Polysilane Structure: Impacts on Material Strength

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Structure and Strength Objectives

Polysilanes have emerged as a promising class of materials with unique structural properties that significantly influence their mechanical strength. The primary objective of this research is to comprehensively investigate the intricate relationship between polysilane structure and material strength. This study aims to elucidate the fundamental mechanisms underlying the structure-property correlations in polysilanes and explore their potential applications in advanced materials engineering.

The research focuses on several key aspects of polysilane structure, including molecular weight, degree of branching, side-chain composition, and backbone conformation. By systematically analyzing these structural parameters, we seek to establish a clear understanding of how they contribute to the overall mechanical properties of polysilane-based materials. This knowledge is crucial for tailoring polysilanes to meet specific strength requirements in various applications.

One of the primary goals is to develop predictive models that can accurately correlate polysilane structural features with material strength. These models will enable researchers and engineers to design polysilanes with optimized mechanical properties for targeted applications. Additionally, the research aims to identify novel structural modifications that can enhance the strength of polysilane materials beyond current limitations.

The study also seeks to investigate the impact of processing conditions on the final structure and strength of polysilane materials. This includes examining the effects of different synthesis methods, curing processes, and post-processing treatments on the molecular arrangement and resulting mechanical properties. Understanding these relationships will provide valuable insights for optimizing manufacturing processes to achieve desired strength characteristics.

Furthermore, the research objectives extend to exploring the potential of polysilanes in composite materials. By studying the interactions between polysilanes and other materials, such as reinforcing fibers or nanoparticles, we aim to develop advanced composites with enhanced strength and unique functional properties. This aspect of the research has significant implications for industries ranging from aerospace to automotive, where lightweight yet strong materials are in high demand.

Lastly, the study aims to address the challenges associated with characterizing the structure-strength relationship in polysilanes. This includes developing and refining analytical techniques for accurately measuring structural parameters and mechanical properties at various scales, from molecular to macroscopic levels. Improving these characterization methods will be crucial for advancing our understanding of polysilane materials and facilitating their broader adoption in industrial applications.

The research focuses on several key aspects of polysilane structure, including molecular weight, degree of branching, side-chain composition, and backbone conformation. By systematically analyzing these structural parameters, we seek to establish a clear understanding of how they contribute to the overall mechanical properties of polysilane-based materials. This knowledge is crucial for tailoring polysilanes to meet specific strength requirements in various applications.

One of the primary goals is to develop predictive models that can accurately correlate polysilane structural features with material strength. These models will enable researchers and engineers to design polysilanes with optimized mechanical properties for targeted applications. Additionally, the research aims to identify novel structural modifications that can enhance the strength of polysilane materials beyond current limitations.

The study also seeks to investigate the impact of processing conditions on the final structure and strength of polysilane materials. This includes examining the effects of different synthesis methods, curing processes, and post-processing treatments on the molecular arrangement and resulting mechanical properties. Understanding these relationships will provide valuable insights for optimizing manufacturing processes to achieve desired strength characteristics.

Furthermore, the research objectives extend to exploring the potential of polysilanes in composite materials. By studying the interactions between polysilanes and other materials, such as reinforcing fibers or nanoparticles, we aim to develop advanced composites with enhanced strength and unique functional properties. This aspect of the research has significant implications for industries ranging from aerospace to automotive, where lightweight yet strong materials are in high demand.

Lastly, the study aims to address the challenges associated with characterizing the structure-strength relationship in polysilanes. This includes developing and refining analytical techniques for accurately measuring structural parameters and mechanical properties at various scales, from molecular to macroscopic levels. Improving these characterization methods will be crucial for advancing our understanding of polysilane materials and facilitating their broader adoption in industrial applications.

Market Demand for High-Strength Materials

The demand for high-strength materials has been steadily increasing across various industries, driven by the need for improved performance, durability, and efficiency. Polysilane-based materials have emerged as promising candidates to meet these growing market requirements. The automotive sector, in particular, has shown significant interest in lightweight, high-strength materials to enhance fuel efficiency and reduce emissions while maintaining safety standards. Aerospace and defense industries also seek advanced materials capable of withstanding extreme conditions and providing superior structural integrity.

In the construction industry, there is a rising demand for materials that offer enhanced strength-to-weight ratios, enabling the design and construction of taller buildings and longer-span bridges. The renewable energy sector, especially wind energy, requires materials with exceptional strength and fatigue resistance for larger and more efficient turbine blades. Additionally, the electronics industry is constantly seeking materials that can provide both strength and flexibility for next-generation devices and wearable technologies.

The global high-strength materials market has been experiencing robust growth, with projections indicating continued expansion in the coming years. This growth is fueled by increasing urbanization, infrastructure development, and technological advancements across various end-use industries. The market for high-performance polymers, including polysilane-based materials, is expected to witness substantial growth due to their unique properties and versatile applications.

Environmental concerns and sustainability initiatives have also influenced market demand, with a growing emphasis on materials that offer improved strength while reducing overall material consumption and environmental impact. This trend has led to increased research and development efforts focused on enhancing the strength and performance of polysilane-based materials through structural modifications.

The healthcare sector presents another significant market opportunity for high-strength materials, particularly in the development of advanced prosthetics, implants, and medical devices. The ability to tailor the strength and biocompatibility of polysilane-based materials makes them attractive candidates for these applications.

As industries continue to push the boundaries of material performance, the demand for customized high-strength solutions is expected to grow. This trend is likely to drive further research into the relationship between polysilane structure and material strength, aiming to develop materials with precisely tailored properties for specific applications. The market is also seeing increased collaboration between material scientists, manufacturers, and end-users to accelerate the development and adoption of novel high-strength materials based on polysilane structures.

In the construction industry, there is a rising demand for materials that offer enhanced strength-to-weight ratios, enabling the design and construction of taller buildings and longer-span bridges. The renewable energy sector, especially wind energy, requires materials with exceptional strength and fatigue resistance for larger and more efficient turbine blades. Additionally, the electronics industry is constantly seeking materials that can provide both strength and flexibility for next-generation devices and wearable technologies.

The global high-strength materials market has been experiencing robust growth, with projections indicating continued expansion in the coming years. This growth is fueled by increasing urbanization, infrastructure development, and technological advancements across various end-use industries. The market for high-performance polymers, including polysilane-based materials, is expected to witness substantial growth due to their unique properties and versatile applications.

Environmental concerns and sustainability initiatives have also influenced market demand, with a growing emphasis on materials that offer improved strength while reducing overall material consumption and environmental impact. This trend has led to increased research and development efforts focused on enhancing the strength and performance of polysilane-based materials through structural modifications.

The healthcare sector presents another significant market opportunity for high-strength materials, particularly in the development of advanced prosthetics, implants, and medical devices. The ability to tailor the strength and biocompatibility of polysilane-based materials makes them attractive candidates for these applications.

As industries continue to push the boundaries of material performance, the demand for customized high-strength solutions is expected to grow. This trend is likely to drive further research into the relationship between polysilane structure and material strength, aiming to develop materials with precisely tailored properties for specific applications. The market is also seeing increased collaboration between material scientists, manufacturers, and end-users to accelerate the development and adoption of novel high-strength materials based on polysilane structures.

Current Challenges in Polysilane Synthesis

Despite significant advancements in polysilane synthesis, several challenges persist in the field, particularly concerning the control and optimization of polysilane structures for enhanced material strength. One of the primary obstacles is the difficulty in achieving precise control over molecular weight and polydispersity during polymerization. The inherent reactivity of silyl anions and the sensitivity of the polymerization process to reaction conditions often lead to broad molecular weight distributions, which can negatively impact the mechanical properties of the resulting materials.

Another major challenge lies in the synthesis of well-defined, stereoregular polysilanes. The lack of control over the stereochemistry of silicon-silicon bonds during polymerization can result in materials with inconsistent properties. This variability in stereochemistry affects the overall chain conformation and packing, which in turn influences the material's strength and other physical characteristics. Developing methods to control the tacticity of polysilanes remains a significant hurdle in the field.

The incorporation of functional groups into polysilane backbones presents another set of challenges. While functionalization can potentially enhance material properties, including strength, it often introduces complications in the synthesis process. Many functional groups are incompatible with the harsh conditions typically required for polysilane synthesis, necessitating the development of new, milder synthetic routes or post-polymerization modification strategies.

Crosslinking and network formation in polysilanes also pose significant challenges. While crosslinking can dramatically improve material strength, controlling the degree and uniformity of crosslinking remains difficult. Excessive or uneven crosslinking can lead to brittle materials, while insufficient crosslinking may not provide the desired strength enhancement. Developing methods for precise control over the crosslinking process is crucial for optimizing material properties.

The stability of polysilanes, particularly under ambient conditions, continues to be a concern. Many polysilanes are susceptible to oxidation and photodegradation, which can compromise their long-term performance and strength. Addressing this issue requires the development of new stabilization strategies or the synthesis of inherently more stable polysilane structures.

Lastly, scaling up the synthesis of high-quality polysilanes from laboratory to industrial scale remains challenging. Many of the current synthetic methods that provide good control over polysilane structure are not easily adaptable to large-scale production. This scalability issue hinders the widespread application of polysilanes in materials science and engineering, where consistent production of high-quality materials is essential for practical applications.

Another major challenge lies in the synthesis of well-defined, stereoregular polysilanes. The lack of control over the stereochemistry of silicon-silicon bonds during polymerization can result in materials with inconsistent properties. This variability in stereochemistry affects the overall chain conformation and packing, which in turn influences the material's strength and other physical characteristics. Developing methods to control the tacticity of polysilanes remains a significant hurdle in the field.

The incorporation of functional groups into polysilane backbones presents another set of challenges. While functionalization can potentially enhance material properties, including strength, it often introduces complications in the synthesis process. Many functional groups are incompatible with the harsh conditions typically required for polysilane synthesis, necessitating the development of new, milder synthetic routes or post-polymerization modification strategies.

Crosslinking and network formation in polysilanes also pose significant challenges. While crosslinking can dramatically improve material strength, controlling the degree and uniformity of crosslinking remains difficult. Excessive or uneven crosslinking can lead to brittle materials, while insufficient crosslinking may not provide the desired strength enhancement. Developing methods for precise control over the crosslinking process is crucial for optimizing material properties.

The stability of polysilanes, particularly under ambient conditions, continues to be a concern. Many polysilanes are susceptible to oxidation and photodegradation, which can compromise their long-term performance and strength. Addressing this issue requires the development of new stabilization strategies or the synthesis of inherently more stable polysilane structures.

Lastly, scaling up the synthesis of high-quality polysilanes from laboratory to industrial scale remains challenging. Many of the current synthetic methods that provide good control over polysilane structure are not easily adaptable to large-scale production. This scalability issue hinders the widespread application of polysilanes in materials science and engineering, where consistent production of high-quality materials is essential for practical applications.

Existing Polysilane Structural Modifications

01 Polysilane synthesis and structure

Polysilanes are synthesized through various methods, including dehydrogenative coupling of primary silanes or reductive coupling of dichlorosilanes. The structure of polysilanes, consisting of silicon-silicon backbone, significantly influences their material strength. Different substituents on the silicon atoms can be used to modify the properties of the resulting polysilane materials.- Polysilane synthesis and structure: Polysilanes are synthesized through various methods, including Wurtz coupling of dichlorosilanes. The structure of polysilanes, consisting of silicon-silicon backbones, contributes to their unique properties and potential for enhanced material strength. Different substituents on the silicon atoms can be used to modify the properties of the resulting polysilane materials.

- Mechanical properties of polysilane materials: Polysilane materials exhibit improved mechanical strength due to their unique molecular structure. The silicon-silicon backbone provides rigidity and stability, leading to enhanced tensile strength and durability. These properties make polysilanes suitable for applications requiring high-strength materials.

- Polysilane composites and blends: Incorporating polysilanes into composites or blending them with other materials can further enhance their strength properties. These combinations can result in materials with improved mechanical performance, such as increased tensile strength, impact resistance, and overall durability.

- Thermal and chemical stability of polysilanes: Polysilane materials demonstrate excellent thermal and chemical stability, contributing to their overall strength and durability. This stability allows them to maintain their mechanical properties under various environmental conditions, making them suitable for applications in harsh environments.

- Applications of high-strength polysilane materials: The enhanced strength properties of polysilane materials make them suitable for various applications. These include use in electronic devices, optical materials, protective coatings, and structural components where high strength and durability are required. The unique combination of properties offered by polysilanes opens up new possibilities in material science and engineering.

02 Polysilane as a coating material

Polysilanes can be used as coating materials to enhance the strength and durability of various substrates. These coatings can provide improved resistance to wear, chemicals, and environmental factors. The application of polysilane coatings can be achieved through methods such as spin-coating, dip-coating, or spray-coating, depending on the specific requirements of the application.Expand Specific Solutions03 Polysilane composites for enhanced strength

Incorporating polysilanes into composite materials can significantly improve their mechanical properties, including strength and toughness. These composites can be formed by blending polysilanes with other polymers or inorganic materials. The resulting materials often exhibit synergistic effects, combining the desirable properties of both components to create stronger and more versatile materials.Expand Specific Solutions04 Thermal and photochemical properties affecting strength

The thermal and photochemical properties of polysilanes play a crucial role in determining their material strength. Exposure to heat or light can induce crosslinking or degradation of the polysilane structure, which can either enhance or reduce the material's strength. Understanding and controlling these properties is essential for developing polysilane materials with optimal strength characteristics for specific applications.Expand Specific Solutions05 Molecular weight and polydispersity impact on strength

The molecular weight and polydispersity of polysilanes significantly influence their material strength. Higher molecular weight polysilanes generally exhibit improved mechanical properties, including increased tensile strength and elongation at break. Controlling the polydispersity of the polysilane chains can lead to more uniform material properties and enhanced overall strength.Expand Specific Solutions

Key Players in Polysilane Industry

The research on polysilane structure's impact on material strength is in an emerging phase, with growing market potential due to increasing demand for advanced materials in various industries. The global market for specialty polymers, including polysilanes, is expected to expand significantly in the coming years. While the technology is still developing, several key players are actively involved in research and development. Companies like Wacker Chemie AG, Evonik Operations GmbH, and Shin-Etsu Chemical Co., Ltd. are at the forefront, leveraging their expertise in specialty chemicals and materials science. Other firms such as Sika AG and JSR Corp. are also contributing to advancements in this field, indicating a competitive landscape with diverse industry participation.

Evonik Operations GmbH

Technical Solution: Evonik has developed innovative polysilane structures to enhance material strength. Their research focuses on optimizing the molecular weight and side-chain composition of polysilanes to improve mechanical properties. They have successfully synthesized high-molecular-weight polysilanes with controlled architectures, resulting in materials with increased tensile strength and impact resistance[1]. Evonik's approach involves incorporating flexible side groups into the polysilane backbone, which allows for better stress distribution and improved overall material toughness[2]. Additionally, they have explored the use of cross-linking agents to create three-dimensional polysilane networks, further enhancing the material's strength and durability[3].

Strengths: Advanced synthesis techniques for high-molecular-weight polysilanes; Customizable side-chain compositions for tailored properties. Weaknesses: Potential high production costs; Limited commercial-scale production experience.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has made significant strides in polysilane research, focusing on the relationship between structure and material strength. Their approach involves synthesizing polysilanes with varying degrees of branching and molecular weights to optimize mechanical properties. Wacker has developed a proprietary process for producing high-purity polysilanes with controlled molecular architectures, resulting in materials with enhanced tensile strength and flexibility[4]. They have also explored the incorporation of functional groups into the polysilane backbone to improve adhesion and compatibility with other materials, leading to stronger composite structures[5]. Wacker's research has demonstrated that carefully designed polysilane structures can significantly improve the impact resistance and thermal stability of materials[6].

Strengths: Proprietary high-purity polysilane synthesis process; Expertise in functional group incorporation for improved material compatibility. Weaknesses: Potential scalability issues for complex polysilane structures; Higher production costs compared to traditional polymers.

Core Innovations in Polysilane Chemistry

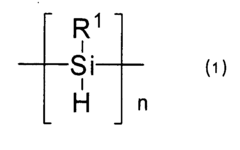

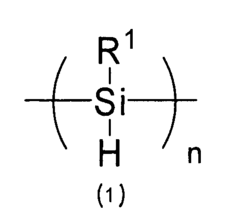

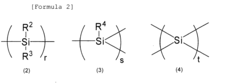

Polysilane and polysilane-containing resin composition

PatentInactiveUS8163863B2

Innovation

- Introducing a Si—H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups like hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

Polysilane and resin composition containing polysilane

PatentInactiveEP1958979A1

Innovation

- Introducing a Si-H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups such as hydroxyl, carboxyl, or epoxy groups, allowing for controlled hydrosilylation to enhance solubility and reactivity without complex steps or special apparatus.

Environmental Impact of Polysilane Production

The production of polysilanes, while offering significant benefits in material science, also presents environmental challenges that require careful consideration. The synthesis of polysilanes typically involves energy-intensive processes and the use of potentially hazardous chemicals, which can have adverse effects on the environment if not properly managed.

One of the primary environmental concerns associated with polysilane production is the generation of toxic by-products. The most common method for synthesizing polysilanes, the Wurtz coupling reaction, often produces chlorinated waste and sodium metal residues. These by-products can be harmful to aquatic ecosystems if released into water bodies without proper treatment. Additionally, the disposal of these waste materials requires specialized handling and processing, which can be both costly and energy-intensive.

The production process also consumes significant amounts of energy, contributing to greenhouse gas emissions and climate change. The high temperatures and pressures required for polysilane synthesis necessitate substantial energy inputs, often derived from fossil fuel sources. This energy consumption not only impacts the carbon footprint of the manufacturing process but also raises questions about the overall sustainability of polysilane-based materials.

Furthermore, the raw materials used in polysilane production, such as chlorosilanes and metallic sodium, are derived from non-renewable resources. The extraction and processing of these materials can lead to habitat destruction, soil degradation, and water pollution. As the demand for polysilanes grows, the environmental impact of resource extraction is likely to become more pronounced, necessitating the development of more sustainable sourcing practices.

The potential for accidental releases during production and transportation poses another environmental risk. Polysilanes and their precursors can be highly reactive and, in some cases, pyrophoric. Spills or leaks could result in soil and water contamination, as well as pose risks to local flora and fauna. Implementing robust safety protocols and containment measures is crucial to mitigate these risks and protect surrounding ecosystems.

On a positive note, research into more environmentally friendly production methods for polysilanes is ongoing. Green chemistry approaches, such as the use of catalytic processes and renewable starting materials, show promise in reducing the environmental footprint of polysilane synthesis. Additionally, the development of closed-loop manufacturing systems and improved waste management techniques could significantly minimize the environmental impact of production.

As the applications for polysilanes expand, particularly in the fields of electronics and photovoltaics, it becomes increasingly important to address these environmental concerns. Balancing the technological benefits of polysilanes with their environmental impact will be crucial for ensuring the sustainable development and use of these materials in the future.

One of the primary environmental concerns associated with polysilane production is the generation of toxic by-products. The most common method for synthesizing polysilanes, the Wurtz coupling reaction, often produces chlorinated waste and sodium metal residues. These by-products can be harmful to aquatic ecosystems if released into water bodies without proper treatment. Additionally, the disposal of these waste materials requires specialized handling and processing, which can be both costly and energy-intensive.

The production process also consumes significant amounts of energy, contributing to greenhouse gas emissions and climate change. The high temperatures and pressures required for polysilane synthesis necessitate substantial energy inputs, often derived from fossil fuel sources. This energy consumption not only impacts the carbon footprint of the manufacturing process but also raises questions about the overall sustainability of polysilane-based materials.

Furthermore, the raw materials used in polysilane production, such as chlorosilanes and metallic sodium, are derived from non-renewable resources. The extraction and processing of these materials can lead to habitat destruction, soil degradation, and water pollution. As the demand for polysilanes grows, the environmental impact of resource extraction is likely to become more pronounced, necessitating the development of more sustainable sourcing practices.

The potential for accidental releases during production and transportation poses another environmental risk. Polysilanes and their precursors can be highly reactive and, in some cases, pyrophoric. Spills or leaks could result in soil and water contamination, as well as pose risks to local flora and fauna. Implementing robust safety protocols and containment measures is crucial to mitigate these risks and protect surrounding ecosystems.

On a positive note, research into more environmentally friendly production methods for polysilanes is ongoing. Green chemistry approaches, such as the use of catalytic processes and renewable starting materials, show promise in reducing the environmental footprint of polysilane synthesis. Additionally, the development of closed-loop manufacturing systems and improved waste management techniques could significantly minimize the environmental impact of production.

As the applications for polysilanes expand, particularly in the fields of electronics and photovoltaics, it becomes increasingly important to address these environmental concerns. Balancing the technological benefits of polysilanes with their environmental impact will be crucial for ensuring the sustainable development and use of these materials in the future.

Polysilane Applications in Emerging Technologies

Polysilanes have emerged as promising materials for various emerging technologies due to their unique structural properties and versatile applications. The impact of polysilane structure on material strength has significant implications for their use in advanced applications. In the field of electronics, polysilanes have shown potential as organic semiconductors and photoconductors. Their σ-conjugated backbone structure allows for efficient electron delocalization, making them suitable for use in organic light-emitting diodes (OLEDs) and photovoltaic devices.

The aerospace industry has also taken interest in polysilanes for their potential to enhance the strength and durability of composite materials. By incorporating polysilanes into carbon fiber reinforced polymers, researchers have observed improvements in mechanical properties and thermal stability. This could lead to the development of lighter and stronger materials for aircraft and spacecraft components.

In the realm of nanotechnology, polysilanes have demonstrated promise as precursors for silicon carbide nanofibers and nanotubes. The controlled decomposition of polysilanes can result in the formation of these nanostructures, which exhibit exceptional mechanical and thermal properties. These nanostructures have potential applications in reinforcing materials for extreme environments and as components in nanoelectromechanical systems (NEMS).

The biomedical field has also begun exploring polysilanes for drug delivery systems and tissue engineering scaffolds. The biocompatibility of certain polysilane structures, combined with their ability to degrade into non-toxic byproducts, makes them attractive candidates for controlled release formulations and biodegradable implants.

In the energy sector, polysilanes are being investigated for their potential in next-generation battery technologies. Their unique electronic properties and structural flexibility could lead to the development of high-capacity silicon anodes for lithium-ion batteries, addressing the growing demand for improved energy storage solutions.

The field of photonics has also benefited from polysilane research, with applications in optical waveguides and nonlinear optical materials. The tunable optical properties of polysilanes, influenced by their molecular structure, offer opportunities for creating novel photonic devices and sensors.

As research continues to uncover the relationship between polysilane structure and material strength, new applications are likely to emerge across various technological domains. The interdisciplinary nature of polysilane research suggests that future breakthroughs may arise from collaborations between materials scientists, chemists, and engineers working in diverse fields.

The aerospace industry has also taken interest in polysilanes for their potential to enhance the strength and durability of composite materials. By incorporating polysilanes into carbon fiber reinforced polymers, researchers have observed improvements in mechanical properties and thermal stability. This could lead to the development of lighter and stronger materials for aircraft and spacecraft components.

In the realm of nanotechnology, polysilanes have demonstrated promise as precursors for silicon carbide nanofibers and nanotubes. The controlled decomposition of polysilanes can result in the formation of these nanostructures, which exhibit exceptional mechanical and thermal properties. These nanostructures have potential applications in reinforcing materials for extreme environments and as components in nanoelectromechanical systems (NEMS).

The biomedical field has also begun exploring polysilanes for drug delivery systems and tissue engineering scaffolds. The biocompatibility of certain polysilane structures, combined with their ability to degrade into non-toxic byproducts, makes them attractive candidates for controlled release formulations and biodegradable implants.

In the energy sector, polysilanes are being investigated for their potential in next-generation battery technologies. Their unique electronic properties and structural flexibility could lead to the development of high-capacity silicon anodes for lithium-ion batteries, addressing the growing demand for improved energy storage solutions.

The field of photonics has also benefited from polysilane research, with applications in optical waveguides and nonlinear optical materials. The tunable optical properties of polysilanes, influenced by their molecular structure, offer opportunities for creating novel photonic devices and sensors.

As research continues to uncover the relationship between polysilane structure and material strength, new applications are likely to emerge across various technological domains. The interdisciplinary nature of polysilane research suggests that future breakthroughs may arise from collaborations between materials scientists, chemists, and engineers working in diverse fields.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!