Polysilane's Contribution to Advanced Optical Component Design

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Optical Evolution

Polysilanes have undergone a remarkable evolution in the field of optical component design, transforming from simple polymeric materials to sophisticated building blocks for advanced photonic devices. The journey of polysilanes in optics began in the 1980s when researchers first recognized their unique electronic and optical properties, stemming from their σ-conjugated backbone structure.

Initially, polysilanes were primarily studied for their photoconductivity and photoluminescence characteristics. These early investigations laid the foundation for understanding the fundamental optical behaviors of polysilanes, including their high refractive indices and nonlinear optical responses. As research progressed, scientists discovered that the optical properties of polysilanes could be finely tuned by modifying their molecular structure and side-chain substituents.

The 1990s marked a significant milestone in polysilane optical evolution with the development of more sophisticated synthesis methods. These advancements allowed for greater control over molecular weight, polydispersity, and structural regularity, leading to polysilanes with enhanced optical performance. During this period, researchers began exploring the potential of polysilanes in various optical applications, including photoresists, optical waveguides, and light-emitting diodes.

The turn of the millennium saw a shift towards integrating polysilanes into more complex optical systems. Hybrid materials combining polysilanes with inorganic components emerged, offering unprecedented control over optical properties. These hybrid materials opened new avenues for creating advanced optical components with tailored refractive indices, optical transparency, and nonlinear optical responses.

In recent years, the focus has shifted towards nanoscale applications of polysilanes in optical component design. The development of polysilane nanostructures, such as nanofibers and nanoparticles, has enabled the creation of novel optical sensors, photonic crystals, and metamaterials. These nanostructured polysilanes exhibit unique optical phenomena, including enhanced light scattering and localized surface plasmon resonance, which are being harnessed for next-generation optical devices.

The latest frontier in polysilane optical evolution involves their integration with other cutting-edge technologies. For instance, researchers are exploring the synergy between polysilanes and two-dimensional materials like graphene to create ultra-thin, flexible optical components. Additionally, the incorporation of polysilanes into quantum dot structures is paving the way for advanced quantum optical devices with tunable emission properties.

As we look to the future, the evolution of polysilanes in optical component design continues to accelerate. Emerging trends include the development of stimuli-responsive polysilane-based optical materials, which can change their optical properties in response to external stimuli such as light, temperature, or electric fields. These adaptive materials hold promise for creating dynamic optical components capable of real-time adjustments in complex photonic systems.

Initially, polysilanes were primarily studied for their photoconductivity and photoluminescence characteristics. These early investigations laid the foundation for understanding the fundamental optical behaviors of polysilanes, including their high refractive indices and nonlinear optical responses. As research progressed, scientists discovered that the optical properties of polysilanes could be finely tuned by modifying their molecular structure and side-chain substituents.

The 1990s marked a significant milestone in polysilane optical evolution with the development of more sophisticated synthesis methods. These advancements allowed for greater control over molecular weight, polydispersity, and structural regularity, leading to polysilanes with enhanced optical performance. During this period, researchers began exploring the potential of polysilanes in various optical applications, including photoresists, optical waveguides, and light-emitting diodes.

The turn of the millennium saw a shift towards integrating polysilanes into more complex optical systems. Hybrid materials combining polysilanes with inorganic components emerged, offering unprecedented control over optical properties. These hybrid materials opened new avenues for creating advanced optical components with tailored refractive indices, optical transparency, and nonlinear optical responses.

In recent years, the focus has shifted towards nanoscale applications of polysilanes in optical component design. The development of polysilane nanostructures, such as nanofibers and nanoparticles, has enabled the creation of novel optical sensors, photonic crystals, and metamaterials. These nanostructured polysilanes exhibit unique optical phenomena, including enhanced light scattering and localized surface plasmon resonance, which are being harnessed for next-generation optical devices.

The latest frontier in polysilane optical evolution involves their integration with other cutting-edge technologies. For instance, researchers are exploring the synergy between polysilanes and two-dimensional materials like graphene to create ultra-thin, flexible optical components. Additionally, the incorporation of polysilanes into quantum dot structures is paving the way for advanced quantum optical devices with tunable emission properties.

As we look to the future, the evolution of polysilanes in optical component design continues to accelerate. Emerging trends include the development of stimuli-responsive polysilane-based optical materials, which can change their optical properties in response to external stimuli such as light, temperature, or electric fields. These adaptive materials hold promise for creating dynamic optical components capable of real-time adjustments in complex photonic systems.

Market Demand Analysis

The market demand for advanced optical components has been experiencing significant growth, driven by the increasing adoption of photonics technologies across various industries. Polysilane, a class of silicon-based polymers, has emerged as a promising material for enhancing the performance and functionality of optical components, thereby addressing the evolving needs of the market.

In the telecommunications sector, the demand for high-speed data transmission and improved network capacity has led to a surge in the development of advanced optical components. Polysilane-based materials offer unique properties that can enhance the efficiency and reliability of optical fibers, waveguides, and other photonic devices. This has resulted in a growing interest from telecom equipment manufacturers and network operators seeking to upgrade their infrastructure to meet the demands of 5G and future communication technologies.

The consumer electronics industry has also shown a keen interest in polysilane-enhanced optical components. With the rise of augmented reality (AR) and virtual reality (VR) technologies, there is an increasing need for high-performance displays and imaging systems. Polysilane's contribution to advanced optical component design has the potential to improve the resolution, brightness, and energy efficiency of these devices, making them more appealing to consumers and driving market growth.

In the automotive sector, the development of advanced driver assistance systems (ADAS) and autonomous vehicles has created a demand for sophisticated optical sensors and LiDAR systems. Polysilane-based materials can enhance the performance of these components, enabling better detection and imaging capabilities in various environmental conditions. This has attracted attention from automotive manufacturers and suppliers looking to improve the safety and functionality of their vehicles.

The healthcare industry has also recognized the potential of polysilane in advanced optical component design. Medical imaging systems, such as endoscopes and microscopes, can benefit from improved optical properties offered by polysilane-based materials. This has led to increased interest from medical device manufacturers seeking to enhance the accuracy and resolution of their diagnostic and surgical equipment.

Furthermore, the aerospace and defense sectors have shown a growing demand for advanced optical components incorporating polysilane technology. Applications such as satellite communications, remote sensing, and surveillance systems require high-performance optical components that can withstand harsh environments. Polysilane's unique properties make it an attractive option for these demanding applications, driving market demand in this sector.

As the global focus on sustainability and energy efficiency intensifies, there is also a rising demand for advanced optical components in the renewable energy sector. Polysilane-based materials can contribute to the development of more efficient solar cells and photovoltaic systems, aligning with the market's need for improved clean energy technologies.

In the telecommunications sector, the demand for high-speed data transmission and improved network capacity has led to a surge in the development of advanced optical components. Polysilane-based materials offer unique properties that can enhance the efficiency and reliability of optical fibers, waveguides, and other photonic devices. This has resulted in a growing interest from telecom equipment manufacturers and network operators seeking to upgrade their infrastructure to meet the demands of 5G and future communication technologies.

The consumer electronics industry has also shown a keen interest in polysilane-enhanced optical components. With the rise of augmented reality (AR) and virtual reality (VR) technologies, there is an increasing need for high-performance displays and imaging systems. Polysilane's contribution to advanced optical component design has the potential to improve the resolution, brightness, and energy efficiency of these devices, making them more appealing to consumers and driving market growth.

In the automotive sector, the development of advanced driver assistance systems (ADAS) and autonomous vehicles has created a demand for sophisticated optical sensors and LiDAR systems. Polysilane-based materials can enhance the performance of these components, enabling better detection and imaging capabilities in various environmental conditions. This has attracted attention from automotive manufacturers and suppliers looking to improve the safety and functionality of their vehicles.

The healthcare industry has also recognized the potential of polysilane in advanced optical component design. Medical imaging systems, such as endoscopes and microscopes, can benefit from improved optical properties offered by polysilane-based materials. This has led to increased interest from medical device manufacturers seeking to enhance the accuracy and resolution of their diagnostic and surgical equipment.

Furthermore, the aerospace and defense sectors have shown a growing demand for advanced optical components incorporating polysilane technology. Applications such as satellite communications, remote sensing, and surveillance systems require high-performance optical components that can withstand harsh environments. Polysilane's unique properties make it an attractive option for these demanding applications, driving market demand in this sector.

As the global focus on sustainability and energy efficiency intensifies, there is also a rising demand for advanced optical components in the renewable energy sector. Polysilane-based materials can contribute to the development of more efficient solar cells and photovoltaic systems, aligning with the market's need for improved clean energy technologies.

Technical Challenges

Polysilane-based materials have shown great promise in advanced optical component design, yet they face several significant technical challenges that need to be addressed for widespread adoption. One of the primary obstacles is the inherent instability of polysilanes under ambient conditions. These materials are highly sensitive to UV light and oxygen, which can lead to rapid degradation of their optical properties. This sensitivity limits their practical applications and poses difficulties in manufacturing, storage, and long-term use of optical components.

Another major challenge lies in controlling the molecular weight and polydispersity of polysilanes. The optical and electronic properties of these materials are closely tied to their molecular structure, and achieving precise control over these parameters is crucial for consistent performance in optical devices. Current synthesis methods often result in a wide distribution of molecular weights, which can lead to inconsistent optical properties across batches.

The integration of polysilanes into existing optical component manufacturing processes presents additional hurdles. Many conventional fabrication techniques are not directly compatible with polysilane materials, necessitating the development of new processing methods. This includes challenges in creating uniform thin films, patterning at the micro and nanoscale, and ensuring good adhesion to various substrates without compromising the material's optical properties.

Thermal stability is another area of concern for polysilane-based optical components. Many applications require materials that can withstand elevated temperatures without significant changes in their optical characteristics. However, polysilanes tend to undergo structural changes at relatively low temperatures, which can alter their refractive index and other optical properties. This thermal sensitivity limits their use in high-temperature environments and complicates their integration with other materials in complex optical systems.

Furthermore, achieving high optical quality in polysilane-based components remains a significant challenge. Impurities, structural defects, and inhomogeneities in the material can lead to scattering, absorption, and other optical losses. Developing purification and processing techniques that can produce high-quality, optically transparent polysilane materials at scale is crucial for their adoption in advanced optical applications.

Lastly, the environmental impact and safety concerns associated with polysilane synthesis and processing need to be addressed. Many of the precursors and solvents used in polysilane production are toxic or environmentally harmful. Developing greener synthesis routes and safer handling procedures is essential for the sustainable development and widespread use of polysilane-based optical components.

Another major challenge lies in controlling the molecular weight and polydispersity of polysilanes. The optical and electronic properties of these materials are closely tied to their molecular structure, and achieving precise control over these parameters is crucial for consistent performance in optical devices. Current synthesis methods often result in a wide distribution of molecular weights, which can lead to inconsistent optical properties across batches.

The integration of polysilanes into existing optical component manufacturing processes presents additional hurdles. Many conventional fabrication techniques are not directly compatible with polysilane materials, necessitating the development of new processing methods. This includes challenges in creating uniform thin films, patterning at the micro and nanoscale, and ensuring good adhesion to various substrates without compromising the material's optical properties.

Thermal stability is another area of concern for polysilane-based optical components. Many applications require materials that can withstand elevated temperatures without significant changes in their optical characteristics. However, polysilanes tend to undergo structural changes at relatively low temperatures, which can alter their refractive index and other optical properties. This thermal sensitivity limits their use in high-temperature environments and complicates their integration with other materials in complex optical systems.

Furthermore, achieving high optical quality in polysilane-based components remains a significant challenge. Impurities, structural defects, and inhomogeneities in the material can lead to scattering, absorption, and other optical losses. Developing purification and processing techniques that can produce high-quality, optically transparent polysilane materials at scale is crucial for their adoption in advanced optical applications.

Lastly, the environmental impact and safety concerns associated with polysilane synthesis and processing need to be addressed. Many of the precursors and solvents used in polysilane production are toxic or environmentally harmful. Developing greener synthesis routes and safer handling procedures is essential for the sustainable development and widespread use of polysilane-based optical components.

Current Polysilane Solutions

01 Optical properties of polysilane films

Polysilane films exhibit unique optical properties, including high transparency and refractive index. These properties make them suitable for various optical applications, such as waveguides and optical coatings. The optical characteristics can be tuned by modifying the molecular structure and composition of the polysilane.- Optical properties of polysilane films: Polysilane films exhibit unique optical properties, including high transparency and refractive index. These properties make them suitable for various optical applications, such as waveguides and optical coatings. The optical characteristics can be tuned by modifying the molecular structure and composition of the polysilane.

- Polysilane-based optical sensors: Polysilanes can be used to develop optical sensors due to their sensitivity to environmental changes. These sensors can detect various stimuli, such as temperature, pressure, or chemical presence, through changes in their optical properties. The high sensitivity and rapid response of polysilane-based sensors make them valuable for real-time monitoring applications.

- Photoluminescence of polysilanes: Polysilanes exhibit photoluminescent properties, emitting light when excited by specific wavelengths. This characteristic makes them suitable for use in light-emitting devices and displays. The photoluminescence can be tailored by adjusting the molecular structure and incorporating various substituents into the polysilane backbone.

- Nonlinear optical properties of polysilanes: Polysilanes demonstrate nonlinear optical properties, making them potential candidates for applications in optical signal processing and photonic devices. These properties arise from the delocalized electronic structure along the silicon backbone and can be enhanced through molecular design and the incorporation of specific functional groups.

- Polysilane-based optical waveguides: Polysilanes can be used to fabricate optical waveguides due to their high refractive index and transparency. These waveguides can be integrated into photonic circuits and devices for applications in optical communication and sensing. The properties of polysilane waveguides can be optimized through careful control of the material composition and processing conditions.

02 Nonlinear optical properties of polysilanes

Polysilanes demonstrate significant nonlinear optical properties, including high third-order nonlinear susceptibility. These properties make them promising materials for applications in optical switching, optical limiting, and other photonic devices. The nonlinear optical response can be enhanced by incorporating specific functional groups or dopants into the polysilane structure.Expand Specific Solutions03 Photoluminescence and electroluminescence of polysilanes

Polysilanes exhibit photoluminescence and electroluminescence properties, making them suitable for light-emitting applications. The emission wavelength can be tuned by modifying the polysilane structure or incorporating chromophores. These properties are particularly useful in the development of organic light-emitting diodes (OLEDs) and other optoelectronic devices.Expand Specific Solutions04 Optical sensing applications of polysilanes

The optical properties of polysilanes can be utilized for sensing applications. Changes in the optical characteristics of polysilanes in response to external stimuli, such as temperature, pressure, or chemical species, make them suitable for developing optical sensors. These sensors can be used in various fields, including environmental monitoring and biomedical diagnostics.Expand Specific Solutions05 Polysilane-based optical waveguides and photonic devices

Polysilanes can be used to fabricate optical waveguides and other photonic devices due to their unique optical properties. The high refractive index and transparency of polysilanes make them suitable for creating low-loss waveguides and optical interconnects. Additionally, their nonlinear optical properties can be exploited for developing active photonic devices, such as optical switches and modulators.Expand Specific Solutions

Key Industry Players

The polysilane technology for advanced optical component design is in a nascent stage of development, with a growing market potential driven by increasing demand for high-performance optical materials. The competitive landscape is characterized by a mix of established chemical companies and emerging specialized firms. Key players like Shin-Etsu Chemical, JSR Corp., and Nissan Chemical are leveraging their expertise in materials science to develop innovative polysilane-based solutions. The technology's maturity is still evolving, with ongoing research at institutions like the Chinese Academy of Science Institute of Chemistry and Wuhan University contributing to advancements. As the field progresses, collaborations between industry and academia are likely to accelerate commercialization efforts and expand applications in optoelectronics and photonics.

JSR Corp.

Technical Solution: JSR Corporation has made significant contributions to advanced optical component design through its innovative polysilane-based materials. The company has developed a range of functionalized polysilanes with tailored optical and electronic properties[1]. These materials feature high transparency in the visible and near-infrared regions, making them suitable for various optical applications[2]. JSR's polysilane photoresists offer high resolution and sensitivity for next-generation lithography processes[3]. Additionally, the company has introduced polysilane-organic hybrid materials that combine the processability of organic polymers with the unique optoelectronic properties of polysilanes, enabling the fabrication of flexible optical devices[4]. Recent research has focused on polysilane-based quantum dot composites for enhanced light emission in display technologies[5].

Strengths: Diverse product portfolio, high-performance materials for cutting-edge applications. Weaknesses: Complex synthesis processes may lead to higher production costs.

Nissan Chemical Corp.

Technical Solution: Nissan Chemical has contributed to advanced optical component design through its polysilane research and development. The company has pioneered the synthesis of hyperbranched polysilanes, which offer unique three-dimensional structures and enhanced optical properties compared to linear polysilanes[1]. These materials exhibit high refractive indices and excellent transparency, making them suitable for anti-reflective coatings and optical waveguides[2]. Nissan Chemical has also developed photo-responsive polysilanes that undergo reversible changes in optical properties upon exposure to specific wavelengths of light, enabling applications in optical switching and data storage[3]. Recent innovations include the integration of polysilanes into organic light-emitting diodes (OLEDs) to improve electron transport and device efficiency[4].

Strengths: Innovative molecular designs, materials with responsive optical properties. Weaknesses: Limited scalability for some specialized polysilane structures.

Polysilane Innovations

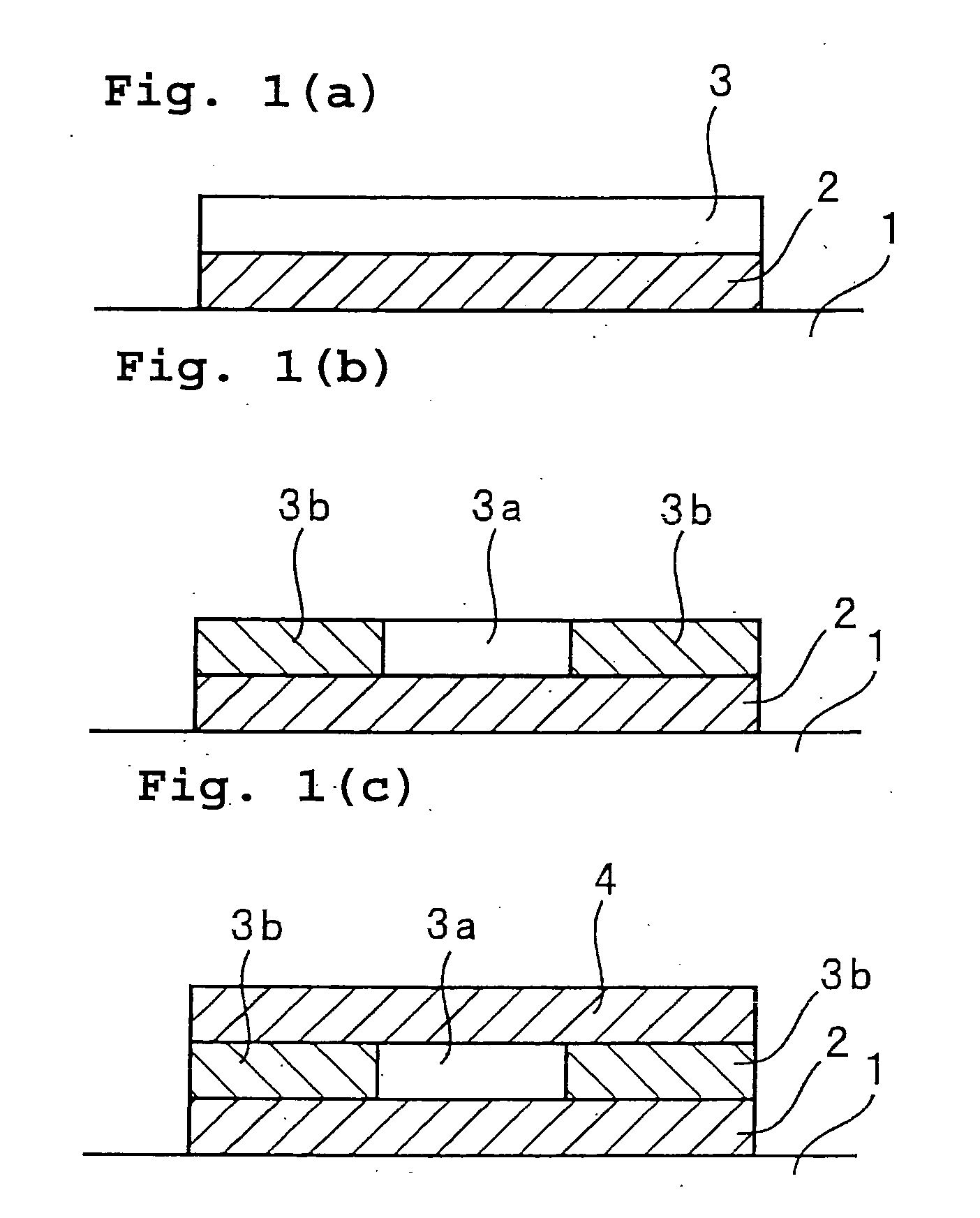

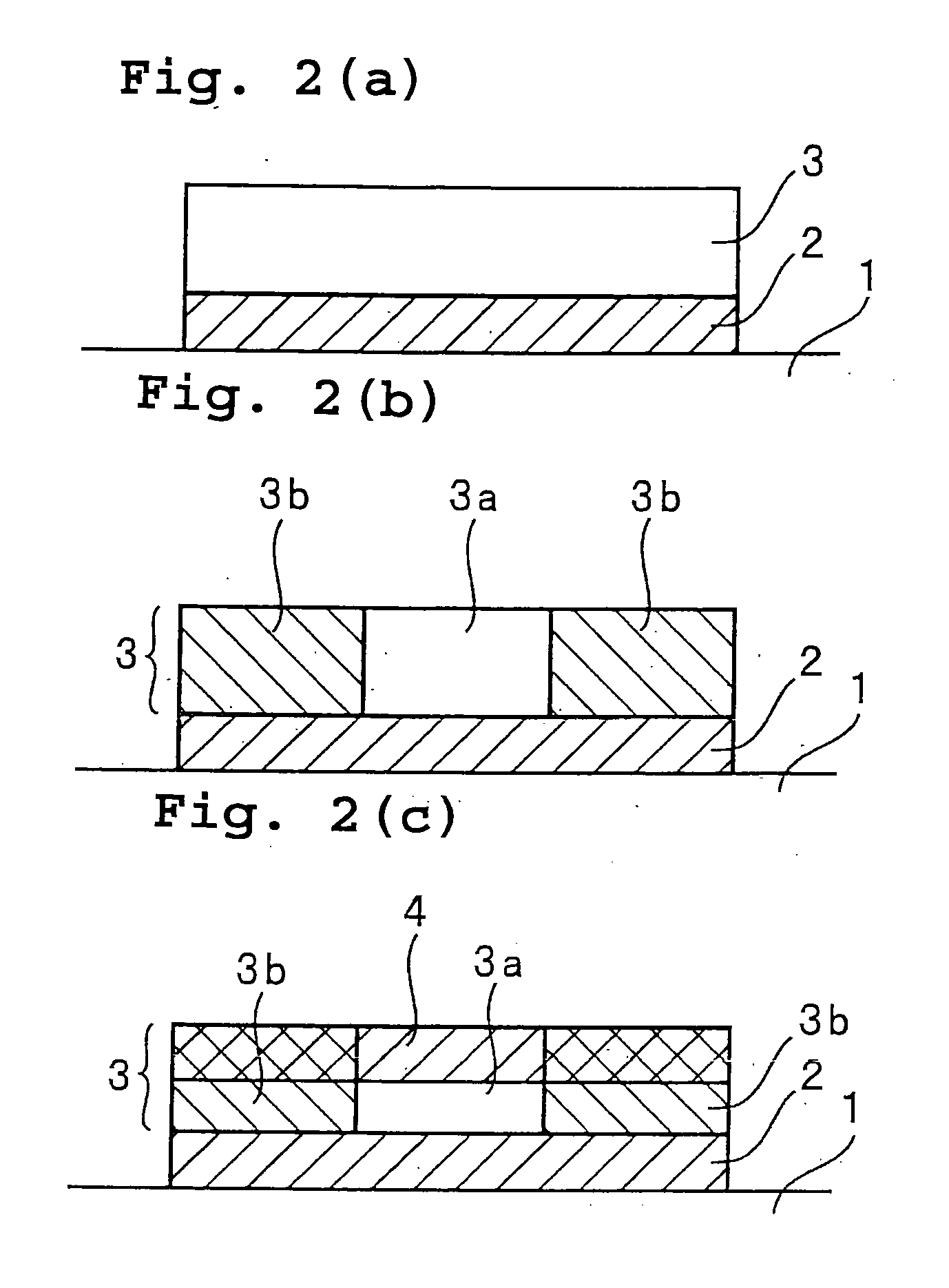

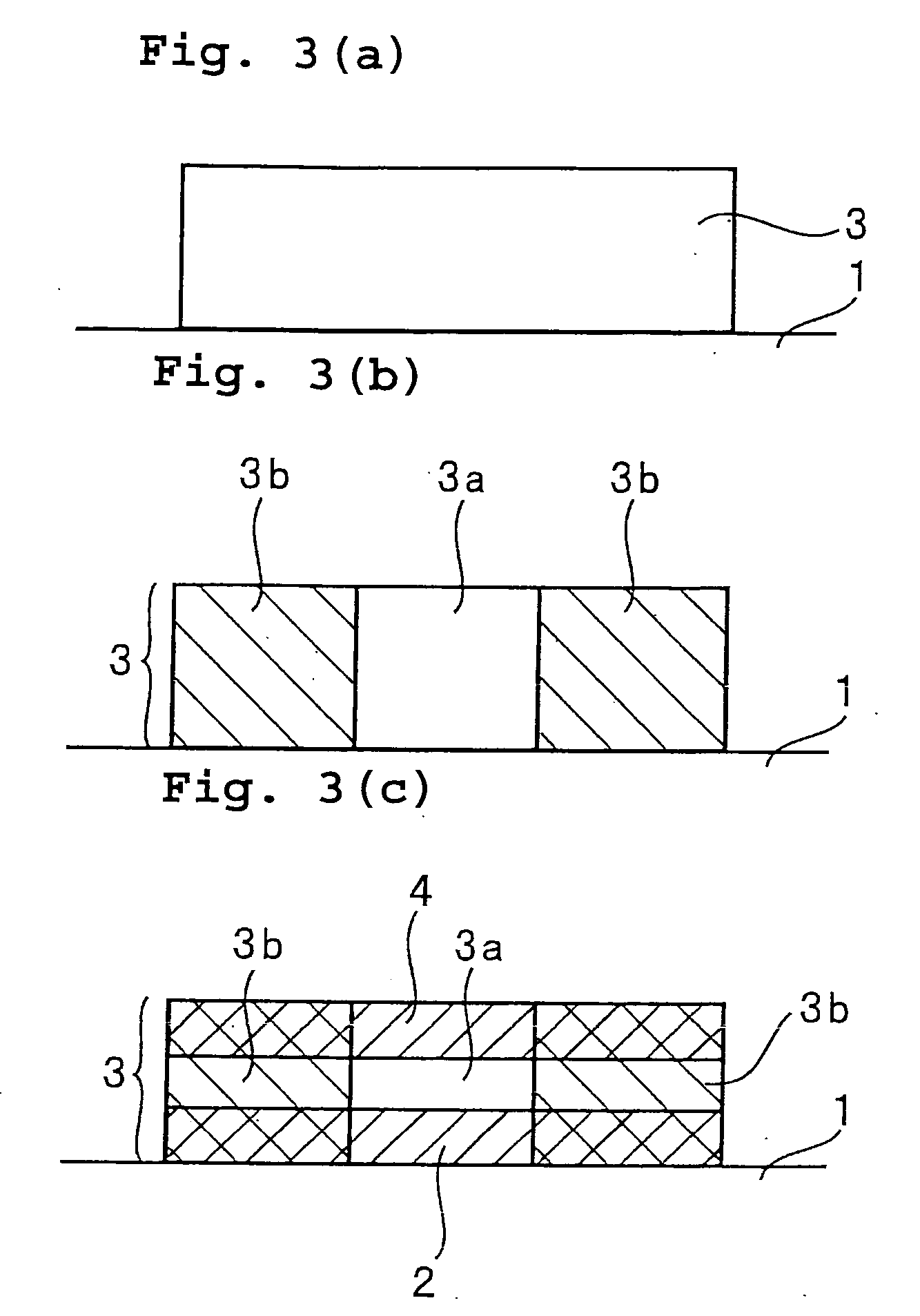

Polysilane composition, optical waveguide and method for fabrication thereof

PatentInactiveUS20060240269A1

Innovation

- A polysilane composition containing a polysilane compound and a double bond-containing silicone compound in a 80:20-95 weight ratio, with an organic peroxide, where the silicone compound accounts for 40-100% by weight, allowing for ultraviolet radiation-induced conversion to a shape-retaining lateral cladding layer, optimizing core shape and minimizing losses.

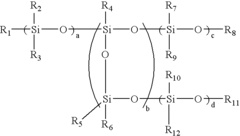

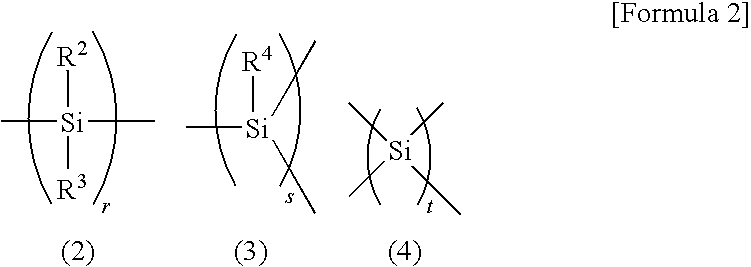

Polysilane and polysilane-containing resin composition

PatentInactiveUS20090156775A1

Innovation

- Introducing a Si—H group into the polysilane main chain and bonding a hydrosilylatable compound with functional groups, such as hydroxyl or carboxyl groups, to enhance solubility and reactivity, allowing for controlled functionality and solubility adjustments through hydrosilylation.

Material Safety Regulations

The development and application of polysilanes in advanced optical component design necessitates careful consideration of material safety regulations. These regulations are crucial for ensuring the safe handling, use, and disposal of polysilanes throughout their lifecycle, from research and development to manufacturing and end-use applications.

Polysilanes, being silicon-based polymers, are subject to various safety regulations that govern the use of silicon-containing materials. The Occupational Safety and Health Administration (OSHA) in the United States, for instance, has established specific guidelines for the handling of silicon-based compounds, including exposure limits and protective measures for workers. Similarly, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes strict requirements on the registration and assessment of chemical substances, including polysilanes.

In the context of optical component design, material safety regulations often focus on the potential health and environmental impacts of polysilanes. These materials may release silane gas during processing or degradation, which is highly flammable and potentially toxic. As a result, regulations typically mandate proper ventilation systems, gas detection equipment, and emergency response protocols in facilities where polysilanes are used or produced.

Environmental considerations also play a significant role in material safety regulations for polysilanes. Many jurisdictions require comprehensive environmental impact assessments and waste management plans for facilities working with these materials. This includes proper disposal methods for polysilane waste and measures to prevent environmental contamination.

The use of polysilanes in optical components intended for consumer products introduces additional regulatory considerations. Product safety standards, such as those set by the International Electrotechnical Commission (IEC) or the Underwriters Laboratories (UL), may impose specific requirements on the use of polysilanes in optical devices. These standards often address issues such as flammability, toxicity, and long-term stability of materials used in consumer electronics.

As the field of advanced optical component design evolves, regulatory bodies are continually updating their guidelines to address new applications and potential risks associated with polysilanes. Researchers and manufacturers must stay informed about these evolving regulations and adapt their practices accordingly. This may involve ongoing safety assessments, regular employee training, and the implementation of new safety technologies as they become available.

Compliance with material safety regulations not only ensures legal and ethical operation but also contributes to the overall sustainability and public acceptance of polysilane-based optical technologies. As such, adherence to these regulations should be viewed as an integral part of the research, development, and commercialization process for advanced optical components utilizing polysilanes.

Polysilanes, being silicon-based polymers, are subject to various safety regulations that govern the use of silicon-containing materials. The Occupational Safety and Health Administration (OSHA) in the United States, for instance, has established specific guidelines for the handling of silicon-based compounds, including exposure limits and protective measures for workers. Similarly, the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) regulation imposes strict requirements on the registration and assessment of chemical substances, including polysilanes.

In the context of optical component design, material safety regulations often focus on the potential health and environmental impacts of polysilanes. These materials may release silane gas during processing or degradation, which is highly flammable and potentially toxic. As a result, regulations typically mandate proper ventilation systems, gas detection equipment, and emergency response protocols in facilities where polysilanes are used or produced.

Environmental considerations also play a significant role in material safety regulations for polysilanes. Many jurisdictions require comprehensive environmental impact assessments and waste management plans for facilities working with these materials. This includes proper disposal methods for polysilane waste and measures to prevent environmental contamination.

The use of polysilanes in optical components intended for consumer products introduces additional regulatory considerations. Product safety standards, such as those set by the International Electrotechnical Commission (IEC) or the Underwriters Laboratories (UL), may impose specific requirements on the use of polysilanes in optical devices. These standards often address issues such as flammability, toxicity, and long-term stability of materials used in consumer electronics.

As the field of advanced optical component design evolves, regulatory bodies are continually updating their guidelines to address new applications and potential risks associated with polysilanes. Researchers and manufacturers must stay informed about these evolving regulations and adapt their practices accordingly. This may involve ongoing safety assessments, regular employee training, and the implementation of new safety technologies as they become available.

Compliance with material safety regulations not only ensures legal and ethical operation but also contributes to the overall sustainability and public acceptance of polysilane-based optical technologies. As such, adherence to these regulations should be viewed as an integral part of the research, development, and commercialization process for advanced optical components utilizing polysilanes.

Eco-friendly Synthesis

The eco-friendly synthesis of polysilanes represents a crucial aspect in the development of advanced optical components. Traditional methods for polysilane production often involve energy-intensive processes and the use of hazardous chemicals, which pose significant environmental concerns. However, recent advancements in green chemistry have paved the way for more sustainable approaches to polysilane synthesis.

One promising eco-friendly method involves the use of catalytic dehydrogenative coupling of primary silanes. This process eliminates the need for harsh reducing agents and operates under milder conditions, significantly reducing energy consumption and waste generation. The catalysts employed in this method are typically transition metal complexes, which can be recycled and reused, further enhancing the sustainability of the process.

Another innovative approach is the electrochemical synthesis of polysilanes. This method utilizes electricity as the primary driving force for the polymerization reaction, eliminating the need for chemical oxidants or reductants. The electrochemical process can be conducted at room temperature and atmospheric pressure, minimizing energy requirements and improving overall efficiency.

Photochemical synthesis has also emerged as a green alternative for polysilane production. This method harnesses the power of light to initiate and propagate the polymerization reaction. By utilizing renewable solar energy, photochemical synthesis offers a sustainable pathway for polysilane production with minimal environmental impact.

Microwave-assisted synthesis is another eco-friendly technique gaining traction in polysilane production. This method provides rapid and efficient heating, reducing reaction times and energy consumption compared to conventional heating methods. The precise control over reaction conditions afforded by microwave technology also leads to improved product quality and reduced waste generation.

Recent research has also focused on the development of biocatalytic approaches for polysilane synthesis. Enzymes derived from microorganisms have shown promise in catalyzing silicon-carbon bond formation under mild, aqueous conditions. This bio-inspired approach not only reduces the environmental footprint of polysilane production but also opens up new possibilities for the synthesis of novel silicon-based materials.

As the demand for advanced optical components continues to grow, the importance of eco-friendly polysilane synthesis cannot be overstated. These sustainable methods not only address environmental concerns but also offer potential cost savings and improved product quality. The ongoing research in this field is likely to yield further innovations, driving the development of more efficient and environmentally benign processes for polysilane production.

One promising eco-friendly method involves the use of catalytic dehydrogenative coupling of primary silanes. This process eliminates the need for harsh reducing agents and operates under milder conditions, significantly reducing energy consumption and waste generation. The catalysts employed in this method are typically transition metal complexes, which can be recycled and reused, further enhancing the sustainability of the process.

Another innovative approach is the electrochemical synthesis of polysilanes. This method utilizes electricity as the primary driving force for the polymerization reaction, eliminating the need for chemical oxidants or reductants. The electrochemical process can be conducted at room temperature and atmospheric pressure, minimizing energy requirements and improving overall efficiency.

Photochemical synthesis has also emerged as a green alternative for polysilane production. This method harnesses the power of light to initiate and propagate the polymerization reaction. By utilizing renewable solar energy, photochemical synthesis offers a sustainable pathway for polysilane production with minimal environmental impact.

Microwave-assisted synthesis is another eco-friendly technique gaining traction in polysilane production. This method provides rapid and efficient heating, reducing reaction times and energy consumption compared to conventional heating methods. The precise control over reaction conditions afforded by microwave technology also leads to improved product quality and reduced waste generation.

Recent research has also focused on the development of biocatalytic approaches for polysilane synthesis. Enzymes derived from microorganisms have shown promise in catalyzing silicon-carbon bond formation under mild, aqueous conditions. This bio-inspired approach not only reduces the environmental footprint of polysilane production but also opens up new possibilities for the synthesis of novel silicon-based materials.

As the demand for advanced optical components continues to grow, the importance of eco-friendly polysilane synthesis cannot be overstated. These sustainable methods not only address environmental concerns but also offer potential cost savings and improved product quality. The ongoing research in this field is likely to yield further innovations, driving the development of more efficient and environmentally benign processes for polysilane production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!