Strategic Perspectives on Polysilane Evolution in Tech Sector

JUL 11, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polysilane Tech Evolution

Polysilanes have emerged as a significant class of materials in the tech sector, with their unique electronic and optical properties driving innovation across multiple industries. The evolution of polysilane technology has been marked by several key milestones and breakthroughs, shaping its current status and future potential.

In the 1980s, researchers first recognized the potential of polysilanes as semiconducting materials, sparking interest in their application in electronic devices. This initial discovery led to intensive research efforts focused on synthesizing and characterizing various polysilane structures. The 1990s saw significant advancements in polymerization techniques, enabling the production of high-molecular-weight polysilanes with improved stability and processability.

The turn of the millennium brought about a shift towards exploring the photophysical properties of polysilanes. Scientists discovered their unique photoluminescence and electroluminescence characteristics, opening up new avenues for application in optoelectronic devices. This period also witnessed the development of novel polysilane-based composite materials, combining the properties of polysilanes with other functional materials to enhance performance and expand potential applications.

In recent years, the focus has shifted towards nanoscale polysilane structures. The advent of nanotechnology has enabled the synthesis of polysilane nanoparticles, nanowires, and thin films, each offering distinct advantages in terms of electronic and optical properties. These nanostructures have shown promise in areas such as solar cells, light-emitting diodes, and chemical sensors.

The most recent developments in polysilane technology have centered on their integration into advanced electronic and photonic devices. Researchers have made significant progress in incorporating polysilanes into organic field-effect transistors, demonstrating their potential as active materials in flexible and printable electronics. Additionally, the exploration of polysilanes in quantum dot technologies has opened up new possibilities in quantum computing and advanced sensing applications.

Looking ahead, the evolution of polysilane technology is expected to continue along several promising trajectories. One area of focus is the development of more efficient and scalable synthesis methods, aimed at producing high-purity polysilanes with precisely controlled structures. Another emerging trend is the exploration of polysilanes in biomedical applications, leveraging their biocompatibility and unique optical properties for imaging and drug delivery systems.

In the 1980s, researchers first recognized the potential of polysilanes as semiconducting materials, sparking interest in their application in electronic devices. This initial discovery led to intensive research efforts focused on synthesizing and characterizing various polysilane structures. The 1990s saw significant advancements in polymerization techniques, enabling the production of high-molecular-weight polysilanes with improved stability and processability.

The turn of the millennium brought about a shift towards exploring the photophysical properties of polysilanes. Scientists discovered their unique photoluminescence and electroluminescence characteristics, opening up new avenues for application in optoelectronic devices. This period also witnessed the development of novel polysilane-based composite materials, combining the properties of polysilanes with other functional materials to enhance performance and expand potential applications.

In recent years, the focus has shifted towards nanoscale polysilane structures. The advent of nanotechnology has enabled the synthesis of polysilane nanoparticles, nanowires, and thin films, each offering distinct advantages in terms of electronic and optical properties. These nanostructures have shown promise in areas such as solar cells, light-emitting diodes, and chemical sensors.

The most recent developments in polysilane technology have centered on their integration into advanced electronic and photonic devices. Researchers have made significant progress in incorporating polysilanes into organic field-effect transistors, demonstrating their potential as active materials in flexible and printable electronics. Additionally, the exploration of polysilanes in quantum dot technologies has opened up new possibilities in quantum computing and advanced sensing applications.

Looking ahead, the evolution of polysilane technology is expected to continue along several promising trajectories. One area of focus is the development of more efficient and scalable synthesis methods, aimed at producing high-purity polysilanes with precisely controlled structures. Another emerging trend is the exploration of polysilanes in biomedical applications, leveraging their biocompatibility and unique optical properties for imaging and drug delivery systems.

Market Demand Analysis

The market demand for polysilane-based technologies has been steadily growing in recent years, driven by advancements in semiconductor manufacturing, photovoltaics, and optoelectronic devices. As the tech sector continues to evolve, polysilanes are emerging as crucial materials for next-generation electronic components and energy solutions.

In the semiconductor industry, polysilanes are gaining traction as potential alternatives to traditional silicon-based materials. Their unique electronic properties and processability make them attractive for developing high-performance transistors and memory devices. The global semiconductor market, valued at over $500 billion, is expected to maintain strong growth, creating significant opportunities for polysilane applications.

The photovoltaic sector represents another major market for polysilanes. As the world shifts towards renewable energy sources, solar panel manufacturers are exploring novel materials to improve efficiency and reduce costs. Polysilanes show promise in enhancing the performance of thin-film solar cells, potentially addressing the limitations of current silicon-based technologies. The global solar energy market, projected to reach $200 billion by 2026, offers substantial growth potential for polysilane-based solutions.

In the field of optoelectronics, polysilanes are finding applications in light-emitting diodes (LEDs), organic light-emitting diodes (OLEDs), and photonic devices. The unique optical properties of polysilanes make them suitable for developing advanced display technologies and optical sensors. With the global display market expected to exceed $150 billion by 2025, the demand for innovative materials like polysilanes is likely to increase significantly.

The automotive industry is also showing interest in polysilane technologies, particularly for the development of advanced batteries and lightweight materials. As electric vehicles gain market share, the demand for high-performance energy storage solutions and lightweight structural components is rising. Polysilanes could play a crucial role in addressing these needs, tapping into the rapidly growing electric vehicle market.

Despite the promising market potential, challenges remain in scaling up polysilane production and optimizing their properties for specific applications. Ongoing research and development efforts are focused on improving synthesis methods, enhancing material stability, and tailoring polysilane structures for diverse technological applications.

As the tech sector continues to evolve, the market demand for polysilanes is expected to grow across multiple industries. Their versatility and unique properties position them as key materials for addressing technological challenges and enabling innovative solutions in electronics, energy, and advanced manufacturing.

In the semiconductor industry, polysilanes are gaining traction as potential alternatives to traditional silicon-based materials. Their unique electronic properties and processability make them attractive for developing high-performance transistors and memory devices. The global semiconductor market, valued at over $500 billion, is expected to maintain strong growth, creating significant opportunities for polysilane applications.

The photovoltaic sector represents another major market for polysilanes. As the world shifts towards renewable energy sources, solar panel manufacturers are exploring novel materials to improve efficiency and reduce costs. Polysilanes show promise in enhancing the performance of thin-film solar cells, potentially addressing the limitations of current silicon-based technologies. The global solar energy market, projected to reach $200 billion by 2026, offers substantial growth potential for polysilane-based solutions.

In the field of optoelectronics, polysilanes are finding applications in light-emitting diodes (LEDs), organic light-emitting diodes (OLEDs), and photonic devices. The unique optical properties of polysilanes make them suitable for developing advanced display technologies and optical sensors. With the global display market expected to exceed $150 billion by 2025, the demand for innovative materials like polysilanes is likely to increase significantly.

The automotive industry is also showing interest in polysilane technologies, particularly for the development of advanced batteries and lightweight materials. As electric vehicles gain market share, the demand for high-performance energy storage solutions and lightweight structural components is rising. Polysilanes could play a crucial role in addressing these needs, tapping into the rapidly growing electric vehicle market.

Despite the promising market potential, challenges remain in scaling up polysilane production and optimizing their properties for specific applications. Ongoing research and development efforts are focused on improving synthesis methods, enhancing material stability, and tailoring polysilane structures for diverse technological applications.

As the tech sector continues to evolve, the market demand for polysilanes is expected to grow across multiple industries. Their versatility and unique properties position them as key materials for addressing technological challenges and enabling innovative solutions in electronics, energy, and advanced manufacturing.

Current Challenges

The polysilane sector currently faces several significant challenges that are shaping its evolution and potential applications in the tech industry. One of the primary obstacles is the complexity of synthesis and processing of polysilanes. The traditional methods of producing these materials often involve harsh conditions, toxic reagents, and low yields, which hinder large-scale production and commercial viability.

Another critical challenge is the stability of polysilanes under ambient conditions. Many polysilane structures are susceptible to oxidation and degradation when exposed to air and moisture, limiting their practical applications in various technological fields. This instability necessitates careful handling and storage, which can increase production costs and complicate integration into existing manufacturing processes.

The optimization of electronic and optical properties of polysilanes remains a significant hurdle. While these materials show promise in areas such as photoresists, semiconductors, and optoelectronic devices, fine-tuning their properties to meet specific performance requirements is still a complex task. Researchers are grappling with controlling factors such as molecular weight, polydispersity, and side-chain structures to achieve desired characteristics consistently.

Environmental concerns and regulatory pressures pose additional challenges to the polysilane industry. The use of certain precursors and solvents in polysilane synthesis may face scrutiny due to their potential environmental impact. This situation is driving the need for greener synthesis routes and more sustainable production methods, which are still in the early stages of development.

The integration of polysilanes into existing manufacturing processes and technologies presents another set of challenges. Many industries have established protocols and equipment optimized for traditional materials, and the introduction of polysilanes may require significant modifications to production lines and quality control procedures. This integration challenge is particularly evident in the semiconductor and electronics industries, where material compatibility and process reliability are crucial.

Cost-effectiveness remains a significant barrier to widespread adoption of polysilane-based technologies. The current production methods and raw materials for high-quality polysilanes are often expensive, making it difficult to compete with established alternatives in many applications. Reducing production costs while maintaining or improving material quality is a key focus for researchers and manufacturers in the field.

Lastly, there is a knowledge gap in understanding the long-term performance and reliability of polysilane-based materials in various applications. Limited data on aging, weathering, and interaction with other materials in complex systems hinders confidence in their use for critical or long-life applications. Addressing this challenge requires extensive testing and real-world trials, which are time-consuming and resource-intensive.

Another critical challenge is the stability of polysilanes under ambient conditions. Many polysilane structures are susceptible to oxidation and degradation when exposed to air and moisture, limiting their practical applications in various technological fields. This instability necessitates careful handling and storage, which can increase production costs and complicate integration into existing manufacturing processes.

The optimization of electronic and optical properties of polysilanes remains a significant hurdle. While these materials show promise in areas such as photoresists, semiconductors, and optoelectronic devices, fine-tuning their properties to meet specific performance requirements is still a complex task. Researchers are grappling with controlling factors such as molecular weight, polydispersity, and side-chain structures to achieve desired characteristics consistently.

Environmental concerns and regulatory pressures pose additional challenges to the polysilane industry. The use of certain precursors and solvents in polysilane synthesis may face scrutiny due to their potential environmental impact. This situation is driving the need for greener synthesis routes and more sustainable production methods, which are still in the early stages of development.

The integration of polysilanes into existing manufacturing processes and technologies presents another set of challenges. Many industries have established protocols and equipment optimized for traditional materials, and the introduction of polysilanes may require significant modifications to production lines and quality control procedures. This integration challenge is particularly evident in the semiconductor and electronics industries, where material compatibility and process reliability are crucial.

Cost-effectiveness remains a significant barrier to widespread adoption of polysilane-based technologies. The current production methods and raw materials for high-quality polysilanes are often expensive, making it difficult to compete with established alternatives in many applications. Reducing production costs while maintaining or improving material quality is a key focus for researchers and manufacturers in the field.

Lastly, there is a knowledge gap in understanding the long-term performance and reliability of polysilane-based materials in various applications. Limited data on aging, weathering, and interaction with other materials in complex systems hinders confidence in their use for critical or long-life applications. Addressing this challenge requires extensive testing and real-world trials, which are time-consuming and resource-intensive.

Existing Tech Solutions

01 Synthesis and properties of polysilanes

Polysilanes are silicon-based polymers with unique electronic and optical properties. They can be synthesized through various methods, including Wurtz coupling of dichlorosilanes. These polymers exhibit interesting characteristics such as photoconductivity and UV absorption, making them suitable for various applications in electronics and materials science.- Synthesis and properties of polysilanes: Polysilanes are synthesized through various methods and exhibit unique properties. These silicon-based polymers have applications in electronics, optics, and materials science due to their electronic and optical characteristics. The synthesis methods and resulting properties can be tailored for specific applications.

- Polysilane-based coatings and films: Polysilanes are used to create coatings and films with specific properties. These coatings can be applied to various substrates to impart characteristics such as improved durability, optical properties, or electrical conductivity. The composition and processing of polysilane-based coatings can be optimized for different applications.

- Polysilanes in photoresist materials: Polysilanes are utilized in photoresist materials for semiconductor manufacturing. Their unique properties make them suitable for lithography processes, allowing for the creation of fine patterns on substrates. The photosensitivity and etch resistance of polysilane-based photoresists can be tailored for specific lithographic requirements.

- Functionalization and modification of polysilanes: Polysilanes can be functionalized or modified to enhance their properties or introduce new functionalities. This includes the incorporation of various side groups, crosslinking, or copolymerization with other materials. These modifications allow for the creation of polysilane-based materials with tailored characteristics for specific applications.

- Polysilanes in energy and electronic applications: Polysilanes have potential applications in energy and electronic devices. Their unique electronic properties make them suitable for use in solar cells, light-emitting diodes, and other optoelectronic devices. Research is ongoing to optimize polysilane-based materials for improved performance in these applications.

02 Applications of polysilanes in coatings and films

Polysilanes can be used to create functional coatings and films with specific properties. These materials can be applied to various substrates to impart characteristics such as improved adhesion, chemical resistance, or optical properties. The versatility of polysilanes allows for their use in diverse applications, including protective coatings and optical films.Expand Specific Solutions03 Polysilanes in photoresist and lithography applications

Polysilanes have found applications in photoresist formulations and lithography processes. Their unique photosensitive properties make them suitable for use in the semiconductor industry for patterning and etching processes. These materials can be tailored to provide high resolution and sensitivity in photolithography applications.Expand Specific Solutions04 Modification and functionalization of polysilanes

Polysilanes can be modified and functionalized to enhance their properties or introduce new functionalities. This can involve the incorporation of various side groups or the creation of copolymers with other materials. Such modifications allow for the fine-tuning of the polymer's electronic, optical, or mechanical properties to suit specific applications.Expand Specific Solutions05 Polysilanes in electronic and optoelectronic devices

The unique electronic properties of polysilanes make them suitable for use in various electronic and optoelectronic devices. They can be employed in the fabrication of solar cells, light-emitting diodes, and other semiconductor devices. The ability to tailor the electronic structure of polysilanes allows for the development of materials with specific conductivity and charge transport properties.Expand Specific Solutions

Key Industry Players

The strategic landscape of polysilane evolution in the tech sector is characterized by a competitive market in its growth phase, with significant potential for expansion. The global market size for polysilanes is projected to increase substantially, driven by their applications in electronics, photovoltaics, and advanced materials. Technologically, polysilanes are in a transitional stage, moving from research to commercial applications. Key players like Air Liquide SA, Wacker Chemie AG, and JSR Corp. are investing heavily in R&D to enhance polysilane properties and production methods. Emerging companies such as Jiangsu Zhongneng Polysilicon Technology Development Co., Ltd. are also making strides in polysilicon technologies, which could impact polysilane development. The involvement of diverse industry leaders suggests a growing recognition of polysilanes' potential across multiple sectors.

JSR Corp.

Technical Solution: JSR Corporation has focused on developing polysilane-based materials for next-generation electronic devices. Their approach involves synthesizing block copolymers containing polysilane segments, which self-assemble into nanostructured materials with tunable electronic properties[5]. JSR has successfully demonstrated the use of these materials in organic light-emitting diodes (OLEDs), achieving improved charge transport and luminescence efficiency[6]. The company has also explored the incorporation of polysilanes into photoresist formulations for extreme ultraviolet (EUV) lithography, enabling the fabrication of semiconductor devices with feature sizes below 5 nm[7]. Furthermore, JSR has investigated the potential of polysilane-based materials in quantum dot displays, leveraging their unique optoelectronic properties to enhance color purity and energy efficiency[8].

Strengths: Innovative applications in display technologies and advanced lithography. Weaknesses: Potential challenges in scaling up production for mass-market adoption and competition from alternative materials.

Wacker Chemie AG

Technical Solution: Wacker Chemie AG has developed advanced polysilane synthesis techniques, focusing on the production of high-purity polysilanes for semiconductor applications. Their process involves controlled polymerization of dichlorosilanes, resulting in polysilanes with precise molecular weight distributions[1]. The company has also pioneered the use of catalytic dehydrocoupling reactions to produce well-defined polysilane structures with enhanced optoelectronic properties[2]. Wacker's polysilanes are utilized in photoresists for lithography, where they serve as high-resolution resist materials capable of sub-10 nm feature sizes[3]. Additionally, they have explored the integration of polysilanes into hybrid organic-inorganic materials for flexible electronics and photovoltaic applications[4].

Strengths: High-purity production, precise molecular weight control, and versatile applications in semiconductors and optoelectronics. Weaknesses: Potentially high production costs and limited scalability for some specialized polysilane structures.

Core Polysilane Patents

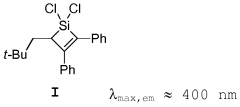

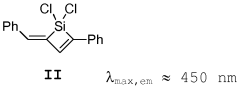

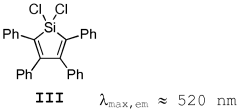

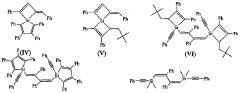

Photoluminescent and/or electroluminescent material, method for production and use thereof and component comprising such a material

PatentWO2013068490A1

Innovation

- Development of polysilanes with stilbene and styrene units that are crosslinked to form stable, moisture-resistant materials with enhanced luminescence efficiency, suitable for use in optoelectronic components.

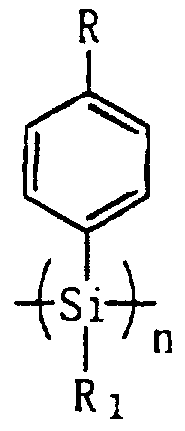

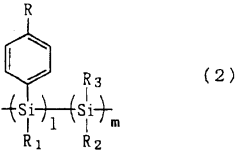

Polysilanes and positive hole transporting materials

PatentWO1997046605A1

Innovation

- The development of novel polysilane compounds with an n-alkyl group in the phenyl side chain, which reduces ionization potential and enhances film-forming properties, allowing for effective hole transport and improved flexibility.

Regulatory Framework

The regulatory framework surrounding polysilanes plays a crucial role in shaping the evolution and adoption of this technology in the tech sector. As polysilanes continue to gain prominence in various applications, governments and regulatory bodies worldwide are developing and refining policies to ensure their safe and responsible use.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) are working to establish global standards for polysilane materials and their applications. These standards aim to provide a common framework for quality control, safety measures, and performance benchmarks across different industries and regions.

In the United States, the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) have taken the lead in regulating polysilane production and usage. The EPA focuses on environmental impact assessments and waste management protocols, while OSHA develops guidelines for worker safety in manufacturing and handling processes.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to polysilanes and their derivatives. This comprehensive framework requires manufacturers and importers to register chemical substances and provide detailed safety information, ensuring a high level of protection for human health and the environment.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks for advanced materials, including polysilanes. These regulations often focus on promoting innovation while maintaining strict safety and environmental standards. China, as a major player in the tech sector, has been developing policies to support the growth of new materials industries, including specific provisions for silicon-based polymers.

As the applications of polysilanes expand into emerging fields such as flexible electronics and advanced photovoltaics, regulatory bodies are adapting their frameworks to address new challenges. This includes developing guidelines for the use of polysilanes in biomedical applications and establishing protocols for the recycling and disposal of polysilane-based products.

The regulatory landscape also encompasses intellectual property rights, with patent offices worldwide developing expertise in polysilane-related innovations. This has led to the establishment of specialized examination procedures and classification systems to handle the increasing number of polysilane patents.

Looking ahead, the regulatory framework for polysilanes is expected to evolve in response to technological advancements and emerging applications. Key areas of focus will likely include nanoscale polysilane materials, integration with other advanced technologies such as artificial intelligence and quantum computing, and the development of circular economy principles for polysilane-based products.

At the international level, organizations such as the International Organization for Standardization (ISO) and the International Electrotechnical Commission (IEC) are working to establish global standards for polysilane materials and their applications. These standards aim to provide a common framework for quality control, safety measures, and performance benchmarks across different industries and regions.

In the United States, the Environmental Protection Agency (EPA) and the Occupational Safety and Health Administration (OSHA) have taken the lead in regulating polysilane production and usage. The EPA focuses on environmental impact assessments and waste management protocols, while OSHA develops guidelines for worker safety in manufacturing and handling processes.

The European Union has implemented the Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) regulation, which applies to polysilanes and their derivatives. This comprehensive framework requires manufacturers and importers to register chemical substances and provide detailed safety information, ensuring a high level of protection for human health and the environment.

In Asia, countries like Japan and South Korea have established their own regulatory frameworks for advanced materials, including polysilanes. These regulations often focus on promoting innovation while maintaining strict safety and environmental standards. China, as a major player in the tech sector, has been developing policies to support the growth of new materials industries, including specific provisions for silicon-based polymers.

As the applications of polysilanes expand into emerging fields such as flexible electronics and advanced photovoltaics, regulatory bodies are adapting their frameworks to address new challenges. This includes developing guidelines for the use of polysilanes in biomedical applications and establishing protocols for the recycling and disposal of polysilane-based products.

The regulatory landscape also encompasses intellectual property rights, with patent offices worldwide developing expertise in polysilane-related innovations. This has led to the establishment of specialized examination procedures and classification systems to handle the increasing number of polysilane patents.

Looking ahead, the regulatory framework for polysilanes is expected to evolve in response to technological advancements and emerging applications. Key areas of focus will likely include nanoscale polysilane materials, integration with other advanced technologies such as artificial intelligence and quantum computing, and the development of circular economy principles for polysilane-based products.

Environmental Impact

The environmental impact of polysilane production and utilization is a critical aspect to consider in the evolution of this technology within the tech sector. Polysilanes, as silicon-based polymers, have shown promising applications in various fields, including electronics, photonics, and energy storage. However, their production and use come with potential environmental consequences that must be carefully evaluated and addressed.

The synthesis of polysilanes typically involves energy-intensive processes and the use of potentially hazardous chemicals. These processes can contribute to increased carbon emissions and the generation of toxic by-products if not properly managed. As the demand for polysilanes grows in the tech sector, there is a pressing need to develop more sustainable and environmentally friendly production methods.

One of the primary environmental concerns associated with polysilanes is their potential for bioaccumulation and persistence in ecosystems. While silicon-based compounds are generally considered less harmful than their carbon-based counterparts, the long-term effects of polysilanes on aquatic and terrestrial environments are not yet fully understood. This uncertainty necessitates further research and monitoring to ensure the safe use and disposal of polysilane-based products.

On the positive side, polysilanes have shown potential in enhancing the efficiency of solar cells and other renewable energy technologies. This application could contribute to the reduction of greenhouse gas emissions by improving the performance of clean energy systems. Additionally, the use of polysilanes in electronic components may lead to more energy-efficient devices, further reducing the overall environmental footprint of the tech sector.

The recyclability and end-of-life management of polysilane-containing products are crucial considerations. As these materials become more prevalent in consumer electronics and other tech applications, developing effective recycling processes and circular economy strategies will be essential to minimize waste and resource depletion. This includes exploring methods for the recovery and reuse of silicon from discarded polysilane-based products.

To address these environmental challenges, the tech sector must invest in research and development focused on green chemistry principles for polysilane production. This includes exploring alternative synthesis routes that use less toxic precursors, require lower energy inputs, and produce fewer waste products. Additionally, life cycle assessments of polysilane-based technologies should be conducted to identify areas for environmental improvement throughout the entire product lifecycle.

The synthesis of polysilanes typically involves energy-intensive processes and the use of potentially hazardous chemicals. These processes can contribute to increased carbon emissions and the generation of toxic by-products if not properly managed. As the demand for polysilanes grows in the tech sector, there is a pressing need to develop more sustainable and environmentally friendly production methods.

One of the primary environmental concerns associated with polysilanes is their potential for bioaccumulation and persistence in ecosystems. While silicon-based compounds are generally considered less harmful than their carbon-based counterparts, the long-term effects of polysilanes on aquatic and terrestrial environments are not yet fully understood. This uncertainty necessitates further research and monitoring to ensure the safe use and disposal of polysilane-based products.

On the positive side, polysilanes have shown potential in enhancing the efficiency of solar cells and other renewable energy technologies. This application could contribute to the reduction of greenhouse gas emissions by improving the performance of clean energy systems. Additionally, the use of polysilanes in electronic components may lead to more energy-efficient devices, further reducing the overall environmental footprint of the tech sector.

The recyclability and end-of-life management of polysilane-containing products are crucial considerations. As these materials become more prevalent in consumer electronics and other tech applications, developing effective recycling processes and circular economy strategies will be essential to minimize waste and resource depletion. This includes exploring methods for the recovery and reuse of silicon from discarded polysilane-based products.

To address these environmental challenges, the tech sector must invest in research and development focused on green chemistry principles for polysilane production. This includes exploring alternative synthesis routes that use less toxic precursors, require lower energy inputs, and produce fewer waste products. Additionally, life cycle assessments of polysilane-based technologies should be conducted to identify areas for environmental improvement throughout the entire product lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!