Analyzing the Influence of Exhaust Heat Shields in LS Engines

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Heat Shield Evolution

The evolution of heat shields in LS engines represents a significant advancement in thermal management and performance optimization. Initially introduced in the late 1990s with the debut of the LS1 engine, heat shields have undergone continuous refinement to address the challenges posed by increasing power outputs and stricter emissions regulations.

In the early stages, heat shields were primarily focused on protecting surrounding components from the extreme temperatures generated by the exhaust system. These first-generation shields were often simple stamped metal designs, offering basic thermal insulation but lacking in advanced features or materials.

As LS engines evolved through the 2000s, so did the heat shield technology. The introduction of the LS2 and LS3 engines saw more sophisticated heat shield designs. Manufacturers began incorporating multi-layer construction, utilizing materials with superior heat-reflective properties. This period marked a shift from mere component protection to active thermal management, with heat shields playing a crucial role in maintaining optimal operating temperatures.

The late 2000s and early 2010s brought about a revolution in heat shield design for LS engines. With the advent of the LS7 and LS9 high-performance variants, heat management became even more critical. Engineers developed advanced composite materials that offered superior heat resistance while significantly reducing weight. These new-generation heat shields not only protected components but also contributed to overall engine efficiency by minimizing heat loss.

Recent years have seen the integration of smart technologies into LS engine heat shields. Some advanced designs now incorporate sensors and adaptive materials that can adjust their thermal properties based on engine operating conditions. This dynamic approach to heat management allows for optimized performance across a wide range of driving scenarios.

The latest developments in LS engine heat shield technology focus on sustainability and emissions reduction. Manufacturers are exploring eco-friendly materials that offer excellent thermal properties while being more recyclable. Additionally, heat shields are now being designed to work in tandem with catalytic converters, helping to maintain ideal operating temperatures for more efficient emissions control.

Throughout this evolution, the role of heat shields in LS engines has expanded from simple protective elements to integral components of the engine's thermal management system. They now contribute significantly to engine efficiency, emissions reduction, and overall performance, showcasing the importance of continuous innovation in automotive engineering.

In the early stages, heat shields were primarily focused on protecting surrounding components from the extreme temperatures generated by the exhaust system. These first-generation shields were often simple stamped metal designs, offering basic thermal insulation but lacking in advanced features or materials.

As LS engines evolved through the 2000s, so did the heat shield technology. The introduction of the LS2 and LS3 engines saw more sophisticated heat shield designs. Manufacturers began incorporating multi-layer construction, utilizing materials with superior heat-reflective properties. This period marked a shift from mere component protection to active thermal management, with heat shields playing a crucial role in maintaining optimal operating temperatures.

The late 2000s and early 2010s brought about a revolution in heat shield design for LS engines. With the advent of the LS7 and LS9 high-performance variants, heat management became even more critical. Engineers developed advanced composite materials that offered superior heat resistance while significantly reducing weight. These new-generation heat shields not only protected components but also contributed to overall engine efficiency by minimizing heat loss.

Recent years have seen the integration of smart technologies into LS engine heat shields. Some advanced designs now incorporate sensors and adaptive materials that can adjust their thermal properties based on engine operating conditions. This dynamic approach to heat management allows for optimized performance across a wide range of driving scenarios.

The latest developments in LS engine heat shield technology focus on sustainability and emissions reduction. Manufacturers are exploring eco-friendly materials that offer excellent thermal properties while being more recyclable. Additionally, heat shields are now being designed to work in tandem with catalytic converters, helping to maintain ideal operating temperatures for more efficient emissions control.

Throughout this evolution, the role of heat shields in LS engines has expanded from simple protective elements to integral components of the engine's thermal management system. They now contribute significantly to engine efficiency, emissions reduction, and overall performance, showcasing the importance of continuous innovation in automotive engineering.

Market Demand Analysis

The market demand for exhaust heat shields in LS engines has been steadily growing, driven by several key factors in the automotive industry. As vehicle manufacturers strive to meet increasingly stringent emissions regulations and fuel efficiency standards, the importance of effective heat management in engine systems has become paramount. Exhaust heat shields play a crucial role in this context by protecting sensitive components from excessive heat exposure and optimizing overall engine performance.

In recent years, the global automotive market has witnessed a surge in demand for high-performance vehicles, particularly in the sports car and luxury segments. This trend has led to increased adoption of LS engines, known for their power and reliability. Consequently, the market for aftermarket exhaust heat shields specifically designed for LS engines has expanded significantly.

The growing awareness among vehicle owners about the benefits of exhaust heat shields has also contributed to market growth. These benefits include improved engine efficiency, extended component lifespan, and enhanced overall vehicle performance. As a result, both OEM manufacturers and aftermarket suppliers have seen a rise in demand for high-quality heat shield solutions.

The market for exhaust heat shields in LS engines is not limited to passenger vehicles alone. Commercial vehicles, particularly in the heavy-duty segment, have also shown increased interest in advanced heat management solutions. This expansion into diverse vehicle categories has further amplified the market potential for exhaust heat shields.

Technological advancements in materials science have led to the development of more efficient and durable heat shield materials. These innovations have opened up new opportunities in the market, with manufacturers offering lightweight yet highly effective heat shield solutions that cater to the specific requirements of LS engines.

The aftermarket sector has emerged as a significant driver of demand for exhaust heat shields in LS engines. Many vehicle owners opt to upgrade their stock heat shields with high-performance alternatives, creating a thriving market for specialized products. This trend is particularly pronounced among automotive enthusiasts and racing communities, where optimal heat management is critical for achieving peak engine performance.

As environmental concerns continue to shape the automotive industry, the demand for exhaust heat shields is expected to grow further. These components play a vital role in reducing heat-related emissions and improving overall engine efficiency, aligning with global efforts to minimize the environmental impact of vehicles.

In conclusion, the market demand for exhaust heat shields in LS engines is robust and multifaceted, driven by regulatory pressures, performance requirements, and consumer awareness. The industry's ongoing focus on heat management and efficiency improvements suggests that this demand will continue to evolve and expand in the coming years.

In recent years, the global automotive market has witnessed a surge in demand for high-performance vehicles, particularly in the sports car and luxury segments. This trend has led to increased adoption of LS engines, known for their power and reliability. Consequently, the market for aftermarket exhaust heat shields specifically designed for LS engines has expanded significantly.

The growing awareness among vehicle owners about the benefits of exhaust heat shields has also contributed to market growth. These benefits include improved engine efficiency, extended component lifespan, and enhanced overall vehicle performance. As a result, both OEM manufacturers and aftermarket suppliers have seen a rise in demand for high-quality heat shield solutions.

The market for exhaust heat shields in LS engines is not limited to passenger vehicles alone. Commercial vehicles, particularly in the heavy-duty segment, have also shown increased interest in advanced heat management solutions. This expansion into diverse vehicle categories has further amplified the market potential for exhaust heat shields.

Technological advancements in materials science have led to the development of more efficient and durable heat shield materials. These innovations have opened up new opportunities in the market, with manufacturers offering lightweight yet highly effective heat shield solutions that cater to the specific requirements of LS engines.

The aftermarket sector has emerged as a significant driver of demand for exhaust heat shields in LS engines. Many vehicle owners opt to upgrade their stock heat shields with high-performance alternatives, creating a thriving market for specialized products. This trend is particularly pronounced among automotive enthusiasts and racing communities, where optimal heat management is critical for achieving peak engine performance.

As environmental concerns continue to shape the automotive industry, the demand for exhaust heat shields is expected to grow further. These components play a vital role in reducing heat-related emissions and improving overall engine efficiency, aligning with global efforts to minimize the environmental impact of vehicles.

In conclusion, the market demand for exhaust heat shields in LS engines is robust and multifaceted, driven by regulatory pressures, performance requirements, and consumer awareness. The industry's ongoing focus on heat management and efficiency improvements suggests that this demand will continue to evolve and expand in the coming years.

Current Challenges

The current challenges in analyzing the influence of exhaust heat shields in LS engines are multifaceted and complex. One of the primary obstacles is the difficulty in accurately measuring and modeling the heat transfer dynamics within the engine compartment. The high temperatures and rapid thermal fluctuations make it challenging to obtain precise, real-time data on heat distribution and dissipation.

Another significant challenge lies in the variability of operating conditions. LS engines are used in a wide range of vehicles and applications, each with unique environmental factors and performance requirements. This diversity complicates the development of standardized testing protocols and makes it difficult to draw universally applicable conclusions about heat shield effectiveness.

Material limitations also pose a considerable challenge. While advanced materials have improved heat shield performance, finding the optimal balance between thermal resistance, durability, and cost-effectiveness remains an ongoing issue. Engineers must contend with the trade-offs between lightweight materials that may offer superior heat reflection but lower durability, and heavier, more robust materials that may impact overall vehicle performance.

The complexity of exhaust system design further complicates the analysis. Modern LS engines often feature intricate exhaust manifolds and catalytic converter configurations, creating numerous heat sources and potential hot spots. This complexity makes it challenging to isolate the specific effects of heat shields and determine their optimal placement and design.

Additionally, the interaction between heat shields and other engine components presents a significant challenge. The presence of heat shields can affect airflow dynamics, potentially impacting engine cooling and overall performance. Understanding these complex interactions requires sophisticated computational fluid dynamics (CFD) modeling and extensive real-world testing.

Regulatory compliance adds another layer of complexity to the analysis. Stringent emissions standards and safety regulations influence exhaust system design, sometimes necessitating compromises in heat shield implementation. Balancing these regulatory requirements with optimal thermal management is an ongoing challenge for engineers and researchers.

Lastly, the long-term effects of heat shield performance under various conditions remain difficult to predict accurately. Factors such as thermal cycling, vibration, and exposure to environmental contaminants can degrade heat shield effectiveness over time. Developing reliable methods for predicting and mitigating these long-term effects is crucial for improving the overall design and implementation of exhaust heat shields in LS engines.

Another significant challenge lies in the variability of operating conditions. LS engines are used in a wide range of vehicles and applications, each with unique environmental factors and performance requirements. This diversity complicates the development of standardized testing protocols and makes it difficult to draw universally applicable conclusions about heat shield effectiveness.

Material limitations also pose a considerable challenge. While advanced materials have improved heat shield performance, finding the optimal balance between thermal resistance, durability, and cost-effectiveness remains an ongoing issue. Engineers must contend with the trade-offs between lightweight materials that may offer superior heat reflection but lower durability, and heavier, more robust materials that may impact overall vehicle performance.

The complexity of exhaust system design further complicates the analysis. Modern LS engines often feature intricate exhaust manifolds and catalytic converter configurations, creating numerous heat sources and potential hot spots. This complexity makes it challenging to isolate the specific effects of heat shields and determine their optimal placement and design.

Additionally, the interaction between heat shields and other engine components presents a significant challenge. The presence of heat shields can affect airflow dynamics, potentially impacting engine cooling and overall performance. Understanding these complex interactions requires sophisticated computational fluid dynamics (CFD) modeling and extensive real-world testing.

Regulatory compliance adds another layer of complexity to the analysis. Stringent emissions standards and safety regulations influence exhaust system design, sometimes necessitating compromises in heat shield implementation. Balancing these regulatory requirements with optimal thermal management is an ongoing challenge for engineers and researchers.

Lastly, the long-term effects of heat shield performance under various conditions remain difficult to predict accurately. Factors such as thermal cycling, vibration, and exposure to environmental contaminants can degrade heat shield effectiveness over time. Developing reliable methods for predicting and mitigating these long-term effects is crucial for improving the overall design and implementation of exhaust heat shields in LS engines.

Existing Heat Shield Solutions

01 Thermal insulation materials for exhaust heat shields

Various thermal insulation materials are used in exhaust heat shields to improve their effectiveness. These materials include ceramic fibers, metallic foils, and composite materials that can withstand high temperatures and provide excellent thermal protection. The choice of insulation material affects the overall performance and durability of the heat shield.- Thermal insulation materials for exhaust heat shields: Various thermal insulation materials are used in exhaust heat shields to effectively reduce heat transfer. These materials include ceramic fibers, metallic foils, and composite structures that can withstand high temperatures while providing excellent insulation properties. The choice of material depends on factors such as temperature range, weight requirements, and durability.

- Design and configuration of exhaust heat shields: The design and configuration of exhaust heat shields play a crucial role in their effectiveness. This includes aspects such as layered structures, air gaps, and strategic placement of shields around exhaust components. Innovative designs may incorporate features like reflective surfaces or heat-dissipating fins to enhance thermal management.

- Integration of heat shields with exhaust systems: The integration of heat shields with exhaust systems involves considerations such as mounting techniques, flexibility to accommodate thermal expansion, and compatibility with other engine components. Proper integration ensures optimal performance of both the heat shield and the exhaust system, while also addressing issues like vibration and noise reduction.

- Heat shield influence on engine performance and emissions: Exhaust heat shields can significantly impact engine performance and emissions. They help maintain optimal operating temperatures, which can improve fuel efficiency and reduce harmful emissions. Additionally, heat shields can protect sensitive components from thermal damage, potentially extending the lifespan of various engine parts.

- Advanced technologies in exhaust heat shield development: Emerging technologies are enhancing the capabilities of exhaust heat shields. These include the use of smart materials that adapt to temperature changes, integration of heat recovery systems to improve overall engine efficiency, and the application of nanotechnology to create more effective insulating materials. Such advancements aim to further improve thermal management in vehicles.

02 Design and configuration of exhaust heat shields

The design and configuration of exhaust heat shields play a crucial role in their effectiveness. This includes factors such as the shape, size, and placement of the shield relative to the exhaust system. Innovative designs may incorporate multiple layers, air gaps, or reflective surfaces to enhance heat dissipation and protection.Expand Specific Solutions03 Integration of heat shields with catalytic converters

Heat shields are often integrated with catalytic converters to manage exhaust temperatures and improve overall system efficiency. This integration can help maintain optimal operating temperatures for the catalytic converter, reduce heat transfer to surrounding components, and potentially improve fuel efficiency and emissions control.Expand Specific Solutions04 Active cooling systems for exhaust heat management

Some advanced exhaust heat shield designs incorporate active cooling systems to enhance their performance. These may include liquid cooling, forced air circulation, or thermoelectric devices. Active cooling can provide more precise temperature control and potentially allow for heat recovery or energy harvesting from exhaust gases.Expand Specific Solutions05 Impact of heat shields on vehicle aerodynamics and weight

The influence of exhaust heat shields extends beyond thermal management to affect vehicle aerodynamics and overall weight. Designers must balance the need for effective heat protection with considerations for drag reduction and lightweight construction. This may involve the use of advanced materials or aerodynamic shapes that serve dual purposes of heat shielding and improved vehicle performance.Expand Specific Solutions

Key Industry Players

The competition landscape for analyzing the influence of exhaust heat shields in LS engines is characterized by a mature market with established players and emerging technologies. The automotive industry is in a transitional phase, with increasing focus on efficiency and emissions reduction. Major players like BorgWarner, Dana Automotive Systems, and Federal-Mogul are leading the development of advanced heat shield solutions. The market size is substantial, driven by stringent emissions regulations and the need for improved engine performance. Technological maturity varies, with traditional manufacturers like Woodward and Mahindra & Mahindra competing against innovative startups like Divergent Technologies, which is leveraging digital manufacturing to disrupt the sector.

BorgWarner, Inc.

Technical Solution: BorgWarner has developed advanced exhaust heat shield solutions for LS engines, focusing on integrated thermal management systems. Their technology incorporates heat recovery systems that capture and repurpose exhaust heat to improve overall engine efficiency[1]. BorgWarner's heat shields utilize advanced materials such as high-temperature alloys and ceramic matrix composites to withstand extreme thermal conditions while providing excellent insulation properties[2]. The company has also implemented innovative design features, such as air gap insulation and dimpled surfaces, to enhance heat reflection and reduce thermal transfer[3]. BorgWarner's solutions are optimized for weight reduction and packaging efficiency, addressing the increasing demands for compact engine bay designs in modern vehicles[4].

Strengths: Expertise in integrated thermal management systems, focus on heat recovery and energy efficiency, and use of advanced materials. Weaknesses: Potential complexity in integration with existing systems and higher initial costs for advanced materials and technologies.

3M Innovative Properties Co.

Technical Solution: 3M has developed innovative materials and coatings for exhaust heat shields applicable to LS engines. Their technology focuses on advanced thermal insulation materials that offer superior heat resistance and reflectivity[1]. 3M's solutions incorporate multi-layer composite materials, including ceramic fibers and metallic foils, to create lightweight yet highly effective heat shields[2]. The company has also developed specialized adhesives and fastening systems that can withstand high temperatures and vibrations, ensuring long-term durability of heat shield installations[3]. 3M's heat shield materials are designed to be easily formable and customizable, allowing for application in complex exhaust system geometries while maintaining optimal thermal performance[4].

Strengths: Expertise in advanced materials and coatings, focus on lightweight solutions, and versatility in application. Weaknesses: May require partnerships with automotive manufacturers for full integration into LS engine systems, potential higher material costs compared to traditional solutions.

Core Innovations

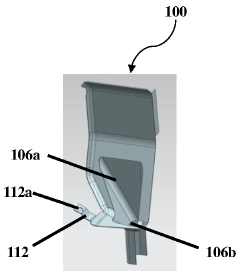

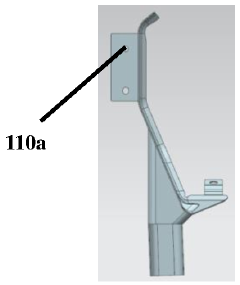

Exhaust manifold heat shield

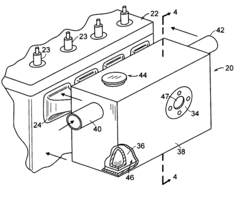

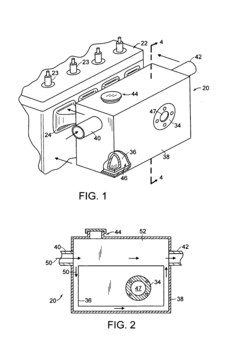

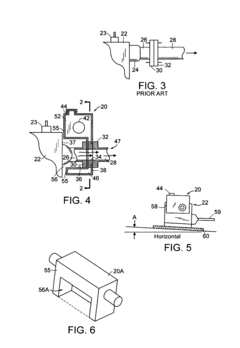

PatentInactiveUS7146807B1

Innovation

- A heat shield with a water-cooled body positioned around the exhaust manifold to carry away radiant and convective heat using the same coolant as the engine block, without altering the engine's physical configuration or performance, thereby avoiding re-certification by using a hollow construction with a boss for attachment and a concavity to envelop the manifold.

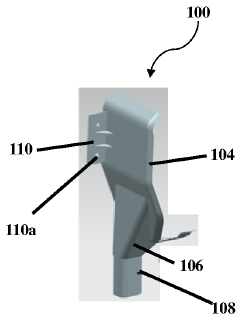

Heat shield for engine exhaust system

PatentPendingIN202111051626A

Innovation

- A heat shield comprising a flat plate with conical guide members and mounting components made of cold-reduced low carbon steel, which channels heat away from the operator's legs and includes a foam layer for temperature reduction, is designed to be simple, easy to assemble, and inexpensive.

Environmental Impact Assessment

The environmental impact of exhaust heat shields in LS engines is a critical consideration in the automotive industry's pursuit of sustainability and reduced emissions. These heat shields play a significant role in managing thermal energy and influencing the overall environmental footprint of vehicles equipped with LS engines.

One of the primary environmental benefits of exhaust heat shields is their contribution to improved fuel efficiency. By effectively managing heat dissipation, these shields help maintain optimal engine temperatures, leading to more efficient combustion processes. This increased efficiency translates to reduced fuel consumption and, consequently, lower greenhouse gas emissions. Studies have shown that properly designed heat shields can contribute to a 1-3% improvement in fuel economy, which, when scaled across millions of vehicles, represents a substantial reduction in carbon dioxide emissions.

Furthermore, exhaust heat shields contribute to the longevity of engine components and catalytic converters. By protecting surrounding parts from excessive heat, these shields help prevent premature wear and degradation. This extended lifespan of engine components reduces the frequency of replacements, thereby decreasing the environmental impact associated with manufacturing and disposing of automotive parts.

The materials used in exhaust heat shields also warrant environmental consideration. Traditional heat shields often utilize metallic materials such as aluminum or stainless steel, which are recyclable but energy-intensive to produce. However, recent advancements have led to the development of composite materials and ceramics that offer superior heat resistance with lower weight. These innovative materials not only enhance the heat shield's performance but also contribute to overall vehicle weight reduction, further improving fuel efficiency and reducing emissions.

Another important aspect is the role of heat shields in noise reduction. By absorbing and deflecting sound waves, these components help mitigate engine noise pollution, which is particularly beneficial in urban environments. This acoustic management contributes to improved quality of life and reduced stress on local ecosystems sensitive to noise disturbances.

However, the environmental impact of exhaust heat shields is not without challenges. The manufacturing process of these components, especially those utilizing advanced materials, can be energy-intensive and may involve the use of potentially harmful chemicals. Additionally, the disposal of heat shields at the end of their lifecycle presents recycling challenges, particularly for composite materials that may not be easily separated into their constituent parts.

In conclusion, while exhaust heat shields in LS engines offer significant environmental benefits through improved fuel efficiency, extended component lifespan, and noise reduction, their full environmental impact must be considered across their entire lifecycle. Future developments in material science and manufacturing processes will be crucial in further enhancing the positive environmental contributions of these essential engine components.

One of the primary environmental benefits of exhaust heat shields is their contribution to improved fuel efficiency. By effectively managing heat dissipation, these shields help maintain optimal engine temperatures, leading to more efficient combustion processes. This increased efficiency translates to reduced fuel consumption and, consequently, lower greenhouse gas emissions. Studies have shown that properly designed heat shields can contribute to a 1-3% improvement in fuel economy, which, when scaled across millions of vehicles, represents a substantial reduction in carbon dioxide emissions.

Furthermore, exhaust heat shields contribute to the longevity of engine components and catalytic converters. By protecting surrounding parts from excessive heat, these shields help prevent premature wear and degradation. This extended lifespan of engine components reduces the frequency of replacements, thereby decreasing the environmental impact associated with manufacturing and disposing of automotive parts.

The materials used in exhaust heat shields also warrant environmental consideration. Traditional heat shields often utilize metallic materials such as aluminum or stainless steel, which are recyclable but energy-intensive to produce. However, recent advancements have led to the development of composite materials and ceramics that offer superior heat resistance with lower weight. These innovative materials not only enhance the heat shield's performance but also contribute to overall vehicle weight reduction, further improving fuel efficiency and reducing emissions.

Another important aspect is the role of heat shields in noise reduction. By absorbing and deflecting sound waves, these components help mitigate engine noise pollution, which is particularly beneficial in urban environments. This acoustic management contributes to improved quality of life and reduced stress on local ecosystems sensitive to noise disturbances.

However, the environmental impact of exhaust heat shields is not without challenges. The manufacturing process of these components, especially those utilizing advanced materials, can be energy-intensive and may involve the use of potentially harmful chemicals. Additionally, the disposal of heat shields at the end of their lifecycle presents recycling challenges, particularly for composite materials that may not be easily separated into their constituent parts.

In conclusion, while exhaust heat shields in LS engines offer significant environmental benefits through improved fuel efficiency, extended component lifespan, and noise reduction, their full environmental impact must be considered across their entire lifecycle. Future developments in material science and manufacturing processes will be crucial in further enhancing the positive environmental contributions of these essential engine components.

Regulatory Compliance

Regulatory compliance plays a crucial role in the development and implementation of exhaust heat shields for LS engines. As automotive manufacturers strive to meet increasingly stringent emissions standards and safety regulations, the design and performance of heat shields must adhere to various national and international guidelines.

In the United States, the Environmental Protection Agency (EPA) sets emissions standards that directly impact exhaust system design, including heat shields. These regulations aim to reduce harmful pollutants and greenhouse gas emissions from vehicles. The California Air Resources Board (CARB) often imposes even stricter requirements, which many other states follow. Manufacturers must ensure that their exhaust heat shields contribute to meeting these standards by effectively managing heat dissipation and preventing thermal damage to surrounding components.

The National Highway Traffic Safety Administration (NHTSA) also influences heat shield design through its safety regulations. These guidelines focus on preventing fire hazards and protecting occupants from excessive heat exposure. Heat shields must be designed to withstand high temperatures and maintain their integrity over the vehicle's lifespan to comply with these safety standards.

Internationally, the United Nations Economic Commission for Europe (UNECE) provides regulations that many countries adopt. These include specific requirements for exhaust system components, including heat shields. Compliance with these standards is essential for manufacturers looking to sell their vehicles in global markets.

Material selection for heat shields is another area heavily influenced by regulatory compliance. Manufacturers must choose materials that not only provide effective heat insulation but also meet environmental and safety standards. This includes considerations for recyclability, toxicity, and fire resistance. The use of asbestos, once common in heat shields, is now strictly regulated or banned in many jurisdictions due to health concerns.

Noise regulations also impact heat shield design, as these components can contribute to overall vehicle noise levels. Manufacturers must ensure that their heat shields do not compromise the vehicle's ability to meet noise emission standards set by various regulatory bodies.

As regulations continue to evolve, manufacturers must stay informed and adapt their heat shield designs accordingly. This often requires ongoing research and development efforts to innovate new materials and design techniques that can meet or exceed regulatory requirements while maintaining performance and cost-effectiveness.

In the United States, the Environmental Protection Agency (EPA) sets emissions standards that directly impact exhaust system design, including heat shields. These regulations aim to reduce harmful pollutants and greenhouse gas emissions from vehicles. The California Air Resources Board (CARB) often imposes even stricter requirements, which many other states follow. Manufacturers must ensure that their exhaust heat shields contribute to meeting these standards by effectively managing heat dissipation and preventing thermal damage to surrounding components.

The National Highway Traffic Safety Administration (NHTSA) also influences heat shield design through its safety regulations. These guidelines focus on preventing fire hazards and protecting occupants from excessive heat exposure. Heat shields must be designed to withstand high temperatures and maintain their integrity over the vehicle's lifespan to comply with these safety standards.

Internationally, the United Nations Economic Commission for Europe (UNECE) provides regulations that many countries adopt. These include specific requirements for exhaust system components, including heat shields. Compliance with these standards is essential for manufacturers looking to sell their vehicles in global markets.

Material selection for heat shields is another area heavily influenced by regulatory compliance. Manufacturers must choose materials that not only provide effective heat insulation but also meet environmental and safety standards. This includes considerations for recyclability, toxicity, and fire resistance. The use of asbestos, once common in heat shields, is now strictly regulated or banned in many jurisdictions due to health concerns.

Noise regulations also impact heat shield design, as these components can contribute to overall vehicle noise levels. Manufacturers must ensure that their heat shields do not compromise the vehicle's ability to meet noise emission standards set by various regulatory bodies.

As regulations continue to evolve, manufacturers must stay informed and adapt their heat shield designs accordingly. This often requires ongoing research and development efforts to innovate new materials and design techniques that can meet or exceed regulatory requirements while maintaining performance and cost-effectiveness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!