How Endoscopic Technologies Aid in LS Engine Inspections

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Endoscopy Background and Objectives

Endoscopic technologies have revolutionized the field of engine diagnostics, particularly in the inspection of LS (Luxury Sport) engines. These advanced optical systems have evolved significantly over the past few decades, enabling engineers and mechanics to perform detailed internal examinations without the need for extensive disassembly. The development of endoscopic technologies for engine inspections can be traced back to the early 1990s when automotive manufacturers began seeking more efficient and less invasive methods for engine diagnostics.

The primary objective of utilizing endoscopic technologies in LS engine inspections is to enhance the accuracy, efficiency, and cost-effectiveness of diagnostic procedures. By providing high-resolution visual access to internal engine components, endoscopes allow for early detection of wear, damage, or potential failures. This proactive approach to engine maintenance can significantly reduce downtime and repair costs, while also extending the overall lifespan of the engine.

As LS engines have become increasingly complex and compact, the need for sophisticated inspection tools has grown proportionally. Modern LS engines, with their advanced designs and tight tolerances, present unique challenges for traditional inspection methods. Endoscopic technologies address these challenges by offering flexible, miniaturized cameras capable of navigating through narrow passages and reaching previously inaccessible areas within the engine.

The evolution of endoscopic technologies for LS engine inspections has been driven by advancements in several key areas. These include improvements in image sensor technology, leading to higher resolution and better low-light performance; the development of more durable and heat-resistant materials for probe construction; and the integration of advanced software for image processing and analysis. Additionally, the incorporation of features such as articulating tips and multiple viewing angles has greatly expanded the capabilities of these devices.

Looking ahead, the future of endoscopic technologies in LS engine inspections is poised for further innovation. Emerging trends include the integration of artificial intelligence for automated defect detection, the development of 3D imaging capabilities for more comprehensive analysis, and the incorporation of augmented reality interfaces to enhance the interpretation of inspection data. These advancements aim to further streamline the inspection process, reduce human error, and provide even more detailed insights into engine condition and performance.

The primary objective of utilizing endoscopic technologies in LS engine inspections is to enhance the accuracy, efficiency, and cost-effectiveness of diagnostic procedures. By providing high-resolution visual access to internal engine components, endoscopes allow for early detection of wear, damage, or potential failures. This proactive approach to engine maintenance can significantly reduce downtime and repair costs, while also extending the overall lifespan of the engine.

As LS engines have become increasingly complex and compact, the need for sophisticated inspection tools has grown proportionally. Modern LS engines, with their advanced designs and tight tolerances, present unique challenges for traditional inspection methods. Endoscopic technologies address these challenges by offering flexible, miniaturized cameras capable of navigating through narrow passages and reaching previously inaccessible areas within the engine.

The evolution of endoscopic technologies for LS engine inspections has been driven by advancements in several key areas. These include improvements in image sensor technology, leading to higher resolution and better low-light performance; the development of more durable and heat-resistant materials for probe construction; and the integration of advanced software for image processing and analysis. Additionally, the incorporation of features such as articulating tips and multiple viewing angles has greatly expanded the capabilities of these devices.

Looking ahead, the future of endoscopic technologies in LS engine inspections is poised for further innovation. Emerging trends include the integration of artificial intelligence for automated defect detection, the development of 3D imaging capabilities for more comprehensive analysis, and the incorporation of augmented reality interfaces to enhance the interpretation of inspection data. These advancements aim to further streamline the inspection process, reduce human error, and provide even more detailed insights into engine condition and performance.

Market Demand for LS Engine Inspection Solutions

The market demand for LS engine inspection solutions has been steadily growing, driven by the increasing complexity of modern engines and the need for more efficient maintenance practices. LS engines, known for their performance and reliability, are widely used in various vehicles, from sports cars to trucks. As these engines age and accumulate mileage, the demand for accurate and non-invasive inspection methods has surged.

Endoscopic technologies have emerged as a crucial tool in meeting this demand. They offer a non-destructive way to inspect internal engine components without the need for extensive disassembly. This capability is particularly valuable for LS engines, where traditional inspection methods can be time-consuming and potentially damaging.

The automotive repair and maintenance industry has shown significant interest in adopting endoscopic technologies for LS engine inspections. Workshops and service centers are increasingly investing in these tools to improve their diagnostic capabilities and service quality. This trend is partly driven by customer expectations for faster and more accurate diagnoses, as well as the desire to minimize unnecessary repairs.

Fleet management companies and commercial vehicle operators have also contributed to the growing demand. These entities require regular and thorough engine inspections to maintain their vehicles' performance and longevity. Endoscopic technologies allow for more frequent inspections without the downtime associated with traditional methods, leading to improved preventive maintenance strategies and reduced operational costs.

The racing and high-performance vehicle sectors represent another significant market segment. In these fields, where engine performance is critical, the ability to conduct detailed inspections without engine disassembly is highly valued. Endoscopic technologies enable teams and enthusiasts to monitor engine wear and optimize performance more effectively.

As environmental regulations become stricter, there's an increasing need for technologies that can help ensure engines operate at peak efficiency. Endoscopic inspections play a role in this by allowing for early detection of issues that could affect emissions or fuel efficiency. This aspect has further boosted the demand for advanced inspection solutions in the LS engine market.

The aftermarket parts industry has also recognized the potential of endoscopic technologies. Manufacturers of performance parts and engine components are developing products that are compatible with or enhance the capabilities of endoscopic inspection tools, further driving market growth.

Endoscopic technologies have emerged as a crucial tool in meeting this demand. They offer a non-destructive way to inspect internal engine components without the need for extensive disassembly. This capability is particularly valuable for LS engines, where traditional inspection methods can be time-consuming and potentially damaging.

The automotive repair and maintenance industry has shown significant interest in adopting endoscopic technologies for LS engine inspections. Workshops and service centers are increasingly investing in these tools to improve their diagnostic capabilities and service quality. This trend is partly driven by customer expectations for faster and more accurate diagnoses, as well as the desire to minimize unnecessary repairs.

Fleet management companies and commercial vehicle operators have also contributed to the growing demand. These entities require regular and thorough engine inspections to maintain their vehicles' performance and longevity. Endoscopic technologies allow for more frequent inspections without the downtime associated with traditional methods, leading to improved preventive maintenance strategies and reduced operational costs.

The racing and high-performance vehicle sectors represent another significant market segment. In these fields, where engine performance is critical, the ability to conduct detailed inspections without engine disassembly is highly valued. Endoscopic technologies enable teams and enthusiasts to monitor engine wear and optimize performance more effectively.

As environmental regulations become stricter, there's an increasing need for technologies that can help ensure engines operate at peak efficiency. Endoscopic inspections play a role in this by allowing for early detection of issues that could affect emissions or fuel efficiency. This aspect has further boosted the demand for advanced inspection solutions in the LS engine market.

The aftermarket parts industry has also recognized the potential of endoscopic technologies. Manufacturers of performance parts and engine components are developing products that are compatible with or enhance the capabilities of endoscopic inspection tools, further driving market growth.

Current Endoscopic Technologies in LS Engine Diagnostics

Endoscopic technologies have revolutionized the field of LS engine diagnostics, offering non-invasive methods for internal inspection and analysis. Current endoscopic technologies employed in LS engine diagnostics primarily consist of borescopes and videoscopes, which have become indispensable tools for mechanics and engineers.

Borescopes, the more traditional endoscopic technology, utilize a rigid or semi-rigid optical tube with a lens system to transmit images from the engine's interior to the viewer's eye or a camera. These devices are particularly useful for inspecting hard-to-reach areas within the engine, such as cylinder walls, valves, and pistons. Modern borescopes often incorporate LED lighting at the tip to illuminate the inspection area, enhancing visibility in the dark confines of an engine.

Videoscopes represent a more advanced iteration of endoscopic technology. These flexible, digital devices feature a miniature camera and light source at the tip, connected to a display screen via a cable. Videoscopes offer superior image quality and the ability to record and store visual data for later analysis. This capability is particularly valuable for documenting engine conditions over time and sharing findings with colleagues or clients.

Both borescopes and videoscopes come in various diameters and lengths to accommodate different engine sizes and access points. For LS engine inspections, technicians typically use scopes with diameters ranging from 4mm to 8mm, which can easily navigate through spark plug holes or other small openings without requiring extensive disassembly of the engine.

Recent advancements in endoscopic technology have introduced features such as articulating tips, which allow for greater maneuverability within the engine. This innovation enables inspectors to view components from multiple angles, providing a more comprehensive assessment of engine condition. Additionally, some high-end videoscopes now incorporate measurement capabilities, allowing technicians to accurately gauge the size of defects or wear patterns.

The integration of digital imaging processing has further enhanced the diagnostic capabilities of endoscopic technologies. Software algorithms can now assist in identifying potential issues by analyzing images for patterns indicative of wear, damage, or contamination. This computer-aided diagnosis helps reduce human error and increases the consistency of engine inspections.

Wireless connectivity is another emerging trend in endoscopic technologies for LS engine diagnostics. Some modern videoscopes can transmit images and video feeds wirelessly to tablets or smartphones, facilitating real-time collaboration between technicians and remote experts. This feature is particularly valuable in complex diagnostic scenarios or when seeking second opinions on unusual findings.

As endoscopic technologies continue to evolve, their role in LS engine diagnostics is becoming increasingly central. These tools not only expedite the inspection process but also enable more accurate and comprehensive assessments of engine health, ultimately leading to more efficient maintenance and repair procedures.

Borescopes, the more traditional endoscopic technology, utilize a rigid or semi-rigid optical tube with a lens system to transmit images from the engine's interior to the viewer's eye or a camera. These devices are particularly useful for inspecting hard-to-reach areas within the engine, such as cylinder walls, valves, and pistons. Modern borescopes often incorporate LED lighting at the tip to illuminate the inspection area, enhancing visibility in the dark confines of an engine.

Videoscopes represent a more advanced iteration of endoscopic technology. These flexible, digital devices feature a miniature camera and light source at the tip, connected to a display screen via a cable. Videoscopes offer superior image quality and the ability to record and store visual data for later analysis. This capability is particularly valuable for documenting engine conditions over time and sharing findings with colleagues or clients.

Both borescopes and videoscopes come in various diameters and lengths to accommodate different engine sizes and access points. For LS engine inspections, technicians typically use scopes with diameters ranging from 4mm to 8mm, which can easily navigate through spark plug holes or other small openings without requiring extensive disassembly of the engine.

Recent advancements in endoscopic technology have introduced features such as articulating tips, which allow for greater maneuverability within the engine. This innovation enables inspectors to view components from multiple angles, providing a more comprehensive assessment of engine condition. Additionally, some high-end videoscopes now incorporate measurement capabilities, allowing technicians to accurately gauge the size of defects or wear patterns.

The integration of digital imaging processing has further enhanced the diagnostic capabilities of endoscopic technologies. Software algorithms can now assist in identifying potential issues by analyzing images for patterns indicative of wear, damage, or contamination. This computer-aided diagnosis helps reduce human error and increases the consistency of engine inspections.

Wireless connectivity is another emerging trend in endoscopic technologies for LS engine diagnostics. Some modern videoscopes can transmit images and video feeds wirelessly to tablets or smartphones, facilitating real-time collaboration between technicians and remote experts. This feature is particularly valuable in complex diagnostic scenarios or when seeking second opinions on unusual findings.

As endoscopic technologies continue to evolve, their role in LS engine diagnostics is becoming increasingly central. These tools not only expedite the inspection process but also enable more accurate and comprehensive assessments of engine health, ultimately leading to more efficient maintenance and repair procedures.

Existing Endoscopic Solutions for LS Engine Inspection

01 Advanced imaging techniques in endoscopy

Modern endoscopic technologies incorporate advanced imaging techniques to enhance visualization and diagnostic capabilities. These may include high-definition imaging, narrow-band imaging, and fluorescence imaging. These techniques allow for better detection of abnormalities and more accurate diagnoses during endoscopic procedures.- Advanced imaging techniques in endoscopy: Modern endoscopic technologies incorporate advanced imaging techniques to enhance visualization and diagnostic capabilities. These may include high-definition imaging, narrow-band imaging, and fluorescence imaging. Such techniques allow for better detection of abnormalities and more accurate diagnoses during endoscopic procedures.

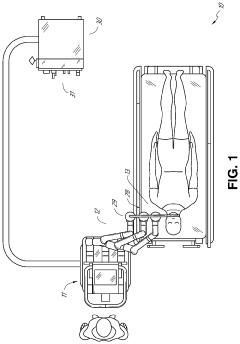

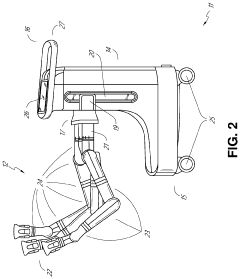

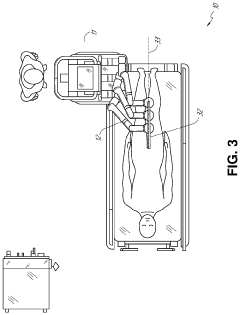

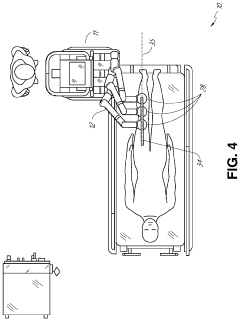

- Robotic-assisted endoscopic systems: Robotic-assisted endoscopic systems are being developed to improve precision and control during procedures. These systems may incorporate advanced navigation, automated movements, and enhanced dexterity, allowing for more complex interventions and potentially reducing procedure times and improving outcomes.

- Artificial intelligence integration in endoscopy: Artificial intelligence (AI) is being integrated into endoscopic technologies to assist in image analysis, lesion detection, and decision-making processes. AI algorithms can help identify potential abnormalities, classify lesions, and provide real-time guidance to endoscopists during procedures.

- Miniaturization and capsule endoscopy: Advancements in miniaturization have led to the development of capsule endoscopy and ultra-thin endoscopes. These technologies allow for less invasive examinations of the gastrointestinal tract and other body cavities, improving patient comfort and enabling access to previously difficult-to-reach areas.

- Multifunctional endoscopic devices: Endoscopic technologies are evolving to incorporate multiple functions within a single device. These multifunctional endoscopes may combine imaging, biopsy capabilities, therapeutic interventions, and advanced sensing technologies, allowing for more comprehensive examinations and treatments in a single procedure.

02 Robotic-assisted endoscopic systems

Robotic-assisted endoscopic systems are being developed to improve precision and control during procedures. These systems may incorporate advanced navigation, automated movements, and enhanced dexterity, allowing for more complex interventions and potentially reducing procedure times and improving outcomes.Expand Specific Solutions03 Miniaturization of endoscopic devices

Ongoing efforts in miniaturization are leading to the development of smaller, more flexible endoscopes. These devices can access previously difficult-to-reach areas of the body, enabling less invasive procedures and potentially improving patient comfort and recovery times.Expand Specific Solutions04 Integration of AI and machine learning in endoscopy

Artificial intelligence and machine learning algorithms are being integrated into endoscopic systems to assist in real-time image analysis, lesion detection, and decision support. These technologies aim to improve diagnostic accuracy and efficiency during endoscopic procedures.Expand Specific Solutions05 Multifunctional endoscopic tools

Development of multifunctional endoscopic tools that combine imaging, biopsy, and therapeutic capabilities in a single device. These tools may incorporate various modalities such as optical coherence tomography, confocal microscopy, or laser-based treatments, enabling more comprehensive diagnostic and therapeutic interventions during a single procedure.Expand Specific Solutions

Key Players in Automotive Endoscopy Industry

The endoscopic technologies for LS engine inspections market is in a growth phase, driven by increasing demand for non-invasive diagnostic tools in automotive maintenance. The market size is expanding as more automotive service centers adopt these technologies. Technological maturity varies among key players, with companies like Olympus Corp. and NEC Corp. leading in innovation. Olympus Corp., a pioneer in endoscopy, offers advanced imaging solutions, while NEC Corp. contributes with its expertise in digital technologies. Emerging players such as Auris Health, Inc. are introducing robotics-assisted endoscopic systems, potentially revolutionizing the field. The competitive landscape is characterized by a mix of established medical technology firms and automotive-focused companies, each bringing unique strengths to this niche market.

Olympus Corp.

Technical Solution: Olympus Corp. has developed advanced endoscopic technologies specifically tailored for LS engine inspections. Their system incorporates high-definition imaging sensors and specialized light sources to provide clear visualization of engine components in confined spaces. The company's endoscopes feature articulating tips with a wide range of motion, allowing for comprehensive examination of hard-to-reach areas within the engine [1]. Olympus has also integrated advanced image processing algorithms that enhance contrast and reduce noise, improving the detection of subtle defects or wear patterns [3]. Their endoscopes are equipped with measurement tools for precise quantification of component dimensions and wear, enabling accurate assessment of engine condition [5].

Strengths: Superior image quality, versatile articulation, and advanced measurement capabilities. Weaknesses: Potentially higher cost compared to simpler inspection tools, may require specialized training for optimal use.

Lufthansa Technik AG

Technical Solution: Lufthansa Technik AG has developed a proprietary endoscopic system for LS engine inspections, focusing on efficiency and reliability in maintenance operations. Their solution incorporates a modular design that allows for easy customization based on specific engine types and inspection requirements [2]. The system features high-resolution cameras with adjustable LED lighting, ensuring optimal visibility in various engine compartments. Lufthansa Technik's endoscopes are integrated with a digital platform that enables real-time collaboration between on-site technicians and remote experts, facilitating faster decision-making during inspections [4]. The company has also implemented machine learning algorithms to assist in identifying potential issues and predicting maintenance needs based on historical inspection data [6].

Strengths: Customizable for different engine types, enables remote collaboration, and incorporates predictive maintenance capabilities. Weaknesses: May require significant initial investment and ongoing software updates to maintain effectiveness.

Core Innovations in LS Engine Endoscopy

Electromagnetic field generator alignment

PatentActiveUS11832889B2

Innovation

- A system comprising EM sensors, a processor, and memory that calculates baseline and updated metrics of EM sensor signals to detect EM distortion by determining differences greater than a threshold value, allowing for real-time detection and adjustment to maintain accurate navigation and localization during medical procedures.

Endoscopy system and corresponding method for examining gas turbines

PatentWO2013045108A8

Innovation

- An endoscopy system with an electronically controlled positioning device and image processing capabilities for precise, automated positioning and alignment of the endoscope within the gas turbine, allowing for standardized image recordings and automatic image acquisition, storage, and comparison, reducing operator dependence and increasing test quality.

Integration with AI and Machine Learning

The integration of AI and machine learning with endoscopic technologies is revolutionizing LS engine inspections, offering unprecedented levels of accuracy, efficiency, and predictive maintenance capabilities. Advanced image recognition algorithms can now analyze endoscopic footage in real-time, identifying potential issues such as wear patterns, cracks, or deposits that might be overlooked by human inspectors. These AI-powered systems can be trained on vast datasets of engine images, enabling them to detect even subtle anomalies with high precision.

Machine learning models are being developed to predict component failures based on historical inspection data and real-time sensor information. By analyzing patterns and trends in engine wear and performance, these models can forecast when specific parts are likely to fail, allowing for proactive maintenance scheduling and minimizing unexpected downtime. This predictive approach significantly enhances the overall reliability and longevity of LS engines.

AI-driven automation is streamlining the inspection process itself. Robotic endoscopes guided by AI can navigate through complex engine geometries, ensuring consistent and thorough coverage of all critical areas. These systems can automatically adjust focus, lighting, and camera angles to capture optimal images for analysis, reducing the reliance on operator skill and improving the consistency of inspection results.

Natural language processing (NLP) technologies are being integrated to generate detailed, automated inspection reports. These systems can convert visual data and AI-generated insights into comprehensive, easy-to-understand reports, complete with recommendations for maintenance or repair actions. This not only saves time in report preparation but also ensures standardized documentation across inspections.

The combination of endoscopic data with other sensor inputs, such as temperature, pressure, and vibration readings, allows for a more holistic analysis of engine health. AI algorithms can correlate these diverse data streams to provide a more comprehensive understanding of engine performance and potential issues, leading to more accurate diagnoses and targeted maintenance strategies.

As these technologies continue to evolve, we can expect to see even more advanced applications, such as real-time 3D mapping of engine interiors, AI-assisted repair guidance, and predictive modeling for engine design optimization. The integration of AI and machine learning with endoscopic technologies is not just enhancing current inspection practices; it is paving the way for a new era of intelligent, proactive engine maintenance and performance optimization.

Machine learning models are being developed to predict component failures based on historical inspection data and real-time sensor information. By analyzing patterns and trends in engine wear and performance, these models can forecast when specific parts are likely to fail, allowing for proactive maintenance scheduling and minimizing unexpected downtime. This predictive approach significantly enhances the overall reliability and longevity of LS engines.

AI-driven automation is streamlining the inspection process itself. Robotic endoscopes guided by AI can navigate through complex engine geometries, ensuring consistent and thorough coverage of all critical areas. These systems can automatically adjust focus, lighting, and camera angles to capture optimal images for analysis, reducing the reliance on operator skill and improving the consistency of inspection results.

Natural language processing (NLP) technologies are being integrated to generate detailed, automated inspection reports. These systems can convert visual data and AI-generated insights into comprehensive, easy-to-understand reports, complete with recommendations for maintenance or repair actions. This not only saves time in report preparation but also ensures standardized documentation across inspections.

The combination of endoscopic data with other sensor inputs, such as temperature, pressure, and vibration readings, allows for a more holistic analysis of engine health. AI algorithms can correlate these diverse data streams to provide a more comprehensive understanding of engine performance and potential issues, leading to more accurate diagnoses and targeted maintenance strategies.

As these technologies continue to evolve, we can expect to see even more advanced applications, such as real-time 3D mapping of engine interiors, AI-assisted repair guidance, and predictive modeling for engine design optimization. The integration of AI and machine learning with endoscopic technologies is not just enhancing current inspection practices; it is paving the way for a new era of intelligent, proactive engine maintenance and performance optimization.

Environmental Impact and Sustainability Considerations

The integration of endoscopic technologies in LS engine inspections brings significant environmental and sustainability benefits to the automotive industry. By enabling non-invasive internal examinations, these technologies reduce the need for extensive disassembly, thereby minimizing waste generation and resource consumption associated with traditional inspection methods. This approach aligns with the growing emphasis on sustainable practices in the automotive sector.

Endoscopic inspections contribute to extended engine life cycles by facilitating early detection of wear and potential issues. This proactive maintenance strategy helps prevent catastrophic failures, reducing the likelihood of premature engine replacements. Consequently, it conserves raw materials and energy that would otherwise be expended in manufacturing new engine components or entire engines.

The precision offered by endoscopic technologies also leads to more targeted repairs and replacements. Instead of replacing entire systems or components, technicians can identify and address specific problem areas. This targeted approach not only reduces waste but also minimizes the environmental impact associated with manufacturing and disposing of unnecessary replacement parts.

Furthermore, endoscopic inspections can play a crucial role in optimizing engine performance and efficiency. By identifying and addressing issues that may affect combustion efficiency or cause increased emissions, these technologies contribute to reduced fuel consumption and lower exhaust emissions. This aspect is particularly relevant in the context of increasingly stringent environmental regulations and the automotive industry's efforts to reduce its carbon footprint.

The use of endoscopic technologies in LS engine inspections also supports the trend towards remanufacturing and refurbishing engines. By providing detailed insights into the condition of internal components, these technologies enable more accurate assessments of an engine's potential for refurbishment. This approach extends the useful life of engines, reducing the demand for new production and associated environmental impacts.

In terms of workplace sustainability, endoscopic inspections contribute to safer and cleaner working environments. The reduction in disassembly requirements minimizes exposure to potentially harmful fluids and reduces the risk of spills or leaks. This not only protects technicians but also decreases the environmental risks associated with handling and disposing of automotive fluids.

As the automotive industry continues to evolve towards more sustainable practices, the role of endoscopic technologies in LS engine inspections is likely to expand. Future developments may include integration with artificial intelligence for automated diagnostics, further enhancing the efficiency and environmental benefits of these inspection methods. The ongoing refinement of these technologies promises to play a significant role in the industry's sustainability efforts, contributing to reduced environmental impact throughout the lifecycle of LS engines.

Endoscopic inspections contribute to extended engine life cycles by facilitating early detection of wear and potential issues. This proactive maintenance strategy helps prevent catastrophic failures, reducing the likelihood of premature engine replacements. Consequently, it conserves raw materials and energy that would otherwise be expended in manufacturing new engine components or entire engines.

The precision offered by endoscopic technologies also leads to more targeted repairs and replacements. Instead of replacing entire systems or components, technicians can identify and address specific problem areas. This targeted approach not only reduces waste but also minimizes the environmental impact associated with manufacturing and disposing of unnecessary replacement parts.

Furthermore, endoscopic inspections can play a crucial role in optimizing engine performance and efficiency. By identifying and addressing issues that may affect combustion efficiency or cause increased emissions, these technologies contribute to reduced fuel consumption and lower exhaust emissions. This aspect is particularly relevant in the context of increasingly stringent environmental regulations and the automotive industry's efforts to reduce its carbon footprint.

The use of endoscopic technologies in LS engine inspections also supports the trend towards remanufacturing and refurbishing engines. By providing detailed insights into the condition of internal components, these technologies enable more accurate assessments of an engine's potential for refurbishment. This approach extends the useful life of engines, reducing the demand for new production and associated environmental impacts.

In terms of workplace sustainability, endoscopic inspections contribute to safer and cleaner working environments. The reduction in disassembly requirements minimizes exposure to potentially harmful fluids and reduces the risk of spills or leaks. This not only protects technicians but also decreases the environmental risks associated with handling and disposing of automotive fluids.

As the automotive industry continues to evolve towards more sustainable practices, the role of endoscopic technologies in LS engine inspections is likely to expand. Future developments may include integration with artificial intelligence for automated diagnostics, further enhancing the efficiency and environmental benefits of these inspection methods. The ongoing refinement of these technologies promises to play a significant role in the industry's sustainability efforts, contributing to reduced environmental impact throughout the lifecycle of LS engines.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!