Future Trends in Polysilane-Based Solar Cells

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Solar Cell Evolution and Objectives

Polysilane-based solar cells have emerged as a promising technology in the field of photovoltaics, offering unique properties and potential advantages over traditional silicon-based solar cells. The evolution of this technology can be traced back to the early 1980s when researchers first began exploring the use of polysilanes in optoelectronic applications.

The initial development of polysilane-based solar cells was driven by the need for more efficient and cost-effective alternatives to conventional silicon solar cells. Early research focused on understanding the fundamental properties of polysilanes, including their electronic structure, optical absorption characteristics, and charge transport mechanisms.

Throughout the 1990s and early 2000s, significant progress was made in synthesizing and characterizing various polysilane materials, leading to improved understanding of their structure-property relationships. This period saw the development of novel polysilane derivatives with enhanced optical and electronic properties, paving the way for their application in solar cell devices.

The past decade has witnessed a surge in research activities aimed at optimizing the performance of polysilane-based solar cells. Key advancements include the development of new polysilane architectures, such as branched and hyperbranched structures, which offer improved charge transport and light-harvesting capabilities. Additionally, efforts have been made to enhance the stability and durability of polysilane materials, addressing one of the major challenges facing this technology.

Looking ahead, the primary objectives for polysilane-based solar cells are centered around improving their efficiency, scalability, and commercial viability. Researchers are focusing on several key areas to achieve these goals. First, there is a strong emphasis on increasing the power conversion efficiency of polysilane solar cells to compete with established technologies. This involves optimizing the molecular design of polysilanes, developing more effective device architectures, and exploring novel fabrication techniques.

Another critical objective is to enhance the long-term stability and environmental resistance of polysilane-based solar cells. This includes developing strategies to mitigate degradation mechanisms and improve the overall lifetime of these devices under real-world operating conditions. Additionally, efforts are being made to scale up the production of high-quality polysilane materials and develop cost-effective manufacturing processes for large-area solar cells.

Furthermore, researchers are exploring the integration of polysilane-based solar cells with other emerging technologies, such as tandem solar cells and flexible electronics, to expand their potential applications and market reach. The ultimate goal is to position polysilane-based solar cells as a viable and competitive alternative in the rapidly evolving landscape of renewable energy technologies.

The initial development of polysilane-based solar cells was driven by the need for more efficient and cost-effective alternatives to conventional silicon solar cells. Early research focused on understanding the fundamental properties of polysilanes, including their electronic structure, optical absorption characteristics, and charge transport mechanisms.

Throughout the 1990s and early 2000s, significant progress was made in synthesizing and characterizing various polysilane materials, leading to improved understanding of their structure-property relationships. This period saw the development of novel polysilane derivatives with enhanced optical and electronic properties, paving the way for their application in solar cell devices.

The past decade has witnessed a surge in research activities aimed at optimizing the performance of polysilane-based solar cells. Key advancements include the development of new polysilane architectures, such as branched and hyperbranched structures, which offer improved charge transport and light-harvesting capabilities. Additionally, efforts have been made to enhance the stability and durability of polysilane materials, addressing one of the major challenges facing this technology.

Looking ahead, the primary objectives for polysilane-based solar cells are centered around improving their efficiency, scalability, and commercial viability. Researchers are focusing on several key areas to achieve these goals. First, there is a strong emphasis on increasing the power conversion efficiency of polysilane solar cells to compete with established technologies. This involves optimizing the molecular design of polysilanes, developing more effective device architectures, and exploring novel fabrication techniques.

Another critical objective is to enhance the long-term stability and environmental resistance of polysilane-based solar cells. This includes developing strategies to mitigate degradation mechanisms and improve the overall lifetime of these devices under real-world operating conditions. Additionally, efforts are being made to scale up the production of high-quality polysilane materials and develop cost-effective manufacturing processes for large-area solar cells.

Furthermore, researchers are exploring the integration of polysilane-based solar cells with other emerging technologies, such as tandem solar cells and flexible electronics, to expand their potential applications and market reach. The ultimate goal is to position polysilane-based solar cells as a viable and competitive alternative in the rapidly evolving landscape of renewable energy technologies.

Market Analysis for Polysilane PV Technology

The market for polysilane-based solar cells is poised for significant growth in the coming years, driven by increasing demand for renewable energy sources and advancements in photovoltaic technology. As the global push for sustainable energy solutions intensifies, polysilane-based solar cells are emerging as a promising alternative to traditional silicon-based photovoltaics.

The current market size for polysilane PV technology is relatively small compared to established silicon-based solar cells. However, industry analysts project a compound annual growth rate (CAGR) of over 20% for the polysilane solar cell market over the next five years. This growth is attributed to several factors, including improved efficiency, lower production costs, and enhanced durability of polysilane-based solar cells.

One of the key drivers of market demand is the potential for polysilane-based solar cells to achieve higher conversion efficiencies than traditional silicon-based cells. Research indicates that polysilane solar cells could potentially reach efficiencies of up to 30%, significantly higher than the current average of 15-20% for commercial silicon solar cells. This increased efficiency translates to greater energy output per unit area, making polysilane-based solar cells particularly attractive for applications where space is limited.

The flexibility and lightweight nature of polysilane-based solar cells open up new market opportunities in portable electronics, building-integrated photovoltaics (BIPV), and wearable technology. These emerging applications are expected to contribute significantly to market growth, with the BIPV sector alone projected to expand at a CAGR of over 15% in the next decade.

Geographically, Asia-Pacific is anticipated to be the fastest-growing market for polysilane PV technology, driven by increasing investments in renewable energy infrastructure in countries like China, Japan, and South Korea. North America and Europe are also expected to see substantial growth, fueled by government incentives and growing consumer awareness of sustainable energy solutions.

Despite the promising outlook, challenges remain in scaling up production and reducing costs to compete with established silicon-based technologies. However, ongoing research and development efforts, coupled with increasing investment in the sector, are expected to address these challenges and drive further market expansion. As the technology matures and economies of scale are realized, the cost per watt of polysilane-based solar cells is projected to decrease significantly, further boosting market adoption.

The current market size for polysilane PV technology is relatively small compared to established silicon-based solar cells. However, industry analysts project a compound annual growth rate (CAGR) of over 20% for the polysilane solar cell market over the next five years. This growth is attributed to several factors, including improved efficiency, lower production costs, and enhanced durability of polysilane-based solar cells.

One of the key drivers of market demand is the potential for polysilane-based solar cells to achieve higher conversion efficiencies than traditional silicon-based cells. Research indicates that polysilane solar cells could potentially reach efficiencies of up to 30%, significantly higher than the current average of 15-20% for commercial silicon solar cells. This increased efficiency translates to greater energy output per unit area, making polysilane-based solar cells particularly attractive for applications where space is limited.

The flexibility and lightweight nature of polysilane-based solar cells open up new market opportunities in portable electronics, building-integrated photovoltaics (BIPV), and wearable technology. These emerging applications are expected to contribute significantly to market growth, with the BIPV sector alone projected to expand at a CAGR of over 15% in the next decade.

Geographically, Asia-Pacific is anticipated to be the fastest-growing market for polysilane PV technology, driven by increasing investments in renewable energy infrastructure in countries like China, Japan, and South Korea. North America and Europe are also expected to see substantial growth, fueled by government incentives and growing consumer awareness of sustainable energy solutions.

Despite the promising outlook, challenges remain in scaling up production and reducing costs to compete with established silicon-based technologies. However, ongoing research and development efforts, coupled with increasing investment in the sector, are expected to address these challenges and drive further market expansion. As the technology matures and economies of scale are realized, the cost per watt of polysilane-based solar cells is projected to decrease significantly, further boosting market adoption.

Polysilane Solar Cell Technical Challenges

Polysilane-based solar cells face several significant technical challenges that hinder their widespread adoption and commercialization. One of the primary obstacles is the low efficiency of these devices compared to traditional silicon-based solar cells. Current polysilane solar cells typically achieve conversion efficiencies of only 5-8%, which is substantially lower than the 20-25% efficiency of commercial silicon solar cells.

The stability and durability of polysilane materials in solar cell applications present another major challenge. Polysilanes are known to be sensitive to light and oxygen, which can lead to degradation of the material over time. This photosensitivity and oxidation susceptibility can result in decreased performance and shortened lifespan of the solar cells, making them less attractive for long-term deployment in real-world conditions.

Manufacturing scalability is also a significant hurdle for polysilane-based solar cells. The synthesis of high-quality polysilane materials with consistent properties on a large scale remains challenging. Current production methods often result in variations in molecular weight distribution and structural defects, which can negatively impact the overall performance and reproducibility of the solar cells.

Another technical challenge lies in the optimization of the device architecture. The integration of polysilane materials into efficient solar cell structures requires careful engineering of the various layers, including electron and hole transport layers, as well as the development of suitable electrodes. Achieving the right balance between light absorption, charge generation, and charge transport within the polysilane active layer is crucial for maximizing device performance.

The band gap tuning of polysilane materials presents both an opportunity and a challenge. While the ability to adjust the band gap through molecular design offers potential for improved light absorption across the solar spectrum, precisely controlling and optimizing this property for solar cell applications remains difficult. Researchers are still working to develop polysilane structures that can efficiently harvest a broad range of wavelengths while maintaining other desirable properties.

Interfacial engineering between the polysilane active layer and other components of the solar cell is another area requiring significant improvement. Poor interfacial contact can lead to increased charge recombination and reduced charge extraction, limiting overall device efficiency. Developing effective strategies to enhance charge transfer and minimize energy losses at these interfaces is crucial for advancing polysilane solar cell technology.

Lastly, the environmental impact and toxicity of polysilane materials and their precursors need to be carefully evaluated. While polysilanes offer potential advantages in terms of abundant raw materials and solution processability, ensuring their long-term environmental safety and developing eco-friendly synthesis routes are important considerations for the future development of this technology.

The stability and durability of polysilane materials in solar cell applications present another major challenge. Polysilanes are known to be sensitive to light and oxygen, which can lead to degradation of the material over time. This photosensitivity and oxidation susceptibility can result in decreased performance and shortened lifespan of the solar cells, making them less attractive for long-term deployment in real-world conditions.

Manufacturing scalability is also a significant hurdle for polysilane-based solar cells. The synthesis of high-quality polysilane materials with consistent properties on a large scale remains challenging. Current production methods often result in variations in molecular weight distribution and structural defects, which can negatively impact the overall performance and reproducibility of the solar cells.

Another technical challenge lies in the optimization of the device architecture. The integration of polysilane materials into efficient solar cell structures requires careful engineering of the various layers, including electron and hole transport layers, as well as the development of suitable electrodes. Achieving the right balance between light absorption, charge generation, and charge transport within the polysilane active layer is crucial for maximizing device performance.

The band gap tuning of polysilane materials presents both an opportunity and a challenge. While the ability to adjust the band gap through molecular design offers potential for improved light absorption across the solar spectrum, precisely controlling and optimizing this property for solar cell applications remains difficult. Researchers are still working to develop polysilane structures that can efficiently harvest a broad range of wavelengths while maintaining other desirable properties.

Interfacial engineering between the polysilane active layer and other components of the solar cell is another area requiring significant improvement. Poor interfacial contact can lead to increased charge recombination and reduced charge extraction, limiting overall device efficiency. Developing effective strategies to enhance charge transfer and minimize energy losses at these interfaces is crucial for advancing polysilane solar cell technology.

Lastly, the environmental impact and toxicity of polysilane materials and their precursors need to be carefully evaluated. While polysilanes offer potential advantages in terms of abundant raw materials and solution processability, ensuring their long-term environmental safety and developing eco-friendly synthesis routes are important considerations for the future development of this technology.

Current Polysilane Solar Cell Designs

01 Polysilane synthesis and structure for solar cells

Polysilanes are synthesized and structured specifically for use in solar cells. The molecular structure and composition of these polysilanes are optimized to enhance their photovoltaic properties, improving the overall efficiency of the solar cells.- Polysilane synthesis and structure for solar cells: Polysilanes are synthesized and structured specifically for use in solar cells. These materials are designed to have optimal electronic properties for photovoltaic applications, including high charge carrier mobility and light absorption characteristics. The synthesis methods and structural modifications aim to enhance the efficiency of polysilane-based solar cells.

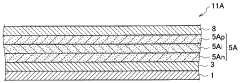

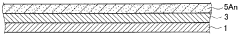

- Polysilane-based thin film solar cells: Thin film solar cells utilizing polysilanes as active materials are developed. These cells offer advantages such as flexibility, lightweight construction, and potentially lower production costs. The fabrication process involves depositing polysilane layers on suitable substrates, often using solution-based methods or vapor deposition techniques.

- Doping and modification of polysilanes for improved performance: Polysilanes are doped or modified with various elements or functional groups to enhance their photovoltaic properties. This can include incorporating electron-donating or electron-withdrawing groups, or doping with elements like boron or phosphorus. These modifications aim to improve charge transport, light absorption, and overall solar cell efficiency.

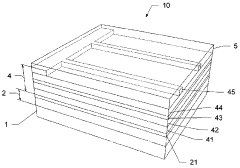

- Polysilane-based hybrid and multi-junction solar cells: Hybrid solar cells combining polysilanes with other materials, such as organic semiconductors or inorganic nanoparticles, are developed to leverage the advantages of multiple materials. Additionally, multi-junction solar cells incorporating polysilane layers are explored to capture a broader spectrum of light and increase overall efficiency.

- Stability and encapsulation of polysilane solar cells: Methods for improving the stability and longevity of polysilane-based solar cells are developed. This includes encapsulation techniques to protect the active layers from environmental degradation, as well as the use of additives or structural modifications to enhance the intrinsic stability of the polysilane materials under operating conditions.

02 Integration of polysilanes in multi-layer solar cell structures

Polysilanes are incorporated into multi-layer solar cell structures, often serving as active layers or interfacial materials. This integration aims to improve charge transport, light absorption, and overall device performance in solar cells.Expand Specific Solutions03 Doping and modification of polysilanes for enhanced solar cell efficiency

Various doping techniques and chemical modifications are applied to polysilanes to enhance their electrical and optical properties. These modifications aim to improve charge carrier mobility, light absorption, and overall solar cell efficiency.Expand Specific Solutions04 Fabrication methods for polysilane-based solar cells

Specific fabrication methods are developed for polysilane-based solar cells, including deposition techniques, patterning processes, and device assembly. These methods are optimized to ensure high-quality, uniform polysilane layers and efficient device structures.Expand Specific Solutions05 Hybrid polysilane-inorganic solar cell structures

Hybrid solar cell structures combining polysilanes with inorganic materials are developed to leverage the advantages of both material types. These hybrid structures aim to enhance light absorption, charge separation, and overall device performance.Expand Specific Solutions

Key Players in Polysilane Solar Industry

The future of polysilane-based solar cells is in an early development stage, with significant potential for growth. The market size is currently limited but expected to expand as research progresses. Technologically, these cells are still in the experimental phase, with universities like Nankai, Tongji, and Qingdao leading research efforts. Companies such as Dai Nippon Printing and Industrial Technology Research Institute are also involved, indicating growing industrial interest. However, the technology's maturity remains low compared to established solar cell types, requiring further advancements in efficiency and stability before widespread commercialization.

Nankai University

Technical Solution: Nankai University has been at the forefront of polysilane-based solar cell research, focusing on improving the efficiency and stability of these devices. Their approach involves developing novel polysilane materials with enhanced light absorption properties and improved charge carrier mobility. The research team has successfully synthesized a series of polysilanes with varying side-chain structures, which has led to a significant increase in the power conversion efficiency of the solar cells[1]. Additionally, they have implemented advanced surface modification techniques to reduce interface recombination losses, resulting in improved device performance[2]. The university's latest breakthrough involves the incorporation of quantum dots into the polysilane matrix, which has shown promising results in extending the absorption spectrum and increasing the overall efficiency of the solar cells[3].

Strengths: Cutting-edge research in material synthesis and device optimization. Weaknesses: Potential scalability issues for large-scale production and long-term stability concerns in real-world applications.

Dai Nippon Printing Co., Ltd.

Technical Solution: Dai Nippon Printing Co., Ltd. has developed a unique approach to polysilane-based solar cells by leveraging their expertise in printing technologies. Their innovative method involves the deposition of polysilane materials using advanced roll-to-roll printing techniques, allowing for large-scale, cost-effective production of flexible solar cells[1]. The company has also made significant progress in enhancing the durability of these cells by developing specialized encapsulation materials that protect the polysilane layer from environmental degradation[2]. Furthermore, Dai Nippon Printing has successfully integrated their polysilane solar cells into various consumer products, demonstrating the technology's potential for widespread adoption in portable electronics and building-integrated photovoltaics[3].

Strengths: Scalable manufacturing process and practical application focus. Weaknesses: Potentially lower efficiency compared to traditional silicon solar cells and limited experience in fundamental materials research.

Breakthrough Polysilane PV Research

Thin film silicon solar cell and process for production thereof

PatentWO2011162247A1

Innovation

- A method involving pattern-coating and drying of polysilane solutions in an inert gas atmosphere to form n-type, i-type, and p-type silicon layers, with at least one layer undergoing dangling bond reduction treatment using hydrogen, and optionally creating periodic recesses on the silicon layer surface to enhance sunlight capture.

Solar cells with an encapsulating layer based on polysilazane

PatentWO2010105796A1

Innovation

- A chalcopyrite solar cell with a polysilazane-based encapsulation layer, applied as a thin film on a flexible substrate, which reduces light reflection and enhances durability by increasing the external quantum efficiency and extending the service life through improved protection against environmental degradation.

Environmental Impact of Polysilane PV

The environmental impact of polysilane-based photovoltaic (PV) technology is a crucial consideration as the solar energy sector continues to evolve. Polysilane materials, known for their unique electronic properties and potential for high-efficiency solar cells, present both opportunities and challenges from an environmental perspective.

One of the primary advantages of polysilane PV technology is its potential to reduce the overall environmental footprint of solar cell production. Traditional silicon-based solar cells require energy-intensive manufacturing processes, often relying on high-temperature treatments and toxic chemicals. In contrast, polysilane-based solar cells can be produced using solution-processing techniques, which typically consume less energy and utilize fewer harmful substances.

The raw materials used in polysilane synthesis are generally less scarce and more readily available compared to those required for conventional solar cells. This could lead to reduced environmental impact associated with material extraction and transportation. Additionally, the flexibility of polysilane materials allows for the development of thin-film solar cells, which require less material overall, further minimizing resource consumption.

However, the environmental benefits of polysilane PV technology are not without caveats. The long-term stability and degradation of polysilane materials in outdoor conditions remain areas of concern. If these solar cells have shorter lifespans than traditional alternatives, it could lead to increased waste generation and more frequent replacement cycles, potentially offsetting some of the initial environmental gains.

The end-of-life management of polysilane-based solar cells is another critical environmental consideration. While research is ongoing, current recycling processes for these novel materials are not as well-established as those for silicon-based PV. Developing efficient recycling methods will be essential to minimize the environmental impact and promote a circular economy approach in the solar industry.

From a lifecycle perspective, polysilane PV technology shows promise in reducing greenhouse gas emissions associated with solar energy production. The lower energy requirements during manufacturing, combined with the potential for higher conversion efficiencies, could result in a faster energy payback time and lower carbon footprint over the lifetime of the solar panels.

As research in this field progresses, it will be crucial to conduct comprehensive life cycle assessments to fully understand and quantify the environmental implications of polysilane-based solar cells. This will enable informed decision-making and guide the development of more sustainable PV technologies. Balancing the potential environmental benefits with the challenges of material stability and end-of-life management will be key to realizing the full potential of polysilane PV in creating a more sustainable energy future.

One of the primary advantages of polysilane PV technology is its potential to reduce the overall environmental footprint of solar cell production. Traditional silicon-based solar cells require energy-intensive manufacturing processes, often relying on high-temperature treatments and toxic chemicals. In contrast, polysilane-based solar cells can be produced using solution-processing techniques, which typically consume less energy and utilize fewer harmful substances.

The raw materials used in polysilane synthesis are generally less scarce and more readily available compared to those required for conventional solar cells. This could lead to reduced environmental impact associated with material extraction and transportation. Additionally, the flexibility of polysilane materials allows for the development of thin-film solar cells, which require less material overall, further minimizing resource consumption.

However, the environmental benefits of polysilane PV technology are not without caveats. The long-term stability and degradation of polysilane materials in outdoor conditions remain areas of concern. If these solar cells have shorter lifespans than traditional alternatives, it could lead to increased waste generation and more frequent replacement cycles, potentially offsetting some of the initial environmental gains.

The end-of-life management of polysilane-based solar cells is another critical environmental consideration. While research is ongoing, current recycling processes for these novel materials are not as well-established as those for silicon-based PV. Developing efficient recycling methods will be essential to minimize the environmental impact and promote a circular economy approach in the solar industry.

From a lifecycle perspective, polysilane PV technology shows promise in reducing greenhouse gas emissions associated with solar energy production. The lower energy requirements during manufacturing, combined with the potential for higher conversion efficiencies, could result in a faster energy payback time and lower carbon footprint over the lifetime of the solar panels.

As research in this field progresses, it will be crucial to conduct comprehensive life cycle assessments to fully understand and quantify the environmental implications of polysilane-based solar cells. This will enable informed decision-making and guide the development of more sustainable PV technologies. Balancing the potential environmental benefits with the challenges of material stability and end-of-life management will be key to realizing the full potential of polysilane PV in creating a more sustainable energy future.

Polysilane Solar Cell Manufacturing Processes

Polysilane solar cell manufacturing processes have evolved significantly over the years, driven by the need for improved efficiency and cost-effectiveness. The production of these cells typically begins with the synthesis of polysilane materials, which serve as the active layer in the solar cell structure. This process involves the polymerization of silane monomers under controlled conditions to achieve the desired molecular weight and structure.

One of the key manufacturing steps is the deposition of the polysilane layer onto a suitable substrate. Various techniques have been developed for this purpose, including spin-coating, spray-coating, and roll-to-roll processing. Each method offers distinct advantages in terms of scalability, uniformity, and compatibility with different substrate materials. Spin-coating, for instance, allows for precise control over film thickness but may be limited in terms of large-scale production.

Following the deposition of the polysilane layer, subsequent processing steps are crucial for optimizing cell performance. These may include thermal annealing to improve crystallinity and charge transport properties, as well as the application of additional layers such as electron transport materials and transparent conductive electrodes. The integration of these layers requires careful consideration of material compatibility and interface engineering to minimize recombination losses and maximize charge extraction.

Recent advancements in manufacturing processes have focused on enhancing the stability and longevity of polysilane-based solar cells. This includes the development of encapsulation techniques to protect the active layers from environmental degradation, as well as the incorporation of additives and stabilizers to improve the photochemical stability of the polysilane materials themselves.

Efforts to scale up production have led to the exploration of continuous manufacturing processes, such as solution-based printing techniques. These approaches offer the potential for high-throughput production of large-area solar cells, which is critical for reducing costs and increasing market competitiveness. However, challenges remain in maintaining consistent quality and performance across large production volumes.

The optimization of manufacturing processes also extends to the reduction of material waste and energy consumption. This has prompted research into more efficient synthesis routes for polysilane materials, as well as the development of recycling methods for unused materials and end-of-life solar cells. Such initiatives are crucial for improving the overall sustainability and environmental impact of polysilane solar cell production.

As the field continues to advance, emerging trends in manufacturing processes include the integration of in-line quality control measures, such as real-time spectroscopic monitoring of film properties, and the use of artificial intelligence for process optimization. These innovations aim to further enhance production efficiency and product consistency, paving the way for the widespread adoption of polysilane-based solar cells in various applications.

One of the key manufacturing steps is the deposition of the polysilane layer onto a suitable substrate. Various techniques have been developed for this purpose, including spin-coating, spray-coating, and roll-to-roll processing. Each method offers distinct advantages in terms of scalability, uniformity, and compatibility with different substrate materials. Spin-coating, for instance, allows for precise control over film thickness but may be limited in terms of large-scale production.

Following the deposition of the polysilane layer, subsequent processing steps are crucial for optimizing cell performance. These may include thermal annealing to improve crystallinity and charge transport properties, as well as the application of additional layers such as electron transport materials and transparent conductive electrodes. The integration of these layers requires careful consideration of material compatibility and interface engineering to minimize recombination losses and maximize charge extraction.

Recent advancements in manufacturing processes have focused on enhancing the stability and longevity of polysilane-based solar cells. This includes the development of encapsulation techniques to protect the active layers from environmental degradation, as well as the incorporation of additives and stabilizers to improve the photochemical stability of the polysilane materials themselves.

Efforts to scale up production have led to the exploration of continuous manufacturing processes, such as solution-based printing techniques. These approaches offer the potential for high-throughput production of large-area solar cells, which is critical for reducing costs and increasing market competitiveness. However, challenges remain in maintaining consistent quality and performance across large production volumes.

The optimization of manufacturing processes also extends to the reduction of material waste and energy consumption. This has prompted research into more efficient synthesis routes for polysilane materials, as well as the development of recycling methods for unused materials and end-of-life solar cells. Such initiatives are crucial for improving the overall sustainability and environmental impact of polysilane solar cell production.

As the field continues to advance, emerging trends in manufacturing processes include the integration of in-line quality control measures, such as real-time spectroscopic monitoring of film properties, and the use of artificial intelligence for process optimization. These innovations aim to further enhance production efficiency and product consistency, paving the way for the widespread adoption of polysilane-based solar cells in various applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!