Cost-Per-Cut Analysis: Carbide Insert Strategies For Production Lines

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Carbide Insert Technology Evolution and Objectives

Carbide inserts have undergone significant technological evolution since their introduction in the early 20th century. Initially developed as an alternative to high-speed steel cutting tools, tungsten carbide inserts revolutionized the manufacturing industry by offering superior hardness, wear resistance, and thermal stability. The 1930s marked the commercial adoption of cemented carbide tools, while the post-World War II era saw rapid advancements in carbide composition and manufacturing techniques.

The 1970s introduced coated carbide inserts, significantly extending tool life and enabling higher cutting speeds. This innovation represented a pivotal moment in machining technology, allowing manufacturers to achieve unprecedented productivity levels. By the 1990s, multi-layer coatings combining materials like titanium nitride, aluminum oxide, and titanium carbonitride became standard, each layer serving specific functions from wear resistance to thermal insulation.

Recent developments have focused on nano-structured carbide grades, optimized geometries, and advanced coating technologies. Modern inserts feature complex chip-breaking geometries, specialized edge preparations, and application-specific designs that maximize performance in particular machining operations. The integration of computational modeling and simulation tools has accelerated this evolution, enabling manufacturers to predict tool performance and optimize designs before physical prototyping.

The primary objective of carbide insert technology development has consistently been to reduce the overall cost per cut in production environments. This metric encompasses not just the initial tool cost, but also factors like tool life, machining time, surface finish quality, and downtime for tool changes. As manufacturing operations face increasing pressure to improve efficiency and reduce waste, the strategic selection and application of carbide inserts have become critical competitive factors.

Current technological objectives include developing inserts with predictable and consistent wear patterns, extending tool life under increasingly demanding cutting conditions, and creating specialized solutions for difficult-to-machine materials like titanium alloys, heat-resistant superalloys, and composite materials. Additionally, there is growing emphasis on sustainability, with research directed toward reducing cobalt content in carbide formulations and developing recycling processes for used inserts.

The evolution trajectory points toward "smart" cutting tools with embedded sensors for real-time monitoring, adaptive geometries that respond to changing cutting conditions, and integration with digital manufacturing systems. These advancements aim to transform carbide inserts from passive components to active elements in the manufacturing process, capable of communicating their status and optimizing their performance autonomously within production lines.

The 1970s introduced coated carbide inserts, significantly extending tool life and enabling higher cutting speeds. This innovation represented a pivotal moment in machining technology, allowing manufacturers to achieve unprecedented productivity levels. By the 1990s, multi-layer coatings combining materials like titanium nitride, aluminum oxide, and titanium carbonitride became standard, each layer serving specific functions from wear resistance to thermal insulation.

Recent developments have focused on nano-structured carbide grades, optimized geometries, and advanced coating technologies. Modern inserts feature complex chip-breaking geometries, specialized edge preparations, and application-specific designs that maximize performance in particular machining operations. The integration of computational modeling and simulation tools has accelerated this evolution, enabling manufacturers to predict tool performance and optimize designs before physical prototyping.

The primary objective of carbide insert technology development has consistently been to reduce the overall cost per cut in production environments. This metric encompasses not just the initial tool cost, but also factors like tool life, machining time, surface finish quality, and downtime for tool changes. As manufacturing operations face increasing pressure to improve efficiency and reduce waste, the strategic selection and application of carbide inserts have become critical competitive factors.

Current technological objectives include developing inserts with predictable and consistent wear patterns, extending tool life under increasingly demanding cutting conditions, and creating specialized solutions for difficult-to-machine materials like titanium alloys, heat-resistant superalloys, and composite materials. Additionally, there is growing emphasis on sustainability, with research directed toward reducing cobalt content in carbide formulations and developing recycling processes for used inserts.

The evolution trajectory points toward "smart" cutting tools with embedded sensors for real-time monitoring, adaptive geometries that respond to changing cutting conditions, and integration with digital manufacturing systems. These advancements aim to transform carbide inserts from passive components to active elements in the manufacturing process, capable of communicating their status and optimizing their performance autonomously within production lines.

Market Demand Analysis for Industrial Cutting Solutions

The global market for industrial cutting solutions has witnessed substantial growth in recent years, driven primarily by the manufacturing sector's increasing focus on efficiency, precision, and cost reduction. The carbide insert market specifically reached approximately $5.7 billion in 2022 and is projected to grow at a CAGR of 6.8% through 2028, highlighting the significant economic importance of cutting tool optimization strategies.

Manufacturing industries, particularly automotive, aerospace, and general machinery production, represent the largest demand segments for advanced cutting solutions. These sectors collectively account for over 65% of the total carbide insert consumption globally, with their production volumes directly influencing market dynamics for cutting tools.

Cost-per-cut analysis has emerged as a critical decision-making framework as manufacturers face increasing pressure to reduce operational expenses while maintaining quality standards. Research indicates that cutting tool costs typically represent only 3-5% of total manufacturing expenses, yet their selection and implementation can impact overall production costs by up to 15-30% through their influence on machine downtime, labor utilization, and energy consumption.

Regional analysis reveals distinct market characteristics, with mature markets like North America and Western Europe focusing on high-performance solutions that maximize tool life and minimize production interruptions. Meanwhile, rapidly industrializing regions in Asia-Pacific, particularly China and India, show the highest growth rates, driven by expanding manufacturing bases and increasing technological sophistication in production processes.

Customer demand patterns have evolved significantly, with a clear shift from purely price-based purchasing decisions toward value-based procurement strategies. Survey data from manufacturing executives indicates that 78% now prioritize total cost of ownership over initial purchase price when selecting cutting tools, representing a fundamental shift in market dynamics.

The aftermarket and service segment has grown substantially, now representing approximately 40% of the total market value. This reflects the increasing importance of tool management services, reconditioning options, and technical support as integral components of cutting solution packages rather than mere product sales.

Environmental regulations and sustainability initiatives are creating new market demands, with 62% of large manufacturers now including environmental impact assessments in their cutting tool procurement processes. This has accelerated the development of longer-lasting carbide inserts and more efficient cutting strategies that reduce material waste and energy consumption.

Manufacturing industries, particularly automotive, aerospace, and general machinery production, represent the largest demand segments for advanced cutting solutions. These sectors collectively account for over 65% of the total carbide insert consumption globally, with their production volumes directly influencing market dynamics for cutting tools.

Cost-per-cut analysis has emerged as a critical decision-making framework as manufacturers face increasing pressure to reduce operational expenses while maintaining quality standards. Research indicates that cutting tool costs typically represent only 3-5% of total manufacturing expenses, yet their selection and implementation can impact overall production costs by up to 15-30% through their influence on machine downtime, labor utilization, and energy consumption.

Regional analysis reveals distinct market characteristics, with mature markets like North America and Western Europe focusing on high-performance solutions that maximize tool life and minimize production interruptions. Meanwhile, rapidly industrializing regions in Asia-Pacific, particularly China and India, show the highest growth rates, driven by expanding manufacturing bases and increasing technological sophistication in production processes.

Customer demand patterns have evolved significantly, with a clear shift from purely price-based purchasing decisions toward value-based procurement strategies. Survey data from manufacturing executives indicates that 78% now prioritize total cost of ownership over initial purchase price when selecting cutting tools, representing a fundamental shift in market dynamics.

The aftermarket and service segment has grown substantially, now representing approximately 40% of the total market value. This reflects the increasing importance of tool management services, reconditioning options, and technical support as integral components of cutting solution packages rather than mere product sales.

Environmental regulations and sustainability initiatives are creating new market demands, with 62% of large manufacturers now including environmental impact assessments in their cutting tool procurement processes. This has accelerated the development of longer-lasting carbide inserts and more efficient cutting strategies that reduce material waste and energy consumption.

Current Challenges in Carbide Insert Implementation

Despite the widespread adoption of carbide inserts in modern manufacturing, several significant challenges persist in their implementation across production lines. The primary obstacle remains the complex balance between initial tooling costs and long-term productivity gains. Manufacturing engineers frequently struggle with accurately calculating the true cost-per-cut when factoring in all relevant variables such as tool life, machine downtime, and quality consistency.

Tool life prediction represents another major challenge, as performance can vary dramatically based on workpiece materials, cutting parameters, and machine conditions. Current predictive models often fail to account for real-world variations in production environments, leading to unexpected tool failures and costly production interruptions. This unpredictability complicates inventory management and production scheduling.

The optimization of cutting parameters presents ongoing difficulties for many manufacturers. While carbide inserts offer superior performance potential, achieving optimal cutting speeds, feeds, and depths requires sophisticated knowledge and testing capabilities that many small to medium enterprises lack. Suboptimal parameter selection significantly reduces insert lifespan and increases overall production costs.

Tool management systems represent another pain point in carbide insert implementation. Many production facilities still rely on manual tracking methods or disconnected software solutions, resulting in inefficient tool utilization, excessive inventory, and inadequate performance data collection. The absence of integrated tool management systems prevents manufacturers from making data-driven decisions about insert selection and replacement strategies.

Environmental considerations are increasingly challenging traditional carbide insert practices. The mining and processing of tungsten carbide and cobalt have substantial environmental impacts, while disposal of used inserts presents additional sustainability concerns. Manufacturers face growing pressure to adopt more environmentally responsible approaches while maintaining productivity and cost-effectiveness.

Supply chain vulnerabilities have emerged as a critical challenge, particularly following recent global disruptions. The concentration of tungsten resources in specific geographic regions creates potential supply risks, while manufacturing bottlenecks can lead to extended lead times and price volatility. These factors complicate long-term planning and cost management for production facilities.

Technical skill gaps among machine operators and maintenance personnel further hinder optimal implementation. The increasing sophistication of carbide insert technologies requires corresponding advances in workforce training and development. Many manufacturers struggle to maintain the necessary technical expertise to fully leverage modern insert capabilities, particularly in automated and high-precision applications.

Tool life prediction represents another major challenge, as performance can vary dramatically based on workpiece materials, cutting parameters, and machine conditions. Current predictive models often fail to account for real-world variations in production environments, leading to unexpected tool failures and costly production interruptions. This unpredictability complicates inventory management and production scheduling.

The optimization of cutting parameters presents ongoing difficulties for many manufacturers. While carbide inserts offer superior performance potential, achieving optimal cutting speeds, feeds, and depths requires sophisticated knowledge and testing capabilities that many small to medium enterprises lack. Suboptimal parameter selection significantly reduces insert lifespan and increases overall production costs.

Tool management systems represent another pain point in carbide insert implementation. Many production facilities still rely on manual tracking methods or disconnected software solutions, resulting in inefficient tool utilization, excessive inventory, and inadequate performance data collection. The absence of integrated tool management systems prevents manufacturers from making data-driven decisions about insert selection and replacement strategies.

Environmental considerations are increasingly challenging traditional carbide insert practices. The mining and processing of tungsten carbide and cobalt have substantial environmental impacts, while disposal of used inserts presents additional sustainability concerns. Manufacturers face growing pressure to adopt more environmentally responsible approaches while maintaining productivity and cost-effectiveness.

Supply chain vulnerabilities have emerged as a critical challenge, particularly following recent global disruptions. The concentration of tungsten resources in specific geographic regions creates potential supply risks, while manufacturing bottlenecks can lead to extended lead times and price volatility. These factors complicate long-term planning and cost management for production facilities.

Technical skill gaps among machine operators and maintenance personnel further hinder optimal implementation. The increasing sophistication of carbide insert technologies requires corresponding advances in workforce training and development. Many manufacturers struggle to maintain the necessary technical expertise to fully leverage modern insert capabilities, particularly in automated and high-precision applications.

Cost-Effective Carbide Insert Solutions for Production

01 Carbide insert design for improved cost-per-cut

Specific design features of carbide inserts can significantly improve their cost-per-cut ratio. These designs include optimized cutting edges, specialized geometries, and strategic placement of carbide material. By enhancing the design, manufacturers can extend the life of the insert while maintaining cutting performance, thereby reducing the overall cost per cutting operation. Advanced designs may incorporate multiple cutting edges on a single insert, allowing for rotation or indexing when one edge becomes worn.- Carbide insert design for improved cost-per-cut: Specific design features of carbide inserts can significantly improve their cost-per-cut ratio. These designs include optimized cutting edges, specialized geometries, and improved chip control features that extend tool life while maintaining cutting efficiency. Advanced designs can reduce the frequency of insert replacement and minimize downtime during manufacturing processes, thereby lowering the overall cost-per-cut in machining operations.

- Coating technologies for carbide inserts: Various coating technologies applied to carbide inserts can enhance their durability and performance, resulting in improved cost-per-cut metrics. These coatings include PVD (Physical Vapor Deposition), CVD (Chemical Vapor Deposition), and multi-layer coatings that provide wear resistance, thermal protection, and reduced friction. By extending the service life of carbide inserts, these coating technologies contribute to lower overall machining costs.

- Material composition of carbide inserts affecting cost-efficiency: The material composition of carbide inserts plays a crucial role in determining their cost-per-cut performance. Various carbide grades, binder materials, and grain sizes can be optimized for specific cutting applications. Advanced carbide formulations with balanced hardness and toughness properties can withstand higher cutting speeds and feeds while resisting wear and fracture, thereby improving the economic efficiency of machining operations.

- Insert mounting and clamping systems for cost optimization: The methods and systems used for mounting and clamping carbide inserts significantly impact their cost-per-cut performance. Innovative clamping mechanisms can ensure proper seating, reduce vibration, and allow for quick insert indexing or replacement. These systems can maximize the utilization of all cutting edges on an insert before replacement is necessary, thereby improving the economic efficiency of the cutting operation.

- Cutting parameters and strategies for optimizing carbide insert economics: Optimizing cutting parameters and strategies can significantly improve the cost-per-cut performance of carbide inserts. This includes determining optimal cutting speeds, feed rates, depth of cut, and coolant applications specific to the workpiece material and insert type. Advanced cutting strategies, such as high-speed machining techniques and tool path optimization, can extend insert life while maintaining productivity, resulting in lower overall machining costs.

02 Material composition and coating technologies

The material composition and coating technologies applied to carbide inserts significantly impact their cost-per-cut performance. Advanced carbide formulations with optimized cobalt binders and grain structures enhance durability. Various coating technologies, including PVD, CVD, and multi-layer coatings, provide wear resistance, heat dissipation, and reduced friction. These material and coating innovations extend insert life, improve cutting efficiency, and ultimately reduce the cost-per-cut in machining operations.Expand Specific Solutions03 Cutting parameters optimization for cost efficiency

Optimizing cutting parameters is crucial for maximizing the cost-efficiency of carbide inserts. Parameters such as cutting speed, feed rate, depth of cut, and coolant application significantly affect insert wear rate and overall performance. By carefully selecting and adjusting these parameters based on the workpiece material and machining requirements, operators can extend insert life while maintaining productivity. This optimization process may involve computational models, empirical testing, or adaptive control systems that continuously adjust parameters during operation.Expand Specific Solutions04 Insert mounting and holder systems

The mounting and holder systems for carbide inserts play a significant role in determining cost-per-cut efficiency. Properly designed tool holders provide stability, reduce vibration, and ensure precise positioning of the insert. Quick-change systems minimize downtime during insert replacement. Advanced clamping mechanisms distribute forces evenly to prevent insert fracture and premature failure. Some systems incorporate features for improved chip evacuation and coolant delivery, further extending insert life and reducing the overall cost-per-cut.Expand Specific Solutions05 Economic analysis and performance monitoring systems

Economic analysis and performance monitoring systems help optimize the cost-per-cut of carbide inserts. These systems track insert wear, cutting forces, surface finish quality, and other performance metrics in real-time. By analyzing this data, manufacturers can determine the optimal time for insert replacement, avoiding both premature replacement and quality issues from excessive wear. Some advanced systems incorporate predictive maintenance algorithms and cost modeling tools that calculate the true cost-per-cut considering factors like material costs, machine time, labor, and downtime.Expand Specific Solutions

Leading Manufacturers and Competitive Landscape

The carbide insert market for production lines is in a mature growth phase, with an estimated global market size exceeding $5 billion annually. Leading players include Sandvik, Seco Tools, and Kennametal, who dominate through advanced R&D capabilities and comprehensive product portfolios. The technology landscape shows varying maturity levels, with established companies like Sandvik Aktiebolag focusing on premium solutions with integrated digital capabilities, while emerging players such as Zhuzhou Huarui and OKE Precision are gaining market share through cost-effective alternatives. Chinese manufacturers including Ningbo Sanhan and Heyuan Yueao are rapidly advancing their technical capabilities, narrowing the performance gap with Western counterparts while maintaining competitive pricing advantages.

Seco Tools AB

Technical Solution: Seco Tools has pioneered a multi-variable Cost-Per-Cut analysis framework called SECO EFFICIENCY that evaluates carbide insert performance across diverse manufacturing environments. Their technical solution incorporates a sophisticated digital twin modeling system that simulates various cutting scenarios before physical implementation. The system analyzes multiple parameters including cutting speed, feed rate, depth of cut, and coolant efficiency to determine optimal insert geometry and grade selection for specific applications. Seco's approach includes their proprietary wear-resistant coatings (Duratomic® technology) that significantly extend insert life in high-temperature applications. Their CPC analysis incorporates machine learning algorithms that continuously refine recommendations based on actual production outcomes, creating a feedback loop that improves accuracy over time. The system also features modular implementation options allowing manufacturers to scale the solution according to their specific needs and budget constraints.

Strengths: Highly adaptable to different manufacturing environments; excellent simulation capabilities before physical implementation; strong focus on user-friendly interfaces for shop floor personnel. Weaknesses: Requires substantial process documentation for maximum effectiveness; some advanced features require subscription-based licensing; limited integration with non-Seco tooling systems.

Sandvik Aktiebolag

Technical Solution: Sandvik has developed an integrated Cost-Per-Cut (CPC) analysis system that combines real-time monitoring with predictive analytics. Their solution incorporates sensors embedded within carbide inserts to track wear patterns, cutting forces, and temperature variations during machining operations. The system utilizes a proprietary algorithm that analyzes tool performance data against production metrics to optimize insert replacement schedules. Sandvik's approach includes their CoroPlus® platform which connects cutting tools to digital systems, enabling manufacturers to collect and analyze cutting data for process optimization. Their solution also features automatic tool path adjustment based on material hardness variations, extending insert life by up to 30% in challenging applications. The system includes comprehensive cost modeling that accounts for not only insert costs but also machine downtime, labor, and energy consumption to provide a holistic view of production economics.

Strengths: Comprehensive integration with existing production systems; advanced predictive maintenance capabilities; extensive material-specific databases for optimization. Weaknesses: Higher initial implementation costs; requires significant data collection period for maximum effectiveness; may require specialized training for operators.

Critical Patents and Innovations in Carbide Technology

Cemented carbide insert

PatentInactiveEP1043416A3

Innovation

- A coated cemented carbide insert with a 5-50 µm thick, essentially gamma phase-free and binder phase-enriched surface zone, composed of TaC and TiC with a specific Ta/Ti ratio, and a highly W-alloyed binder phase, along with a coating of TiCN, Al2O3, and TiN, is developed to enhance toughness without compromising plastic deformation resistance.

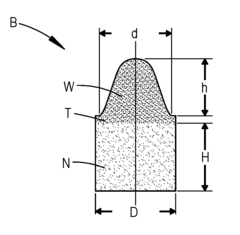

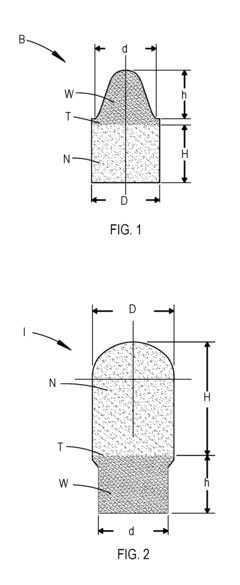

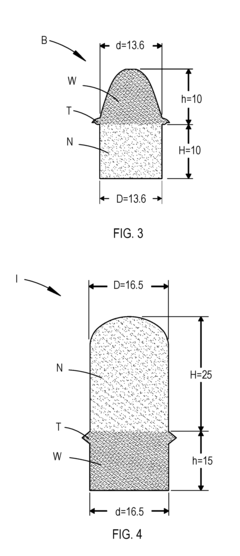

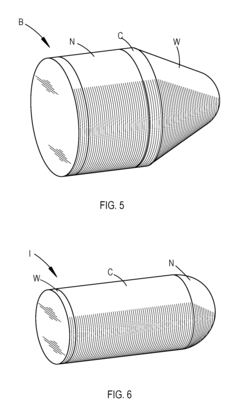

Composite Tungsten Carbide Insert With Heterogeneous Composition And Structure And Manufacturing Method Thereof

PatentActiveUS20170014912A1

Innovation

- A composite tungsten carbide insert with a heterogeneous composition and structure is manufactured, consisting of a working part made from tungsten carbide and cobalt or nickel powder and a non-working part made from a low-density tungsten carbide material, using a steel die for molding and sintering at 1420-1460°C to achieve improved performance and cost ratios.

Total Cost of Ownership Analysis Framework

When evaluating carbide insert strategies for production lines, a comprehensive Total Cost of Ownership (TCO) framework provides critical insights beyond the initial purchase price. This framework encompasses all direct and indirect costs associated with carbide insert implementation throughout their complete lifecycle in manufacturing operations.

The TCO analysis begins with acquisition costs, including not only the purchase price of carbide inserts but also procurement expenses, inventory management costs, and potential volume discounts. These initial expenditures typically represent only 20-30% of the total ownership costs, highlighting the importance of looking beyond purchase price alone.

Operational costs form the largest component of the TCO framework, encompassing machine downtime during insert changes, labor costs for replacement operations, productivity impacts, and energy consumption variations between different insert types. Studies indicate that high-performance carbide inserts may reduce machine downtime by up to 40% compared to standard options, significantly affecting overall operational economics.

Maintenance factors must be carefully evaluated, including insert replacement frequency, tool holder wear patterns, and machine calibration requirements. Premium carbide inserts often demonstrate 30-50% longer tool life, substantially reducing maintenance interventions and associated costs over time.

Performance metrics constitute another critical dimension, measuring cutting speed capabilities, surface finish quality, dimensional accuracy, and material removal rates. Advanced coating technologies on premium carbide inserts can increase cutting speeds by 20-35%, directly impacting production throughput and unit economics.

End-of-life considerations complete the framework, accounting for disposal costs, recycling opportunities, and potential recovery value of spent inserts. Many manufacturers now offer carbide recycling programs that can recover up to 70% of the tungsten carbide material, offsetting a portion of replacement costs.

Risk factors must also be quantified, including production disruptions, quality variations, and supply chain vulnerabilities. The TCO framework should incorporate contingency costs based on historical data and risk probability assessments specific to each insert strategy.

By applying this comprehensive TCO framework, manufacturing operations can make more informed decisions regarding carbide insert strategies, often revealing that higher-priced premium inserts deliver superior long-term economic value through enhanced performance, reduced downtime, and extended service life.

The TCO analysis begins with acquisition costs, including not only the purchase price of carbide inserts but also procurement expenses, inventory management costs, and potential volume discounts. These initial expenditures typically represent only 20-30% of the total ownership costs, highlighting the importance of looking beyond purchase price alone.

Operational costs form the largest component of the TCO framework, encompassing machine downtime during insert changes, labor costs for replacement operations, productivity impacts, and energy consumption variations between different insert types. Studies indicate that high-performance carbide inserts may reduce machine downtime by up to 40% compared to standard options, significantly affecting overall operational economics.

Maintenance factors must be carefully evaluated, including insert replacement frequency, tool holder wear patterns, and machine calibration requirements. Premium carbide inserts often demonstrate 30-50% longer tool life, substantially reducing maintenance interventions and associated costs over time.

Performance metrics constitute another critical dimension, measuring cutting speed capabilities, surface finish quality, dimensional accuracy, and material removal rates. Advanced coating technologies on premium carbide inserts can increase cutting speeds by 20-35%, directly impacting production throughput and unit economics.

End-of-life considerations complete the framework, accounting for disposal costs, recycling opportunities, and potential recovery value of spent inserts. Many manufacturers now offer carbide recycling programs that can recover up to 70% of the tungsten carbide material, offsetting a portion of replacement costs.

Risk factors must also be quantified, including production disruptions, quality variations, and supply chain vulnerabilities. The TCO framework should incorporate contingency costs based on historical data and risk probability assessments specific to each insert strategy.

By applying this comprehensive TCO framework, manufacturing operations can make more informed decisions regarding carbide insert strategies, often revealing that higher-priced premium inserts deliver superior long-term economic value through enhanced performance, reduced downtime, and extended service life.

Sustainability Considerations in Cutting Tool Selection

The environmental impact of cutting tool selection has become increasingly significant in modern manufacturing operations. When evaluating carbide insert strategies for production lines, sustainability considerations must be integrated into the cost-per-cut analysis framework. Traditional metrics focused primarily on immediate economic factors, but contemporary manufacturing demands a more holistic approach that accounts for environmental footprint throughout the tool lifecycle.

Material sourcing represents the first critical sustainability consideration. Tungsten carbide production involves mining operations with substantial environmental impacts, including habitat disruption, water usage, and energy consumption. Manufacturers implementing responsible sourcing policies are increasingly selecting suppliers who demonstrate commitment to sustainable mining practices and transparent supply chains for raw materials.

Tool longevity directly correlates with sustainability performance. Longer-lasting carbide inserts reduce the frequency of replacements, thereby decreasing the overall material consumption and associated environmental impacts. Advanced coating technologies such as PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) significantly extend insert lifespan while maintaining cutting performance, offering both economic and environmental benefits.

Energy efficiency during the operational phase presents another crucial sustainability dimension. Optimized cutting parameters reduce power consumption during machining operations. Research indicates that properly selected carbide inserts can reduce energy consumption by 15-30% compared to suboptimal tooling choices. This reduction translates to lower carbon emissions and operational costs throughout production cycles.

Coolant management practices significantly impact the environmental footprint of cutting operations. Minimum quantity lubrication (MQL) and near-dry machining techniques dramatically reduce fluid consumption compared to traditional flood cooling. Some advanced carbide insert designs specifically engineered for dry machining eliminate coolant requirements entirely, substantially reducing chemical waste and associated treatment costs.

End-of-life considerations complete the sustainability assessment framework. Recycling programs for spent carbide inserts recover valuable materials and prevent hazardous substances from entering landfills. The tungsten recovery rate from recycled carbide tools can exceed 95%, significantly reducing the demand for virgin material extraction. Leading manufacturers now offer take-back programs that facilitate closed-loop material cycles.

Quantifying sustainability benefits remains challenging but essential for comprehensive cost-per-cut analysis. Life Cycle Assessment (LCA) methodologies provide frameworks for evaluating environmental impacts across the entire tool lifecycle. Forward-thinking manufacturers are developing sustainability metrics that complement traditional economic indicators, enabling balanced decision-making that considers both immediate production costs and long-term environmental implications.

Material sourcing represents the first critical sustainability consideration. Tungsten carbide production involves mining operations with substantial environmental impacts, including habitat disruption, water usage, and energy consumption. Manufacturers implementing responsible sourcing policies are increasingly selecting suppliers who demonstrate commitment to sustainable mining practices and transparent supply chains for raw materials.

Tool longevity directly correlates with sustainability performance. Longer-lasting carbide inserts reduce the frequency of replacements, thereby decreasing the overall material consumption and associated environmental impacts. Advanced coating technologies such as PVD (Physical Vapor Deposition) and CVD (Chemical Vapor Deposition) significantly extend insert lifespan while maintaining cutting performance, offering both economic and environmental benefits.

Energy efficiency during the operational phase presents another crucial sustainability dimension. Optimized cutting parameters reduce power consumption during machining operations. Research indicates that properly selected carbide inserts can reduce energy consumption by 15-30% compared to suboptimal tooling choices. This reduction translates to lower carbon emissions and operational costs throughout production cycles.

Coolant management practices significantly impact the environmental footprint of cutting operations. Minimum quantity lubrication (MQL) and near-dry machining techniques dramatically reduce fluid consumption compared to traditional flood cooling. Some advanced carbide insert designs specifically engineered for dry machining eliminate coolant requirements entirely, substantially reducing chemical waste and associated treatment costs.

End-of-life considerations complete the sustainability assessment framework. Recycling programs for spent carbide inserts recover valuable materials and prevent hazardous substances from entering landfills. The tungsten recovery rate from recycled carbide tools can exceed 95%, significantly reducing the demand for virgin material extraction. Leading manufacturers now offer take-back programs that facilitate closed-loop material cycles.

Quantifying sustainability benefits remains challenging but essential for comprehensive cost-per-cut analysis. Life Cycle Assessment (LCA) methodologies provide frameworks for evaluating environmental impacts across the entire tool lifecycle. Forward-thinking manufacturers are developing sustainability metrics that complement traditional economic indicators, enabling balanced decision-making that considers both immediate production costs and long-term environmental implications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!