Polysilane’s Role in Sensor Technology Advancements

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Sensor Tech Background and Objectives

Polysilanes have emerged as a promising material in the field of sensor technology, marking a significant milestone in the evolution of advanced sensing devices. The development of polysilane-based sensors can be traced back to the late 1980s when researchers first recognized the unique electronic and optical properties of these silicon-based polymers. Since then, the field has witnessed remarkable progress, driven by the increasing demand for more sensitive, selective, and robust sensing platforms across various industries.

The technological trajectory of polysilane sensors has been characterized by continuous improvements in synthesis methods, structural modifications, and integration techniques. Early research focused primarily on exploiting the photoconductivity and photoluminescence of polysilanes for optical sensing applications. As the understanding of structure-property relationships deepened, scientists began to explore the potential of polysilanes in chemical and biological sensing, leveraging their high sensitivity to environmental changes and their ability to be functionalized with specific recognition elements.

Recent advancements in nanotechnology and materials science have further accelerated the development of polysilane-based sensors. The incorporation of nanostructures, such as nanoparticles and nanofibers, has led to enhanced surface area and improved sensitivity. Additionally, the advent of flexible electronics has opened new avenues for polysilane sensors in wearable and implantable devices, addressing the growing need for real-time health monitoring and environmental sensing.

The primary objectives of current polysilane sensor technology research are multifaceted. Firstly, there is a strong focus on enhancing the sensitivity and selectivity of these sensors to detect increasingly lower concentrations of target analytes with higher accuracy. This involves optimizing the molecular structure of polysilanes and developing novel sensing mechanisms. Secondly, researchers aim to expand the range of detectable substances, particularly in complex matrices, to broaden the applicability of polysilane sensors in fields such as healthcare, environmental monitoring, and industrial process control.

Another crucial objective is to improve the stability and durability of polysilane sensors under various operating conditions. This includes developing strategies to mitigate degradation caused by exposure to light, heat, and chemical agents, thereby extending the sensor's lifetime and reliability. Furthermore, there is a growing emphasis on creating multifunctional sensing platforms that can simultaneously detect multiple analytes, offering more comprehensive and efficient sensing solutions.

As the field progresses, the integration of polysilane sensors with advanced data processing and artificial intelligence is becoming increasingly important. This convergence aims to enable real-time data analysis, pattern recognition, and predictive capabilities, transforming raw sensor outputs into actionable insights. Ultimately, the overarching goal is to develop next-generation sensing technologies that are not only highly sensitive and selective but also cost-effective, scalable, and easily integrated into existing systems and emerging Internet of Things (IoT) infrastructures.

The technological trajectory of polysilane sensors has been characterized by continuous improvements in synthesis methods, structural modifications, and integration techniques. Early research focused primarily on exploiting the photoconductivity and photoluminescence of polysilanes for optical sensing applications. As the understanding of structure-property relationships deepened, scientists began to explore the potential of polysilanes in chemical and biological sensing, leveraging their high sensitivity to environmental changes and their ability to be functionalized with specific recognition elements.

Recent advancements in nanotechnology and materials science have further accelerated the development of polysilane-based sensors. The incorporation of nanostructures, such as nanoparticles and nanofibers, has led to enhanced surface area and improved sensitivity. Additionally, the advent of flexible electronics has opened new avenues for polysilane sensors in wearable and implantable devices, addressing the growing need for real-time health monitoring and environmental sensing.

The primary objectives of current polysilane sensor technology research are multifaceted. Firstly, there is a strong focus on enhancing the sensitivity and selectivity of these sensors to detect increasingly lower concentrations of target analytes with higher accuracy. This involves optimizing the molecular structure of polysilanes and developing novel sensing mechanisms. Secondly, researchers aim to expand the range of detectable substances, particularly in complex matrices, to broaden the applicability of polysilane sensors in fields such as healthcare, environmental monitoring, and industrial process control.

Another crucial objective is to improve the stability and durability of polysilane sensors under various operating conditions. This includes developing strategies to mitigate degradation caused by exposure to light, heat, and chemical agents, thereby extending the sensor's lifetime and reliability. Furthermore, there is a growing emphasis on creating multifunctional sensing platforms that can simultaneously detect multiple analytes, offering more comprehensive and efficient sensing solutions.

As the field progresses, the integration of polysilane sensors with advanced data processing and artificial intelligence is becoming increasingly important. This convergence aims to enable real-time data analysis, pattern recognition, and predictive capabilities, transforming raw sensor outputs into actionable insights. Ultimately, the overarching goal is to develop next-generation sensing technologies that are not only highly sensitive and selective but also cost-effective, scalable, and easily integrated into existing systems and emerging Internet of Things (IoT) infrastructures.

Market Analysis for Polysilane-based Sensors

The market for polysilane-based sensors is experiencing significant growth, driven by the increasing demand for advanced sensing technologies across various industries. Polysilanes, a class of silicon-based polymers, have emerged as promising materials for sensor applications due to their unique electrical and optical properties. These properties make them particularly suitable for developing highly sensitive and selective sensors for a wide range of analytes.

In the healthcare sector, polysilane-based sensors are gaining traction for their potential in biosensing applications. The ability of polysilanes to detect specific biomolecules with high sensitivity and selectivity has led to their integration into point-of-care diagnostic devices and wearable health monitors. This trend is expected to continue as the global focus on personalized medicine and remote patient monitoring intensifies.

The environmental monitoring industry is another key market for polysilane-based sensors. These sensors are being developed for the detection of various pollutants, including volatile organic compounds (VOCs) and heavy metals in air and water. The increasing emphasis on environmental protection and stringent regulations regarding pollution control are driving the demand for more accurate and reliable sensing technologies, positioning polysilane-based sensors as a promising solution.

In the automotive industry, polysilane sensors are finding applications in advanced driver assistance systems (ADAS) and autonomous vehicles. Their ability to operate in harsh environments and provide rapid response times makes them suitable for various sensing tasks, including proximity detection and gas sensing within vehicle cabins. As the automotive industry continues its shift towards electrification and autonomy, the demand for advanced sensors is expected to grow substantially.

The industrial sector is also adopting polysilane-based sensors for process monitoring and quality control applications. These sensors offer advantages in terms of miniaturization, low power consumption, and compatibility with existing manufacturing processes. Industries such as chemical processing, food and beverage, and pharmaceuticals are exploring the integration of polysilane sensors to enhance their production efficiency and product quality.

The global market for polysilane-based sensors is characterized by ongoing research and development activities aimed at improving sensor performance and expanding their application range. Key market players are investing in the development of novel polysilane materials and sensor designs to address specific industry needs. Collaborations between academic institutions and industry partners are accelerating the commercialization of polysilane sensor technologies.

While the market shows promising growth potential, challenges such as high production costs and the need for standardization in sensor performance metrics need to be addressed. As manufacturing processes improve and economies of scale are achieved, the cost of polysilane-based sensors is expected to decrease, making them more accessible to a broader range of applications and industries.

In the healthcare sector, polysilane-based sensors are gaining traction for their potential in biosensing applications. The ability of polysilanes to detect specific biomolecules with high sensitivity and selectivity has led to their integration into point-of-care diagnostic devices and wearable health monitors. This trend is expected to continue as the global focus on personalized medicine and remote patient monitoring intensifies.

The environmental monitoring industry is another key market for polysilane-based sensors. These sensors are being developed for the detection of various pollutants, including volatile organic compounds (VOCs) and heavy metals in air and water. The increasing emphasis on environmental protection and stringent regulations regarding pollution control are driving the demand for more accurate and reliable sensing technologies, positioning polysilane-based sensors as a promising solution.

In the automotive industry, polysilane sensors are finding applications in advanced driver assistance systems (ADAS) and autonomous vehicles. Their ability to operate in harsh environments and provide rapid response times makes them suitable for various sensing tasks, including proximity detection and gas sensing within vehicle cabins. As the automotive industry continues its shift towards electrification and autonomy, the demand for advanced sensors is expected to grow substantially.

The industrial sector is also adopting polysilane-based sensors for process monitoring and quality control applications. These sensors offer advantages in terms of miniaturization, low power consumption, and compatibility with existing manufacturing processes. Industries such as chemical processing, food and beverage, and pharmaceuticals are exploring the integration of polysilane sensors to enhance their production efficiency and product quality.

The global market for polysilane-based sensors is characterized by ongoing research and development activities aimed at improving sensor performance and expanding their application range. Key market players are investing in the development of novel polysilane materials and sensor designs to address specific industry needs. Collaborations between academic institutions and industry partners are accelerating the commercialization of polysilane sensor technologies.

While the market shows promising growth potential, challenges such as high production costs and the need for standardization in sensor performance metrics need to be addressed. As manufacturing processes improve and economies of scale are achieved, the cost of polysilane-based sensors is expected to decrease, making them more accessible to a broader range of applications and industries.

Current Challenges in Polysilane Sensor Development

Despite the promising potential of polysilane-based sensors, several significant challenges currently hinder their widespread adoption and development. One of the primary obstacles is the stability of polysilane materials under various environmental conditions. Polysilanes are known to be sensitive to UV light, which can cause degradation of the polymer backbone, leading to changes in their optical and electrical properties. This photosensitivity, while beneficial for certain applications, poses a challenge for long-term stability and reliability in sensor devices exposed to ambient light.

Another critical challenge lies in the processability and integration of polysilanes into existing sensor fabrication techniques. The unique chemical structure of polysilanes often results in poor solubility in common solvents, making it difficult to form uniform thin films or incorporate them into complex device architectures. This limitation restricts the ability to produce large-scale, reproducible sensor devices using conventional manufacturing processes.

The electrical conductivity of polysilanes presents both an opportunity and a challenge. While their semiconducting properties are valuable for sensor applications, controlling and optimizing the conductivity for specific sensing requirements remains a significant hurdle. The charge transport mechanisms in polysilanes are not fully understood, and tailoring their electronic properties to match diverse sensing needs is an ongoing area of research.

Selectivity and sensitivity are crucial factors in sensor performance, and polysilane-based sensors face challenges in both areas. Improving the specificity of polysilane sensors to target analytes while minimizing cross-sensitivity to interfering substances is a complex task. Additionally, enhancing the sensitivity to detect low concentrations of analytes without compromising the signal-to-noise ratio requires further development of both material design and device engineering.

The long-term reliability and drift of polysilane sensors under continuous operation or in harsh environments remain concerns for their practical implementation. Understanding and mitigating the aging processes, such as oxidation or structural reorganization, that can affect sensor performance over time is essential for developing robust and dependable devices.

Lastly, the cost-effectiveness of polysilane-based sensors compared to existing technologies is a significant consideration. While polysilanes offer unique properties, the current synthesis methods and material costs may limit their competitiveness in the sensor market. Developing more efficient and scalable production techniques for high-quality polysilanes is crucial for their commercial viability in sensor applications.

Another critical challenge lies in the processability and integration of polysilanes into existing sensor fabrication techniques. The unique chemical structure of polysilanes often results in poor solubility in common solvents, making it difficult to form uniform thin films or incorporate them into complex device architectures. This limitation restricts the ability to produce large-scale, reproducible sensor devices using conventional manufacturing processes.

The electrical conductivity of polysilanes presents both an opportunity and a challenge. While their semiconducting properties are valuable for sensor applications, controlling and optimizing the conductivity for specific sensing requirements remains a significant hurdle. The charge transport mechanisms in polysilanes are not fully understood, and tailoring their electronic properties to match diverse sensing needs is an ongoing area of research.

Selectivity and sensitivity are crucial factors in sensor performance, and polysilane-based sensors face challenges in both areas. Improving the specificity of polysilane sensors to target analytes while minimizing cross-sensitivity to interfering substances is a complex task. Additionally, enhancing the sensitivity to detect low concentrations of analytes without compromising the signal-to-noise ratio requires further development of both material design and device engineering.

The long-term reliability and drift of polysilane sensors under continuous operation or in harsh environments remain concerns for their practical implementation. Understanding and mitigating the aging processes, such as oxidation or structural reorganization, that can affect sensor performance over time is essential for developing robust and dependable devices.

Lastly, the cost-effectiveness of polysilane-based sensors compared to existing technologies is a significant consideration. While polysilanes offer unique properties, the current synthesis methods and material costs may limit their competitiveness in the sensor market. Developing more efficient and scalable production techniques for high-quality polysilanes is crucial for their commercial viability in sensor applications.

Existing Polysilane Sensor Solutions

01 Synthesis and properties of polysilanes

Polysilanes are synthesized through various methods and exhibit unique properties. These silicon-based polymers have applications in electronics, optics, and materials science due to their electronic and optical characteristics. The synthesis methods and resulting properties can be tailored for specific applications.- Synthesis and properties of polysilanes: Polysilanes are silicon-based polymers with a Si-Si backbone. They can be synthesized through various methods and exhibit unique optical and electronic properties. These materials have applications in photoresists, semiconductors, and optoelectronic devices due to their high thermal stability and conductivity.

- Polysilane-based coatings and films: Polysilanes can be used to create thin films and coatings with specific properties. These films can be applied to various substrates and may exhibit characteristics such as improved adhesion, chemical resistance, or optical properties. The coating process often involves techniques like spin-coating or vapor deposition.

- Polysilane applications in photoresists: Polysilanes are utilized in photoresist formulations for semiconductor manufacturing. They can act as both positive and negative photoresists, offering high resolution and sensitivity to UV light. The silicon-based structure of polysilanes contributes to their resistance to plasma etching processes.

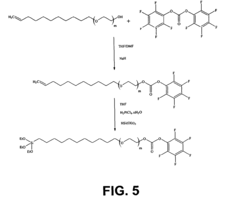

- Functionalization and modification of polysilanes: Polysilanes can be functionalized or modified to enhance their properties or create new materials. This may involve the incorporation of organic side groups, crosslinking, or copolymerization with other monomers. Such modifications can lead to improved solubility, processability, or specific functional characteristics.

- Polysilane-based composites and hybrid materials: Polysilanes can be combined with other materials to create composites or hybrid materials with enhanced properties. These may include nanocomposites, polymer blends, or inorganic-organic hybrid materials. Such combinations can result in materials with improved mechanical, thermal, or electrical properties for various applications.

02 Polysilane-based coatings and films

Polysilanes are used to create coatings and films with specific properties. These coatings can be applied to various substrates to impart characteristics such as improved durability, optical properties, or electrical conductivity. The composition and processing of polysilane-based coatings can be optimized for different applications.Expand Specific Solutions03 Polysilanes in photoresist and lithography applications

Polysilanes play a role in photoresist formulations and lithography processes. Their unique optical and electronic properties make them suitable for use in semiconductor manufacturing and other microfabrication techniques. The photosensitivity and etch resistance of polysilanes can be exploited in these applications.Expand Specific Solutions04 Functionalization and modification of polysilanes

Polysilanes can be functionalized or modified to enhance their properties or introduce new functionalities. This includes the incorporation of various side groups, crosslinking, or combining polysilanes with other materials to create hybrid structures. These modifications allow for the fine-tuning of polysilane properties for specific applications.Expand Specific Solutions05 Polysilanes in electronic and optoelectronic devices

Polysilanes are utilized in the development of electronic and optoelectronic devices. Their unique electronic structure and charge transport properties make them suitable for applications such as organic light-emitting diodes (OLEDs), photovoltaic cells, and other semiconductor devices. The processing and integration of polysilanes into these devices are areas of ongoing research and development.Expand Specific Solutions

Key Players in Polysilane Sensor Industry

The polysilane sensor technology market is in an early growth stage, with increasing interest from both academia and industry. The market size is expanding as applications in various sensing domains emerge. While the technology shows promise, it is still evolving towards maturity. Key players like Osaka Gas, Imec, and Nippon Paint are actively researching and developing polysilane-based sensors, leveraging their expertise in materials science and electronics. Universities such as Kanazawa University and South China Normal University are contributing to fundamental research, while companies like Medtronic MiniMed and JSR Corp are exploring potential commercial applications. The involvement of diverse organizations indicates growing recognition of polysilane's potential in advancing sensor technology.

Japan Science & Technology Agency

Technical Solution: The Japan Science & Technology Agency (JST) has been actively supporting research into polysilane-based sensor technologies through various funding initiatives and collaborative projects. Their efforts have led to several breakthroughs in the field. One notable project focused on developing polysilane-based chemosensors for the detection of metal ions in aqueous environments. The research team created functionalized polysilanes with specific binding sites for target metal ions, resulting in highly selective and sensitive sensors[13]. Another JST-funded project explored the use of polysilanes in pressure-sensitive sensors, taking advantage of the material's piezoelectric properties. These sensors demonstrated excellent sensitivity and response times, with potential applications in touch interfaces and wearable devices[14]. Additionally, JST has supported research into polysilane-based biosensors, where the polymer's unique electronic properties are used to detect biomolecules through changes in conductivity or fluorescence[15].

Strengths: Diverse range of sensor applications, strong focus on fundamental research, and potential for interdisciplinary collaborations. Weaknesses: Longer timeline for commercialization and potential challenges in scaling up laboratory-scale discoveries.

Naval Research Laboratory

Technical Solution: The Naval Research Laboratory has made significant advancements in polysilane-based sensor technology. They have developed a novel approach using polysilanes as active materials in chemical and biological sensors. Their research focuses on the unique photophysical properties of polysilanes, particularly their sigma-conjugation, which allows for efficient energy transfer along the polymer backbone[1]. This property is exploited to create highly sensitive and selective sensors. The NRL's polysilane sensors utilize a "turn-on" fluorescence mechanism, where the presence of specific analytes triggers an increase in fluorescence intensity[2]. This approach has shown promise in detecting various chemical and biological agents, including explosives and nerve agents[3].

Strengths: High sensitivity and selectivity, rapid response times, and potential for miniaturization. Weaknesses: May be affected by environmental factors such as temperature and humidity, and could require specialized manufacturing processes.

Core Innovations in Polysilane Sensor Technology

Silane molecules with pre-activated and protein-resistant functionalities and silane films comprising such molecules

PatentInactiveEP1607743B1

Innovation

- Development of silane molecules that combine pre-activated and protein-resistant functionalities, allowing for the formation of well-ordered self-assembled monolayers on substrates, which provide both a pre-activated function for biomolecule immobilization and protein resistance, reducing non-specific adsorption and enhancing sensitivity and specificity.

Combined sensor and infusion set using separated sites

PatentActiveEP2190502A1

Innovation

- The development of a combined sensor and infusion apparatus with separate piercing members for the cannula and sensor, positioned in distinct in vivo environments, ensures that infused fluids do not contact the sensor, thereby preventing interference and stabilizing sensor readings by anchoring the apparatus to the skin.

Environmental Impact of Polysilane Sensors

The environmental impact of polysilane sensors is a critical consideration in the advancement of sensor technology. These innovative sensors offer significant potential for environmental monitoring and protection, but their production and disposal also raise important ecological concerns.

Polysilane-based sensors demonstrate exceptional sensitivity and selectivity in detecting various environmental pollutants, including volatile organic compounds, heavy metals, and greenhouse gases. This capability enables more accurate and real-time monitoring of air and water quality, contributing to improved environmental management and public health protection. The high performance of polysilane sensors allows for the early detection of pollutants at lower concentrations, potentially preventing environmental disasters and facilitating timely interventions.

However, the production of polysilane sensors involves the use of silicon-based materials and various chemical processes, which can have environmental implications. The synthesis of polysilanes often requires energy-intensive procedures and may involve the use of toxic precursors or solvents. Efforts are being made to develop greener synthesis methods, such as using renewable resources or implementing more environmentally friendly catalysts, to mitigate these impacts.

The disposal of polysilane sensors at the end of their lifecycle presents another environmental challenge. While silicon-based materials are generally considered inert, the complex composition of these sensors, including electronic components and other materials, necessitates proper recycling and waste management strategies. Researchers are exploring biodegradable polysilane formulations and modular sensor designs to facilitate easier recycling and reduce electronic waste.

On the positive side, the durability and long lifespan of polysilane sensors contribute to reduced waste generation compared to traditional sensors that require frequent replacement. Additionally, the improved accuracy and reliability of these sensors can lead to more efficient resource utilization and reduced environmental impact in various industries, such as manufacturing and agriculture.

The miniaturization potential of polysilane sensors also offers environmental benefits. Smaller sensors require less material to produce and consume less energy during operation, aligning with the principles of green electronics. This miniaturization enables the development of extensive sensor networks for comprehensive environmental monitoring with minimal physical footprint.

As the technology evolves, ongoing research focuses on enhancing the eco-friendliness of polysilane sensors throughout their lifecycle. This includes exploring bio-based precursors, optimizing energy efficiency in sensor operation, and developing closed-loop recycling processes for sensor components. The goal is to maximize the environmental benefits of polysilane sensor technology while minimizing its ecological footprint.

Polysilane-based sensors demonstrate exceptional sensitivity and selectivity in detecting various environmental pollutants, including volatile organic compounds, heavy metals, and greenhouse gases. This capability enables more accurate and real-time monitoring of air and water quality, contributing to improved environmental management and public health protection. The high performance of polysilane sensors allows for the early detection of pollutants at lower concentrations, potentially preventing environmental disasters and facilitating timely interventions.

However, the production of polysilane sensors involves the use of silicon-based materials and various chemical processes, which can have environmental implications. The synthesis of polysilanes often requires energy-intensive procedures and may involve the use of toxic precursors or solvents. Efforts are being made to develop greener synthesis methods, such as using renewable resources or implementing more environmentally friendly catalysts, to mitigate these impacts.

The disposal of polysilane sensors at the end of their lifecycle presents another environmental challenge. While silicon-based materials are generally considered inert, the complex composition of these sensors, including electronic components and other materials, necessitates proper recycling and waste management strategies. Researchers are exploring biodegradable polysilane formulations and modular sensor designs to facilitate easier recycling and reduce electronic waste.

On the positive side, the durability and long lifespan of polysilane sensors contribute to reduced waste generation compared to traditional sensors that require frequent replacement. Additionally, the improved accuracy and reliability of these sensors can lead to more efficient resource utilization and reduced environmental impact in various industries, such as manufacturing and agriculture.

The miniaturization potential of polysilane sensors also offers environmental benefits. Smaller sensors require less material to produce and consume less energy during operation, aligning with the principles of green electronics. This miniaturization enables the development of extensive sensor networks for comprehensive environmental monitoring with minimal physical footprint.

As the technology evolves, ongoing research focuses on enhancing the eco-friendliness of polysilane sensors throughout their lifecycle. This includes exploring bio-based precursors, optimizing energy efficiency in sensor operation, and developing closed-loop recycling processes for sensor components. The goal is to maximize the environmental benefits of polysilane sensor technology while minimizing its ecological footprint.

Polysilane Sensor Manufacturing Processes

The manufacturing processes for polysilane-based sensors involve several key steps that leverage the unique properties of these silicon-based polymers. The process typically begins with the synthesis of polysilane materials, which can be achieved through various methods such as Wurtz coupling or electrochemical polymerization. These methods allow for precise control over the molecular structure and properties of the resulting polysilanes.

Once synthesized, the polysilane materials undergo purification and characterization to ensure their quality and suitability for sensor applications. This may involve techniques such as gel permeation chromatography, nuclear magnetic resonance spectroscopy, and thermal analysis to determine molecular weight distribution, chemical composition, and thermal stability.

The next stage in the manufacturing process involves the deposition of polysilane thin films onto suitable substrates. This can be accomplished through various techniques, including spin-coating, dip-coating, or chemical vapor deposition. The choice of deposition method depends on the specific sensor design and the desired film thickness and uniformity.

Following deposition, the polysilane films are often subjected to post-processing treatments to enhance their sensing capabilities. These treatments may include thermal annealing, UV irradiation, or chemical modification to optimize the film's structure and surface properties for improved sensor performance.

The integration of polysilane films into functional sensor devices requires the incorporation of electrodes and other necessary components. This may involve photolithography techniques to pattern electrodes onto the substrate, followed by the deposition of the polysilane sensing layer. In some cases, additional layers or protective coatings may be applied to enhance sensor stability and longevity.

Quality control and testing are crucial steps in the manufacturing process. This includes evaluating the sensor's response to target analytes, assessing its sensitivity, selectivity, and stability under various environmental conditions. Advanced characterization techniques such as atomic force microscopy, X-ray photoelectron spectroscopy, and impedance spectroscopy may be employed to analyze the sensor's surface morphology, chemical composition, and electrical properties.

Finally, the manufacturing process concludes with the packaging and encapsulation of the polysilane-based sensors. This step is critical for protecting the sensitive components from environmental factors and ensuring the sensor's long-term performance and reliability. Depending on the specific application, various packaging materials and techniques may be utilized, such as hermetic sealing or the use of protective polymeric coatings.

Once synthesized, the polysilane materials undergo purification and characterization to ensure their quality and suitability for sensor applications. This may involve techniques such as gel permeation chromatography, nuclear magnetic resonance spectroscopy, and thermal analysis to determine molecular weight distribution, chemical composition, and thermal stability.

The next stage in the manufacturing process involves the deposition of polysilane thin films onto suitable substrates. This can be accomplished through various techniques, including spin-coating, dip-coating, or chemical vapor deposition. The choice of deposition method depends on the specific sensor design and the desired film thickness and uniformity.

Following deposition, the polysilane films are often subjected to post-processing treatments to enhance their sensing capabilities. These treatments may include thermal annealing, UV irradiation, or chemical modification to optimize the film's structure and surface properties for improved sensor performance.

The integration of polysilane films into functional sensor devices requires the incorporation of electrodes and other necessary components. This may involve photolithography techniques to pattern electrodes onto the substrate, followed by the deposition of the polysilane sensing layer. In some cases, additional layers or protective coatings may be applied to enhance sensor stability and longevity.

Quality control and testing are crucial steps in the manufacturing process. This includes evaluating the sensor's response to target analytes, assessing its sensitivity, selectivity, and stability under various environmental conditions. Advanced characterization techniques such as atomic force microscopy, X-ray photoelectron spectroscopy, and impedance spectroscopy may be employed to analyze the sensor's surface morphology, chemical composition, and electrical properties.

Finally, the manufacturing process concludes with the packaging and encapsulation of the polysilane-based sensors. This step is critical for protecting the sensitive components from environmental factors and ensuring the sensor's long-term performance and reliability. Depending on the specific application, various packaging materials and techniques may be utilized, such as hermetic sealing or the use of protective polymeric coatings.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!