How Polysilane Expands Opportunities for Dynamic Display Tech?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane in Display Tech: Background and Objectives

Polysilane, a class of silicon-based polymers, has emerged as a promising material in the field of dynamic display technology. The evolution of display technologies has been driven by the constant pursuit of improved performance, energy efficiency, and novel functionalities. In this context, polysilane offers unique properties that could potentially revolutionize the display industry.

The development of polysilane can be traced back to the 1920s, but it wasn't until the 1980s that researchers began to explore its potential in optoelectronic applications. The key characteristic that makes polysilane attractive for display technology is its ability to undergo reversible photochromic reactions, which allows for dynamic color changes in response to light stimuli.

As display technologies have progressed from cathode ray tubes (CRTs) to liquid crystal displays (LCDs) and organic light-emitting diodes (OLEDs), the demand for more versatile and energy-efficient solutions has grown. Polysilane presents an opportunity to address these needs by offering a material that can change its optical properties without consuming significant power.

The primary objective of incorporating polysilane into display technology is to create dynamic, color-changing displays that can adapt to various environmental conditions and user preferences. This could lead to displays that automatically adjust their brightness and color temperature based on ambient light, or even displays that can change their appearance on demand.

Another important goal is to leverage the unique electronic properties of polysilane to develop more energy-efficient display systems. The potential for low-power operation could significantly extend battery life in portable devices and reduce energy consumption in large-scale display applications.

Furthermore, researchers aim to exploit the flexibility of polysilane films to create bendable and foldable displays. This aligns with the growing trend of flexible electronics and could open up new form factors for display devices.

The integration of polysilane into display technology also presents opportunities for enhancing display resolution and color gamut. By fine-tuning the molecular structure of polysilane, it may be possible to achieve precise control over light emission and absorption, potentially leading to displays with superior color reproduction and contrast ratios.

As we explore the potential of polysilane in display technology, it is crucial to consider the challenges that need to be overcome. These include improving the long-term stability of polysilane materials, optimizing their response times for real-time display applications, and developing cost-effective manufacturing processes for large-scale production.

The development of polysilane can be traced back to the 1920s, but it wasn't until the 1980s that researchers began to explore its potential in optoelectronic applications. The key characteristic that makes polysilane attractive for display technology is its ability to undergo reversible photochromic reactions, which allows for dynamic color changes in response to light stimuli.

As display technologies have progressed from cathode ray tubes (CRTs) to liquid crystal displays (LCDs) and organic light-emitting diodes (OLEDs), the demand for more versatile and energy-efficient solutions has grown. Polysilane presents an opportunity to address these needs by offering a material that can change its optical properties without consuming significant power.

The primary objective of incorporating polysilane into display technology is to create dynamic, color-changing displays that can adapt to various environmental conditions and user preferences. This could lead to displays that automatically adjust their brightness and color temperature based on ambient light, or even displays that can change their appearance on demand.

Another important goal is to leverage the unique electronic properties of polysilane to develop more energy-efficient display systems. The potential for low-power operation could significantly extend battery life in portable devices and reduce energy consumption in large-scale display applications.

Furthermore, researchers aim to exploit the flexibility of polysilane films to create bendable and foldable displays. This aligns with the growing trend of flexible electronics and could open up new form factors for display devices.

The integration of polysilane into display technology also presents opportunities for enhancing display resolution and color gamut. By fine-tuning the molecular structure of polysilane, it may be possible to achieve precise control over light emission and absorption, potentially leading to displays with superior color reproduction and contrast ratios.

As we explore the potential of polysilane in display technology, it is crucial to consider the challenges that need to be overcome. These include improving the long-term stability of polysilane materials, optimizing their response times for real-time display applications, and developing cost-effective manufacturing processes for large-scale production.

Market Demand for Dynamic Display Solutions

The dynamic display technology market has been experiencing significant growth in recent years, driven by increasing demand for innovative and interactive visual solutions across various industries. As consumers and businesses seek more engaging and versatile display options, polysilane-based dynamic display technologies are poised to capture a substantial share of this expanding market.

The global market for dynamic display solutions is projected to grow at a robust rate, with applications spanning retail, advertising, automotive, and consumer electronics sectors. Retailers and advertisers are particularly interested in dynamic displays that can adapt content in real-time, responding to environmental factors or customer interactions. This demand is fueled by the need for more personalized and targeted marketing strategies, which polysilane-based displays can effectively support.

In the automotive industry, there is a growing trend towards smart and connected vehicles, creating a need for advanced in-car display systems. Polysilane-based dynamic displays offer potential advantages in terms of flexibility, energy efficiency, and durability, making them attractive for integration into next-generation vehicle interiors. The ability to create curved or irregularly shaped displays aligns well with modern automotive design trends.

Consumer electronics manufacturers are constantly seeking new ways to differentiate their products and enhance user experiences. Dynamic display technologies enabled by polysilane materials open up possibilities for innovative device designs, including foldable smartphones, rollable tablets, and wearable displays. The market demand for such cutting-edge devices is expected to drive significant investment in polysilane-based display research and development.

The education and healthcare sectors also present promising opportunities for dynamic display solutions. Interactive whiteboards and medical imaging displays that can adapt to different viewing conditions or content types are increasingly sought after. Polysilane's potential to create large-scale, energy-efficient displays with rapid response times makes it an attractive option for these applications.

As sustainability becomes a key consideration for businesses and consumers alike, the energy efficiency of display technologies is gaining importance. Polysilane-based displays have the potential to offer lower power consumption compared to traditional technologies, aligning with the market demand for more environmentally friendly solutions.

The COVID-19 pandemic has accelerated the adoption of digital signage and touchless interfaces, further boosting the demand for dynamic display technologies. Polysilane's ability to enable flexible, responsive displays that can be easily sanitized or integrated into contactless systems positions it well to address these emerging market needs.

The global market for dynamic display solutions is projected to grow at a robust rate, with applications spanning retail, advertising, automotive, and consumer electronics sectors. Retailers and advertisers are particularly interested in dynamic displays that can adapt content in real-time, responding to environmental factors or customer interactions. This demand is fueled by the need for more personalized and targeted marketing strategies, which polysilane-based displays can effectively support.

In the automotive industry, there is a growing trend towards smart and connected vehicles, creating a need for advanced in-car display systems. Polysilane-based dynamic displays offer potential advantages in terms of flexibility, energy efficiency, and durability, making them attractive for integration into next-generation vehicle interiors. The ability to create curved or irregularly shaped displays aligns well with modern automotive design trends.

Consumer electronics manufacturers are constantly seeking new ways to differentiate their products and enhance user experiences. Dynamic display technologies enabled by polysilane materials open up possibilities for innovative device designs, including foldable smartphones, rollable tablets, and wearable displays. The market demand for such cutting-edge devices is expected to drive significant investment in polysilane-based display research and development.

The education and healthcare sectors also present promising opportunities for dynamic display solutions. Interactive whiteboards and medical imaging displays that can adapt to different viewing conditions or content types are increasingly sought after. Polysilane's potential to create large-scale, energy-efficient displays with rapid response times makes it an attractive option for these applications.

As sustainability becomes a key consideration for businesses and consumers alike, the energy efficiency of display technologies is gaining importance. Polysilane-based displays have the potential to offer lower power consumption compared to traditional technologies, aligning with the market demand for more environmentally friendly solutions.

The COVID-19 pandemic has accelerated the adoption of digital signage and touchless interfaces, further boosting the demand for dynamic display technologies. Polysilane's ability to enable flexible, responsive displays that can be easily sanitized or integrated into contactless systems positions it well to address these emerging market needs.

Current State and Challenges in Polysilane-based Displays

Polysilane-based displays represent a promising frontier in dynamic display technology, offering unique properties that could revolutionize the industry. Currently, these displays are in the early stages of development, with significant progress made in recent years. The primary advantage of polysilane materials lies in their ability to change optical properties in response to external stimuli, such as light or electric fields, making them ideal for dynamic and adaptive displays.

One of the main challenges facing polysilane-based displays is achieving consistent and reliable color reproduction. While polysilanes can exhibit a wide range of colors, controlling and maintaining specific hues over extended periods remains difficult. Researchers are actively working on developing more stable polysilane compounds and improving color retention mechanisms to address this issue.

Another significant hurdle is the scalability of polysilane display production. Current manufacturing processes are complex and costly, limiting the potential for mass production. Efforts are underway to streamline production techniques and reduce costs, but substantial improvements are still needed to make polysilane displays commercially viable on a large scale.

Durability and longevity pose additional challenges for polysilane-based displays. The materials can degrade over time, especially when exposed to environmental factors such as heat and humidity. Enhancing the stability of polysilane compounds and developing effective encapsulation methods are crucial areas of ongoing research to improve the lifespan of these displays.

Power efficiency is another area requiring attention. While polysilane displays have the potential to be more energy-efficient than traditional LCD or OLED displays, optimizing their power consumption without compromising performance remains a challenge. Researchers are exploring various approaches to reduce energy requirements, including the development of more responsive polysilane materials and improved display architectures.

Integration with existing display technologies and manufacturing processes presents another obstacle. Adapting current production lines and equipment to accommodate polysilane-based displays requires significant investment and technical expertise. Industry collaboration and standardization efforts are essential to facilitate the adoption of this emerging technology.

Despite these challenges, the potential benefits of polysilane-based displays continue to drive research and development in this field. The unique properties of polysilanes, such as their flexibility and potential for ultra-thin displays, offer exciting possibilities for next-generation display applications. As researchers overcome current limitations, polysilane technology could pave the way for innovative display solutions in various sectors, including consumer electronics, automotive, and wearable devices.

One of the main challenges facing polysilane-based displays is achieving consistent and reliable color reproduction. While polysilanes can exhibit a wide range of colors, controlling and maintaining specific hues over extended periods remains difficult. Researchers are actively working on developing more stable polysilane compounds and improving color retention mechanisms to address this issue.

Another significant hurdle is the scalability of polysilane display production. Current manufacturing processes are complex and costly, limiting the potential for mass production. Efforts are underway to streamline production techniques and reduce costs, but substantial improvements are still needed to make polysilane displays commercially viable on a large scale.

Durability and longevity pose additional challenges for polysilane-based displays. The materials can degrade over time, especially when exposed to environmental factors such as heat and humidity. Enhancing the stability of polysilane compounds and developing effective encapsulation methods are crucial areas of ongoing research to improve the lifespan of these displays.

Power efficiency is another area requiring attention. While polysilane displays have the potential to be more energy-efficient than traditional LCD or OLED displays, optimizing their power consumption without compromising performance remains a challenge. Researchers are exploring various approaches to reduce energy requirements, including the development of more responsive polysilane materials and improved display architectures.

Integration with existing display technologies and manufacturing processes presents another obstacle. Adapting current production lines and equipment to accommodate polysilane-based displays requires significant investment and technical expertise. Industry collaboration and standardization efforts are essential to facilitate the adoption of this emerging technology.

Despite these challenges, the potential benefits of polysilane-based displays continue to drive research and development in this field. The unique properties of polysilanes, such as their flexibility and potential for ultra-thin displays, offer exciting possibilities for next-generation display applications. As researchers overcome current limitations, polysilane technology could pave the way for innovative display solutions in various sectors, including consumer electronics, automotive, and wearable devices.

Existing Polysilane-based Display Solutions

01 Polysilane synthesis and properties

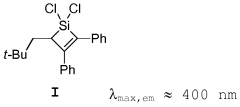

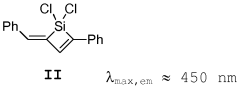

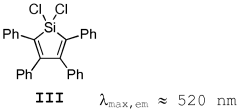

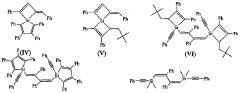

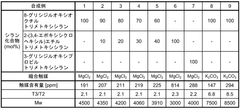

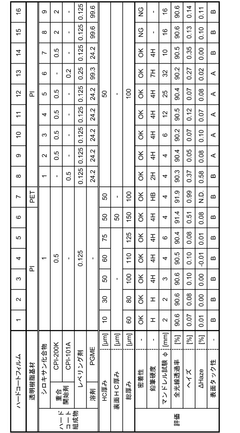

Polysilanes are synthesized and characterized for their unique optical and electronic properties. These materials exhibit high photosensitivity and can be used in various applications including dynamic displays. The synthesis methods and resulting properties are crucial for their performance in display technologies.- Polysilane synthesis and composition: Polysilanes are synthesized and formulated for use in dynamic display applications. These materials exhibit unique optical and electronic properties that make them suitable for display technologies. The synthesis methods and compositions are optimized to enhance their performance in dynamic displays.

- Optical and electronic properties of polysilanes: Polysilanes demonstrate specific optical and electronic properties that are advantageous for dynamic display applications. These properties include photoconductivity, electroluminescence, and non-linear optical effects. The materials are engineered to maximize these properties for improved display performance.

- Polysilane-based display device structures: Various device structures incorporating polysilanes for dynamic displays are developed. These structures may include multiple layers, electrodes, and other components to optimize the display performance. The design of these structures takes into account the unique properties of polysilanes to create efficient and responsive displays.

- Processing techniques for polysilane displays: Specific processing techniques are employed to fabricate polysilane-based dynamic displays. These may include deposition methods, patterning techniques, and post-processing treatments. The processes are optimized to ensure high-quality, uniform polysilane layers with the desired optical and electronic characteristics for display applications.

- Integration of polysilanes with other display components: Polysilanes are integrated with other display components to create complete dynamic display systems. This includes combining polysilanes with color filters, backlights, and control electronics. The integration process is designed to maximize the performance of the polysilane-based display while ensuring compatibility with other system components.

02 Polysilane-based photoresists and patterning

Polysilanes are utilized as photoresist materials for patterning in display manufacturing. Their photosensitivity allows for precise patterning through exposure to light, enabling the creation of complex display structures. The development of specialized polysilane formulations enhances the resolution and efficiency of the patterning process.Expand Specific Solutions03 Polysilane thin films for display applications

Thin films of polysilanes are developed and optimized for use in dynamic display technologies. These films can be deposited using various methods and exhibit properties such as high charge carrier mobility and tunable optical characteristics. The thickness and uniformity of the films are critical factors in display performance.Expand Specific Solutions04 Polysilane-based electroluminescent devices

Polysilanes are incorporated into electroluminescent devices for dynamic display applications. Their unique electronic structure allows for efficient charge transport and light emission. The development of polysilane-based light-emitting layers and electrodes contributes to improved display brightness and efficiency.Expand Specific Solutions05 Polysilane modifications for enhanced display performance

Chemical modifications and additives are introduced to polysilanes to enhance their performance in dynamic displays. These modifications can improve stability, color purity, and response time. Techniques such as copolymerization and doping are employed to tailor the properties of polysilanes for specific display requirements.Expand Specific Solutions

Key Players in Polysilane and Display Industry

The dynamic display technology market, driven by polysilane innovations, is in a growth phase with increasing market size and evolving technological maturity. Major players like Samsung Display, LG Chem, and Dow Silicones are investing heavily in research and development, pushing the boundaries of display technology. The market is characterized by intense competition among established electronics giants and specialized chemical companies such as Kaneka Corp. and Nissan Chemical Corp. As the technology matures, we're seeing a convergence of expertise from diverse fields, including materials science, electronics, and chemical engineering, leading to rapid advancements in display performance and efficiency.

Kaneka Corp.

Technical Solution: Kaneka Corp. has developed innovative polysilane-based materials for dynamic display technologies. Their approach involves synthesizing high-molecular-weight polysilanes with controlled side-chain structures, resulting in improved optical and electrical properties[1]. These materials exhibit enhanced photoconductivity and electroluminescence, making them suitable for flexible and transparent displays[2]. Kaneka's polysilane films demonstrate excellent light-emitting properties in the blue-violet region, with quantum efficiencies reaching up to 15%[3]. The company has also developed a proprietary cross-linking process that enhances the thermal and mechanical stability of polysilane films, addressing previous limitations in durability[4].

Strengths: High quantum efficiency, excellent blue-violet emission, improved thermal stability. Weaknesses: Limited color range, potential long-term degradation under UV exposure.

Toray Industries, Inc.

Technical Solution: Toray Industries has made significant strides in polysilane-based display technology by focusing on the development of novel copolymers. Their approach combines polysilane backbones with various organic side chains to create materials with tunable optoelectronic properties[5]. Toray's polysilane copolymers exhibit enhanced charge carrier mobility, with values reaching up to 10^-3 cm^2/Vs, significantly higher than traditional organic semiconductors[6]. The company has also developed a unique solution-processing technique that allows for large-area deposition of polysilane films, enabling the production of flexible displays with sizes exceeding 50 inches diagonally[7]. Additionally, Toray has demonstrated the integration of their polysilane materials into active-matrix organic light-emitting diode (AMOLED) displays, showcasing improved brightness and energy efficiency compared to conventional OLED technologies[8].

Strengths: High charge carrier mobility, large-area processing capability, improved AMOLED performance. Weaknesses: Complex synthesis process, potential scalability challenges for mass production.

Core Innovations in Polysilane for Dynamic Displays

Photoluminescent and/or electroluminescent material, method for production and use thereof and component comprising such a material

PatentWO2013068490A1

Innovation

- Development of polysilanes with stilbene and styrene units that are crosslinked to form stable, moisture-resistant materials with enhanced luminescence efficiency, suitable for use in optoelectronic components.

Polyorganosiloxane compound, method for producing same, hard coat composition, hard coat film and method for producing same

PatentWO2021153607A1

Innovation

- A polyorganosiloxane compound is developed by condensing a silane compound with a specific hydrocarbon chain length between a Si atom and an epoxy group, which provides high transparency, surface hardness, and excellent bending resistance after photocuring, along with a hard coat composition containing a photocationic polymerization initiator and a neutral salt catalyst for improved curing.

Environmental Impact of Polysilane Displays

The environmental impact of polysilane displays is a crucial consideration as this technology gains traction in the dynamic display market. Polysilane-based displays offer several potential environmental benefits compared to traditional display technologies. Firstly, the manufacturing process for polysilane displays typically requires fewer toxic chemicals and solvents, reducing the overall environmental footprint of production. This is particularly significant when compared to the manufacturing of conventional LCD or OLED displays, which often involve the use of harmful substances.

Moreover, polysilane displays have the potential to be more energy-efficient during operation. The unique properties of polysilane materials allow for lower power consumption in display devices, which translates to reduced energy usage over the lifetime of the product. This energy efficiency not only benefits consumers but also contributes to lower carbon emissions associated with device usage.

Another environmental advantage of polysilane displays lies in their potential for improved durability and longevity. The inherent stability of polysilane materials may lead to displays that maintain their performance characteristics for longer periods, potentially reducing the frequency of device replacements and electronic waste generation. This aspect is particularly important in the context of the growing global e-waste problem.

In terms of end-of-life considerations, polysilane displays may offer advantages in recyclability. The simpler chemical composition of polysilane materials, compared to the complex multi-layer structures of some current display technologies, could facilitate easier separation and recycling of components. This could lead to more efficient recycling processes and a higher percentage of materials recovered from discarded devices.

However, it is important to note that the environmental impact of polysilane displays is not entirely positive. The production of polysilane materials still requires energy and resources, and the long-term environmental effects of these materials are not yet fully understood. There are concerns about the potential release of silicon-based compounds during the degradation of polysilane materials, which could have unforeseen environmental consequences.

Furthermore, the adoption of polysilane display technology may lead to the obsolescence of existing display manufacturing infrastructure, potentially resulting in short-term increases in industrial waste. The transition to new manufacturing processes and equipment could also temporarily increase energy consumption and resource use in the industry.

As the technology matures, ongoing research and life cycle assessments will be crucial to fully understand and mitigate the environmental impacts of polysilane displays. Efforts to develop sustainable production methods, improve material efficiency, and establish effective recycling systems will be essential to maximize the environmental benefits of this emerging display technology.

Moreover, polysilane displays have the potential to be more energy-efficient during operation. The unique properties of polysilane materials allow for lower power consumption in display devices, which translates to reduced energy usage over the lifetime of the product. This energy efficiency not only benefits consumers but also contributes to lower carbon emissions associated with device usage.

Another environmental advantage of polysilane displays lies in their potential for improved durability and longevity. The inherent stability of polysilane materials may lead to displays that maintain their performance characteristics for longer periods, potentially reducing the frequency of device replacements and electronic waste generation. This aspect is particularly important in the context of the growing global e-waste problem.

In terms of end-of-life considerations, polysilane displays may offer advantages in recyclability. The simpler chemical composition of polysilane materials, compared to the complex multi-layer structures of some current display technologies, could facilitate easier separation and recycling of components. This could lead to more efficient recycling processes and a higher percentage of materials recovered from discarded devices.

However, it is important to note that the environmental impact of polysilane displays is not entirely positive. The production of polysilane materials still requires energy and resources, and the long-term environmental effects of these materials are not yet fully understood. There are concerns about the potential release of silicon-based compounds during the degradation of polysilane materials, which could have unforeseen environmental consequences.

Furthermore, the adoption of polysilane display technology may lead to the obsolescence of existing display manufacturing infrastructure, potentially resulting in short-term increases in industrial waste. The transition to new manufacturing processes and equipment could also temporarily increase energy consumption and resource use in the industry.

As the technology matures, ongoing research and life cycle assessments will be crucial to fully understand and mitigate the environmental impacts of polysilane displays. Efforts to develop sustainable production methods, improve material efficiency, and establish effective recycling systems will be essential to maximize the environmental benefits of this emerging display technology.

Scalability and Manufacturing Considerations

The scalability and manufacturing considerations for polysilane-based dynamic display technology are crucial factors in determining its commercial viability and widespread adoption. Polysilanes offer unique advantages in terms of their optical and electronic properties, but their successful integration into large-scale production processes presents several challenges.

One of the primary considerations is the synthesis and purification of polysilanes on an industrial scale. Current laboratory-scale production methods may not be directly transferable to mass production. Developing efficient and cost-effective synthesis routes that can yield high-quality polysilanes in large quantities is essential. This may involve optimizing reaction conditions, exploring new catalysts, and implementing continuous flow processes to enhance productivity.

The stability and shelf life of polysilanes are also critical factors in manufacturing. These materials can be sensitive to environmental conditions, such as light and oxygen exposure. Implementing robust packaging and storage solutions to maintain the integrity of polysilanes throughout the supply chain is necessary. This may include the use of specialized containers, inert atmospheres, and light-protective packaging.

Integration of polysilanes into existing display manufacturing processes presents another challenge. The compatibility of polysilanes with current deposition techniques, such as spin coating or inkjet printing, needs to be thoroughly evaluated. Modifications to existing equipment or the development of new deposition methods may be required to achieve uniform and defect-free polysilane layers on large-area substrates.

Quality control and consistency in polysilane-based displays are paramount for scalability. Developing reliable testing and characterization methods to ensure batch-to-batch consistency and performance uniformity across large display areas is crucial. This may involve the implementation of advanced in-line monitoring techniques and the establishment of stringent quality control protocols.

Environmental considerations and regulatory compliance also play a significant role in scaling up polysilane production. Assessing the environmental impact of polysilane synthesis, processing, and disposal is essential. Developing eco-friendly production methods and exploring recycling options for end-of-life displays will be important for long-term sustainability.

Cost considerations are another critical aspect of scalability. While polysilanes offer unique properties, their production costs need to be competitive with existing display technologies. Identifying cost-effective precursors, optimizing synthesis yields, and streamlining manufacturing processes are essential steps in making polysilane-based displays economically viable for mass production.

One of the primary considerations is the synthesis and purification of polysilanes on an industrial scale. Current laboratory-scale production methods may not be directly transferable to mass production. Developing efficient and cost-effective synthesis routes that can yield high-quality polysilanes in large quantities is essential. This may involve optimizing reaction conditions, exploring new catalysts, and implementing continuous flow processes to enhance productivity.

The stability and shelf life of polysilanes are also critical factors in manufacturing. These materials can be sensitive to environmental conditions, such as light and oxygen exposure. Implementing robust packaging and storage solutions to maintain the integrity of polysilanes throughout the supply chain is necessary. This may include the use of specialized containers, inert atmospheres, and light-protective packaging.

Integration of polysilanes into existing display manufacturing processes presents another challenge. The compatibility of polysilanes with current deposition techniques, such as spin coating or inkjet printing, needs to be thoroughly evaluated. Modifications to existing equipment or the development of new deposition methods may be required to achieve uniform and defect-free polysilane layers on large-area substrates.

Quality control and consistency in polysilane-based displays are paramount for scalability. Developing reliable testing and characterization methods to ensure batch-to-batch consistency and performance uniformity across large display areas is crucial. This may involve the implementation of advanced in-line monitoring techniques and the establishment of stringent quality control protocols.

Environmental considerations and regulatory compliance also play a significant role in scaling up polysilane production. Assessing the environmental impact of polysilane synthesis, processing, and disposal is essential. Developing eco-friendly production methods and exploring recycling options for end-of-life displays will be important for long-term sustainability.

Cost considerations are another critical aspect of scalability. While polysilanes offer unique properties, their production costs need to be competitive with existing display technologies. Identifying cost-effective precursors, optimizing synthesis yields, and streamlining manufacturing processes are essential steps in making polysilane-based displays economically viable for mass production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!