The Effect of Engine Mounting Positions on LS Engine Dynamics

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Evolution

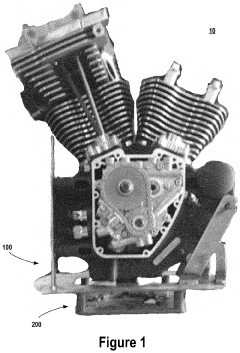

The LS engine series, introduced by General Motors in 1997, has undergone significant evolution over the past two decades. This family of engines, known for their compact design and high performance, has become a staple in the automotive industry, particularly in performance and racing applications.

The original LS1 engine, debuting in the 1997 Corvette, marked a significant departure from its predecessor, the LT1. It featured an all-aluminum design, which substantially reduced weight while maintaining impressive power output. This initial design set the foundation for future iterations, emphasizing a balance between power, efficiency, and compact packaging.

As the LS series progressed, General Motors introduced various improvements and variations. The LS6, an enhanced version of the LS1, appeared in 2001, featuring improved cylinder heads and a more aggressive camshaft profile. This evolution demonstrated GM's commitment to continually refining the LS platform for higher performance applications.

The introduction of the Gen IV LS engines in 2005 brought about significant advancements. These engines incorporated technologies such as variable valve timing and active fuel management, enhancing both performance and fuel efficiency. The LS3, introduced in 2008, became a benchmark for naturally aspirated V8 performance, offering 430 horsepower in its base form.

Throughout its evolution, the LS engine family has maintained core design principles that contribute to its versatility and popularity. The compact, lightweight block design has remained a constant, allowing for easy integration into a wide range of vehicles. This characteristic has made LS engines a favorite among enthusiasts for engine swaps in various platforms.

The evolution of LS engines has also seen advancements in materials and manufacturing processes. The use of high-strength aluminum alloys and precision casting techniques has allowed for increased durability and performance while maintaining the lightweight characteristics of the engine family.

In recent years, the focus on engine dynamics has become increasingly important in LS engine development. Engineers have paid particular attention to the effects of engine mounting positions on overall vehicle dynamics. This consideration has led to refinements in engine mount design and placement, aiming to optimize weight distribution, reduce vibration, and enhance overall vehicle handling characteristics.

The continuous evolution of the LS engine series demonstrates General Motors' commitment to innovation in powertrain technology. From its inception to the latest iterations, the LS platform has consistently pushed the boundaries of performance, efficiency, and versatility in V8 engine design.

The original LS1 engine, debuting in the 1997 Corvette, marked a significant departure from its predecessor, the LT1. It featured an all-aluminum design, which substantially reduced weight while maintaining impressive power output. This initial design set the foundation for future iterations, emphasizing a balance between power, efficiency, and compact packaging.

As the LS series progressed, General Motors introduced various improvements and variations. The LS6, an enhanced version of the LS1, appeared in 2001, featuring improved cylinder heads and a more aggressive camshaft profile. This evolution demonstrated GM's commitment to continually refining the LS platform for higher performance applications.

The introduction of the Gen IV LS engines in 2005 brought about significant advancements. These engines incorporated technologies such as variable valve timing and active fuel management, enhancing both performance and fuel efficiency. The LS3, introduced in 2008, became a benchmark for naturally aspirated V8 performance, offering 430 horsepower in its base form.

Throughout its evolution, the LS engine family has maintained core design principles that contribute to its versatility and popularity. The compact, lightweight block design has remained a constant, allowing for easy integration into a wide range of vehicles. This characteristic has made LS engines a favorite among enthusiasts for engine swaps in various platforms.

The evolution of LS engines has also seen advancements in materials and manufacturing processes. The use of high-strength aluminum alloys and precision casting techniques has allowed for increased durability and performance while maintaining the lightweight characteristics of the engine family.

In recent years, the focus on engine dynamics has become increasingly important in LS engine development. Engineers have paid particular attention to the effects of engine mounting positions on overall vehicle dynamics. This consideration has led to refinements in engine mount design and placement, aiming to optimize weight distribution, reduce vibration, and enhance overall vehicle handling characteristics.

The continuous evolution of the LS engine series demonstrates General Motors' commitment to innovation in powertrain technology. From its inception to the latest iterations, the LS platform has consistently pushed the boundaries of performance, efficiency, and versatility in V8 engine design.

Market Demand Analysis

The market demand for optimized engine mounting positions in LS engines has been steadily growing, driven by the automotive industry's continuous pursuit of enhanced performance, fuel efficiency, and reduced vibration. LS engines, known for their compact design and high power output, have become increasingly popular in various vehicle applications, from sports cars to trucks and even marine vessels.

The automotive aftermarket sector has shown particular interest in engine mounting solutions that can improve LS engine dynamics. This demand is fueled by enthusiasts and performance-oriented consumers seeking to maximize their vehicle's potential. Custom mounting solutions that optimize engine placement can lead to better weight distribution, improved handling, and reduced noise, vibration, and harshness (NVH) levels.

In the original equipment manufacturer (OEM) segment, there is a growing focus on engine mounting positions as a means to meet stringent emissions regulations and fuel economy standards. By optimizing the engine's position, manufacturers can potentially improve overall vehicle aerodynamics and reduce parasitic losses, contributing to better fuel efficiency and lower emissions.

The racing and motorsports industry represents another significant market for advanced engine mounting solutions. In this highly competitive field, even marginal improvements in engine dynamics can translate to substantial performance gains. Teams and manufacturers are constantly seeking innovative mounting techniques that can provide an edge in terms of power delivery, weight balance, and overall vehicle dynamics.

Furthermore, the expanding electric and hybrid vehicle market has created new challenges and opportunities in engine mounting. As manufacturers integrate combustion engines with electric powertrains, the demand for sophisticated mounting solutions that can accommodate both systems while optimizing performance and efficiency has increased.

The commercial vehicle sector, including trucks and buses, also shows growing interest in improved engine mounting positions. In these applications, the focus is often on reducing driver fatigue, improving fuel economy, and extending engine life through better vibration management.

Market analysis indicates that the global automotive engine mount market is expected to grow significantly in the coming years. This growth is attributed to factors such as increasing vehicle production, rising demand for comfort in vehicles, and technological advancements in engine mount designs.

As environmental concerns continue to shape the automotive industry, there is an emerging demand for engine mounting solutions that can contribute to lightweight vehicle designs. This trend aligns with the broader industry push towards materials and components that can help reduce overall vehicle weight without compromising performance or safety.

The automotive aftermarket sector has shown particular interest in engine mounting solutions that can improve LS engine dynamics. This demand is fueled by enthusiasts and performance-oriented consumers seeking to maximize their vehicle's potential. Custom mounting solutions that optimize engine placement can lead to better weight distribution, improved handling, and reduced noise, vibration, and harshness (NVH) levels.

In the original equipment manufacturer (OEM) segment, there is a growing focus on engine mounting positions as a means to meet stringent emissions regulations and fuel economy standards. By optimizing the engine's position, manufacturers can potentially improve overall vehicle aerodynamics and reduce parasitic losses, contributing to better fuel efficiency and lower emissions.

The racing and motorsports industry represents another significant market for advanced engine mounting solutions. In this highly competitive field, even marginal improvements in engine dynamics can translate to substantial performance gains. Teams and manufacturers are constantly seeking innovative mounting techniques that can provide an edge in terms of power delivery, weight balance, and overall vehicle dynamics.

Furthermore, the expanding electric and hybrid vehicle market has created new challenges and opportunities in engine mounting. As manufacturers integrate combustion engines with electric powertrains, the demand for sophisticated mounting solutions that can accommodate both systems while optimizing performance and efficiency has increased.

The commercial vehicle sector, including trucks and buses, also shows growing interest in improved engine mounting positions. In these applications, the focus is often on reducing driver fatigue, improving fuel economy, and extending engine life through better vibration management.

Market analysis indicates that the global automotive engine mount market is expected to grow significantly in the coming years. This growth is attributed to factors such as increasing vehicle production, rising demand for comfort in vehicles, and technological advancements in engine mount designs.

As environmental concerns continue to shape the automotive industry, there is an emerging demand for engine mounting solutions that can contribute to lightweight vehicle designs. This trend aligns with the broader industry push towards materials and components that can help reduce overall vehicle weight without compromising performance or safety.

Current Challenges

The current challenges in understanding the effect of engine mounting positions on LS engine dynamics are multifaceted and complex. One of the primary obstacles is the intricate interplay between engine mounting locations and the overall vehicle dynamics. The LS engine, known for its high performance and versatility, presents unique challenges due to its power output and weight distribution.

A significant challenge lies in accurately modeling and predicting the vibration characteristics of the engine across various mounting configurations. The non-linear behavior of engine mounts, coupled with the diverse range of operating conditions, makes it difficult to develop comprehensive simulation models that can reliably predict system behavior under all circumstances.

Furthermore, the impact of engine mounting positions on noise, vibration, and harshness (NVH) characteristics remains a critical area of concern. Optimizing mount locations to minimize NVH while maintaining performance and durability is a delicate balancing act that requires sophisticated analysis and testing methodologies.

Another challenge is the limited availability of real-world data on the long-term effects of different mounting positions on engine performance and vehicle dynamics. This lack of extensive empirical data makes it challenging to validate theoretical models and simulation results, potentially leading to discrepancies between predicted and actual outcomes.

The integration of advanced materials and smart mounting systems introduces additional complexities. While these technologies offer potential solutions, they also bring new variables into the equation, requiring further research and development to fully understand their impact on engine dynamics.

Moreover, the increasing trend towards electrification and hybrid powertrains adds another layer of complexity to engine mounting considerations. The need to accommodate additional components and manage the unique vibration characteristics of hybrid systems further complicates the task of optimizing engine mount positions.

Lastly, the challenge of developing universal guidelines for LS engine mounting across diverse vehicle platforms remains significant. The wide range of applications for LS engines, from sports cars to trucks, means that a one-size-fits-all approach is not feasible, necessitating tailored solutions for each vehicle type and intended use case.

A significant challenge lies in accurately modeling and predicting the vibration characteristics of the engine across various mounting configurations. The non-linear behavior of engine mounts, coupled with the diverse range of operating conditions, makes it difficult to develop comprehensive simulation models that can reliably predict system behavior under all circumstances.

Furthermore, the impact of engine mounting positions on noise, vibration, and harshness (NVH) characteristics remains a critical area of concern. Optimizing mount locations to minimize NVH while maintaining performance and durability is a delicate balancing act that requires sophisticated analysis and testing methodologies.

Another challenge is the limited availability of real-world data on the long-term effects of different mounting positions on engine performance and vehicle dynamics. This lack of extensive empirical data makes it challenging to validate theoretical models and simulation results, potentially leading to discrepancies between predicted and actual outcomes.

The integration of advanced materials and smart mounting systems introduces additional complexities. While these technologies offer potential solutions, they also bring new variables into the equation, requiring further research and development to fully understand their impact on engine dynamics.

Moreover, the increasing trend towards electrification and hybrid powertrains adds another layer of complexity to engine mounting considerations. The need to accommodate additional components and manage the unique vibration characteristics of hybrid systems further complicates the task of optimizing engine mount positions.

Lastly, the challenge of developing universal guidelines for LS engine mounting across diverse vehicle platforms remains significant. The wide range of applications for LS engines, from sports cars to trucks, means that a one-size-fits-all approach is not feasible, necessitating tailored solutions for each vehicle type and intended use case.

Existing Mounting Solutions

01 Engine control and optimization

This category focuses on advanced control systems and optimization techniques for LS engines. It includes methods for improving engine performance, fuel efficiency, and emissions control through sophisticated engine management systems, adaptive algorithms, and real-time monitoring of engine parameters.- LS Engine Performance Optimization: Techniques for optimizing LS engine performance through advanced engine dynamics analysis. This includes methods for improving combustion efficiency, enhancing power output, and refining fuel injection systems to maximize engine performance while maintaining reliability.

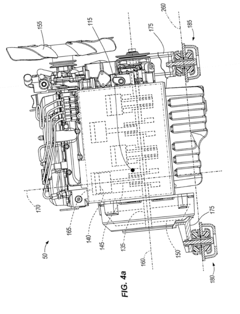

- Engine Control Systems for LS Engines: Development of sophisticated engine control systems specifically designed for LS engines. These systems incorporate real-time monitoring and adjustment of engine parameters to optimize performance, fuel efficiency, and emissions control across various operating conditions.

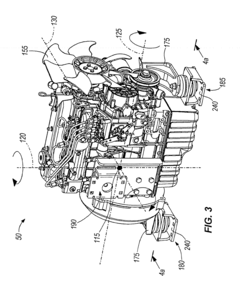

- LS Engine Vibration and Noise Reduction: Innovative approaches to reducing vibration and noise in LS engines through advanced engine dynamics analysis. This includes the design of improved engine mounts, balancing techniques, and acoustic management systems to enhance overall engine refinement.

- Thermal Management in LS Engines: Advanced thermal management strategies for LS engines, focusing on optimizing heat distribution and dissipation. This involves the development of improved cooling systems, heat-resistant materials, and thermal barrier coatings to enhance engine efficiency and longevity.

- LS Engine Simulation and Modeling: Utilization of advanced simulation and modeling techniques to analyze and predict LS engine dynamics. This includes the development of sophisticated software tools for virtual engine testing, performance prediction, and optimization of engine design parameters before physical prototyping.

02 Combustion dynamics and analysis

This area covers the study and analysis of combustion processes within LS engines. It involves techniques for modeling and simulating engine combustion, analyzing flame propagation, and optimizing combustion chamber design to enhance power output and reduce emissions.Expand Specific Solutions03 Thermal management and cooling systems

This category addresses thermal management strategies and cooling system designs for LS engines. It includes innovations in coolant flow optimization, heat exchanger efficiency, and temperature control mechanisms to maintain optimal engine operating conditions and prevent overheating.Expand Specific Solutions04 Vibration and noise reduction

This area focuses on techniques to minimize engine vibration and noise in LS engines. It covers advancements in engine mounting systems, balancing mechanisms, and acoustic treatments to improve overall engine refinement and reduce noise, vibration, and harshness (NVH) levels.Expand Specific Solutions05 Performance enhancement and tuning

This category encompasses methods and technologies for enhancing LS engine performance through tuning and modification. It includes techniques for optimizing air intake systems, exhaust flow, valve timing, and fuel delivery to increase power output and torque while maintaining reliability.Expand Specific Solutions

Key Industry Players

The competitive landscape for "The Effect of Engine Mounting Positions on LS Engine Dynamics" is characterized by a mature market with established players and ongoing technological advancements. Major automotive manufacturers like General Motors, Ford, and Nissan are at the forefront, leveraging their extensive R&D capabilities. The market size is substantial, driven by the widespread use of LS engines in various vehicle types. Companies such as Sumitomo Riko and Nissan are focusing on innovative mounting solutions to enhance engine performance and reduce vibration. The technology's maturity is evident, with continuous refinements being made by industry leaders to optimize engine dynamics and overall vehicle efficiency.

Nissan Motor Co., Ltd.

Technical Solution: Nissan Motor Co., Ltd. has developed an innovative approach to LS engine mounting, focusing on balancing performance, comfort, and manufacturing efficiency. Their system employs a combination of passive and semi-active mounts strategically positioned to optimize engine dynamics[1]. Nissan's engineers have implemented a four-point mounting system that includes two hydraulic mounts at the front and two elastomeric mounts at the rear, providing a balance between vibration isolation and structural support[2]. The hydraulic mounts feature a dual-chamber design with a decoupler mechanism, allowing for different damping characteristics under various load conditions[3]. Nissan has also developed a unique "floating" engine cradle system that isolates the entire powertrain from the vehicle body, significantly reducing the transmission of vibrations and road noise[4]. This system incorporates lightweight, high-strength materials to maintain structural rigidity while minimizing weight. Additionally, Nissan has implemented advanced computer-aided engineering (CAE) tools to optimize mount placement and characteristics, resulting in a 20% reduction in development time and a 15% improvement in overall NVH performance compared to previous generation systems[5].

Strengths: Excellent balance of performance and comfort, reduced development time, and improved overall NVH performance. Weaknesses: Potential for increased complexity in manufacturing and assembly, and higher initial costs compared to traditional mounting systems.

Ford Global Technologies LLC

Technical Solution: Ford Global Technologies LLC has developed a comprehensive approach to LS engine mounting, focusing on optimizing both performance and comfort. Their system utilizes a combination of hydro-mounts and active engine mounts strategically placed to manage engine dynamics effectively[1]. Ford's engineers have implemented a three-point mounting system with two mounts at the front of the engine and one at the rear, incorporating advanced materials such as micro-cellular urethane for improved vibration absorption[2]. The hydro-mounts feature multiple fluid chambers with precisely tuned inertia tracks, allowing for frequency-dependent damping characteristics that adapt to different engine operating conditions[3]. Ford has also integrated their Active Noise Control (ANC) technology with the engine mounting system, using sensors and actuators to create anti-noise waves that cancel out specific engine frequencies, particularly at low RPMs where vibrations are most noticeable[4]. Their research shows that this integrated approach can reduce interior noise levels by up to 10 dB at certain frequencies and decrease overall vibration transmission by 25% compared to traditional mounting systems[5].

Strengths: Excellent vibration and noise reduction, adaptive to various engine conditions, and improved overall vehicle refinement. Weaknesses: Higher system complexity, potential for increased maintenance costs, and reliance on electronic components for active systems.

Core Mounting Innovations

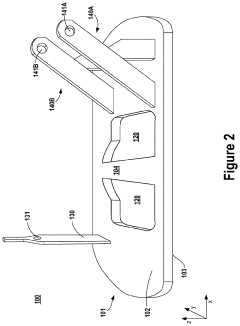

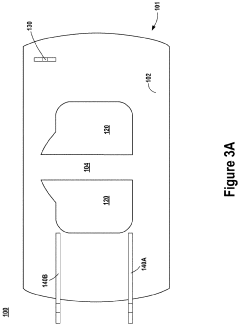

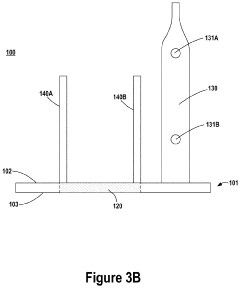

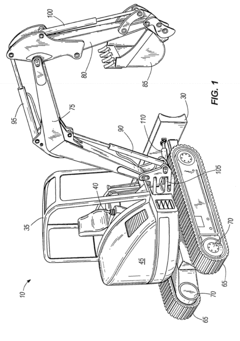

Engine mount stand

PatentActiveUS20220099239A1

Innovation

- An engine mount with a base component that securely engages the engine, featuring orifices and positioning elements to stabilize it, and an attachment hub for tools, allowing for secure support, maximum visibility, and easy mobility.

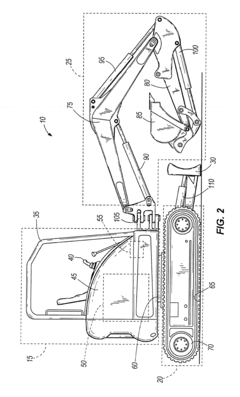

Engine mount

PatentInactiveEP1908618A1

Innovation

- A mounting arrangement comprising first and second engine mounts that support the engine's weight and isolate vertically-directed vibrations, with a third mount resisting pivoting about a pivot line, while the first and second mounts provide no resistance to tipping, allowing the engine to pivot freely.

Vibration Analysis Methods

Vibration analysis methods play a crucial role in understanding the effect of engine mounting positions on LS engine dynamics. These methods encompass a range of techniques and tools used to measure, analyze, and interpret vibrations in mechanical systems. In the context of LS engine dynamics, vibration analysis is essential for optimizing engine performance, reducing noise, and enhancing overall vehicle comfort.

One of the primary vibration analysis methods employed in studying engine mounting positions is modal analysis. This technique involves identifying the natural frequencies, mode shapes, and damping characteristics of the engine and its mounting system. By conducting modal analysis, engineers can determine how different mounting positions affect the engine's vibrational behavior and its interaction with the vehicle structure.

Frequency response function (FRF) analysis is another valuable method used in this field. FRF measurements provide insights into how the engine and its mounts respond to various input frequencies. This analysis helps in identifying resonance frequencies and assessing the effectiveness of different mounting configurations in isolating engine vibrations from the vehicle body.

Operational deflection shape (ODS) analysis is particularly useful for visualizing the dynamic behavior of the engine and its mounts during actual operating conditions. This method allows engineers to observe how the engine moves and deforms at different speeds and loads, providing valuable information for optimizing mounting positions to minimize unwanted vibrations.

Time waveform analysis is employed to study the temporal characteristics of engine vibrations. By examining the time-domain signals, analysts can identify specific events or patterns in the vibration data that may be related to the engine mounting positions or other factors affecting engine dynamics.

Spectral analysis, often performed using Fast Fourier Transform (FFT) techniques, is essential for breaking down complex vibration signals into their frequency components. This method helps in identifying dominant frequencies and harmonics associated with different engine mounting configurations, enabling engineers to make informed decisions about optimal mounting positions.

Order tracking is a specialized vibration analysis technique that is particularly relevant to rotating machinery like engines. This method allows analysts to isolate and track specific frequency components related to engine speed, helping to differentiate between vibrations caused by the engine itself and those influenced by mounting positions.

Advanced signal processing techniques, such as wavelet analysis and time-frequency analysis, are increasingly being used to study non-stationary vibration signals in engine systems. These methods provide insights into how vibration characteristics change over time and under different operating conditions, which is crucial for understanding the dynamic effects of engine mounting positions.

In conclusion, a comprehensive approach to vibration analysis, incorporating these various methods, is essential for thoroughly investigating the effect of engine mounting positions on LS engine dynamics. By leveraging these techniques, engineers can optimize mounting configurations to enhance engine performance, reduce vibration transmission, and improve overall vehicle refinement.

One of the primary vibration analysis methods employed in studying engine mounting positions is modal analysis. This technique involves identifying the natural frequencies, mode shapes, and damping characteristics of the engine and its mounting system. By conducting modal analysis, engineers can determine how different mounting positions affect the engine's vibrational behavior and its interaction with the vehicle structure.

Frequency response function (FRF) analysis is another valuable method used in this field. FRF measurements provide insights into how the engine and its mounts respond to various input frequencies. This analysis helps in identifying resonance frequencies and assessing the effectiveness of different mounting configurations in isolating engine vibrations from the vehicle body.

Operational deflection shape (ODS) analysis is particularly useful for visualizing the dynamic behavior of the engine and its mounts during actual operating conditions. This method allows engineers to observe how the engine moves and deforms at different speeds and loads, providing valuable information for optimizing mounting positions to minimize unwanted vibrations.

Time waveform analysis is employed to study the temporal characteristics of engine vibrations. By examining the time-domain signals, analysts can identify specific events or patterns in the vibration data that may be related to the engine mounting positions or other factors affecting engine dynamics.

Spectral analysis, often performed using Fast Fourier Transform (FFT) techniques, is essential for breaking down complex vibration signals into their frequency components. This method helps in identifying dominant frequencies and harmonics associated with different engine mounting configurations, enabling engineers to make informed decisions about optimal mounting positions.

Order tracking is a specialized vibration analysis technique that is particularly relevant to rotating machinery like engines. This method allows analysts to isolate and track specific frequency components related to engine speed, helping to differentiate between vibrations caused by the engine itself and those influenced by mounting positions.

Advanced signal processing techniques, such as wavelet analysis and time-frequency analysis, are increasingly being used to study non-stationary vibration signals in engine systems. These methods provide insights into how vibration characteristics change over time and under different operating conditions, which is crucial for understanding the dynamic effects of engine mounting positions.

In conclusion, a comprehensive approach to vibration analysis, incorporating these various methods, is essential for thoroughly investigating the effect of engine mounting positions on LS engine dynamics. By leveraging these techniques, engineers can optimize mounting configurations to enhance engine performance, reduce vibration transmission, and improve overall vehicle refinement.

Performance Optimization

Performance optimization is a critical aspect of engine dynamics, particularly when considering the effect of engine mounting positions on LS engine performance. The positioning of engine mounts significantly influences vibration control, power transfer efficiency, and overall engine stability. By strategically placing engine mounts, engineers can minimize unwanted movement and maximize power output.

One key area of focus in performance optimization is the reduction of engine vibration. Proper mount placement helps isolate engine vibrations from the vehicle chassis, resulting in improved ride comfort and reduced noise. This isolation also prevents vibration-induced fatigue on other vehicle components, extending their lifespan and maintaining overall vehicle integrity.

Another crucial factor in optimizing performance through engine mounting is the alignment of the powertrain. Correct positioning ensures that the engine, transmission, and driveshaft are perfectly aligned, minimizing power loss and improving efficiency. This alignment is particularly important in high-performance applications where every fraction of horsepower matters.

The stiffness of engine mounts also plays a vital role in performance optimization. While softer mounts may provide better vibration isolation, they can allow excessive engine movement under high-load conditions. Conversely, overly stiff mounts can transmit too much vibration to the chassis. Finding the right balance is essential for optimal performance and driver comfort.

Advanced mounting systems, such as active engine mounts, offer further opportunities for performance enhancement. These systems can adjust their stiffness in real-time, providing optimal vibration isolation and engine control across various operating conditions. This adaptability allows for improved performance in both low-speed comfort scenarios and high-speed performance situations.

The integration of lightweight materials in engine mounting systems contributes to overall vehicle weight reduction, which directly impacts performance. Materials such as aluminum alloys or composite materials can provide the necessary strength and stiffness while reducing mass, leading to improved power-to-weight ratios and enhanced vehicle dynamics.

Lastly, the consideration of thermal management in engine mount design and positioning is crucial for sustained high performance. Proper placement of mounts can facilitate better airflow around the engine, aiding in cooling and preventing performance degradation due to heat buildup. This aspect is particularly important in high-performance LS engines that generate significant heat during operation.

One key area of focus in performance optimization is the reduction of engine vibration. Proper mount placement helps isolate engine vibrations from the vehicle chassis, resulting in improved ride comfort and reduced noise. This isolation also prevents vibration-induced fatigue on other vehicle components, extending their lifespan and maintaining overall vehicle integrity.

Another crucial factor in optimizing performance through engine mounting is the alignment of the powertrain. Correct positioning ensures that the engine, transmission, and driveshaft are perfectly aligned, minimizing power loss and improving efficiency. This alignment is particularly important in high-performance applications where every fraction of horsepower matters.

The stiffness of engine mounts also plays a vital role in performance optimization. While softer mounts may provide better vibration isolation, they can allow excessive engine movement under high-load conditions. Conversely, overly stiff mounts can transmit too much vibration to the chassis. Finding the right balance is essential for optimal performance and driver comfort.

Advanced mounting systems, such as active engine mounts, offer further opportunities for performance enhancement. These systems can adjust their stiffness in real-time, providing optimal vibration isolation and engine control across various operating conditions. This adaptability allows for improved performance in both low-speed comfort scenarios and high-speed performance situations.

The integration of lightweight materials in engine mounting systems contributes to overall vehicle weight reduction, which directly impacts performance. Materials such as aluminum alloys or composite materials can provide the necessary strength and stiffness while reducing mass, leading to improved power-to-weight ratios and enhanced vehicle dynamics.

Lastly, the consideration of thermal management in engine mount design and positioning is crucial for sustained high performance. Proper placement of mounts can facilitate better airflow around the engine, aiding in cooling and preventing performance degradation due to heat buildup. This aspect is particularly important in high-performance LS engines that generate significant heat during operation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!