Polysilane's Future in Flexible Electronic Devices

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Evolution

Polysilanes have undergone a remarkable evolution since their initial discovery in the 1920s. Initially considered as mere scientific curiosities, these silicon-based polymers have gradually emerged as promising materials for flexible electronic devices. The journey of polysilanes began with the synthesis of simple linear structures, which exhibited unique electronic properties due to their σ-conjugated backbone.

In the 1980s, research into polysilanes gained momentum as scientists recognized their potential in optoelectronic applications. This period saw significant advancements in synthesis methods, leading to the development of more complex and diverse polysilane structures. The introduction of substituents on the silicon atoms allowed for fine-tuning of the material's properties, opening up new possibilities for their application in electronic devices.

The 1990s marked a turning point in polysilane research, with a focus on their photoconductivity and electroluminescent properties. This led to early experiments in using polysilanes for organic light-emitting diodes (OLEDs) and photovoltaic cells. However, challenges in processability and stability limited their widespread adoption in these fields.

The early 2000s witnessed a shift towards exploring polysilanes in the context of flexible electronics. Researchers began investigating their potential as semiconducting materials in thin-film transistors and as components in flexible displays. The inherent flexibility of polysilane chains, combined with their unique electronic properties, made them attractive candidates for bendable and stretchable electronic devices.

Recent years have seen a resurgence of interest in polysilanes, driven by advancements in nanotechnology and the growing demand for flexible electronics. Innovations in synthesis techniques have enabled the creation of polysilane nanostructures, such as nanowires and nanoparticles, which exhibit enhanced electronic properties compared to their bulk counterparts. These developments have opened up new avenues for integrating polysilanes into next-generation flexible electronic devices.

The evolution of polysilanes has also been marked by improvements in their environmental stability and processability. Early polysilanes were highly sensitive to oxygen and moisture, limiting their practical applications. However, recent research has focused on developing more stable polysilane derivatives and protective encapsulation methods, addressing these long-standing challenges.

As we look to the future, the evolution of polysilanes in flexible electronic devices continues to accelerate. Current research is exploring hybrid materials that combine polysilanes with other organic and inorganic components to create multifunctional flexible electronic systems. The ongoing development of new polysilane architectures and functionalization strategies promises to further enhance their performance and expand their potential applications in the rapidly growing field of flexible electronics.

In the 1980s, research into polysilanes gained momentum as scientists recognized their potential in optoelectronic applications. This period saw significant advancements in synthesis methods, leading to the development of more complex and diverse polysilane structures. The introduction of substituents on the silicon atoms allowed for fine-tuning of the material's properties, opening up new possibilities for their application in electronic devices.

The 1990s marked a turning point in polysilane research, with a focus on their photoconductivity and electroluminescent properties. This led to early experiments in using polysilanes for organic light-emitting diodes (OLEDs) and photovoltaic cells. However, challenges in processability and stability limited their widespread adoption in these fields.

The early 2000s witnessed a shift towards exploring polysilanes in the context of flexible electronics. Researchers began investigating their potential as semiconducting materials in thin-film transistors and as components in flexible displays. The inherent flexibility of polysilane chains, combined with their unique electronic properties, made them attractive candidates for bendable and stretchable electronic devices.

Recent years have seen a resurgence of interest in polysilanes, driven by advancements in nanotechnology and the growing demand for flexible electronics. Innovations in synthesis techniques have enabled the creation of polysilane nanostructures, such as nanowires and nanoparticles, which exhibit enhanced electronic properties compared to their bulk counterparts. These developments have opened up new avenues for integrating polysilanes into next-generation flexible electronic devices.

The evolution of polysilanes has also been marked by improvements in their environmental stability and processability. Early polysilanes were highly sensitive to oxygen and moisture, limiting their practical applications. However, recent research has focused on developing more stable polysilane derivatives and protective encapsulation methods, addressing these long-standing challenges.

As we look to the future, the evolution of polysilanes in flexible electronic devices continues to accelerate. Current research is exploring hybrid materials that combine polysilanes with other organic and inorganic components to create multifunctional flexible electronic systems. The ongoing development of new polysilane architectures and functionalization strategies promises to further enhance their performance and expand their potential applications in the rapidly growing field of flexible electronics.

Flexible Electronics Market

The flexible electronics market has been experiencing rapid growth and transformation in recent years, driven by advancements in materials science and manufacturing technologies. This market segment encompasses a wide range of products, including flexible displays, sensors, batteries, and wearable devices, all of which offer unique advantages over traditional rigid electronics.

The global flexible electronics market is projected to expand significantly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 10% through 2025. This growth is fueled by increasing demand for lightweight, portable, and conformable electronic devices across various industries, including consumer electronics, healthcare, automotive, and aerospace.

One of the key drivers of market growth is the rising adoption of flexible displays in smartphones, tablets, and wearable devices. Major technology companies are investing heavily in the development of foldable and rollable screens, which offer enhanced user experiences and novel form factors. This trend is expected to continue, with flexible displays potentially becoming the norm in mobile devices within the next decade.

The healthcare sector is another significant contributor to the flexible electronics market. Wearable medical devices, such as smart patches and electronic skin sensors, are gaining traction due to their ability to provide continuous, non-invasive monitoring of vital signs and other health parameters. These devices offer improved patient comfort and enable remote healthcare monitoring, addressing the growing need for telemedicine solutions.

In the automotive industry, flexible electronics are being integrated into vehicle interiors for enhanced user interfaces and improved safety features. Curved displays, touch-sensitive surfaces, and flexible lighting solutions are becoming increasingly common in modern vehicles, contributing to the overall market growth.

The development of flexible batteries and energy storage solutions is another crucial aspect of the flexible electronics market. These power sources enable the creation of truly flexible and conformable devices, opening up new possibilities for product design and functionality across various applications.

However, the market also faces challenges, including high production costs, technical limitations in certain applications, and concerns about long-term durability. Overcoming these obstacles will be crucial for the continued expansion of the flexible electronics market and the realization of its full potential across diverse industries.

As the technology matures and production costs decrease, the flexible electronics market is expected to see increased adoption in emerging applications such as smart textiles, flexible solar cells, and printed electronics. These developments will likely drive further innovation and create new opportunities for market growth in the coming years.

The global flexible electronics market is projected to expand significantly in the coming years, with estimates suggesting a compound annual growth rate (CAGR) of over 10% through 2025. This growth is fueled by increasing demand for lightweight, portable, and conformable electronic devices across various industries, including consumer electronics, healthcare, automotive, and aerospace.

One of the key drivers of market growth is the rising adoption of flexible displays in smartphones, tablets, and wearable devices. Major technology companies are investing heavily in the development of foldable and rollable screens, which offer enhanced user experiences and novel form factors. This trend is expected to continue, with flexible displays potentially becoming the norm in mobile devices within the next decade.

The healthcare sector is another significant contributor to the flexible electronics market. Wearable medical devices, such as smart patches and electronic skin sensors, are gaining traction due to their ability to provide continuous, non-invasive monitoring of vital signs and other health parameters. These devices offer improved patient comfort and enable remote healthcare monitoring, addressing the growing need for telemedicine solutions.

In the automotive industry, flexible electronics are being integrated into vehicle interiors for enhanced user interfaces and improved safety features. Curved displays, touch-sensitive surfaces, and flexible lighting solutions are becoming increasingly common in modern vehicles, contributing to the overall market growth.

The development of flexible batteries and energy storage solutions is another crucial aspect of the flexible electronics market. These power sources enable the creation of truly flexible and conformable devices, opening up new possibilities for product design and functionality across various applications.

However, the market also faces challenges, including high production costs, technical limitations in certain applications, and concerns about long-term durability. Overcoming these obstacles will be crucial for the continued expansion of the flexible electronics market and the realization of its full potential across diverse industries.

As the technology matures and production costs decrease, the flexible electronics market is expected to see increased adoption in emerging applications such as smart textiles, flexible solar cells, and printed electronics. These developments will likely drive further innovation and create new opportunities for market growth in the coming years.

Polysilane Challenges

Despite the promising potential of polysilanes in flexible electronic devices, several significant challenges hinder their widespread adoption and commercial viability. One of the primary obstacles is the inherent instability of polysilanes when exposed to ultraviolet (UV) light. This photosensitivity can lead to degradation of the material's electronic properties and structural integrity, limiting its long-term reliability in applications exposed to sunlight or other UV sources.

Another critical challenge lies in the synthesis and processing of polysilanes. Current manufacturing methods often result in polydisperse materials with varying chain lengths and molecular weights, which can lead to inconsistent performance in electronic devices. Achieving precise control over the molecular structure and uniformity of polysilanes remains a significant hurdle for large-scale production and integration into flexible electronics.

The electrical conductivity of polysilanes, while promising, still falls short of the levels required for many high-performance electronic applications. Enhancing the charge carrier mobility and overall conductivity of polysilane-based materials without compromising their flexibility and processability is a key area of ongoing research and development.

Compatibility with existing manufacturing processes and materials used in flexible electronics presents another challenge. Integrating polysilanes into established production lines and ensuring their compatibility with other components, such as electrodes and encapsulation materials, requires extensive optimization and potentially costly modifications to existing manufacturing infrastructure.

Environmental stability is also a concern for polysilane-based devices. Many polysilanes are sensitive to oxygen and moisture, which can lead to degradation of their electronic properties over time. Developing effective encapsulation techniques or improving the inherent stability of polysilanes against environmental factors is crucial for ensuring the longevity and reliability of flexible electronic devices.

The cost-effectiveness of polysilane production and device fabrication remains a significant barrier to commercialization. Current synthesis methods and purification processes can be expensive, making polysilane-based devices less competitive compared to established technologies. Developing more economical production methods and scaling up manufacturing processes are essential steps towards making polysilane-based flexible electronics commercially viable.

Lastly, the lack of standardization and comprehensive understanding of structure-property relationships in polysilanes poses challenges for device design and optimization. Establishing clear guidelines for material selection, processing parameters, and device architectures specific to polysilane-based flexible electronics is necessary to accelerate their development and adoption in the industry.

Another critical challenge lies in the synthesis and processing of polysilanes. Current manufacturing methods often result in polydisperse materials with varying chain lengths and molecular weights, which can lead to inconsistent performance in electronic devices. Achieving precise control over the molecular structure and uniformity of polysilanes remains a significant hurdle for large-scale production and integration into flexible electronics.

The electrical conductivity of polysilanes, while promising, still falls short of the levels required for many high-performance electronic applications. Enhancing the charge carrier mobility and overall conductivity of polysilane-based materials without compromising their flexibility and processability is a key area of ongoing research and development.

Compatibility with existing manufacturing processes and materials used in flexible electronics presents another challenge. Integrating polysilanes into established production lines and ensuring their compatibility with other components, such as electrodes and encapsulation materials, requires extensive optimization and potentially costly modifications to existing manufacturing infrastructure.

Environmental stability is also a concern for polysilane-based devices. Many polysilanes are sensitive to oxygen and moisture, which can lead to degradation of their electronic properties over time. Developing effective encapsulation techniques or improving the inherent stability of polysilanes against environmental factors is crucial for ensuring the longevity and reliability of flexible electronic devices.

The cost-effectiveness of polysilane production and device fabrication remains a significant barrier to commercialization. Current synthesis methods and purification processes can be expensive, making polysilane-based devices less competitive compared to established technologies. Developing more economical production methods and scaling up manufacturing processes are essential steps towards making polysilane-based flexible electronics commercially viable.

Lastly, the lack of standardization and comprehensive understanding of structure-property relationships in polysilanes poses challenges for device design and optimization. Establishing clear guidelines for material selection, processing parameters, and device architectures specific to polysilane-based flexible electronics is necessary to accelerate their development and adoption in the industry.

Current Polysilane Solutions

01 Synthesis and properties of polysilanes

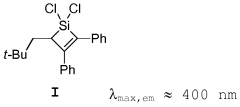

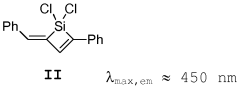

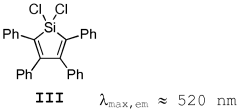

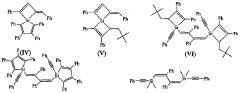

Polysilanes are synthesized through various methods and exhibit unique properties. These silicon-based polymers have a backbone consisting of silicon atoms and can be modified with different substituents. They possess interesting optical and electronic properties, making them suitable for various applications in materials science and electronics.- Synthesis and properties of polysilanes: Polysilanes are silicon-based polymers with unique electronic and optical properties. They can be synthesized through various methods, including Wurtz coupling of dichlorosilanes. These polymers exhibit interesting characteristics such as photoconductivity, luminescence, and high thermal stability, making them suitable for various applications in electronics and materials science.

- Applications of polysilanes in coatings and films: Polysilanes can be used to create functional coatings and thin films with specific properties. These materials can be applied in various industries, including electronics, optics, and protective coatings. The unique structure of polysilanes allows for the development of films with controlled thickness, refractive index, and surface properties.

- Polysilanes in photoresist and lithography applications: Polysilanes have found applications in photoresist formulations and lithography processes. Their photosensitive nature and ability to undergo photochemical reactions make them suitable for use in the fabrication of microelectronic devices and other patterning applications. These materials can be used to create high-resolution patterns and structures on various substrates.

- Modification and functionalization of polysilanes: Polysilanes can be modified and functionalized to enhance their properties or introduce new functionalities. This can involve the incorporation of various side groups, crosslinking agents, or other reactive moieties. Modified polysilanes can exhibit improved thermal stability, mechanical properties, or specific chemical reactivities, expanding their potential applications.

- Polysilanes in composite materials: Polysilanes can be used as components in composite materials, where they can impart unique properties to the final product. These composites may combine the characteristics of polysilanes with those of other materials, such as organic polymers or inorganic fillers. The resulting materials can exhibit enhanced mechanical, thermal, or optical properties, making them suitable for various advanced applications.

02 Applications of polysilanes in coatings and films

Polysilanes are utilized in the production of coatings and thin films. They can be applied to various substrates to create protective or functional layers. These coatings may exhibit properties such as improved adhesion, thermal stability, or optical characteristics, making them valuable in industries like electronics and automotive.Expand Specific Solutions03 Polysilanes in photoresist and lithography applications

Polysilanes find use in photoresist formulations and lithography processes. Their photosensitive nature allows for patterning and selective removal when exposed to light. This makes them valuable in the production of microelectronic devices and other applications requiring precise patterning of materials.Expand Specific Solutions04 Functionalization and modification of polysilanes

Polysilanes can be functionalized or modified to enhance their properties or introduce new functionalities. This may involve the addition of specific side groups, cross-linking, or incorporation of other elements into the polymer structure. Such modifications can tailor the polysilanes for specific applications or improve their performance in various fields.Expand Specific Solutions05 Polysilanes in semiconductor and electronic applications

Polysilanes have potential applications in semiconductor and electronic devices. Their unique electronic properties, such as charge transport capabilities and luminescence, make them interesting materials for use in organic electronics, photovoltaics, and other optoelectronic applications. Research is ongoing to explore their full potential in these fields.Expand Specific Solutions

Key Industry Players

The polysilane market for flexible electronic devices is in an early growth stage, with significant potential for expansion as the technology matures. The market size is currently modest but expected to grow rapidly as applications in flexible displays, sensors, and wearable electronics increase. Technologically, polysilanes are still evolving, with ongoing research to improve their properties and processability. Companies like Kaneka Corp., Wacker Chemie AG, and Toyobo Co., Ltd. are at the forefront of polysilane development, focusing on enhancing conductivity, flexibility, and stability. Academic institutions such as Sichuan University and Soochow University are also contributing to fundamental research in this field, indicating a collaborative ecosystem between industry and academia to advance polysilane technology for flexible electronics applications.

Kaneka Corp.

Technical Solution: Kaneka has developed innovative polysilane-based materials for flexible electronic devices. Their approach involves synthesizing high-molecular-weight polysilanes with controlled side-chain structures, resulting in improved thermal stability and electrical conductivity[1]. The company has successfully incorporated these materials into flexible organic light-emitting diodes (OLEDs) and thin-film transistors (TFTs), demonstrating enhanced performance and flexibility compared to traditional silicon-based counterparts[2]. Kaneka's polysilane films exhibit excellent transparency and can be processed at low temperatures, making them suitable for roll-to-roll manufacturing of large-area flexible displays[3].

Strengths: Superior flexibility, high transparency, and low-temperature processing. Weaknesses: Potential limitations in long-term stability and scalability of production.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has made significant strides in polysilane technology for flexible electronics. Their approach focuses on developing silicone-based elastomers with polysilane additives, creating hybrid materials that combine the flexibility of silicones with the electrical properties of polysilanes[4]. These materials have shown promise in stretchable electronics and wearable sensors, maintaining conductivity even under high strain conditions[5]. Wacker has also developed UV-curable polysilane formulations that enable rapid patterning and fabrication of flexible circuit boards[6].

Strengths: Excellent stretchability and durability, suitable for wearable electronics. Weaknesses: Potentially higher production costs and limited high-frequency performance.

Polysilane Innovations

Polysilane and polysilane-containing resin composition

PatentInactiveUS8163863B2

Innovation

- Introducing a Si—H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups like hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

Photoluminescent and/or electroluminescent material, method for production and use thereof and component comprising such a material

PatentWO2013068490A1

Innovation

- Development of polysilanes with stilbene and styrene units that are crosslinked to form stable, moisture-resistant materials with enhanced luminescence efficiency, suitable for use in optoelectronic components.

Environmental Impact

The environmental impact of polysilane-based flexible electronic devices is a crucial consideration in their development and adoption. As these materials gain traction in the electronics industry, it is essential to assess their ecological footprint throughout their lifecycle.

Polysilanes offer several environmental advantages compared to traditional electronic materials. Their potential for biodegradability and recyclability presents a significant opportunity to reduce electronic waste, a growing concern in the tech industry. The ability to create flexible, lightweight devices using polysilanes can lead to reduced material consumption and energy usage during manufacturing processes.

However, the production of polysilanes and their incorporation into electronic devices is not without environmental challenges. The synthesis of these materials often involves energy-intensive processes and the use of potentially harmful chemicals. As research progresses, it is crucial to develop greener synthesis methods that minimize the use of toxic reagents and reduce energy consumption.

The durability and longevity of polysilane-based devices also play a role in their environmental impact. While flexibility can enhance device lifespan by reducing physical damage, the overall stability of polysilanes under various environmental conditions needs further investigation. Improved stability could lead to longer-lasting devices, reducing the frequency of replacements and associated waste.

End-of-life considerations for polysilane-based electronics are particularly important. The potential for biodegradability offers a significant advantage over traditional electronic materials, which often contribute to persistent environmental pollution. However, the development of efficient recycling and disposal methods specific to polysilane-containing devices is necessary to fully realize this benefit.

The energy efficiency of polysilane-based flexible electronics during operation is another critical factor. These materials have the potential to enable low-power devices, which could contribute to reduced energy consumption over their lifetime. This aspect is particularly relevant in the context of the growing Internet of Things (IoT) and wearable technology markets.

As the adoption of polysilane-based flexible electronics increases, it is essential to conduct comprehensive life cycle assessments. These studies should compare the environmental impact of polysilane devices with traditional electronics across all stages, from raw material extraction to disposal. Such assessments will provide valuable insights for guiding future research and development efforts towards more sustainable electronic technologies.

Polysilanes offer several environmental advantages compared to traditional electronic materials. Their potential for biodegradability and recyclability presents a significant opportunity to reduce electronic waste, a growing concern in the tech industry. The ability to create flexible, lightweight devices using polysilanes can lead to reduced material consumption and energy usage during manufacturing processes.

However, the production of polysilanes and their incorporation into electronic devices is not without environmental challenges. The synthesis of these materials often involves energy-intensive processes and the use of potentially harmful chemicals. As research progresses, it is crucial to develop greener synthesis methods that minimize the use of toxic reagents and reduce energy consumption.

The durability and longevity of polysilane-based devices also play a role in their environmental impact. While flexibility can enhance device lifespan by reducing physical damage, the overall stability of polysilanes under various environmental conditions needs further investigation. Improved stability could lead to longer-lasting devices, reducing the frequency of replacements and associated waste.

End-of-life considerations for polysilane-based electronics are particularly important. The potential for biodegradability offers a significant advantage over traditional electronic materials, which often contribute to persistent environmental pollution. However, the development of efficient recycling and disposal methods specific to polysilane-containing devices is necessary to fully realize this benefit.

The energy efficiency of polysilane-based flexible electronics during operation is another critical factor. These materials have the potential to enable low-power devices, which could contribute to reduced energy consumption over their lifetime. This aspect is particularly relevant in the context of the growing Internet of Things (IoT) and wearable technology markets.

As the adoption of polysilane-based flexible electronics increases, it is essential to conduct comprehensive life cycle assessments. These studies should compare the environmental impact of polysilane devices with traditional electronics across all stages, from raw material extraction to disposal. Such assessments will provide valuable insights for guiding future research and development efforts towards more sustainable electronic technologies.

Scalability and Production

The scalability and production of polysilane-based flexible electronic devices present both challenges and opportunities for the industry. As the demand for flexible electronics continues to grow, manufacturers must address several key factors to ensure successful large-scale production.

One of the primary challenges in scaling up polysilane production is maintaining consistent quality across larger batches. The synthesis of polysilane materials often involves complex chemical reactions that can be sensitive to environmental conditions and process parameters. Developing robust manufacturing processes that can reliably produce high-quality polysilane materials at industrial scales is crucial for the widespread adoption of this technology in flexible electronic devices.

Another important aspect of scalability is the development of efficient deposition techniques for polysilane thin films. Current methods, such as spin-coating and vapor deposition, may need to be adapted or replaced with more scalable alternatives to meet the demands of high-volume production. Roll-to-roll processing, for instance, shows promise for continuous, large-area fabrication of flexible electronic devices.

The integration of polysilane materials into existing manufacturing workflows presents another challenge. Many electronic device manufacturers have established production lines optimized for traditional rigid electronics. Adapting these lines to accommodate flexible substrates and polysilane-based components may require significant investment in new equipment and process development.

Cost-effectiveness is a critical factor in the scalability of polysilane-based flexible electronics. As production volumes increase, economies of scale should help drive down costs. However, the industry must focus on optimizing material utilization, reducing waste, and improving process efficiency to make polysilane-based devices economically competitive with existing technologies.

Environmental considerations also play a role in the scalability and production of polysilane-based electronics. Manufacturers must develop sustainable production processes that minimize the use of hazardous chemicals and reduce energy consumption. Additionally, end-of-life recycling and disposal strategies for polysilane-based devices should be considered to ensure long-term environmental sustainability.

As the technology matures, standardization of materials, processes, and testing methods will become increasingly important. Industry-wide standards can help streamline production, improve quality control, and facilitate the integration of polysilane-based components into a wider range of electronic devices.

One of the primary challenges in scaling up polysilane production is maintaining consistent quality across larger batches. The synthesis of polysilane materials often involves complex chemical reactions that can be sensitive to environmental conditions and process parameters. Developing robust manufacturing processes that can reliably produce high-quality polysilane materials at industrial scales is crucial for the widespread adoption of this technology in flexible electronic devices.

Another important aspect of scalability is the development of efficient deposition techniques for polysilane thin films. Current methods, such as spin-coating and vapor deposition, may need to be adapted or replaced with more scalable alternatives to meet the demands of high-volume production. Roll-to-roll processing, for instance, shows promise for continuous, large-area fabrication of flexible electronic devices.

The integration of polysilane materials into existing manufacturing workflows presents another challenge. Many electronic device manufacturers have established production lines optimized for traditional rigid electronics. Adapting these lines to accommodate flexible substrates and polysilane-based components may require significant investment in new equipment and process development.

Cost-effectiveness is a critical factor in the scalability of polysilane-based flexible electronics. As production volumes increase, economies of scale should help drive down costs. However, the industry must focus on optimizing material utilization, reducing waste, and improving process efficiency to make polysilane-based devices economically competitive with existing technologies.

Environmental considerations also play a role in the scalability and production of polysilane-based electronics. Manufacturers must develop sustainable production processes that minimize the use of hazardous chemicals and reduce energy consumption. Additionally, end-of-life recycling and disposal strategies for polysilane-based devices should be considered to ensure long-term environmental sustainability.

As the technology matures, standardization of materials, processes, and testing methods will become increasingly important. Industry-wide standards can help streamline production, improve quality control, and facilitate the integration of polysilane-based components into a wider range of electronic devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!