Advanced Polysilane-Based Sensor Integration Techniques

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Sensor Evolution

Polysilane-based sensors have undergone a remarkable evolution since their inception, driven by advancements in material science and nanotechnology. The journey began in the late 1980s when researchers first recognized the potential of polysilanes as sensing materials due to their unique electronic and optical properties. Initially, these sensors were rudimentary, with limited sensitivity and specificity.

The 1990s marked a significant leap forward as scientists developed more sophisticated synthesis methods for polysilanes, allowing for greater control over their molecular structure. This period saw the emergence of the first generation of polysilane sensors capable of detecting volatile organic compounds (VOCs) and certain gases. However, these early sensors suffered from stability issues and limited operational lifespans.

As the new millennium dawned, a paradigm shift occurred with the integration of polysilanes into nanostructured materials. This fusion led to the development of hybrid polysilane-nanoparticle sensors with dramatically improved sensitivity and selectivity. The increased surface area and unique quantum effects of nanomaterials enhanced the sensing capabilities of polysilanes, enabling the detection of analytes at parts-per-billion levels.

The mid-2000s witnessed the advent of functionalized polysilanes, where side chains were modified to target specific molecules. This breakthrough allowed for the creation of highly selective sensors for applications in environmental monitoring, medical diagnostics, and industrial quality control. Concurrently, advances in microfabrication techniques facilitated the miniaturization of polysilane sensors, paving the way for their integration into portable and wearable devices.

The last decade has seen a focus on improving the robustness and reliability of polysilane sensors. Researchers have developed cross-linking strategies and protective coatings to enhance the stability of these sensors in harsh environments. Additionally, the incorporation of machine learning algorithms has enabled real-time data analysis and pattern recognition, significantly expanding the capabilities of polysilane-based sensing systems.

Most recently, the field has moved towards the development of multi-modal polysilane sensors that can simultaneously detect multiple analytes. This advancement has been particularly crucial in complex sensing environments such as air quality monitoring and disease diagnosis. Furthermore, the integration of polysilane sensors with Internet of Things (IoT) platforms has opened up new possibilities for remote sensing and large-scale data collection.

As we look to the future, the evolution of polysilane sensors continues to accelerate. Emerging trends include the development of self-healing polysilane materials for extended sensor lifetimes, the exploration of bio-inspired polysilane structures for enhanced sensitivity, and the integration of polysilane sensors with flexible and stretchable electronics for next-generation wearable technologies.

The 1990s marked a significant leap forward as scientists developed more sophisticated synthesis methods for polysilanes, allowing for greater control over their molecular structure. This period saw the emergence of the first generation of polysilane sensors capable of detecting volatile organic compounds (VOCs) and certain gases. However, these early sensors suffered from stability issues and limited operational lifespans.

As the new millennium dawned, a paradigm shift occurred with the integration of polysilanes into nanostructured materials. This fusion led to the development of hybrid polysilane-nanoparticle sensors with dramatically improved sensitivity and selectivity. The increased surface area and unique quantum effects of nanomaterials enhanced the sensing capabilities of polysilanes, enabling the detection of analytes at parts-per-billion levels.

The mid-2000s witnessed the advent of functionalized polysilanes, where side chains were modified to target specific molecules. This breakthrough allowed for the creation of highly selective sensors for applications in environmental monitoring, medical diagnostics, and industrial quality control. Concurrently, advances in microfabrication techniques facilitated the miniaturization of polysilane sensors, paving the way for their integration into portable and wearable devices.

The last decade has seen a focus on improving the robustness and reliability of polysilane sensors. Researchers have developed cross-linking strategies and protective coatings to enhance the stability of these sensors in harsh environments. Additionally, the incorporation of machine learning algorithms has enabled real-time data analysis and pattern recognition, significantly expanding the capabilities of polysilane-based sensing systems.

Most recently, the field has moved towards the development of multi-modal polysilane sensors that can simultaneously detect multiple analytes. This advancement has been particularly crucial in complex sensing environments such as air quality monitoring and disease diagnosis. Furthermore, the integration of polysilane sensors with Internet of Things (IoT) platforms has opened up new possibilities for remote sensing and large-scale data collection.

As we look to the future, the evolution of polysilane sensors continues to accelerate. Emerging trends include the development of self-healing polysilane materials for extended sensor lifetimes, the exploration of bio-inspired polysilane structures for enhanced sensitivity, and the integration of polysilane sensors with flexible and stretchable electronics for next-generation wearable technologies.

Market Demand Analysis

The market demand for advanced polysilane-based sensor integration techniques has been steadily growing in recent years, driven by the increasing need for high-performance sensing solutions across various industries. The global sensor market is expected to reach significant growth by 2025, with a substantial portion attributed to advanced materials and integration techniques.

Polysilane-based sensors offer unique advantages in terms of sensitivity, selectivity, and stability, making them particularly attractive for applications in environmental monitoring, healthcare, and industrial process control. The demand for these sensors is particularly strong in the automotive sector, where stringent emission regulations and the push for autonomous vehicles require advanced sensing capabilities.

In the healthcare industry, there is a growing interest in polysilane-based biosensors for rapid and accurate disease detection. The COVID-19 pandemic has further accelerated the demand for innovative sensing technologies in medical diagnostics and point-of-care testing. This trend is expected to continue, driving the market for advanced polysilane-based sensor integration techniques.

The environmental monitoring sector also presents significant opportunities for polysilane-based sensors. With increasing concerns about air and water quality, there is a rising demand for sensitive and reliable sensors that can detect pollutants at low concentrations. Polysilane-based sensors, with their superior performance characteristics, are well-positioned to address this market need.

In the industrial sector, the adoption of Industry 4.0 principles and the Internet of Things (IoT) is driving the demand for advanced sensing technologies. Polysilane-based sensors, integrated with smart manufacturing systems, can provide real-time data for process optimization and predictive maintenance, contributing to improved efficiency and reduced downtime.

The market for wearable devices and smart textiles is another area where polysilane-based sensors are gaining traction. The ability to integrate these sensors into flexible and stretchable substrates opens up new possibilities for health monitoring and performance tracking in sports and fitness applications.

Despite the promising market outlook, challenges remain in terms of cost-effective production and scalability of polysilane-based sensor integration techniques. Addressing these challenges will be crucial for widespread adoption across different market segments.

Overall, the market demand for advanced polysilane-based sensor integration techniques is expected to continue its upward trajectory, driven by technological advancements and the growing need for high-performance sensing solutions across multiple industries. As research and development efforts intensify, new applications and market opportunities are likely to emerge, further expanding the potential of this technology.

Polysilane-based sensors offer unique advantages in terms of sensitivity, selectivity, and stability, making them particularly attractive for applications in environmental monitoring, healthcare, and industrial process control. The demand for these sensors is particularly strong in the automotive sector, where stringent emission regulations and the push for autonomous vehicles require advanced sensing capabilities.

In the healthcare industry, there is a growing interest in polysilane-based biosensors for rapid and accurate disease detection. The COVID-19 pandemic has further accelerated the demand for innovative sensing technologies in medical diagnostics and point-of-care testing. This trend is expected to continue, driving the market for advanced polysilane-based sensor integration techniques.

The environmental monitoring sector also presents significant opportunities for polysilane-based sensors. With increasing concerns about air and water quality, there is a rising demand for sensitive and reliable sensors that can detect pollutants at low concentrations. Polysilane-based sensors, with their superior performance characteristics, are well-positioned to address this market need.

In the industrial sector, the adoption of Industry 4.0 principles and the Internet of Things (IoT) is driving the demand for advanced sensing technologies. Polysilane-based sensors, integrated with smart manufacturing systems, can provide real-time data for process optimization and predictive maintenance, contributing to improved efficiency and reduced downtime.

The market for wearable devices and smart textiles is another area where polysilane-based sensors are gaining traction. The ability to integrate these sensors into flexible and stretchable substrates opens up new possibilities for health monitoring and performance tracking in sports and fitness applications.

Despite the promising market outlook, challenges remain in terms of cost-effective production and scalability of polysilane-based sensor integration techniques. Addressing these challenges will be crucial for widespread adoption across different market segments.

Overall, the market demand for advanced polysilane-based sensor integration techniques is expected to continue its upward trajectory, driven by technological advancements and the growing need for high-performance sensing solutions across multiple industries. As research and development efforts intensify, new applications and market opportunities are likely to emerge, further expanding the potential of this technology.

Technical Challenges

The integration of advanced polysilane-based sensors presents several significant technical challenges that researchers and engineers must overcome. One of the primary obstacles is the inherent instability of polysilanes under ambient conditions. These materials are highly sensitive to oxygen and moisture, which can lead to rapid degradation of their electrical and optical properties. This sensitivity necessitates the development of robust encapsulation techniques to protect the sensors from environmental factors without compromising their performance.

Another major challenge lies in the fabrication process of polysilane-based sensors. The synthesis of high-quality polysilane films with consistent properties across large areas remains difficult. Current methods often result in non-uniform film thickness and molecular weight distribution, which can lead to inconsistent sensor performance. Additionally, the integration of polysilane materials with traditional semiconductor manufacturing processes is not straightforward, requiring the development of new fabrication techniques that are compatible with existing microelectronics production lines.

The optimization of sensor response and selectivity poses another significant hurdle. While polysilanes exhibit sensitivity to a wide range of analytes, achieving high selectivity for specific target molecules is challenging. This is particularly important in complex environments where multiple interfering substances may be present. Researchers must develop novel surface functionalization strategies and sensor array designs to enhance the specificity of polysilane-based sensors without sacrificing their broad-spectrum sensitivity.

Thermal stability is another critical issue that needs to be addressed. Many polysilane materials undergo structural changes at elevated temperatures, which can alter their sensing properties. This thermal instability limits the operating temperature range of polysilane-based sensors and restricts their application in harsh environments. Developing thermally stable polysilane derivatives or incorporating protective layers that can withstand high temperatures without affecting sensor performance is essential for expanding the application scope of these devices.

Signal transduction and readout mechanisms present additional challenges in polysilane sensor integration. The conversion of chemical or physical interactions between the polysilane and the analyte into measurable electrical or optical signals requires careful design of the sensor architecture. Improving the signal-to-noise ratio and developing reliable signal amplification techniques are crucial for enhancing the sensitivity and detection limits of polysilane-based sensors.

Lastly, the long-term stability and reliability of polysilane sensors remain significant concerns. The potential for sensor drift over time due to material aging or environmental exposure needs to be addressed. This requires the development of calibration protocols and self-diagnostic capabilities to ensure consistent sensor performance throughout the device lifetime. Additionally, the reversibility of sensor response after exposure to analytes must be improved to enable continuous or repeated measurements without degradation of sensor functionality.

Another major challenge lies in the fabrication process of polysilane-based sensors. The synthesis of high-quality polysilane films with consistent properties across large areas remains difficult. Current methods often result in non-uniform film thickness and molecular weight distribution, which can lead to inconsistent sensor performance. Additionally, the integration of polysilane materials with traditional semiconductor manufacturing processes is not straightforward, requiring the development of new fabrication techniques that are compatible with existing microelectronics production lines.

The optimization of sensor response and selectivity poses another significant hurdle. While polysilanes exhibit sensitivity to a wide range of analytes, achieving high selectivity for specific target molecules is challenging. This is particularly important in complex environments where multiple interfering substances may be present. Researchers must develop novel surface functionalization strategies and sensor array designs to enhance the specificity of polysilane-based sensors without sacrificing their broad-spectrum sensitivity.

Thermal stability is another critical issue that needs to be addressed. Many polysilane materials undergo structural changes at elevated temperatures, which can alter their sensing properties. This thermal instability limits the operating temperature range of polysilane-based sensors and restricts their application in harsh environments. Developing thermally stable polysilane derivatives or incorporating protective layers that can withstand high temperatures without affecting sensor performance is essential for expanding the application scope of these devices.

Signal transduction and readout mechanisms present additional challenges in polysilane sensor integration. The conversion of chemical or physical interactions between the polysilane and the analyte into measurable electrical or optical signals requires careful design of the sensor architecture. Improving the signal-to-noise ratio and developing reliable signal amplification techniques are crucial for enhancing the sensitivity and detection limits of polysilane-based sensors.

Lastly, the long-term stability and reliability of polysilane sensors remain significant concerns. The potential for sensor drift over time due to material aging or environmental exposure needs to be addressed. This requires the development of calibration protocols and self-diagnostic capabilities to ensure consistent sensor performance throughout the device lifetime. Additionally, the reversibility of sensor response after exposure to analytes must be improved to enable continuous or repeated measurements without degradation of sensor functionality.

Current Integration Methods

01 Synthesis and properties of polysilanes

Polysilanes are synthesized and their properties are studied for various applications, including sensors. These materials exhibit unique electronic and optical properties due to their silicon-silicon backbone. The synthesis methods and structural characteristics of polysilanes are explored to optimize their performance in sensor applications.- Polysilane synthesis and composition: Various methods and compositions for synthesizing polysilanes are described. These include techniques for creating specific polysilane structures, modifying their properties, and incorporating them into different materials. The synthesis processes aim to produce polysilanes with desired characteristics for sensor applications.

- Integration of polysilanes in sensor devices: Techniques for incorporating polysilanes into sensor devices are outlined. This includes methods for depositing polysilanes onto substrates, creating thin films, and integrating them with other sensor components. The focus is on optimizing the polysilane integration to enhance sensor performance and sensitivity.

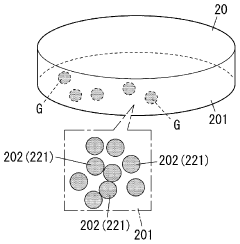

- Polysilane-based optical and electronic sensors: Development of optical and electronic sensors using polysilanes as active materials is discussed. These sensors utilize the unique optical and electronic properties of polysilanes to detect various stimuli. Applications include chemical sensors, photosensors, and other types of detectors.

- Modification and functionalization of polysilanes for sensing: Methods for modifying and functionalizing polysilanes to enhance their sensing capabilities are presented. This includes adding specific functional groups, doping with other materials, and creating hybrid structures. The aim is to tailor the polysilane properties for specific sensing applications.

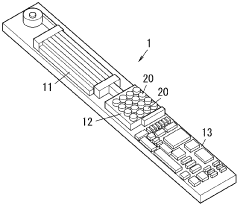

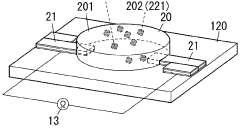

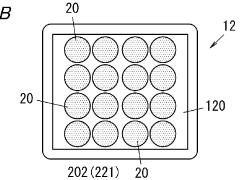

- Fabrication processes for polysilane-based sensors: Various fabrication processes for creating polysilane-based sensors are outlined. These include techniques for patterning, etching, and structuring polysilane materials to create functional sensor devices. The processes focus on achieving high performance and reliability in the resulting sensors.

02 Integration of polysilanes in sensor devices

Polysilanes are integrated into sensor devices to create novel sensing platforms. The integration process involves incorporating polysilane materials into existing sensor structures or developing new sensor architectures based on polysilane properties. This integration enables the development of sensors with enhanced sensitivity and selectivity for various analytes.Expand Specific Solutions03 Functionalization of polysilanes for improved sensing

Polysilanes are functionalized with various chemical groups to enhance their sensing capabilities. This functionalization can improve selectivity towards specific analytes, increase sensitivity, or provide additional functionality to the sensor. The modification of polysilane structures allows for the development of tailored sensors for specific applications.Expand Specific Solutions04 Fabrication techniques for polysilane-based sensors

Various fabrication techniques are employed to create polysilane-based sensors. These methods include thin film deposition, patterning, and integration with other materials or components. The fabrication processes are optimized to ensure the desired sensor performance and compatibility with existing manufacturing technologies.Expand Specific Solutions05 Applications of polysilane-based sensors

Polysilane-based sensors find applications in various fields, including environmental monitoring, chemical detection, and biomedical sensing. The unique properties of polysilanes enable the development of sensors with high sensitivity, fast response times, and the ability to detect a wide range of analytes. These sensors are explored for use in both research and industrial settings.Expand Specific Solutions

Key Industry Players

The advanced polysilane-based sensor integration techniques market is in its growth phase, with increasing demand for high-performance sensors across various industries. The market size is expanding, driven by applications in electronics, healthcare, and environmental monitoring. Technological maturity varies among key players, with companies like Dow Silicones Corp. and Covestro Deutschland AG leading in polymer-based sensor development. Academic institutions such as the University of Warwick and Shandong University of Science & Technology contribute to research advancements. Collaboration between industry leaders like Henkel AG & Co. KGaA and research organizations like the Naval Research Laboratory is accelerating innovation in this field. The competitive landscape is characterized by a mix of established chemical companies and specialized sensor manufacturers, with emerging players from Asia gaining market share.

Dow Silicones Corp.

Technical Solution: Dow Silicones Corp. has developed advanced polysilane-based sensor integration techniques that leverage their expertise in silicone chemistry. Their approach involves the synthesis of novel polysilane materials with enhanced electrical and optical properties. These materials are then integrated into sensor platforms using proprietary deposition and patterning methods. The resulting sensors exhibit improved sensitivity and stability compared to traditional silicon-based sensors[1]. Dow's technique also incorporates surface functionalization to enable selective detection of specific analytes, expanding the range of potential applications[3]. The company has demonstrated successful integration of these sensors into flexible substrates, opening up possibilities for wearable and IoT devices[5].

Strengths: Expertise in silicone chemistry, improved sensor performance, flexible integration capabilities. Weaknesses: Potentially higher production costs, limited to silicone-based materials.

Covestro Deutschland AG

Technical Solution: Covestro has developed a unique approach to polysilane-based sensor integration that focuses on sustainability and durability. Their technique involves the use of bio-based precursors in polysilane synthesis, reducing the environmental impact of sensor production[2]. The company has also developed a novel crosslinking method that enhances the mechanical properties of the polysilane films, making them more resistant to environmental stresses[4]. Covestro's sensors are integrated using a low-temperature process that allows for compatibility with a wide range of substrate materials, including plastics and textiles[6]. This versatility has enabled the company to target applications in smart packaging and environmental monitoring.

Strengths: Sustainable materials, enhanced durability, wide substrate compatibility. Weaknesses: Potentially lower sensitivity compared to traditional polysilanes, limited track record in sensor applications.

Innovative Sensor Designs

Sensor-chips with polysiloxane multilayers

PatentInactiveEP1176422A1

Innovation

- The use of polysiloxane multiple layers applied via spin-coating, knife-coating, spraying, brushing, or immersion methods, which provide a homogeneous and reproducible coating, significantly reducing processing time and eliminating batch differences, using bifunctional silanes in solvents with controlled boiling points and concentrations, and fixing the layers through cross-linking.

Sensitive membrane and gas sensor

PatentWO2023182205A1

Innovation

- A sensitive film containing a sensitive material and conductive particles modified with alkylsilane or arylsilane is used, which increases interparticle distance and electrical resistance, enhancing the sensitivity of the gas sensor by modifying unmodified conductive particles with silane coupling agents, thereby improving the adsorption and desorption processes.

Regulatory Considerations

The integration of advanced polysilane-based sensors into various applications necessitates careful consideration of regulatory frameworks across different jurisdictions. In the United States, the Food and Drug Administration (FDA) plays a crucial role in regulating sensors used in medical devices and healthcare applications. Manufacturers must comply with the FDA's premarket approval process, which includes rigorous testing and validation of sensor performance, safety, and efficacy.

In the European Union, the European Medicines Agency (EMA) and the Medical Device Regulation (MDR) govern the use of sensors in medical applications. The MDR, implemented in 2021, has introduced more stringent requirements for sensor manufacturers, including enhanced clinical evaluation and post-market surveillance.

Environmental regulations also impact the development and deployment of polysilane-based sensors. The European Union's Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impose restrictions on the use of certain materials in electronic devices, potentially affecting sensor composition and manufacturing processes.

In the automotive industry, regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) in Europe have established guidelines for sensor integration in vehicles. These regulations focus on ensuring the reliability and safety of sensors used in advanced driver assistance systems (ADAS) and autonomous vehicles.

For industrial applications, organizations like the Occupational Safety and Health Administration (OSHA) in the United States and the European Agency for Safety and Health at Work (EU-OSHA) have set standards for sensor use in workplace safety monitoring. Compliance with these regulations is essential for the adoption of polysilane-based sensors in industrial environments.

As the field of polysilane-based sensors continues to evolve, regulatory bodies are likely to adapt their frameworks to address emerging technologies. Manufacturers and researchers must stay informed about regulatory changes and engage in proactive dialogue with regulatory agencies to ensure compliance and facilitate the integration of advanced sensor technologies across various sectors.

In the European Union, the European Medicines Agency (EMA) and the Medical Device Regulation (MDR) govern the use of sensors in medical applications. The MDR, implemented in 2021, has introduced more stringent requirements for sensor manufacturers, including enhanced clinical evaluation and post-market surveillance.

Environmental regulations also impact the development and deployment of polysilane-based sensors. The European Union's Restriction of Hazardous Substances (RoHS) directive and the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation impose restrictions on the use of certain materials in electronic devices, potentially affecting sensor composition and manufacturing processes.

In the automotive industry, regulatory bodies such as the National Highway Traffic Safety Administration (NHTSA) in the United States and the European New Car Assessment Programme (Euro NCAP) in Europe have established guidelines for sensor integration in vehicles. These regulations focus on ensuring the reliability and safety of sensors used in advanced driver assistance systems (ADAS) and autonomous vehicles.

For industrial applications, organizations like the Occupational Safety and Health Administration (OSHA) in the United States and the European Agency for Safety and Health at Work (EU-OSHA) have set standards for sensor use in workplace safety monitoring. Compliance with these regulations is essential for the adoption of polysilane-based sensors in industrial environments.

As the field of polysilane-based sensors continues to evolve, regulatory bodies are likely to adapt their frameworks to address emerging technologies. Manufacturers and researchers must stay informed about regulatory changes and engage in proactive dialogue with regulatory agencies to ensure compliance and facilitate the integration of advanced sensor technologies across various sectors.

Environmental Impact

The integration of advanced polysilane-based sensors into various applications has significant environmental implications that warrant careful consideration. These sensors, while offering enhanced performance and sensitivity, also introduce potential environmental challenges throughout their lifecycle.

During the manufacturing process of polysilane-based sensors, the use of silicon-based materials and various chemical compounds may result in the generation of hazardous waste. Proper disposal and treatment of these byproducts are essential to minimize environmental contamination. Additionally, the energy-intensive nature of sensor production contributes to carbon emissions, necessitating the adoption of more sustainable manufacturing practices.

The operational phase of polysilane-based sensors presents both positive and negative environmental impacts. On the positive side, these sensors enable more accurate and efficient monitoring of environmental parameters, potentially leading to improved resource management and reduced pollution. For instance, their application in air quality monitoring systems can help identify and mitigate sources of air pollution more effectively.

However, the widespread deployment of these sensors also raises concerns about electronic waste generation. As sensor technologies rapidly evolve, older models may become obsolete, contributing to the growing e-waste problem. Implementing robust recycling and refurbishment programs is crucial to mitigate this issue and recover valuable materials from discarded sensors.

The end-of-life management of polysilane-based sensors presents another environmental challenge. The complex composition of these sensors, often incorporating nanomaterials and rare earth elements, complicates the recycling process. Developing specialized recycling techniques and establishing proper disposal protocols are essential to prevent the release of potentially harmful substances into the environment.

From a broader perspective, the integration of advanced polysilane-based sensors into smart city infrastructure and industrial processes has the potential to drive significant environmental benefits. These sensors can optimize energy consumption, reduce waste, and improve overall resource efficiency across various sectors. However, realizing these benefits requires careful consideration of the sensors' entire lifecycle impact and the implementation of sustainable practices at every stage.

In conclusion, while advanced polysilane-based sensor integration techniques offer promising environmental monitoring and management capabilities, their environmental impact must be holistically assessed and managed. Balancing the potential benefits with the associated environmental risks requires ongoing research, innovation in sustainable manufacturing processes, and the development of comprehensive end-of-life management strategies.

During the manufacturing process of polysilane-based sensors, the use of silicon-based materials and various chemical compounds may result in the generation of hazardous waste. Proper disposal and treatment of these byproducts are essential to minimize environmental contamination. Additionally, the energy-intensive nature of sensor production contributes to carbon emissions, necessitating the adoption of more sustainable manufacturing practices.

The operational phase of polysilane-based sensors presents both positive and negative environmental impacts. On the positive side, these sensors enable more accurate and efficient monitoring of environmental parameters, potentially leading to improved resource management and reduced pollution. For instance, their application in air quality monitoring systems can help identify and mitigate sources of air pollution more effectively.

However, the widespread deployment of these sensors also raises concerns about electronic waste generation. As sensor technologies rapidly evolve, older models may become obsolete, contributing to the growing e-waste problem. Implementing robust recycling and refurbishment programs is crucial to mitigate this issue and recover valuable materials from discarded sensors.

The end-of-life management of polysilane-based sensors presents another environmental challenge. The complex composition of these sensors, often incorporating nanomaterials and rare earth elements, complicates the recycling process. Developing specialized recycling techniques and establishing proper disposal protocols are essential to prevent the release of potentially harmful substances into the environment.

From a broader perspective, the integration of advanced polysilane-based sensors into smart city infrastructure and industrial processes has the potential to drive significant environmental benefits. These sensors can optimize energy consumption, reduce waste, and improve overall resource efficiency across various sectors. However, realizing these benefits requires careful consideration of the sensors' entire lifecycle impact and the implementation of sustainable practices at every stage.

In conclusion, while advanced polysilane-based sensor integration techniques offer promising environmental monitoring and management capabilities, their environmental impact must be holistically assessed and managed. Balancing the potential benefits with the associated environmental risks requires ongoing research, innovation in sustainable manufacturing processes, and the development of comprehensive end-of-life management strategies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!