolution and Performance Objectives

Carbide cutting tools have undergone significant evolution since their introduction in the early 20th century. Initially developed as simple tungsten carbide inserts, these tools have transformed through decades of metallurgical advancements and engineering innovations. The progression from basic cemented carbide compositions to today's sophisticated multi-layer coated tools represents a remarkable technological journey driven by industrial demands for higher productivity and efficiency.

The evolution of carbide tools has been characterized by several key developmental phases. The first generation focused primarily on material composition, experimenting with various carbide formulations and binder metals to enhance hardness and wear resistance. The second phase introduced geometric innovations, with tool designers optimizing cutting edges, rake angles, and chip breakers to improve performance across diverse machining applications. The third and current phase has centered on surface engineering, particularly advanced coating technologies that significantly extend tool life and enable higher cutting speeds.

Performance objectives for modern carbide tools have become increasingly demanding as manufacturing industries push for greater productivity, precision, and cost-effectiveness. Primary objectives include maximizing tool life under high-speed cutting conditions, maintaining dimensional accuracy throughout the tool's service life, and achieving consistent surface finish quality on machined components. Additionally, there is growing emphasis on tool performance predictability, which enables more precise production planning and reduced downtime.

The trade-off relationships between coatings, coolant strategies, and tool geometry represent a complex optimization challenge. Enhanced coating technologies like PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) have enabled significant improvements in wear resistance and thermal stability, but must be carefully matched with appropriate tool geometries to maximize effectiveness. Similarly, advanced coolant delivery methods, including high-pressure coolant and minimum quantity lubrication (MQL), interact with both coating properties and geometric features to influence overall tool performance.

Current technological trends point toward more application-specific optimization approaches, where carbide tools are engineered for particular material combinations and cutting conditions rather than general-purpose use. This specialization trend is supported by advances in computational modeling and simulation tools that enable more precise prediction of tool behavior under various operating conditions. The industry is also witnessing increased integration of sensor technologies for real-time monitoring of tool condition, allowing for predictive maintenance and optimized tool utilization.

The evolution of carbide tools has been characterized by several key developmental phases. The first generation focused primarily on material composition, experimenting with various carbide formulations and binder metals to enhance hardness and wear resistance. The second phase introduced geometric innovations, with tool designers optimizing cutting edges, rake angles, and chip breakers to improve performance across diverse machining applications. The third and current phase has centered on surface engineering, particularly advanced coating technologies that significantly extend tool life and enable higher cutting speeds.

Performance objectives for modern carbide tools have become increasingly demanding as manufacturing industries push for greater productivity, precision, and cost-effectiveness. Primary objectives include maximizing tool life under high-speed cutting conditions, maintaining dimensional accuracy throughout the tool's service life, and achieving consistent surface finish quality on machined components. Additionally, there is growing emphasis on tool performance predictability, which enables more precise production planning and reduced downtime.

The trade-off relationships between coatings, coolant strategies, and tool geometry represent a complex optimization challenge. Enhanced coating technologies like PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) have enabled significant improvements in wear resistance and thermal stability, but must be carefully matched with appropriate tool geometries to maximize effectiveness. Similarly, advanced coolant delivery methods, including high-pressure coolant and minimum quantity lubrication (MQL), interact with both coating properties and geometric features to influence overall tool performance.

Current technological trends point toward more application-specific optimization approaches, where carbide tools are engineered for particular material combinations and cutting conditions rather than general-purpose use. This specialization trend is supported by advances in computational modeling and simulation tools that enable more precise prediction of tool behavior under various operating conditions. The industry is also witnessing increased integration of sensor technologies for real-time monitoring of tool condition, allowing for predictive maintenance and optimized tool utilization.

Market Analysis for Advanced Machining Solutions

The global advanced machining solutions market is experiencing robust growth, driven by increasing demand for precision components across automotive, aerospace, medical, and electronics industries. Currently valued at approximately 25 billion USD, this market is projected to grow at a compound annual growth rate of 7.2% through 2028, with carbide tooling representing nearly 40% of the total market share.

The demand for optimized carbide tools is particularly strong in regions with high manufacturing output. Asia-Pacific leads with 38% market share, followed by North America (27%) and Europe (24%). China and India are showing the fastest growth rates at 9.3% and 8.7% respectively, reflecting their expanding manufacturing bases and increasing adoption of advanced machining technologies.

Key market drivers include the growing complexity of manufactured components, stricter tolerance requirements, and the push for higher productivity in machining operations. The automotive sector remains the largest end-user, consuming approximately 32% of advanced carbide tooling solutions, followed by aerospace (21%) and general engineering (18%). The medical device manufacturing segment, though smaller at 9%, is showing the highest growth rate at 11.2% annually.

Customer demands are evolving toward comprehensive tooling solutions rather than standalone products. End-users increasingly seek integrated packages that optimize tool life through balanced combinations of coatings, coolant strategies, and geometry designs. This shift has created a premium segment within the market, growing at 10.5% annually, where manufacturers offer customized solutions with documented performance improvements.

The market for specialized coatings alone is valued at 3.8 billion USD, with PVD (Physical Vapor Deposition) coatings dominating at 65% market share. Coolant optimization solutions represent a 2.1 billion USD segment, with high-pressure coolant systems showing the strongest growth at 13.4% annually.

Economic analysis indicates that end-users are willing to pay premium prices for tooling solutions that demonstrably reduce total machining costs. Case studies from automotive manufacturing show that optimized carbide tools with appropriate coating-coolant-geometry combinations can reduce overall production costs by 15-22% through extended tool life, reduced downtime, and higher cutting speeds.

Market research indicates that customers prioritize tool life predictability over maximum life span, suggesting that solutions offering consistent performance are more valuable than those with occasionally longer but unpredictable lifespans.

The demand for optimized carbide tools is particularly strong in regions with high manufacturing output. Asia-Pacific leads with 38% market share, followed by North America (27%) and Europe (24%). China and India are showing the fastest growth rates at 9.3% and 8.7% respectively, reflecting their expanding manufacturing bases and increasing adoption of advanced machining technologies.

Key market drivers include the growing complexity of manufactured components, stricter tolerance requirements, and the push for higher productivity in machining operations. The automotive sector remains the largest end-user, consuming approximately 32% of advanced carbide tooling solutions, followed by aerospace (21%) and general engineering (18%). The medical device manufacturing segment, though smaller at 9%, is showing the highest growth rate at 11.2% annually.

Customer demands are evolving toward comprehensive tooling solutions rather than standalone products. End-users increasingly seek integrated packages that optimize tool life through balanced combinations of coatings, coolant strategies, and geometry designs. This shift has created a premium segment within the market, growing at 10.5% annually, where manufacturers offer customized solutions with documented performance improvements.

The market for specialized coatings alone is valued at 3.8 billion USD, with PVD (Physical Vapor Deposition) coatings dominating at 65% market share. Coolant optimization solutions represent a 2.1 billion USD segment, with high-pressure coolant systems showing the strongest growth at 13.4% annually.

Economic analysis indicates that end-users are willing to pay premium prices for tooling solutions that demonstrably reduce total machining costs. Case studies from automotive manufacturing show that optimized carbide tools with appropriate coating-coolant-geometry combinations can reduce overall production costs by 15-22% through extended tool life, reduced downtime, and higher cutting speeds.

Market research indicates that customers prioritize tool life predictability over maximum life span, suggesting that solutions offering consistent performance are more valuable than those with occasionally longer but unpredictable lifespans.

Current Challenges in Carbide Tool Technology

Despite significant advancements in carbide tool technology, several critical challenges persist that limit optimal performance and tool life in modern manufacturing environments. The fundamental challenge remains balancing the three key factors: coating technology, coolant application, and tool geometry. Each represents a complex trade-off that manufacturers must navigate to achieve optimal cutting performance.

Coating technology faces challenges in developing formulations that simultaneously provide wear resistance, thermal stability, and chemical inertness across diverse workpiece materials. Current PVD and CVD coatings often excel in one property at the expense of others. Multi-layer coatings show promise but struggle with adhesion issues between layers, particularly under thermal cycling conditions common in intermittent cutting operations.

Coolant application presents significant environmental and economic challenges. Traditional flood cooling systems consume excessive resources and create disposal issues, while minimum quantity lubrication (MQL) systems struggle to provide adequate cooling in high-speed, high-feed applications. The industry lacks standardized methodologies for optimizing coolant delivery parameters specific to tool-workpiece combinations.

Tool geometry optimization remains highly empirical, with limited predictive modeling capabilities that accurately account for dynamic cutting conditions. Micro-geometry features such as edge preparation, chip breakers, and flute design significantly impact tool performance, yet their interactions with coatings and coolants are poorly understood at a fundamental level.

Material inconsistencies in carbide substrates continue to create variability in tool performance. The industry faces challenges in developing consistent quality control methods for evaluating substrate properties such as grain size distribution, cobalt content uniformity, and porosity levels.

Advanced manufacturing sectors, particularly aerospace and medical device industries, face increasingly stringent requirements for surface integrity that current carbide tool technologies struggle to consistently deliver. This includes challenges in managing residual stresses, microstructural alterations, and surface roughness parameters.

Digital integration represents another significant challenge, with limited implementation of real-time monitoring systems that can detect tool wear progression and automatically adjust cutting parameters. The industry lacks robust algorithms that can effectively process sensor data to predict tool failure before it occurs.

These challenges are compounded by economic pressures to reduce tooling costs while improving productivity, creating a complex optimization problem that requires interdisciplinary approaches combining materials science, fluid dynamics, mechanical engineering, and data analytics.

Coating technology faces challenges in developing formulations that simultaneously provide wear resistance, thermal stability, and chemical inertness across diverse workpiece materials. Current PVD and CVD coatings often excel in one property at the expense of others. Multi-layer coatings show promise but struggle with adhesion issues between layers, particularly under thermal cycling conditions common in intermittent cutting operations.

Coolant application presents significant environmental and economic challenges. Traditional flood cooling systems consume excessive resources and create disposal issues, while minimum quantity lubrication (MQL) systems struggle to provide adequate cooling in high-speed, high-feed applications. The industry lacks standardized methodologies for optimizing coolant delivery parameters specific to tool-workpiece combinations.

Tool geometry optimization remains highly empirical, with limited predictive modeling capabilities that accurately account for dynamic cutting conditions. Micro-geometry features such as edge preparation, chip breakers, and flute design significantly impact tool performance, yet their interactions with coatings and coolants are poorly understood at a fundamental level.

Material inconsistencies in carbide substrates continue to create variability in tool performance. The industry faces challenges in developing consistent quality control methods for evaluating substrate properties such as grain size distribution, cobalt content uniformity, and porosity levels.

Advanced manufacturing sectors, particularly aerospace and medical device industries, face increasingly stringent requirements for surface integrity that current carbide tool technologies struggle to consistently deliver. This includes challenges in managing residual stresses, microstructural alterations, and surface roughness parameters.

Digital integration represents another significant challenge, with limited implementation of real-time monitoring systems that can detect tool wear progression and automatically adjust cutting parameters. The industry lacks robust algorithms that can effectively process sensor data to predict tool failure before it occurs.

These challenges are compounded by economic pressures to reduce tooling costs while improving productivity, creating a complex optimization problem that requires interdisciplinary approaches combining materials science, fluid dynamics, mechanical engineering, and data analytics.

Cutting-Edge Coating and Geometry Solutions

01 Coating technologies for carbide tools

Various coating technologies can be applied to carbide tools to enhance their tool life. These coatings include PVD (Physical Vapor Deposition), CVD (Chemical Vapor Deposition), and multi-layer coatings that provide wear resistance, reduced friction, and protection against high temperatures. Advanced coating materials such as titanium nitride, aluminum oxide, and diamond-like carbon significantly improve the durability and performance of carbide cutting tools in demanding applications.- Coating technologies for carbide tools: Various coating technologies can be applied to carbide tools to enhance their tool life. These coatings, such as titanium nitride (TiN), titanium aluminum nitride (TiAlN), and diamond-like carbon (DLC), provide improved wear resistance, reduced friction, and protection against high temperatures. The coatings create a barrier between the tool and workpiece, preventing direct contact and reducing wear mechanisms like abrasion and adhesion, ultimately extending the tool life significantly.

- Carbide composition and microstructure optimization: The composition and microstructure of carbide tools significantly impact their tool life. By optimizing the tungsten carbide grain size, cobalt binder content, and adding other carbide-forming elements like titanium, tantalum, or niobium, manufacturers can enhance hardness, toughness, and wear resistance. Fine-grained carbides typically offer better wear resistance, while controlled cobalt distribution ensures optimal balance between hardness and fracture toughness, leading to extended tool life in various cutting applications.

- Cutting parameters and machining strategies: Proper selection of cutting parameters and machining strategies significantly affects carbide tool life. Optimized cutting speeds, feed rates, depth of cut, and engagement angles can reduce thermal and mechanical stresses on the tool. Advanced machining strategies like high-speed machining with light cuts, trochoidal milling, or adaptive toolpaths help maintain consistent cutting forces and temperature, preventing premature tool failure and extending the useful life of carbide cutting tools.

- Cooling and lubrication techniques: Effective cooling and lubrication techniques play a crucial role in extending carbide tool life. Various methods including flood coolant, minimum quantity lubrication (MQL), cryogenic cooling, and high-pressure coolant delivery systems help manage heat generation during cutting operations. These techniques reduce thermal degradation of the tool, prevent built-up edge formation, and facilitate chip evacuation, all contributing to significant improvements in tool life and performance consistency across different machining conditions.

- Tool geometry and edge preparation: Specialized tool geometry and edge preparation techniques can substantially improve carbide tool life. Features such as chip breakers, variable helix angles, optimized rake angles, and controlled edge honing help manage cutting forces and heat distribution. Micro-geometry modifications like edge rounding, T-land preparation, or waterfall edges strengthen the cutting edge against chipping while maintaining sharpness. These design elements reduce stress concentrations and improve wear resistance, resulting in extended tool life during machining operations.

02 Carbide composition and microstructure optimization

The tool life of carbide tools can be significantly improved by optimizing the composition and microstructure of the carbide material. This includes controlling the grain size, cobalt binder content, and the addition of other elements such as titanium, tantalum, and niobium. Fine-grained carbides with optimized cobalt distribution provide better wear resistance and toughness, leading to extended tool life in various cutting operations.Expand Specific Solutions03 Cooling and lubrication techniques

Implementing effective cooling and lubrication techniques significantly extends the life of carbide tools. These include flood cooling, minimum quantity lubrication (MQL), cryogenic cooling, and through-tool coolant delivery systems. Proper cooling reduces thermal stress, prevents premature tool failure, and allows for higher cutting speeds while maintaining tool integrity, particularly in high-temperature machining operations.Expand Specific Solutions04 Tool geometry and design innovations

Innovative tool geometry and design features can substantially improve carbide tool life. This includes optimized cutting edge preparation, chip breaker designs, variable helix angles, and specialized geometries for specific applications. Advanced design elements reduce cutting forces, improve chip evacuation, and distribute stress more evenly across the tool, resulting in reduced wear and extended service life.Expand Specific Solutions05 Machining parameters and tool path strategies

Optimizing machining parameters and tool path strategies is crucial for maximizing carbide tool life. This includes selecting appropriate cutting speeds, feed rates, depth of cut, and engagement strategies based on workpiece material and tool characteristics. Advanced tool path techniques such as trochoidal milling, high-efficiency machining, and adaptive toolpaths help maintain consistent cutting loads, reduce vibration, and prevent premature tool failure.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The carbide tool life optimization market is currently in a mature growth phase, characterized by established technologies and incremental innovations focusing on performance enhancement. The global market size for carbide cutting tools is estimated at $15-18 billion, with steady annual growth of 5-7%. Leading players like Sandvik, Kennametal, and Kyocera dominate with advanced coating technologies, while Japanese manufacturers (Sumitomo, Tungaloy, OSG) excel in precision engineering and specialized applications. Chinese companies such as Zhuzhou Cemented Carbide are rapidly advancing their technological capabilities, particularly in cost-effective solutions. Research collaborations between industry leaders and academic institutions like Xiamen University and Qingdao University of Technology are accelerating innovations in coating technologies, coolant optimization, and geometric designs to extend tool life while maintaining cutting performance.

Seco Tools AB

Technical Solution: Seco Tools has pioneered the Duratomic® coating technology specifically for carbide cutting tools, which manipulates the atomic structure of aluminum oxide at the quantum level to create optimized crystalline structures with controlled oxygen vacancies. This technology increases tool life by up to 40% compared to conventional coatings. Their Jetstream Tooling® technology features precisely positioned coolant channels that direct high-pressure coolant (70-100 bar) directly to the cutting edge, reducing thermal loading and enabling higher cutting speeds. Geometrically, Seco implements their Multi-Directional Turning (MDT) approach with specialized wiper geometries and programmed tool paths that distribute wear more evenly across the cutting edge. Their Steadyline® damping system incorporates dynamic vibration absorption technology that reduces chatter in long-overhang applications, preventing premature tool failure and extending carbide tool life in challenging operations.

Strengths: Quantum-engineered coating technology with exceptional wear resistance; integrated coolant delivery systems that significantly improve chip evacuation; vibration-dampening tool holders that extend tool life in challenging applications. Weaknesses: Full system benefits require compatible machine tool interfaces; higher initial investment compared to standard tooling; some solutions optimized for specific material groups rather than universal application.

Sumitomo Electric Industries Ltd.

Technical Solution: Sumitomo Electric has developed their proprietary Super ZX coating technology for carbide tools, featuring nano-multilayered structures with alternating layers of AlTiN and AlCrN that provide exceptional wear resistance and thermal stability. Their Super FF Coating incorporates friction-reducing outer layers that decrease cutting forces by up to 25%. For coolant optimization, Sumitomo implements their Direct Coolant System with precision-engineered microchannels that deliver coolant directly to the cutting edge at pressures up to 200 bar. Geometrically, their tools feature the Multi-Corner design philosophy with specialized edge preparations that include controlled microchipping to improve chip formation and reduce cutting forces. Their patented Double Clamp system provides exceptional rigidity in turning applications, minimizing vibration and extending tool life in interrupted cutting operations where thermal and mechanical shock typically cause premature tool failure.

Strengths: Nano-multilayered coating technology with exceptional thermal stability; friction-reducing surface treatments that significantly lower cutting forces; specialized geometric designs for interrupted cutting applications. Weaknesses: Some solutions require specialized machine interfaces for optimal performance; higher initial investment compared to conventional tooling; full benefits require proper application engineering support.

Critical Patents in Tool Life Enhancement

Coated cemented carbide insert

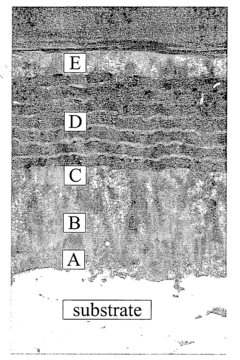

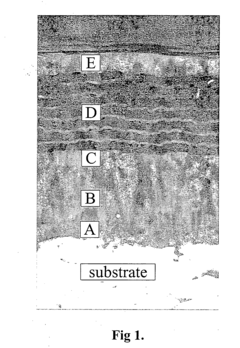

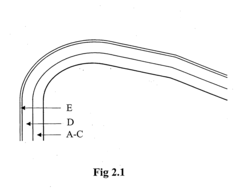

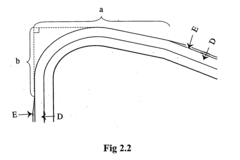

PatentInactiveUS20040180241A1

Innovation

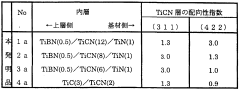

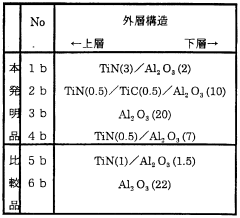

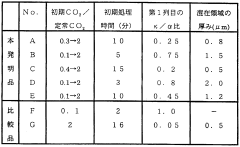

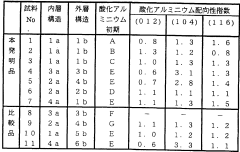

- A coated cemented carbide cutting tool insert with a specific multilayer coating structure comprising TiC_xN_yO_z layers and Al_2O_3 layers, combined with a WC+Co-based substrate and a post-treatment process to expose the multilayer along the edge line, reducing wear and enhancing toughness.

Coated cemented carbide cutting tool

PatentWO1999052662A1

Innovation

- A multi-layered coating structure with a tungsten carbide base material, an inner layer of Ti(CwBxNyOz) containing α-type and κ-type aluminum oxide with mixed crystal structures, and a columnar titanium carbonitride inner layer, where the α-type aluminum oxide grows directly on the inner layer with a non-uniform structure and pores, enhancing adhesion and mechanical wear resistance.

Sustainability Aspects of Coolant Technologies

The sustainability aspects of coolant technologies in carbide tool applications have become increasingly critical as industries face mounting environmental pressures and regulatory requirements. Traditional coolant systems, while effective for heat dissipation and lubrication, often contain harmful chemicals that pose significant environmental and health risks. These conventional formulations typically include mineral oils, biocides, and other additives that contribute to environmental pollution when improperly disposed of.

Recent advancements have focused on developing biodegradable and environmentally friendly coolant alternatives that maintain or improve machining performance while reducing ecological impact. Vegetable-based coolants, for instance, offer comparable performance to petroleum-based products but with significantly reduced toxicity and improved biodegradability. These bio-based formulations typically degrade 60-90% within 28 days compared to less than 40% for conventional coolants.

Minimum Quantity Lubrication (MQL) represents another sustainable approach, dramatically reducing coolant consumption by up to 95% compared to flood cooling methods. This technique delivers precisely metered amounts of lubricant directly to the cutting zone, minimizing waste while maintaining effective tool cooling and lubrication. The reduced volume translates directly to decreased environmental footprint and lower disposal costs.

Dry machining technologies eliminate coolants entirely, representing the ultimate sustainable solution when feasible. This approach relies heavily on advanced tool coatings and geometries to manage heat generation and dissipation. While not suitable for all applications, dry machining can eliminate coolant-related environmental concerns completely in appropriate scenarios.

Coolant recycling and filtration systems have also evolved significantly, extending coolant life by removing contaminants and maintaining performance characteristics. Modern systems can extend coolant life by 300-500%, dramatically reducing waste generation and resource consumption. These closed-loop systems represent a circular economy approach to coolant management.

The economic implications of sustainable coolant technologies present a complex picture. While initial implementation costs may be higher, long-term savings from reduced consumption, extended tool life, decreased waste disposal costs, and improved worker health often result in positive return on investment. Companies implementing sustainable coolant strategies typically report 15-30% reduction in total coolant-related costs over a five-year period.

Regulatory frameworks worldwide are increasingly mandating reduced environmental impact from manufacturing processes, making sustainable coolant technologies not just environmentally responsible but also a compliance necessity. Forward-thinking manufacturers are proactively adopting these technologies to future-proof their operations against tightening regulations.

Recent advancements have focused on developing biodegradable and environmentally friendly coolant alternatives that maintain or improve machining performance while reducing ecological impact. Vegetable-based coolants, for instance, offer comparable performance to petroleum-based products but with significantly reduced toxicity and improved biodegradability. These bio-based formulations typically degrade 60-90% within 28 days compared to less than 40% for conventional coolants.

Minimum Quantity Lubrication (MQL) represents another sustainable approach, dramatically reducing coolant consumption by up to 95% compared to flood cooling methods. This technique delivers precisely metered amounts of lubricant directly to the cutting zone, minimizing waste while maintaining effective tool cooling and lubrication. The reduced volume translates directly to decreased environmental footprint and lower disposal costs.

Dry machining technologies eliminate coolants entirely, representing the ultimate sustainable solution when feasible. This approach relies heavily on advanced tool coatings and geometries to manage heat generation and dissipation. While not suitable for all applications, dry machining can eliminate coolant-related environmental concerns completely in appropriate scenarios.

Coolant recycling and filtration systems have also evolved significantly, extending coolant life by removing contaminants and maintaining performance characteristics. Modern systems can extend coolant life by 300-500%, dramatically reducing waste generation and resource consumption. These closed-loop systems represent a circular economy approach to coolant management.

The economic implications of sustainable coolant technologies present a complex picture. While initial implementation costs may be higher, long-term savings from reduced consumption, extended tool life, decreased waste disposal costs, and improved worker health often result in positive return on investment. Companies implementing sustainable coolant strategies typically report 15-30% reduction in total coolant-related costs over a five-year period.

Regulatory frameworks worldwide are increasingly mandating reduced environmental impact from manufacturing processes, making sustainable coolant technologies not just environmentally responsible but also a compliance necessity. Forward-thinking manufacturers are proactively adopting these technologies to future-proof their operations against tightening regulations.

Economic Impact of Tool Life Optimization

The economic implications of carbide tool life optimization extend far beyond the immediate cost of tooling. Manufacturing operations worldwide face increasing pressure to maximize productivity while minimizing costs, making tool life a critical factor in overall economic performance.

Tool replacement costs represent only the tip of the economic iceberg. When a cutting tool fails or requires replacement, production must be interrupted, resulting in significant downtime costs. Industry analyses indicate that for high-volume manufacturing operations, downtime costs can range from $1,000 to $10,000 per hour depending on the sector and production scale. Optimized tool life directly translates to fewer interruptions and higher machine utilization rates.

Quality consistency also plays a substantial economic role. As tools wear, dimensional accuracy and surface finish quality gradually deteriorate, potentially leading to increased scrap rates and rework requirements. Studies from automotive manufacturing environments demonstrate that optimized tool life management can reduce scrap rates by 15-25%, representing substantial material and labor savings.

Energy consumption presents another economic dimension often overlooked in tool life considerations. Worn tools require greater cutting forces, resulting in higher energy consumption. Research indicates that properly optimized carbide tools can reduce energy consumption by 8-12% compared to operations using tools beyond their optimal life span.

The trade-offs between coating technologies, coolant strategies, and tool geometry directly impact return on investment calculations. While premium coatings like AlTiN or nanocomposite coatings may increase initial tool costs by 30-50%, they can extend tool life by 200-300% in appropriate applications, yielding positive economic returns. Similarly, advanced coolant strategies may require higher initial investment but deliver superior long-term economic performance through extended tool life.

Inventory management efficiency represents another economic benefit of optimized tool life. Predictable tool performance allows for more accurate inventory planning, reducing capital tied up in excessive tool inventory while preventing costly stockouts. Manufacturing operations implementing scientific tool life optimization programs report inventory reductions of 20-30% without compromising production capabilities.

Labor productivity also improves with optimized tool life. Operators spend less time changing tools and making adjustments, allowing them to focus on value-adding activities. This productivity enhancement, while difficult to quantify precisely, contributes significantly to overall operational efficiency and economic performance.

Tool replacement costs represent only the tip of the economic iceberg. When a cutting tool fails or requires replacement, production must be interrupted, resulting in significant downtime costs. Industry analyses indicate that for high-volume manufacturing operations, downtime costs can range from $1,000 to $10,000 per hour depending on the sector and production scale. Optimized tool life directly translates to fewer interruptions and higher machine utilization rates.

Quality consistency also plays a substantial economic role. As tools wear, dimensional accuracy and surface finish quality gradually deteriorate, potentially leading to increased scrap rates and rework requirements. Studies from automotive manufacturing environments demonstrate that optimized tool life management can reduce scrap rates by 15-25%, representing substantial material and labor savings.

Energy consumption presents another economic dimension often overlooked in tool life considerations. Worn tools require greater cutting forces, resulting in higher energy consumption. Research indicates that properly optimized carbide tools can reduce energy consumption by 8-12% compared to operations using tools beyond their optimal life span.

The trade-offs between coating technologies, coolant strategies, and tool geometry directly impact return on investment calculations. While premium coatings like AlTiN or nanocomposite coatings may increase initial tool costs by 30-50%, they can extend tool life by 200-300% in appropriate applications, yielding positive economic returns. Similarly, advanced coolant strategies may require higher initial investment but deliver superior long-term economic performance through extended tool life.

Inventory management efficiency represents another economic benefit of optimized tool life. Predictable tool performance allows for more accurate inventory planning, reducing capital tied up in excessive tool inventory while preventing costly stockouts. Manufacturing operations implementing scientific tool life optimization programs report inventory reductions of 20-30% without compromising production capabilities.

Labor productivity also improves with optimized tool life. Operators spend less time changing tools and making adjustments, allowing them to focus on value-adding activities. This productivity enhancement, while difficult to quantify precisely, contributes significantly to overall operational efficiency and economic performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!