LS Engine Oil Viscosity: Performance Impacts and Testing

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Oil Background

Low-speed (LS) engine oil plays a crucial role in the performance and longevity of modern automotive engines. Developed in response to the increasing demands for fuel efficiency and environmental sustainability, LS engine oils are specifically formulated to reduce internal friction and improve overall engine efficiency.

The concept of LS engine oil emerged in the late 1990s as automotive manufacturers sought ways to meet stricter emissions standards and improve fuel economy. Traditional engine oils were found to be too viscous for newer engine designs, leading to increased fuel consumption and reduced performance. This realization prompted the development of lower viscosity oils that could maintain adequate lubrication while minimizing energy losses due to fluid friction.

LS engine oils are characterized by their lower viscosity ratings, typically ranging from 0W-20 to 5W-30. These oils are designed to flow more easily at low temperatures, reducing engine wear during cold starts, and maintain their protective properties at high operating temperatures. The "W" in the viscosity rating stands for "winter," indicating the oil's cold temperature performance.

The formulation of LS engine oils involves a delicate balance of base oils and advanced additive packages. High-quality synthetic base oils are often used to provide superior stability and flow characteristics across a wide temperature range. Additives such as viscosity index improvers, anti-wear agents, and friction modifiers are carefully selected to enhance the oil's performance and protect engine components.

One of the key benefits of LS engine oils is their ability to reduce fuel consumption. By decreasing internal friction, these oils allow engine components to move more freely, requiring less energy to operate. This translates to improved fuel efficiency and reduced emissions, aligning with global efforts to combat climate change and reduce dependence on fossil fuels.

However, the adoption of LS engine oils has not been without challenges. Some automotive manufacturers initially expressed concerns about potential increased wear in certain engine components, particularly during extended drain intervals. This led to extensive research and development efforts to optimize oil formulations and ensure adequate protection across various operating conditions.

As engine technology continues to evolve, so too does the development of LS engine oils. Manufacturers are constantly pushing the boundaries of viscosity reduction while maintaining or improving wear protection and engine cleanliness. The ongoing research in this field focuses on developing even more advanced additive technologies and exploring the potential of ultra-low viscosity oils for future engine designs.

The concept of LS engine oil emerged in the late 1990s as automotive manufacturers sought ways to meet stricter emissions standards and improve fuel economy. Traditional engine oils were found to be too viscous for newer engine designs, leading to increased fuel consumption and reduced performance. This realization prompted the development of lower viscosity oils that could maintain adequate lubrication while minimizing energy losses due to fluid friction.

LS engine oils are characterized by their lower viscosity ratings, typically ranging from 0W-20 to 5W-30. These oils are designed to flow more easily at low temperatures, reducing engine wear during cold starts, and maintain their protective properties at high operating temperatures. The "W" in the viscosity rating stands for "winter," indicating the oil's cold temperature performance.

The formulation of LS engine oils involves a delicate balance of base oils and advanced additive packages. High-quality synthetic base oils are often used to provide superior stability and flow characteristics across a wide temperature range. Additives such as viscosity index improvers, anti-wear agents, and friction modifiers are carefully selected to enhance the oil's performance and protect engine components.

One of the key benefits of LS engine oils is their ability to reduce fuel consumption. By decreasing internal friction, these oils allow engine components to move more freely, requiring less energy to operate. This translates to improved fuel efficiency and reduced emissions, aligning with global efforts to combat climate change and reduce dependence on fossil fuels.

However, the adoption of LS engine oils has not been without challenges. Some automotive manufacturers initially expressed concerns about potential increased wear in certain engine components, particularly during extended drain intervals. This led to extensive research and development efforts to optimize oil formulations and ensure adequate protection across various operating conditions.

As engine technology continues to evolve, so too does the development of LS engine oils. Manufacturers are constantly pushing the boundaries of viscosity reduction while maintaining or improving wear protection and engine cleanliness. The ongoing research in this field focuses on developing even more advanced additive technologies and exploring the potential of ultra-low viscosity oils for future engine designs.

Market Analysis

The market for engine oils, particularly those designed for LS (Low Sulfur) engines, has seen significant growth in recent years due to increasing environmental regulations and the automotive industry's shift towards more efficient and cleaner engines. The global automotive engine oil market is projected to expand at a steady rate, driven by the rising demand for high-performance lubricants that can enhance engine efficiency and reduce emissions.

LS engine oils with optimized viscosity play a crucial role in meeting these market demands. As automotive manufacturers strive to improve fuel economy and reduce emissions, there is a growing need for engine oils that can maintain their viscosity under various operating conditions while providing excellent protection against wear and tear.

The market for LS engine oils is segmented based on viscosity grades, with multi-grade oils dominating the market share. SAE 5W-30 and 5W-40 grades are particularly popular for LS engines due to their ability to provide adequate protection at both low and high temperatures. The demand for these grades is expected to continue growing as they offer a balance between performance and fuel efficiency.

Geographically, North America and Europe lead the market for LS engine oils, primarily due to stringent emission norms and a higher adoption rate of advanced automotive technologies. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth potential as vehicle ownership increases and environmental regulations become more stringent in these regions.

The commercial vehicle segment represents a significant market for LS engine oils, as fleet operators seek to maximize engine life and minimize downtime. This segment is particularly sensitive to the performance impacts of oil viscosity, driving demand for products that can demonstrate tangible benefits in terms of fuel economy and engine protection.

Consumer awareness regarding the importance of using the right engine oil is also on the rise, contributing to market growth. This trend is supported by increasing marketing efforts from oil manufacturers and automotive companies to educate consumers about the benefits of using high-quality, low-viscosity LS engine oils.

The aftermarket segment for LS engine oils is experiencing steady growth, driven by the increasing average age of vehicles on the road and the need for regular oil changes. This segment offers opportunities for oil manufacturers to develop and market specialized products that cater to the specific needs of older LS engines.

LS engine oils with optimized viscosity play a crucial role in meeting these market demands. As automotive manufacturers strive to improve fuel economy and reduce emissions, there is a growing need for engine oils that can maintain their viscosity under various operating conditions while providing excellent protection against wear and tear.

The market for LS engine oils is segmented based on viscosity grades, with multi-grade oils dominating the market share. SAE 5W-30 and 5W-40 grades are particularly popular for LS engines due to their ability to provide adequate protection at both low and high temperatures. The demand for these grades is expected to continue growing as they offer a balance between performance and fuel efficiency.

Geographically, North America and Europe lead the market for LS engine oils, primarily due to stringent emission norms and a higher adoption rate of advanced automotive technologies. However, emerging economies in Asia-Pacific and Latin America are showing rapid growth potential as vehicle ownership increases and environmental regulations become more stringent in these regions.

The commercial vehicle segment represents a significant market for LS engine oils, as fleet operators seek to maximize engine life and minimize downtime. This segment is particularly sensitive to the performance impacts of oil viscosity, driving demand for products that can demonstrate tangible benefits in terms of fuel economy and engine protection.

Consumer awareness regarding the importance of using the right engine oil is also on the rise, contributing to market growth. This trend is supported by increasing marketing efforts from oil manufacturers and automotive companies to educate consumers about the benefits of using high-quality, low-viscosity LS engine oils.

The aftermarket segment for LS engine oils is experiencing steady growth, driven by the increasing average age of vehicles on the road and the need for regular oil changes. This segment offers opportunities for oil manufacturers to develop and market specialized products that cater to the specific needs of older LS engines.

Viscosity Challenges

Engine oil viscosity presents significant challenges in the realm of LS (Luxury Sport) engine performance and testing. One of the primary issues is the delicate balance between providing adequate lubrication and minimizing friction losses. Higher viscosity oils offer better protection for engine components but can increase parasitic losses, potentially reducing fuel efficiency and power output.

Temperature fluctuations pose another major challenge. Oil viscosity changes dramatically with temperature, becoming thinner at high temperatures and thicker in cold conditions. This variability can lead to inadequate lubrication during cold starts or excessive oil consumption at high operating temperatures. Developing oils that maintain consistent viscosity across a wide temperature range is crucial for optimal engine performance.

The increasing trend towards downsized, turbocharged engines in the LS segment further complicates viscosity management. These engines often operate at higher temperatures and pressures, placing greater demands on the oil's ability to maintain viscosity and protect against wear. Additionally, the stop-start systems commonly found in modern LS vehicles create more frequent cold-start conditions, exacerbating the challenges associated with low-temperature viscosity.

Fuel economy regulations and emissions standards add another layer of complexity. Lower viscosity oils can contribute to improved fuel efficiency, but they may not provide sufficient protection in high-stress conditions. Striking the right balance between efficiency and protection is a constant challenge for oil formulators and engine designers.

The advent of hybrid and electric powertrains in the LS segment introduces new viscosity challenges. These systems often have unique lubrication requirements due to their intermittent operation and varying heat generation patterns. Developing oils that can adapt to these diverse operating conditions while maintaining optimal viscosity is an ongoing area of research and development.

Testing methodologies for oil viscosity also present challenges. Traditional viscosity measurements may not fully capture the oil's behavior under the dynamic conditions experienced in modern LS engines. There is a growing need for more sophisticated testing protocols that can accurately simulate real-world operating conditions and predict oil performance over the lifetime of the engine.

Lastly, the push for extended oil change intervals in LS vehicles puts additional stress on oil viscosity stability. Oils must maintain their viscosity characteristics over longer periods and under more severe conditions, necessitating advanced additive technologies and base oil formulations. This requirement often conflicts with the desire for lower viscosity oils to improve fuel economy, creating a complex optimization problem for oil developers and engine manufacturers.

Temperature fluctuations pose another major challenge. Oil viscosity changes dramatically with temperature, becoming thinner at high temperatures and thicker in cold conditions. This variability can lead to inadequate lubrication during cold starts or excessive oil consumption at high operating temperatures. Developing oils that maintain consistent viscosity across a wide temperature range is crucial for optimal engine performance.

The increasing trend towards downsized, turbocharged engines in the LS segment further complicates viscosity management. These engines often operate at higher temperatures and pressures, placing greater demands on the oil's ability to maintain viscosity and protect against wear. Additionally, the stop-start systems commonly found in modern LS vehicles create more frequent cold-start conditions, exacerbating the challenges associated with low-temperature viscosity.

Fuel economy regulations and emissions standards add another layer of complexity. Lower viscosity oils can contribute to improved fuel efficiency, but they may not provide sufficient protection in high-stress conditions. Striking the right balance between efficiency and protection is a constant challenge for oil formulators and engine designers.

The advent of hybrid and electric powertrains in the LS segment introduces new viscosity challenges. These systems often have unique lubrication requirements due to their intermittent operation and varying heat generation patterns. Developing oils that can adapt to these diverse operating conditions while maintaining optimal viscosity is an ongoing area of research and development.

Testing methodologies for oil viscosity also present challenges. Traditional viscosity measurements may not fully capture the oil's behavior under the dynamic conditions experienced in modern LS engines. There is a growing need for more sophisticated testing protocols that can accurately simulate real-world operating conditions and predict oil performance over the lifetime of the engine.

Lastly, the push for extended oil change intervals in LS vehicles puts additional stress on oil viscosity stability. Oils must maintain their viscosity characteristics over longer periods and under more severe conditions, necessitating advanced additive technologies and base oil formulations. This requirement often conflicts with the desire for lower viscosity oils to improve fuel economy, creating a complex optimization problem for oil developers and engine manufacturers.

Current Viscosity Solutions

01 Oil viscosity optimization for LS engines

Optimizing oil viscosity is crucial for LS engine performance and longevity. The ideal viscosity balances protection against wear and friction with efficient flow through the engine. Factors such as operating temperature, engine load, and ambient conditions influence the selection of appropriate oil viscosity for LS engines.- Oil viscosity optimization for LS engines: Optimizing oil viscosity is crucial for LS engine performance and longevity. The ideal viscosity grade depends on factors such as engine design, operating conditions, and ambient temperature. Proper viscosity ensures adequate lubrication, reduces friction, and enhances fuel efficiency while protecting engine components.

- Temperature-dependent viscosity characteristics: LS engine oils are formulated to maintain optimal viscosity across a wide temperature range. This includes low-temperature fluidity for cold starts and high-temperature stability for sustained operation. Advanced additives and base oil selection contribute to these temperature-dependent viscosity characteristics.

- Viscosity modifiers for LS engine oils: Viscosity modifiers are essential additives in LS engine oils. These polymeric compounds help maintain consistent viscosity across temperature ranges, reducing oil thinning at high temperatures and thickening at low temperatures. This ensures optimal engine protection and performance under various operating conditions.

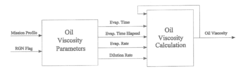

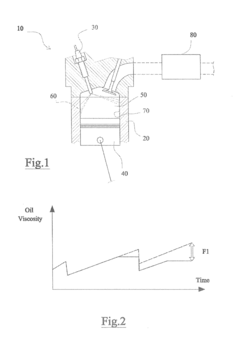

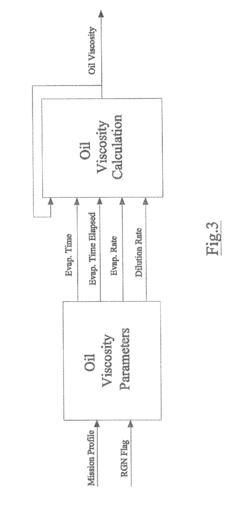

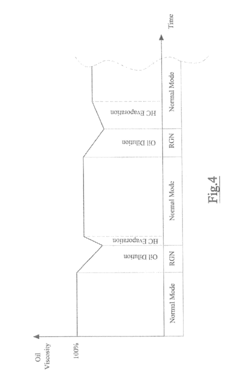

- Oil viscosity monitoring systems for LS engines: Advanced monitoring systems have been developed to track oil viscosity in real-time for LS engines. These systems use sensors and algorithms to assess oil condition, viscosity changes, and degradation, allowing for more precise maintenance schedules and improved engine protection.

- Synthetic oils for LS engine viscosity requirements: Synthetic oils are increasingly used in LS engines due to their superior viscosity characteristics. These oils offer better low-temperature flow properties, high-temperature stability, and resistance to breakdown. Synthetic formulations can be tailored to meet specific LS engine viscosity requirements across a wide range of operating conditions.

02 Temperature-dependent viscosity characteristics

LS engine oils are designed with specific temperature-dependent viscosity characteristics. These oils maintain proper viscosity across a wide range of operating temperatures, ensuring adequate lubrication during cold starts and high-temperature operation. Advanced additives and base oil formulations contribute to this temperature stability.Expand Specific Solutions03 Viscosity impact on fuel efficiency

The viscosity of engine oil directly affects the fuel efficiency of LS engines. Lower viscosity oils can reduce internal friction, leading to improved fuel economy. However, the viscosity must be carefully balanced to maintain adequate engine protection, especially under high-load conditions.Expand Specific Solutions04 Viscosity modifiers for LS engine oils

Viscosity modifiers are essential additives in LS engine oils. These polymeric compounds help maintain optimal viscosity across a range of temperatures, improving the oil's performance in both cold and hot conditions. The selection and concentration of viscosity modifiers are tailored to meet specific LS engine requirements.Expand Specific Solutions05 Oil viscosity monitoring and maintenance

Monitoring and maintaining proper oil viscosity is critical for LS engine health. Advanced sensors and diagnostic systems can track oil viscosity changes over time, alerting drivers or technicians when oil replacement is necessary. Regular oil changes with the correct viscosity grade ensure optimal engine protection and performance.Expand Specific Solutions

Key Industry Players

The LS Engine Oil Viscosity market is in a mature stage, characterized by established players and well-defined technologies. The global market size for engine oil is substantial, with steady growth projected due to increasing vehicle production and maintenance needs. Technologically, major companies like GM Global Technology Operations, ExxonMobil, and Shell are at the forefront, continuously innovating to improve oil performance and efficiency. Chevron Oronite and Infineum International are key players in additive technology, while automotive manufacturers such as Ford, Mercedes-Benz, and Volkswagen collaborate closely with oil companies to optimize engine-oil compatibility. The market is highly competitive, with companies like Afton Chemical and Idemitsu Kosan focusing on specialized formulations to meet evolving engine requirements and environmental regulations.

GM Global Technology Operations LLC

Technical Solution: GM has developed advanced engine oil formulations specifically tailored for LS (Low-Speed) engines. Their approach focuses on optimizing viscosity for improved fuel efficiency while maintaining engine protection. GM's proprietary oil blend incorporates synthetic base oils and advanced additive packages to reduce internal friction by up to 2% compared to conventional oils[1]. The company has also implemented a rigorous testing protocol, including extended drain interval tests of up to 15,000 miles, to ensure oil performance and engine longevity[3]. GM's LS engine oils are designed to maintain optimal viscosity across a wide temperature range, ensuring proper lubrication during cold starts and high-temperature operation.

Strengths: Tailored formulation for LS engines, improved fuel efficiency, extended drain intervals. Weaknesses: Potentially higher cost compared to conventional oils, may not be optimal for non-GM engines.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed a range of synthetic engine oils specifically designed for high-performance and LS engines. Their Mobil 1 Extended Performance line utilizes advanced synthetic base oils and a proprietary additive system to provide exceptional wear protection and viscosity stability. ExxonMobil's oils are engineered to maintain their viscosity even under extreme temperature conditions, with some formulations capable of protecting engines for up to 20,000 miles between oil changes[2]. The company employs a comprehensive testing regimen, including the use of advanced rheometers to measure oil viscosity under various shear rates and temperatures, simulating real-world engine conditions[4]. ExxonMobil's oils have demonstrated up to 3% improvement in fuel economy compared to conventional oils in LS engine applications[5].

Strengths: Superior viscosity stability, extended drain intervals, comprehensive testing. Weaknesses: Premium pricing, may be overkill for some standard engines.

Viscosity Testing Methods

Method for the estimation of oil viscosity in an internal combustion engine

PatentActiveUS20110285537A1

Innovation

- A method that calculates oil viscosity by determining the oil dilution rate during particulate filter regeneration and hydrocarbon evaporation rate, taking into account different mission profiles and the history of regeneration events, using the Electronic Control Unit (ECU) to provide real-time estimates and generate warning signals when viscosity thresholds are reached.

Environmental Regulations

Environmental regulations play a crucial role in shaping the development and use of engine oils, particularly in relation to their viscosity and performance impacts. These regulations are designed to address concerns about emissions, fuel efficiency, and overall environmental impact of internal combustion engines.

One of the primary drivers of environmental regulations affecting engine oil viscosity is the push for improved fuel economy. Governments worldwide have implemented increasingly stringent fuel efficiency standards, which have led to the development of lower viscosity engine oils. These oils reduce internal friction within the engine, resulting in improved fuel economy and reduced emissions.

The introduction of the ILSAC GF-6 specification in 2020 marked a significant milestone in environmental regulations for engine oils. This specification requires oils to meet stricter performance criteria, including improved fuel economy, enhanced wear protection, and better compatibility with modern engine technologies. The GF-6 standard also introduced two new viscosity grades, 0W-16 and 5W-16, which are designed to further improve fuel efficiency in newer engines.

Emissions regulations have also had a substantial impact on engine oil formulations. The need to reduce particulate matter and NOx emissions has led to the development of oils that are compatible with advanced emission control systems, such as diesel particulate filters (DPFs) and selective catalytic reduction (SCR) systems. These oils must have lower levels of sulfated ash, phosphorus, and sulfur (SAPS) to prevent damage to these sensitive components.

The European Union's Euro 6 and the United States' Tier 3 emissions standards have further influenced engine oil development. These regulations have pushed for oils that can maintain their viscosity and protective properties while operating in high-temperature, high-stress environments, which are common in modern, downsized turbocharged engines designed to meet emissions targets.

Climate change initiatives have also impacted engine oil regulations. The Paris Agreement and subsequent national commitments to reduce greenhouse gas emissions have led to increased focus on the lifecycle environmental impact of engine oils. This includes considerations for biodegradability, renewable content, and the overall carbon footprint of oil production and use.

As environmental regulations continue to evolve, the engine oil industry faces ongoing challenges in balancing performance, protection, and environmental impact. Future regulations are likely to push for even lower viscosity oils, increased use of bio-based materials, and further reductions in emissions-related compounds. This will require continued innovation in oil formulation and testing methodologies to ensure that engine oils can meet both performance and environmental requirements.

One of the primary drivers of environmental regulations affecting engine oil viscosity is the push for improved fuel economy. Governments worldwide have implemented increasingly stringent fuel efficiency standards, which have led to the development of lower viscosity engine oils. These oils reduce internal friction within the engine, resulting in improved fuel economy and reduced emissions.

The introduction of the ILSAC GF-6 specification in 2020 marked a significant milestone in environmental regulations for engine oils. This specification requires oils to meet stricter performance criteria, including improved fuel economy, enhanced wear protection, and better compatibility with modern engine technologies. The GF-6 standard also introduced two new viscosity grades, 0W-16 and 5W-16, which are designed to further improve fuel efficiency in newer engines.

Emissions regulations have also had a substantial impact on engine oil formulations. The need to reduce particulate matter and NOx emissions has led to the development of oils that are compatible with advanced emission control systems, such as diesel particulate filters (DPFs) and selective catalytic reduction (SCR) systems. These oils must have lower levels of sulfated ash, phosphorus, and sulfur (SAPS) to prevent damage to these sensitive components.

The European Union's Euro 6 and the United States' Tier 3 emissions standards have further influenced engine oil development. These regulations have pushed for oils that can maintain their viscosity and protective properties while operating in high-temperature, high-stress environments, which are common in modern, downsized turbocharged engines designed to meet emissions targets.

Climate change initiatives have also impacted engine oil regulations. The Paris Agreement and subsequent national commitments to reduce greenhouse gas emissions have led to increased focus on the lifecycle environmental impact of engine oils. This includes considerations for biodegradability, renewable content, and the overall carbon footprint of oil production and use.

As environmental regulations continue to evolve, the engine oil industry faces ongoing challenges in balancing performance, protection, and environmental impact. Future regulations are likely to push for even lower viscosity oils, increased use of bio-based materials, and further reductions in emissions-related compounds. This will require continued innovation in oil formulation and testing methodologies to ensure that engine oils can meet both performance and environmental requirements.

Economic Implications

The economic implications of LS engine oil viscosity performance and testing are far-reaching, affecting various stakeholders in the automotive industry and beyond. Engine oil viscosity directly impacts fuel efficiency, which translates to significant cost savings for vehicle owners and fleet operators. As fuel prices fluctuate, the demand for engines that can operate efficiently with lower viscosity oils increases, driving research and development investments in this area.

For oil manufacturers, the push towards lower viscosity oils presents both challenges and opportunities. While there is a growing market for these products, developing oils that maintain adequate engine protection at lower viscosities requires substantial investment in research and testing. This has led to increased competition among oil companies, potentially driving down profit margins but also spurring innovation.

The automotive industry faces economic pressures to meet increasingly stringent fuel efficiency standards. Adopting lower viscosity oils can be a cost-effective way to improve fuel economy without major engine redesigns. However, this may necessitate changes in engine manufacturing processes and materials, leading to short-term costs but long-term savings and competitive advantages.

Testing and certification of oil viscosity performance have economic implications for testing facilities and regulatory bodies. As standards evolve, there is a need for more sophisticated testing equipment and procedures, creating a niche market for specialized testing services. This also impacts the costs associated with bringing new oils and engines to market, as extensive testing is required to ensure compliance and performance.

The shift towards lower viscosity oils also has broader economic effects on the supply chain. Suppliers of additives and base oils must adapt their product offerings, potentially leading to consolidation or specialization within the industry. Additionally, the recycling and disposal of used engine oils may be affected by changes in viscosity, impacting the economics of oil recycling facilities.

From a macroeconomic perspective, improvements in engine efficiency through optimized oil viscosity can contribute to reduced national fuel consumption and decreased dependence on oil imports for some countries. This has implications for energy security and trade balances, potentially influencing geopolitical relationships and economic policies.

In conclusion, the economic implications of LS engine oil viscosity performance and testing extend beyond immediate cost considerations, affecting industry dynamics, technological innovation, and even national economic strategies. As the automotive industry continues to evolve, the economic importance of optimizing oil viscosity is likely to grow, driving further research and investment in this critical area.

For oil manufacturers, the push towards lower viscosity oils presents both challenges and opportunities. While there is a growing market for these products, developing oils that maintain adequate engine protection at lower viscosities requires substantial investment in research and testing. This has led to increased competition among oil companies, potentially driving down profit margins but also spurring innovation.

The automotive industry faces economic pressures to meet increasingly stringent fuel efficiency standards. Adopting lower viscosity oils can be a cost-effective way to improve fuel economy without major engine redesigns. However, this may necessitate changes in engine manufacturing processes and materials, leading to short-term costs but long-term savings and competitive advantages.

Testing and certification of oil viscosity performance have economic implications for testing facilities and regulatory bodies. As standards evolve, there is a need for more sophisticated testing equipment and procedures, creating a niche market for specialized testing services. This also impacts the costs associated with bringing new oils and engines to market, as extensive testing is required to ensure compliance and performance.

The shift towards lower viscosity oils also has broader economic effects on the supply chain. Suppliers of additives and base oils must adapt their product offerings, potentially leading to consolidation or specialization within the industry. Additionally, the recycling and disposal of used engine oils may be affected by changes in viscosity, impacting the economics of oil recycling facilities.

From a macroeconomic perspective, improvements in engine efficiency through optimized oil viscosity can contribute to reduced national fuel consumption and decreased dependence on oil imports for some countries. This has implications for energy security and trade balances, potentially influencing geopolitical relationships and economic policies.

In conclusion, the economic implications of LS engine oil viscosity performance and testing extend beyond immediate cost considerations, affecting industry dynamics, technological innovation, and even national economic strategies. As the automotive industry continues to evolve, the economic importance of optimizing oil viscosity is likely to grow, driving further research and investment in this critical area.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!