How to Improve Thermal Stability in Polysilane Polymers?

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Thermal Stability Background and Objectives

Polysilanes, a class of silicon-based polymers with a backbone consisting of silicon atoms, have garnered significant attention in materials science and polymer chemistry over the past few decades. These unique macromolecules exhibit remarkable electronic and optical properties, making them promising candidates for various applications in optoelectronics, photoresists, and preceramic materials. However, the widespread adoption of polysilanes has been hindered by their inherent thermal instability, which limits their practical use in high-temperature environments.

The development of polysilanes can be traced back to the 1920s, with significant advancements made in the 1980s and 1990s. Initially, researchers focused on synthesizing and characterizing these novel polymers, exploring their unique σ-conjugated electronic structure. As the field progressed, the potential applications of polysilanes became increasingly apparent, driving further research into their properties and synthesis methods.

The thermal stability of polysilanes emerged as a critical challenge early in their development. At elevated temperatures, these polymers tend to undergo depolymerization and structural rearrangements, leading to the loss of their desirable properties. This thermal instability has been a major obstacle in realizing the full potential of polysilanes in various technological applications, particularly those requiring exposure to high temperatures or prolonged thermal stress.

The primary objective in improving the thermal stability of polysilane polymers is to enhance their resistance to thermal degradation while maintaining their unique electronic and optical properties. This goal encompasses several key aspects, including increasing the temperature at which depolymerization occurs, minimizing structural changes during thermal exposure, and preserving the σ-conjugation along the polymer backbone.

To achieve these objectives, researchers have been exploring various strategies, such as modifying the chemical structure of polysilanes, incorporating stabilizing additives, and developing novel synthesis techniques. The ultimate aim is to create polysilane polymers that can withstand higher temperatures for extended periods without significant degradation, thereby expanding their potential applications in demanding environments.

As the field of materials science continues to advance, the improvement of thermal stability in polysilane polymers remains a crucial area of research. Success in this endeavor could unlock new possibilities for these materials in cutting-edge technologies, including high-performance electronics, aerospace applications, and advanced optical devices. The ongoing efforts to enhance the thermal properties of polysilanes reflect the broader trend in polymer science towards developing materials with superior thermal and mechanical characteristics to meet the evolving demands of modern technology.

The development of polysilanes can be traced back to the 1920s, with significant advancements made in the 1980s and 1990s. Initially, researchers focused on synthesizing and characterizing these novel polymers, exploring their unique σ-conjugated electronic structure. As the field progressed, the potential applications of polysilanes became increasingly apparent, driving further research into their properties and synthesis methods.

The thermal stability of polysilanes emerged as a critical challenge early in their development. At elevated temperatures, these polymers tend to undergo depolymerization and structural rearrangements, leading to the loss of their desirable properties. This thermal instability has been a major obstacle in realizing the full potential of polysilanes in various technological applications, particularly those requiring exposure to high temperatures or prolonged thermal stress.

The primary objective in improving the thermal stability of polysilane polymers is to enhance their resistance to thermal degradation while maintaining their unique electronic and optical properties. This goal encompasses several key aspects, including increasing the temperature at which depolymerization occurs, minimizing structural changes during thermal exposure, and preserving the σ-conjugation along the polymer backbone.

To achieve these objectives, researchers have been exploring various strategies, such as modifying the chemical structure of polysilanes, incorporating stabilizing additives, and developing novel synthesis techniques. The ultimate aim is to create polysilane polymers that can withstand higher temperatures for extended periods without significant degradation, thereby expanding their potential applications in demanding environments.

As the field of materials science continues to advance, the improvement of thermal stability in polysilane polymers remains a crucial area of research. Success in this endeavor could unlock new possibilities for these materials in cutting-edge technologies, including high-performance electronics, aerospace applications, and advanced optical devices. The ongoing efforts to enhance the thermal properties of polysilanes reflect the broader trend in polymer science towards developing materials with superior thermal and mechanical characteristics to meet the evolving demands of modern technology.

Market Analysis for Heat-Resistant Polysilane Applications

The market for heat-resistant polysilane applications is experiencing significant growth, driven by the increasing demand for high-performance materials in various industries. Polysilanes, known for their unique electronic and optical properties, are finding new applications in sectors where thermal stability is crucial. The automotive industry, in particular, is showing a keen interest in heat-resistant polysilanes for use in engine components and exhaust systems, where materials must withstand extreme temperatures.

In the electronics sector, the miniaturization of devices and the push for higher performance are creating opportunities for heat-resistant polysilanes in semiconductor manufacturing and packaging. These materials offer potential solutions for thermal management in compact, high-power electronic systems. The aerospace industry is another key market, where polysilanes' lightweight nature and thermal stability make them attractive for use in aircraft and spacecraft components.

The global market for high-temperature resistant polymers, which includes polysilanes, is projected to grow steadily over the next five years. This growth is fueled by the ongoing development of advanced materials for emerging technologies such as 5G infrastructure, electric vehicles, and renewable energy systems. In these applications, the ability of polysilanes to maintain their properties at elevated temperatures is a critical advantage.

Regionally, Asia-Pacific is expected to be the fastest-growing market for heat-resistant polysilane applications, due to rapid industrialization and increasing investments in research and development. North America and Europe remain significant markets, driven by their strong presence in aerospace and advanced electronics industries.

However, the market faces challenges, including the high cost of production for specialized polysilane formulations and competition from other high-performance polymers. The development of cost-effective manufacturing processes for heat-resistant polysilanes will be crucial for expanding their market penetration.

Despite these challenges, the potential for growth remains strong. As industries continue to push the boundaries of material performance, the demand for heat-resistant polysilanes is likely to increase. This trend is further supported by the growing emphasis on energy efficiency and sustainability, where the unique properties of polysilanes can contribute to the development of more durable and efficient products.

In the electronics sector, the miniaturization of devices and the push for higher performance are creating opportunities for heat-resistant polysilanes in semiconductor manufacturing and packaging. These materials offer potential solutions for thermal management in compact, high-power electronic systems. The aerospace industry is another key market, where polysilanes' lightweight nature and thermal stability make them attractive for use in aircraft and spacecraft components.

The global market for high-temperature resistant polymers, which includes polysilanes, is projected to grow steadily over the next five years. This growth is fueled by the ongoing development of advanced materials for emerging technologies such as 5G infrastructure, electric vehicles, and renewable energy systems. In these applications, the ability of polysilanes to maintain their properties at elevated temperatures is a critical advantage.

Regionally, Asia-Pacific is expected to be the fastest-growing market for heat-resistant polysilane applications, due to rapid industrialization and increasing investments in research and development. North America and Europe remain significant markets, driven by their strong presence in aerospace and advanced electronics industries.

However, the market faces challenges, including the high cost of production for specialized polysilane formulations and competition from other high-performance polymers. The development of cost-effective manufacturing processes for heat-resistant polysilanes will be crucial for expanding their market penetration.

Despite these challenges, the potential for growth remains strong. As industries continue to push the boundaries of material performance, the demand for heat-resistant polysilanes is likely to increase. This trend is further supported by the growing emphasis on energy efficiency and sustainability, where the unique properties of polysilanes can contribute to the development of more durable and efficient products.

Current Challenges in Polysilane Thermal Stability

Polysilane polymers have garnered significant attention in various applications due to their unique electronic and optical properties. However, their widespread adoption has been hindered by challenges related to thermal stability. The current state of polysilane thermal stability presents several key obstacles that researchers and industry professionals must address.

One of the primary challenges is the susceptibility of polysilane polymers to thermal degradation at relatively low temperatures. This degradation process typically involves the scission of Si-Si bonds in the polymer backbone, leading to a loss of molecular weight and a consequent deterioration of the material's properties. The onset of thermal degradation can occur at temperatures as low as 200-300°C, which limits the use of polysilanes in high-temperature applications.

Another significant issue is the formation of cyclic oligomers during thermal decomposition. As the polymer chains break down, they can rearrange to form stable cyclic structures, which not only alters the material's composition but also affects its physical and chemical properties. This process can lead to changes in the polymer's solubility, optical characteristics, and overall performance.

The presence of impurities and structural defects in polysilane polymers further exacerbates their thermal instability. Trace amounts of oxygen, moisture, or other reactive species can catalyze the degradation process, even at lower temperatures. Additionally, irregularities in the polymer structure, such as branching or crosslinking, can create weak points that are more susceptible to thermal breakdown.

The challenge of maintaining the desired molecular weight distribution during thermal processing is also a critical concern. As polysilanes undergo thermal treatment, there is a tendency for the polymer chains to either degrade or crosslink, both of which can significantly alter the material's properties. Controlling this process to achieve a consistent and optimal molecular weight distribution remains a complex task.

Furthermore, the thermal stability of polysilanes is highly dependent on the specific side groups attached to the silicon atoms in the backbone. While some side groups may enhance thermal stability, they often do so at the expense of other desirable properties, such as solubility or processability. Striking the right balance between thermal stability and other functional requirements presents an ongoing challenge for materials scientists and engineers.

Lastly, the development of reliable and standardized methods for assessing the thermal stability of polysilanes remains an area of active research. Current techniques may not fully capture the complex degradation mechanisms or provide accurate predictions of long-term stability under various environmental conditions. This lack of standardization complicates the comparison of different polysilane formulations and hinders the establishment of clear performance benchmarks for industrial applications.

One of the primary challenges is the susceptibility of polysilane polymers to thermal degradation at relatively low temperatures. This degradation process typically involves the scission of Si-Si bonds in the polymer backbone, leading to a loss of molecular weight and a consequent deterioration of the material's properties. The onset of thermal degradation can occur at temperatures as low as 200-300°C, which limits the use of polysilanes in high-temperature applications.

Another significant issue is the formation of cyclic oligomers during thermal decomposition. As the polymer chains break down, they can rearrange to form stable cyclic structures, which not only alters the material's composition but also affects its physical and chemical properties. This process can lead to changes in the polymer's solubility, optical characteristics, and overall performance.

The presence of impurities and structural defects in polysilane polymers further exacerbates their thermal instability. Trace amounts of oxygen, moisture, or other reactive species can catalyze the degradation process, even at lower temperatures. Additionally, irregularities in the polymer structure, such as branching or crosslinking, can create weak points that are more susceptible to thermal breakdown.

The challenge of maintaining the desired molecular weight distribution during thermal processing is also a critical concern. As polysilanes undergo thermal treatment, there is a tendency for the polymer chains to either degrade or crosslink, both of which can significantly alter the material's properties. Controlling this process to achieve a consistent and optimal molecular weight distribution remains a complex task.

Furthermore, the thermal stability of polysilanes is highly dependent on the specific side groups attached to the silicon atoms in the backbone. While some side groups may enhance thermal stability, they often do so at the expense of other desirable properties, such as solubility or processability. Striking the right balance between thermal stability and other functional requirements presents an ongoing challenge for materials scientists and engineers.

Lastly, the development of reliable and standardized methods for assessing the thermal stability of polysilanes remains an area of active research. Current techniques may not fully capture the complex degradation mechanisms or provide accurate predictions of long-term stability under various environmental conditions. This lack of standardization complicates the comparison of different polysilane formulations and hinders the establishment of clear performance benchmarks for industrial applications.

Existing Approaches to Enhance Polysilane Thermal Stability

01 Synthesis methods for thermally stable polysilanes

Various synthesis methods are employed to create polysilanes with enhanced thermal stability. These methods include using specific catalysts, controlling reaction conditions, and incorporating stabilizing elements or functional groups into the polymer backbone. The resulting polysilanes exhibit improved resistance to thermal degradation, making them suitable for high-temperature applications.- Synthesis methods for thermally stable polysilanes: Various synthesis methods are employed to create polysilanes with enhanced thermal stability. These methods include the use of specific catalysts, controlled polymerization conditions, and the incorporation of stabilizing functional groups into the polymer backbone. The resulting polysilanes exhibit improved resistance to thermal degradation, making them suitable for high-temperature applications.

- Structural modifications for improved thermal stability: Structural modifications of polysilane polymers can significantly enhance their thermal stability. These modifications include the introduction of branching, cross-linking, or the incorporation of thermally stable substituents. Such structural changes can increase the polymer's resistance to thermal decomposition and improve its overall performance at elevated temperatures.

- Additives and fillers for enhancing thermal stability: The addition of specific additives and fillers to polysilane polymers can improve their thermal stability. These additives may include antioxidants, heat stabilizers, or inorganic fillers that can enhance the polymer's resistance to thermal degradation. The careful selection and incorporation of these additives can result in polysilane compositions with superior thermal properties.

- Characterization and testing of thermal stability: Various methods and techniques are used to characterize and test the thermal stability of polysilane polymers. These may include thermogravimetric analysis, differential scanning calorimetry, and other thermal analysis techniques. Understanding the thermal behavior of polysilanes is crucial for optimizing their performance in high-temperature applications and developing more thermally stable compositions.

- Applications of thermally stable polysilanes: Thermally stable polysilane polymers find applications in various fields where high-temperature resistance is required. These applications may include electronic materials, high-performance coatings, and advanced composite materials. The improved thermal stability of these polymers enables their use in demanding environments and expands their potential applications in industry.

02 Structural modifications for improved thermal stability

Structural modifications of polysilanes can significantly enhance their thermal stability. These modifications may include the introduction of bulky side groups, cross-linking between polymer chains, or the incorporation of thermally resistant moieties. Such structural changes can increase the polymer's resistance to thermal decomposition and maintain its properties at elevated temperatures.Expand Specific Solutions03 Additives and fillers for thermal stabilization

The addition of specific additives and fillers to polysilane polymers can improve their thermal stability. These additives may include antioxidants, heat stabilizers, or inorganic fillers. The incorporation of these materials can help prevent thermal degradation, reduce chain scission, and maintain the polymer's structural integrity at high temperatures.Expand Specific Solutions04 Characterization and testing of thermal stability

Various methods and techniques are used to characterize and test the thermal stability of polysilane polymers. These may include thermogravimetric analysis (TGA), differential scanning calorimetry (DSC), and other thermal analysis techniques. Such characterization helps in understanding the polymer's behavior under different temperature conditions and in optimizing its thermal stability properties.Expand Specific Solutions05 Applications of thermally stable polysilanes

Thermally stable polysilanes find applications in various high-temperature environments. These may include use as precursors for ceramic materials, as components in high-temperature coatings, or as materials for electronic and optoelectronic devices. The improved thermal stability of these polymers enables their use in demanding thermal conditions while maintaining their desired properties.Expand Specific Solutions

Key Players in Polysilane Research and Development

The thermal stability improvement of polysilane polymers is currently in a developmental stage, with a growing market driven by increasing demand for high-performance materials in various industries. The global market for advanced polymers is expanding, with polysilanes showing promise in applications requiring thermal resistance. Companies like BASF Corp., Wacker Chemie AG, and DuPont de Nemours, Inc. are at the forefront of research and development in this field. The technology is progressing, but challenges remain in achieving optimal thermal stability while maintaining other desirable properties. Collaboration between industry leaders and research institutions is accelerating progress, indicating a competitive yet collaborative landscape in this niche but promising area of polymer science.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has developed innovative approaches to improve the thermal stability of polysilane polymers. They have implemented a cross-linking strategy using silsesquioxane-based additives, which form a three-dimensional network structure within the polysilane matrix[1]. This network enhances the thermal resistance of the polymer by restricting chain movement at elevated temperatures. Additionally, Wacker has incorporated heat-resistant functional groups, such as phenyl rings, into the polysilane backbone, further improving its thermal properties[3]. The company has also explored the use of nanocomposite technology, dispersing thermally stable nanoparticles throughout the polysilane to create a more heat-resistant material[5].

Strengths: Improved thermal stability, enhanced mechanical properties, and potential for customization. Weaknesses: Increased production costs and potential changes in optical properties.

DuPont de Nemours, Inc.

Technical Solution: DuPont has focused on developing advanced copolymer systems to enhance the thermal stability of polysilanes. Their approach involves the synthesis of block copolymers that combine polysilane segments with thermally stable organic polymers[2]. This creates a hybrid material that retains the unique electronic properties of polysilanes while benefiting from the thermal resistance of the organic component. DuPont has also explored the use of end-group modification techniques, introducing thermally stable moieties at the chain ends to improve overall stability[4]. Furthermore, they have investigated the incorporation of transition metal complexes as stabilizers, which can act as radical scavengers and prevent thermal degradation[6].

Strengths: Versatile approach applicable to various polysilane types, improved processability. Weaknesses: Potential reduction in electrical conductivity, increased complexity in synthesis.

Innovative Techniques for Improving Polysilane Heat Resistance

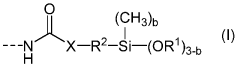

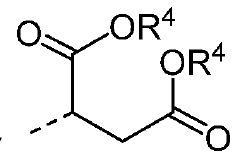

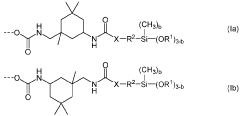

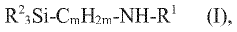

Silane group-containing branched polymer

PatentWO2021160493A1

Innovation

- A branched polymer containing silane groups is developed through the reaction of a polymer with isocyanate groups, produced from a polyether triol, with amino-, mercapto-, or hydroxysilane, achieving a stoichiometric ratio of at least 1:1, resulting in a polymer that is free from isocyanate groups and has multiple silane groups per molecule, enhancing thermal stability without sacrificing strength and extensibility.

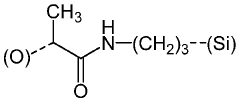

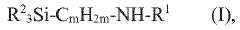

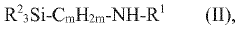

Stabilizers for adhesives, sealants and coating compositions

PatentWO2018073102A1

Innovation

- Incorporating aminosilanes with secondary amino groups as stabilizers in adhesive, sealant, and coating compositions to enhance thermal resistance and prevent oxidative degradation, thereby maintaining mechanical properties even at elevated temperatures.

Environmental Impact of Polysilane Production and Use

The production and use of polysilane polymers have significant environmental implications that warrant careful consideration. The synthesis of polysilanes typically involves energy-intensive processes and the use of potentially hazardous chemicals, which can contribute to air and water pollution if not properly managed. The primary raw materials for polysilane production, such as silicon and chlorine compounds, are often derived from non-renewable resources, raising concerns about long-term sustainability.

During the manufacturing process, volatile organic compounds (VOCs) and other potentially harmful emissions may be released, necessitating robust air quality control measures. Additionally, the use of solvents in polysilane production can lead to the generation of hazardous waste streams that require specialized treatment and disposal methods to prevent environmental contamination.

The environmental impact of polysilane use is closely tied to their thermal stability. As efforts to improve thermal stability in polysilane polymers progress, the potential for extended product lifespans and reduced material waste increases. However, enhanced thermal stability may also lead to challenges in end-of-life management and recycling, as these materials become more resistant to degradation.

Polysilanes' unique optical and electronic properties make them attractive for various applications, including photovoltaics and electronic devices. While these applications can contribute to renewable energy solutions and energy-efficient technologies, the production of such devices may involve additional environmental considerations, such as the use of rare earth elements or toxic materials in manufacturing processes.

The disposal and recycling of polysilane-containing products present another environmental challenge. As these materials become more widespread in consumer and industrial applications, developing effective recycling strategies becomes crucial to minimize landfill waste and recover valuable resources. However, the complex nature of polysilane polymers may complicate recycling efforts, potentially requiring the development of specialized recycling technologies.

Addressing the environmental impact of polysilane production and use requires a holistic approach. This includes optimizing manufacturing processes to reduce energy consumption and emissions, exploring bio-based or renewable feedstocks for polysilane synthesis, and designing products with end-of-life considerations in mind. Furthermore, implementing closed-loop recycling systems and investing in research for more environmentally friendly alternatives can help mitigate the long-term ecological footprint of polysilane technologies.

During the manufacturing process, volatile organic compounds (VOCs) and other potentially harmful emissions may be released, necessitating robust air quality control measures. Additionally, the use of solvents in polysilane production can lead to the generation of hazardous waste streams that require specialized treatment and disposal methods to prevent environmental contamination.

The environmental impact of polysilane use is closely tied to their thermal stability. As efforts to improve thermal stability in polysilane polymers progress, the potential for extended product lifespans and reduced material waste increases. However, enhanced thermal stability may also lead to challenges in end-of-life management and recycling, as these materials become more resistant to degradation.

Polysilanes' unique optical and electronic properties make them attractive for various applications, including photovoltaics and electronic devices. While these applications can contribute to renewable energy solutions and energy-efficient technologies, the production of such devices may involve additional environmental considerations, such as the use of rare earth elements or toxic materials in manufacturing processes.

The disposal and recycling of polysilane-containing products present another environmental challenge. As these materials become more widespread in consumer and industrial applications, developing effective recycling strategies becomes crucial to minimize landfill waste and recover valuable resources. However, the complex nature of polysilane polymers may complicate recycling efforts, potentially requiring the development of specialized recycling technologies.

Addressing the environmental impact of polysilane production and use requires a holistic approach. This includes optimizing manufacturing processes to reduce energy consumption and emissions, exploring bio-based or renewable feedstocks for polysilane synthesis, and designing products with end-of-life considerations in mind. Furthermore, implementing closed-loop recycling systems and investing in research for more environmentally friendly alternatives can help mitigate the long-term ecological footprint of polysilane technologies.

Scalability and Cost-Effectiveness of Thermal Stabilization Methods

When considering the scalability and cost-effectiveness of thermal stabilization methods for polysilane polymers, several factors come into play. The primary challenge lies in developing techniques that can be applied on an industrial scale while maintaining economic viability.

One of the most promising approaches for large-scale thermal stabilization is the incorporation of heat-resistant additives. These additives, such as silica nanoparticles or metal oxides, can be easily mixed with polysilane polymers during the manufacturing process. This method offers excellent scalability as it can be integrated into existing production lines with minimal modifications. However, the cost-effectiveness of this approach depends on the price and availability of the additives used.

Another scalable method is the use of cross-linking agents to improve the thermal stability of polysilane polymers. This technique involves introducing chemical bonds between polymer chains, which can be achieved through various means, including UV irradiation or thermal treatment. The scalability of this method is high, as it can be implemented as a post-processing step in existing manufacturing facilities. The cost-effectiveness, however, may vary depending on the specific cross-linking agents and the energy requirements of the process.

Surface modification techniques, such as plasma treatment or chemical vapor deposition, offer another avenue for enhancing thermal stability. These methods can be applied to polysilane polymer films or fibers on a continuous basis, making them suitable for large-scale production. While the initial investment in equipment may be substantial, the operational costs can be relatively low, potentially offering good cost-effectiveness in the long run.

Copolymerization with thermally stable monomers is another scalable approach. This method involves incorporating heat-resistant components directly into the polymer structure during synthesis. The scalability of this technique is high, as it can be integrated into existing polymerization processes. However, the cost-effectiveness may be impacted by the price of the co-monomers and potential changes in processing conditions.

When evaluating the cost-effectiveness of these methods, it's crucial to consider not only the direct material and processing costs but also the potential savings in terms of improved product performance and longevity. Methods that significantly extend the thermal stability and lifespan of polysilane polymers may justify higher upfront costs through reduced replacement and maintenance expenses in end-use applications.

In conclusion, while several scalable methods exist for improving the thermal stability of polysilane polymers, their cost-effectiveness can vary widely. The optimal choice depends on factors such as production volume, target application, and available infrastructure. Ongoing research and development efforts are focused on refining these methods to achieve an optimal balance between scalability, cost-effectiveness, and performance enhancement.

One of the most promising approaches for large-scale thermal stabilization is the incorporation of heat-resistant additives. These additives, such as silica nanoparticles or metal oxides, can be easily mixed with polysilane polymers during the manufacturing process. This method offers excellent scalability as it can be integrated into existing production lines with minimal modifications. However, the cost-effectiveness of this approach depends on the price and availability of the additives used.

Another scalable method is the use of cross-linking agents to improve the thermal stability of polysilane polymers. This technique involves introducing chemical bonds between polymer chains, which can be achieved through various means, including UV irradiation or thermal treatment. The scalability of this method is high, as it can be implemented as a post-processing step in existing manufacturing facilities. The cost-effectiveness, however, may vary depending on the specific cross-linking agents and the energy requirements of the process.

Surface modification techniques, such as plasma treatment or chemical vapor deposition, offer another avenue for enhancing thermal stability. These methods can be applied to polysilane polymer films or fibers on a continuous basis, making them suitable for large-scale production. While the initial investment in equipment may be substantial, the operational costs can be relatively low, potentially offering good cost-effectiveness in the long run.

Copolymerization with thermally stable monomers is another scalable approach. This method involves incorporating heat-resistant components directly into the polymer structure during synthesis. The scalability of this technique is high, as it can be integrated into existing polymerization processes. However, the cost-effectiveness may be impacted by the price of the co-monomers and potential changes in processing conditions.

When evaluating the cost-effectiveness of these methods, it's crucial to consider not only the direct material and processing costs but also the potential savings in terms of improved product performance and longevity. Methods that significantly extend the thermal stability and lifespan of polysilane polymers may justify higher upfront costs through reduced replacement and maintenance expenses in end-use applications.

In conclusion, while several scalable methods exist for improving the thermal stability of polysilane polymers, their cost-effectiveness can vary widely. The optimal choice depends on factors such as production volume, target application, and available infrastructure. Ongoing research and development efforts are focused on refining these methods to achieve an optimal balance between scalability, cost-effectiveness, and performance enhancement.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!