Analysis of LS Engine Timing Chain vs. Timing Belt Performance

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Timing Evolution

The evolution of timing systems in LS engines represents a significant chapter in automotive engineering, showcasing the continuous pursuit of performance, reliability, and efficiency. Initially introduced in 1997 with the LS1 engine, the LS series has undergone several iterations, each bringing improvements to the timing mechanism.

The first-generation LS engines utilized a timing chain system, a departure from the belt-driven systems common in many contemporary engines. This choice was driven by the need for increased durability and reduced maintenance requirements. The timing chain, constructed from high-strength materials, offered superior longevity compared to rubber timing belts, potentially lasting the entire lifespan of the engine without replacement.

As the LS engine family expanded, so did the refinements to its timing system. The second-generation LS engines, introduced in the early 2000s, featured an updated timing chain design with improved tensioners and guides. These enhancements were aimed at reducing chain slack and minimizing the potential for timing-related issues, further bolstering the system's reliability.

The introduction of variable valve timing (VVT) in later LS engines marked a significant milestone in the evolution of their timing systems. This technology allowed for dynamic adjustment of valve timing, optimizing engine performance across a broader range of operating conditions. The implementation of VVT necessitated further refinements to the timing chain system, including the addition of a cam phaser on the camshaft sprocket.

Throughout its evolution, the LS engine timing system has consistently favored chain-driven designs over belt-driven alternatives. This preference stems from several key advantages offered by timing chains. Firstly, chains exhibit superior strength and durability, reducing the likelihood of catastrophic failure. Secondly, they require less frequent maintenance or replacement, aligning with the LS engine's reputation for reliability and longevity.

However, the evolution of LS engine timing systems has not been without challenges. Early iterations faced issues such as chain stretch and tensioner wear, particularly in high-mileage applications. These concerns prompted ongoing refinements, including the use of more robust chain materials and improved tensioner designs in subsequent generations.

The most recent developments in LS engine timing systems have focused on noise reduction and further improvements in efficiency. Advanced chain designs with optimized tooth profiles and enhanced tensioning mechanisms have been introduced to minimize chain slap and reduce overall engine noise. Additionally, efforts have been made to reduce the parasitic losses associated with the timing drive system, contributing to incremental gains in engine efficiency.

The first-generation LS engines utilized a timing chain system, a departure from the belt-driven systems common in many contemporary engines. This choice was driven by the need for increased durability and reduced maintenance requirements. The timing chain, constructed from high-strength materials, offered superior longevity compared to rubber timing belts, potentially lasting the entire lifespan of the engine without replacement.

As the LS engine family expanded, so did the refinements to its timing system. The second-generation LS engines, introduced in the early 2000s, featured an updated timing chain design with improved tensioners and guides. These enhancements were aimed at reducing chain slack and minimizing the potential for timing-related issues, further bolstering the system's reliability.

The introduction of variable valve timing (VVT) in later LS engines marked a significant milestone in the evolution of their timing systems. This technology allowed for dynamic adjustment of valve timing, optimizing engine performance across a broader range of operating conditions. The implementation of VVT necessitated further refinements to the timing chain system, including the addition of a cam phaser on the camshaft sprocket.

Throughout its evolution, the LS engine timing system has consistently favored chain-driven designs over belt-driven alternatives. This preference stems from several key advantages offered by timing chains. Firstly, chains exhibit superior strength and durability, reducing the likelihood of catastrophic failure. Secondly, they require less frequent maintenance or replacement, aligning with the LS engine's reputation for reliability and longevity.

However, the evolution of LS engine timing systems has not been without challenges. Early iterations faced issues such as chain stretch and tensioner wear, particularly in high-mileage applications. These concerns prompted ongoing refinements, including the use of more robust chain materials and improved tensioner designs in subsequent generations.

The most recent developments in LS engine timing systems have focused on noise reduction and further improvements in efficiency. Advanced chain designs with optimized tooth profiles and enhanced tensioning mechanisms have been introduced to minimize chain slap and reduce overall engine noise. Additionally, efforts have been made to reduce the parasitic losses associated with the timing drive system, contributing to incremental gains in engine efficiency.

Market Demand Analysis

The market demand for LS engine timing systems, particularly the comparison between timing chains and timing belts, has been significantly influenced by the automotive industry's evolving requirements for performance, durability, and efficiency. As vehicle manufacturers strive to meet stringent emissions standards and fuel economy regulations, the choice between timing chains and belts has become a critical consideration in engine design and development.

Timing chains have seen a resurgence in popularity, especially in high-performance applications like the LS engine series. This trend is driven by the automotive market's increasing demand for engines that offer both longevity and reduced maintenance requirements. Timing chains, known for their durability and longer service life, align well with consumer expectations for engines that can operate reliably for extended periods without major servicing.

The performance vehicle segment, where LS engines are particularly prevalent, has shown a strong preference for timing chain systems. This market segment values the robustness and precision timing that chains offer, especially under high-stress conditions often encountered in performance and racing applications. The ability of timing chains to withstand higher engine speeds and loads without stretching or breaking has made them a preferred choice among enthusiasts and professional racers alike.

However, the market for timing belts remains significant, particularly in certain vehicle categories and regions. Timing belts are often favored in applications where noise reduction and cost-effectiveness are primary concerns. Some manufacturers continue to use timing belts in their engine designs, citing benefits such as lower production costs and reduced engine weight.

The aftermarket sector has also seen substantial demand for both timing chains and belts, driven by the need for replacement parts and performance upgrades. This sector has witnessed growth in the development of high-strength timing chains and advanced belt materials, catering to consumers seeking improved durability or performance enhancements for their LS engines.

Global market trends indicate a gradual shift towards timing chain systems, particularly in regions with a strong focus on vehicle longevity and reduced maintenance costs. However, regional variations exist, with some markets still showing a preference for timing belt systems due to local manufacturing capabilities or specific consumer preferences.

The commercial vehicle sector, including light trucks and vans often equipped with LS engines, has shown a clear preference for timing chain systems. This preference is driven by the need for engines that can withstand high mileage and frequent use without requiring frequent maintenance interventions, aligning well with the operational demands of fleet operators and businesses.

Timing chains have seen a resurgence in popularity, especially in high-performance applications like the LS engine series. This trend is driven by the automotive market's increasing demand for engines that offer both longevity and reduced maintenance requirements. Timing chains, known for their durability and longer service life, align well with consumer expectations for engines that can operate reliably for extended periods without major servicing.

The performance vehicle segment, where LS engines are particularly prevalent, has shown a strong preference for timing chain systems. This market segment values the robustness and precision timing that chains offer, especially under high-stress conditions often encountered in performance and racing applications. The ability of timing chains to withstand higher engine speeds and loads without stretching or breaking has made them a preferred choice among enthusiasts and professional racers alike.

However, the market for timing belts remains significant, particularly in certain vehicle categories and regions. Timing belts are often favored in applications where noise reduction and cost-effectiveness are primary concerns. Some manufacturers continue to use timing belts in their engine designs, citing benefits such as lower production costs and reduced engine weight.

The aftermarket sector has also seen substantial demand for both timing chains and belts, driven by the need for replacement parts and performance upgrades. This sector has witnessed growth in the development of high-strength timing chains and advanced belt materials, catering to consumers seeking improved durability or performance enhancements for their LS engines.

Global market trends indicate a gradual shift towards timing chain systems, particularly in regions with a strong focus on vehicle longevity and reduced maintenance costs. However, regional variations exist, with some markets still showing a preference for timing belt systems due to local manufacturing capabilities or specific consumer preferences.

The commercial vehicle sector, including light trucks and vans often equipped with LS engines, has shown a clear preference for timing chain systems. This preference is driven by the need for engines that can withstand high mileage and frequent use without requiring frequent maintenance interventions, aligning well with the operational demands of fleet operators and businesses.

Current Tech Challenges

The current technological landscape for LS engine timing systems presents several challenges and constraints. One of the primary issues is the ongoing debate between the reliability and performance of timing chains versus timing belts. Timing chains, while generally more durable and longer-lasting, can introduce additional noise and vibration to the engine, potentially affecting overall performance and driver comfort.

Conversely, timing belts offer quieter operation but typically require more frequent replacement, leading to increased maintenance costs over the engine's lifetime. This trade-off between longevity and noise reduction continues to be a significant challenge for engineers and manufacturers.

Another critical challenge lies in the materials used for both timing chains and belts. For chains, the focus is on developing alloys that can withstand high temperatures and stress while minimizing weight and friction. Belt manufacturers face the challenge of creating compounds that can endure extreme conditions without stretching or breaking, all while maintaining flexibility and reducing noise.

The integration of variable valve timing (VVT) systems with timing chains or belts presents additional complexities. Engineers must design timing systems that can accommodate the precise control required for VVT while maintaining reliability and efficiency. This integration often leads to more intricate designs, potentially increasing manufacturing costs and complexity.

Durability under high-performance conditions remains a significant hurdle. As LS engines are often used in high-performance applications, timing systems must withstand increased stress and heat. This is particularly challenging for timing belts, which are more susceptible to degradation under extreme conditions.

Environmental concerns also play a role in current technological challenges. Manufacturers are under pressure to develop timing systems that contribute to overall engine efficiency and reduced emissions. This includes creating lighter components to improve fuel economy and designing systems that minimize friction to reduce energy loss.

The advent of start-stop technology in modern vehicles has introduced new stresses on timing systems. Frequent engine restarts can accelerate wear on both chains and belts, necessitating the development of more robust materials and designs to cope with these additional cycles.

Lastly, the push for longer service intervals presents a significant challenge, particularly for timing belts. While chains generally offer longer life, there is ongoing research to extend the lifespan of timing belts to match or exceed that of chains, potentially altering the long-standing paradigm in engine design and maintenance schedules.

Conversely, timing belts offer quieter operation but typically require more frequent replacement, leading to increased maintenance costs over the engine's lifetime. This trade-off between longevity and noise reduction continues to be a significant challenge for engineers and manufacturers.

Another critical challenge lies in the materials used for both timing chains and belts. For chains, the focus is on developing alloys that can withstand high temperatures and stress while minimizing weight and friction. Belt manufacturers face the challenge of creating compounds that can endure extreme conditions without stretching or breaking, all while maintaining flexibility and reducing noise.

The integration of variable valve timing (VVT) systems with timing chains or belts presents additional complexities. Engineers must design timing systems that can accommodate the precise control required for VVT while maintaining reliability and efficiency. This integration often leads to more intricate designs, potentially increasing manufacturing costs and complexity.

Durability under high-performance conditions remains a significant hurdle. As LS engines are often used in high-performance applications, timing systems must withstand increased stress and heat. This is particularly challenging for timing belts, which are more susceptible to degradation under extreme conditions.

Environmental concerns also play a role in current technological challenges. Manufacturers are under pressure to develop timing systems that contribute to overall engine efficiency and reduced emissions. This includes creating lighter components to improve fuel economy and designing systems that minimize friction to reduce energy loss.

The advent of start-stop technology in modern vehicles has introduced new stresses on timing systems. Frequent engine restarts can accelerate wear on both chains and belts, necessitating the development of more robust materials and designs to cope with these additional cycles.

Lastly, the push for longer service intervals presents a significant challenge, particularly for timing belts. While chains generally offer longer life, there is ongoing research to extend the lifespan of timing belts to match or exceed that of chains, potentially altering the long-standing paradigm in engine design and maintenance schedules.

Chain vs Belt Solutions

01 Timing chain design for improved performance

Advanced timing chain designs in LS engines focus on reducing friction, noise, and wear while improving overall engine efficiency. These designs may incorporate features such as optimized chain links, tensioners, and guides to ensure precise timing and longevity.- Timing chain design and materials: Improved timing chain designs and materials enhance durability and performance in LS engines. Advanced materials like high-strength alloys and composite materials are used to reduce wear and increase longevity. Specialized coatings and surface treatments further improve chain resistance to friction and stretching.

- Timing belt performance enhancements: Innovations in timing belt technology for LS engines focus on improving tensile strength, reducing noise, and increasing heat resistance. New fiber reinforcements and elastomer compounds contribute to extended belt life and more precise timing control. Some designs incorporate self-tensioning mechanisms for consistent performance.

- Tensioner and guide systems: Advanced tensioner and guide systems play a crucial role in maintaining optimal timing chain or belt performance. Hydraulic and mechanical tensioners with improved damping characteristics help reduce vibration and ensure consistent tension. Specialized guide materials and designs minimize friction and wear on the chain or belt.

- Lubrication and cooling solutions: Enhanced lubrication and cooling systems are developed to improve the performance and longevity of timing components in LS engines. These include optimized oil flow channels, specialized lubricants, and integrated cooling passages. Some designs incorporate oil jet systems to directly target high-stress areas of the timing chain or belt.

- Timing control and adjustment mechanisms: Advanced timing control and adjustment mechanisms are implemented to optimize engine performance across various operating conditions. These include variable valve timing systems, electronic timing adjusters, and adaptive control algorithms. Some designs allow for real-time timing adjustments based on engine load and speed.

02 Timing belt materials and construction

High-performance timing belts for LS engines utilize advanced materials and construction techniques to enhance durability and reduce stretching. These belts may incorporate reinforced fibers, heat-resistant compounds, and optimized tooth profiles to maintain accurate timing under various operating conditions.Expand Specific Solutions03 Tensioning systems for timing chains and belts

Innovative tensioning systems are employed to maintain optimal tension in timing chains and belts, ensuring consistent performance and reducing the risk of timing-related issues. These systems may include hydraulic or mechanical tensioners with advanced damping mechanisms to compensate for chain or belt wear over time.Expand Specific Solutions04 Lubrication systems for timing components

Specialized lubrication systems are developed to enhance the performance and longevity of timing chains and related components in LS engines. These systems may incorporate targeted oil delivery, improved oil flow paths, and advanced filtration to reduce wear and maintain optimal timing accuracy.Expand Specific Solutions05 Integration of variable valve timing with timing systems

Advanced LS engine designs incorporate variable valve timing systems that work in conjunction with timing chains or belts to optimize engine performance across various operating conditions. These integrated systems may utilize cam phasers or other mechanisms to adjust valve timing dynamically, improving power output and efficiency.Expand Specific Solutions

Key Industry Players

The competitive landscape for LS Engine Timing Chain vs. Timing Belt Performance is characterized by a mature market with established players and ongoing technological advancements. Major automotive manufacturers like Hyundai, Renault, Ford, and Volkswagen are actively involved, alongside specialized component suppliers such as Gates Corp. and BorgWarner. The market size is substantial, driven by the global automotive industry's demand for reliable engine timing systems. Technologically, both chains and belts continue to evolve, with companies like GM Global Technology Operations and Litens Automotive leading innovation. The presence of diverse players, from OEMs to aftermarket suppliers, indicates a competitive and dynamic environment focused on improving engine performance and durability.

GM Global Technology Operations LLC

Technical Solution: General Motors has developed a state-of-the-art timing chain system for their LS engines, focusing on reliability and performance. Their latest design incorporates a multi-link chain architecture that distributes load more evenly, reducing wear and extending service life. GM's timing chains are made from a high-strength nickel-chromium alloy that offers superior resistance to stretching and wear. The company has also implemented an innovative oil jet system that precisely directs lubricant to critical chain components, ensuring optimal performance under all operating conditions. GM's timing chains are designed to last up to 200,000 miles without replacement, significantly outperforming traditional timing belts[9]. Additionally, GM has developed an advanced computer-controlled variable valve timing system that works in harmony with the timing chain to optimize engine performance and fuel efficiency across a wide range of operating conditions[10].

Strengths: Exceptional durability, advanced lubrication system, integration with sophisticated engine management systems. Weaknesses: Higher initial cost, potential for increased complexity in engine design and maintenance procedures.

Ford Global Technologies LLC

Technical Solution: Ford has invested heavily in LS engine timing chain technology, focusing on reliability and performance. Their latest timing chain systems incorporate advanced materials such as high-strength steel alloys and low-friction coatings to enhance durability. Ford's proprietary chain design features optimized link geometry that reduces wear and improves tension distribution. The company has also developed intelligent variable valve timing systems that work in conjunction with their timing chains to improve engine efficiency and power output. Ford's timing chains are designed to last up to 150,000 miles without replacement, significantly outlasting typical timing belts[3]. Additionally, Ford has implemented advanced manufacturing techniques, including precision laser welding for chain assembly, to ensure consistent quality and performance[4].

Strengths: Long-lasting durability, integration with advanced engine management systems. Weaknesses: Potentially higher manufacturing costs, more complex installation process compared to belts.

Core Timing Innovations

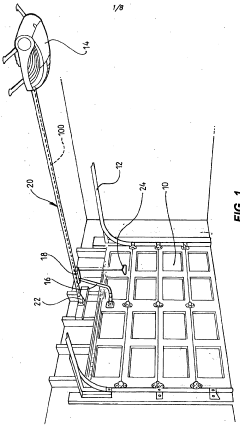

Improvements relating to drive assemblies

PatentInactiveNZ605218A

Innovation

- A drive assembly featuring a connector with a slot configuration that allows the belt to be engaged transversely, preventing disengagement and eliminating the need for clamping or fasteners, along with a camming mechanism for selective engagement between the trolley and the longitudinal drive, enabling easy adjustment and maintenance without damaging the belt.

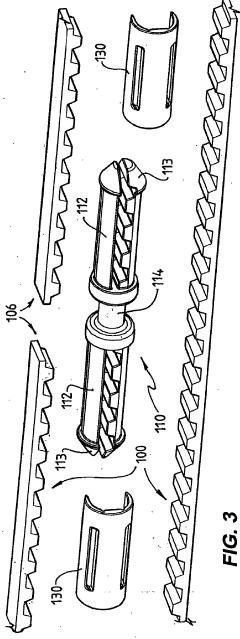

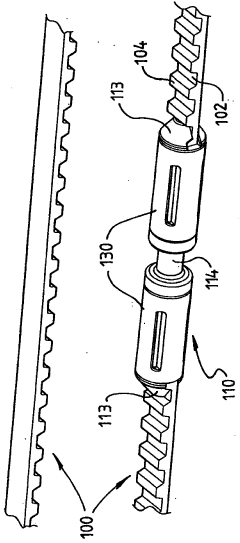

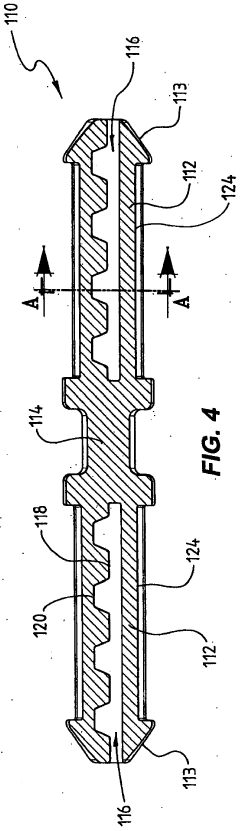

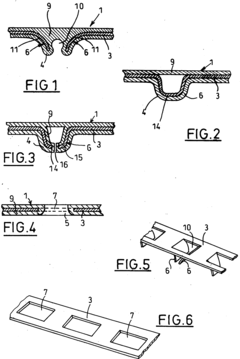

Belt, especially for positive driving in the timing system of an internal combustion engine and method of making such a belt

PatentInactiveEP0499499A1

Innovation

- A timing belt with a core made of a high elastic limit metal alloy strip, coated with a polymer film, featuring specific meshing elements such as protrusions, perforations, or stampings, which provide improved mechanical strength, thermal conductivity, and magnetic permeability for enhanced performance and durability.

Environmental Impact

The environmental impact of timing chains versus timing belts in LS engines is a crucial consideration in the automotive industry's pursuit of sustainability. Timing chains, typically made of metal, have a longer lifespan and require less frequent replacement compared to timing belts, which are usually composed of reinforced rubber. This durability difference translates to reduced waste generation over the engine's lifetime, as fewer replacement parts are needed for timing chain systems.

However, the production process of timing chains involves more energy-intensive metal manufacturing, potentially resulting in higher carbon emissions during the initial manufacturing phase. In contrast, timing belts, being primarily rubber-based, may have a lower carbon footprint in production but require more frequent replacements, leading to increased waste over time.

The weight difference between timing chains and belts also plays a role in fuel efficiency. Timing chains are generally heavier, which can marginally increase the overall weight of the engine, potentially leading to slightly higher fuel consumption. This factor, while minor, can accumulate over the lifespan of numerous vehicles, contributing to increased carbon emissions.

Recycling and end-of-life considerations also differ between the two components. Metal timing chains are more readily recyclable, aligning with circular economy principles. Timing belts, being a composite of rubber and fiber reinforcements, present more challenges in recycling and often end up in landfills, contributing to long-term environmental pollution.

The lubricant requirements for timing chains versus belts also have environmental implications. Timing chains typically require more frequent oil changes to maintain optimal performance, potentially leading to increased oil consumption and disposal. This aspect needs to be balanced against the longer lifespan of timing chains when assessing overall environmental impact.

In terms of noise pollution, timing chains generally produce more noise than timing belts, especially as they wear over time. While this may not have a direct environmental impact, it contributes to overall vehicle noise emissions, which is an increasing concern in urban environments.

Considering the full lifecycle analysis, the environmental trade-offs between timing chains and belts in LS engines are complex. While timing chains offer advantages in longevity and recyclability, their production and weight impacts cannot be overlooked. Conversely, timing belts present challenges in terms of more frequent replacements and end-of-life disposal. As automotive technology advances, ongoing research into more sustainable materials and designs for both timing systems will be crucial in minimizing their environmental footprint.

However, the production process of timing chains involves more energy-intensive metal manufacturing, potentially resulting in higher carbon emissions during the initial manufacturing phase. In contrast, timing belts, being primarily rubber-based, may have a lower carbon footprint in production but require more frequent replacements, leading to increased waste over time.

The weight difference between timing chains and belts also plays a role in fuel efficiency. Timing chains are generally heavier, which can marginally increase the overall weight of the engine, potentially leading to slightly higher fuel consumption. This factor, while minor, can accumulate over the lifespan of numerous vehicles, contributing to increased carbon emissions.

Recycling and end-of-life considerations also differ between the two components. Metal timing chains are more readily recyclable, aligning with circular economy principles. Timing belts, being a composite of rubber and fiber reinforcements, present more challenges in recycling and often end up in landfills, contributing to long-term environmental pollution.

The lubricant requirements for timing chains versus belts also have environmental implications. Timing chains typically require more frequent oil changes to maintain optimal performance, potentially leading to increased oil consumption and disposal. This aspect needs to be balanced against the longer lifespan of timing chains when assessing overall environmental impact.

In terms of noise pollution, timing chains generally produce more noise than timing belts, especially as they wear over time. While this may not have a direct environmental impact, it contributes to overall vehicle noise emissions, which is an increasing concern in urban environments.

Considering the full lifecycle analysis, the environmental trade-offs between timing chains and belts in LS engines are complex. While timing chains offer advantages in longevity and recyclability, their production and weight impacts cannot be overlooked. Conversely, timing belts present challenges in terms of more frequent replacements and end-of-life disposal. As automotive technology advances, ongoing research into more sustainable materials and designs for both timing systems will be crucial in minimizing their environmental footprint.

Cost-Benefit Analysis

The cost-benefit analysis of LS engine timing chains versus timing belts reveals significant differences in terms of longevity, maintenance requirements, and overall performance. Timing chains, typically made of metal, offer superior durability and longevity compared to rubber timing belts. The initial cost of a timing chain system is generally higher than that of a timing belt system. However, this upfront investment is often offset by the reduced frequency of replacement and lower long-term maintenance costs.

Timing chains in LS engines are designed to last the lifetime of the engine, potentially eliminating the need for replacement under normal operating conditions. This longevity translates to substantial cost savings over the life of the vehicle, as timing belt replacements are typically recommended every 60,000 to 100,000 miles. The elimination of scheduled replacements not only reduces direct parts and labor costs but also minimizes vehicle downtime and associated inconvenience for owners.

From a performance perspective, timing chains offer greater precision in valve timing control, which can contribute to improved engine efficiency and power output. This precision is maintained over a longer period due to the chain's resistance to stretching, unlike rubber belts which can degrade and stretch over time, potentially leading to reduced engine performance or even catastrophic failure if left unaddressed.

However, it's important to note that timing chain systems are not without their drawbacks. They tend to be noisier than belt systems, particularly as they age, which may impact driver comfort. Additionally, in the rare event of a timing chain failure, the repair costs can be significantly higher than those associated with a timing belt replacement, due to the more complex nature of the chain system and potential for increased engine damage.

Maintenance requirements also differ between the two systems. While timing chains generally require less frequent attention, they do necessitate regular oil changes with high-quality lubricants to ensure proper function and longevity. Timing belts, on the other hand, may require more frequent inspections and eventual replacement, but these maintenance procedures are often simpler and less costly on a per-service basis.

In conclusion, the cost-benefit analysis favors timing chains for LS engines in terms of long-term reliability and reduced maintenance frequency. While the initial cost may be higher, the extended service life and potential for improved engine performance offer compelling advantages for vehicle manufacturers and consumers alike. However, the choice between timing chains and belts ultimately depends on specific engine design requirements, target market considerations, and overall vehicle lifecycle cost projections.

Timing chains in LS engines are designed to last the lifetime of the engine, potentially eliminating the need for replacement under normal operating conditions. This longevity translates to substantial cost savings over the life of the vehicle, as timing belt replacements are typically recommended every 60,000 to 100,000 miles. The elimination of scheduled replacements not only reduces direct parts and labor costs but also minimizes vehicle downtime and associated inconvenience for owners.

From a performance perspective, timing chains offer greater precision in valve timing control, which can contribute to improved engine efficiency and power output. This precision is maintained over a longer period due to the chain's resistance to stretching, unlike rubber belts which can degrade and stretch over time, potentially leading to reduced engine performance or even catastrophic failure if left unaddressed.

However, it's important to note that timing chain systems are not without their drawbacks. They tend to be noisier than belt systems, particularly as they age, which may impact driver comfort. Additionally, in the rare event of a timing chain failure, the repair costs can be significantly higher than those associated with a timing belt replacement, due to the more complex nature of the chain system and potential for increased engine damage.

Maintenance requirements also differ between the two systems. While timing chains generally require less frequent attention, they do necessitate regular oil changes with high-quality lubricants to ensure proper function and longevity. Timing belts, on the other hand, may require more frequent inspections and eventual replacement, but these maintenance procedures are often simpler and less costly on a per-service basis.

In conclusion, the cost-benefit analysis favors timing chains for LS engines in terms of long-term reliability and reduced maintenance frequency. While the initial cost may be higher, the extended service life and potential for improved engine performance offer compelling advantages for vehicle manufacturers and consumers alike. However, the choice between timing chains and belts ultimately depends on specific engine design requirements, target market considerations, and overall vehicle lifecycle cost projections.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!