Using Cloud-Based Analysis for LS Engine Development Optimization

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Cloud Analysis Background and Objectives

The development of LS (Luxury Sport) engines has been a cornerstone of automotive engineering for decades, with continuous advancements in performance, efficiency, and reliability. As the automotive industry faces increasing pressure to innovate and optimize, cloud-based analysis has emerged as a powerful tool for engine development. This technological approach leverages the vast computational resources and advanced analytics capabilities of cloud computing to revolutionize the engine design and optimization process.

The primary objective of utilizing cloud-based analysis for LS engine development optimization is to accelerate the design cycle, reduce costs, and enhance overall engine performance. By harnessing the power of cloud computing, engineers can perform complex simulations, analyze vast amounts of data, and iterate designs at unprecedented speeds. This approach allows for more comprehensive testing and validation of engine components and systems, leading to improved reliability and efficiency.

Historically, engine development has relied heavily on physical prototyping and testing, which is both time-consuming and expensive. The advent of computer-aided engineering (CAE) tools marked a significant shift in the industry, enabling more efficient design processes. However, the limitations of on-premises computing resources often constrained the scope and complexity of simulations that could be performed. Cloud-based analysis represents the next evolutionary step in this progression, offering virtually unlimited computational power and storage capacity.

The technological trend in LS engine development is moving towards more integrated and holistic approaches. Cloud-based analysis facilitates this by enabling simultaneous optimization of multiple engine parameters, considering factors such as combustion efficiency, thermal management, emissions control, and structural integrity. This comprehensive approach allows engineers to identify synergies and trade-offs that may not have been apparent with traditional methods.

As environmental regulations become increasingly stringent, the automotive industry faces the challenge of developing engines that deliver high performance while meeting strict emissions standards. Cloud-based analysis plays a crucial role in addressing this challenge by enabling more accurate predictions of engine emissions under various operating conditions. This capability allows engineers to fine-tune engine designs to achieve optimal balance between performance and environmental compliance.

The ultimate goal of implementing cloud-based analysis in LS engine development is to create a more agile, data-driven, and efficient design process. By leveraging advanced algorithms, machine learning, and big data analytics, engineers can uncover insights that drive innovation and lead to breakthrough technologies in engine design. This approach not only promises to enhance the performance and efficiency of LS engines but also has the potential to significantly reduce development time and costs, giving automotive manufacturers a competitive edge in a rapidly evolving market.

The primary objective of utilizing cloud-based analysis for LS engine development optimization is to accelerate the design cycle, reduce costs, and enhance overall engine performance. By harnessing the power of cloud computing, engineers can perform complex simulations, analyze vast amounts of data, and iterate designs at unprecedented speeds. This approach allows for more comprehensive testing and validation of engine components and systems, leading to improved reliability and efficiency.

Historically, engine development has relied heavily on physical prototyping and testing, which is both time-consuming and expensive. The advent of computer-aided engineering (CAE) tools marked a significant shift in the industry, enabling more efficient design processes. However, the limitations of on-premises computing resources often constrained the scope and complexity of simulations that could be performed. Cloud-based analysis represents the next evolutionary step in this progression, offering virtually unlimited computational power and storage capacity.

The technological trend in LS engine development is moving towards more integrated and holistic approaches. Cloud-based analysis facilitates this by enabling simultaneous optimization of multiple engine parameters, considering factors such as combustion efficiency, thermal management, emissions control, and structural integrity. This comprehensive approach allows engineers to identify synergies and trade-offs that may not have been apparent with traditional methods.

As environmental regulations become increasingly stringent, the automotive industry faces the challenge of developing engines that deliver high performance while meeting strict emissions standards. Cloud-based analysis plays a crucial role in addressing this challenge by enabling more accurate predictions of engine emissions under various operating conditions. This capability allows engineers to fine-tune engine designs to achieve optimal balance between performance and environmental compliance.

The ultimate goal of implementing cloud-based analysis in LS engine development is to create a more agile, data-driven, and efficient design process. By leveraging advanced algorithms, machine learning, and big data analytics, engineers can uncover insights that drive innovation and lead to breakthrough technologies in engine design. This approach not only promises to enhance the performance and efficiency of LS engines but also has the potential to significantly reduce development time and costs, giving automotive manufacturers a competitive edge in a rapidly evolving market.

Market Demand for Cloud-Based Engine Development

The market demand for cloud-based engine development solutions has been steadily increasing in recent years, driven by the automotive industry's need for more efficient, cost-effective, and collaborative development processes. As vehicle manufacturers face growing pressure to reduce emissions, improve fuel efficiency, and accelerate time-to-market, cloud-based analysis tools for engine development have become increasingly attractive.

The global automotive engine market is projected to reach a value of over $100 billion by 2025, with a significant portion of this growth attributed to the adoption of advanced development technologies. Cloud-based solutions for engine development are expected to capture a growing share of this market, with some analysts predicting a compound annual growth rate (CAGR) of 15-20% for cloud-based automotive engineering services over the next five years.

One of the key drivers of market demand is the need for faster and more iterative development cycles. Traditional engine development processes often involve time-consuming physical prototyping and testing, which can be both expensive and slow. Cloud-based analysis tools enable engineers to perform complex simulations and optimizations in virtual environments, significantly reducing the time and cost associated with physical prototyping.

Another factor contributing to the growing demand is the increasing complexity of modern engines. As manufacturers strive to meet stringent emissions regulations and performance targets, engine designs have become more sophisticated, requiring more advanced analysis tools. Cloud-based solutions offer the computational power and scalability needed to handle these complex simulations, making them particularly appealing to automotive companies of all sizes.

Collaboration and data sharing capabilities provided by cloud-based platforms are also driving market demand. With global teams working on engine development projects, the ability to access and share data in real-time across different locations has become crucial. Cloud-based solutions facilitate seamless collaboration, enabling engineers to work together more effectively and make data-driven decisions faster.

The COVID-19 pandemic has further accelerated the adoption of cloud-based tools in engine development. With remote work becoming more prevalent, the ability to access powerful analysis tools from anywhere has become essential. This shift is expected to have a lasting impact on the industry, with many companies likely to continue leveraging cloud-based solutions even as in-person work resumes.

As the automotive industry continues to evolve towards electrification, the demand for cloud-based analysis tools is expected to extend beyond traditional internal combustion engines. Electric powertrain development, battery optimization, and thermal management are all areas where cloud-based solutions can provide significant value, further expanding the market potential for these technologies.

The global automotive engine market is projected to reach a value of over $100 billion by 2025, with a significant portion of this growth attributed to the adoption of advanced development technologies. Cloud-based solutions for engine development are expected to capture a growing share of this market, with some analysts predicting a compound annual growth rate (CAGR) of 15-20% for cloud-based automotive engineering services over the next five years.

One of the key drivers of market demand is the need for faster and more iterative development cycles. Traditional engine development processes often involve time-consuming physical prototyping and testing, which can be both expensive and slow. Cloud-based analysis tools enable engineers to perform complex simulations and optimizations in virtual environments, significantly reducing the time and cost associated with physical prototyping.

Another factor contributing to the growing demand is the increasing complexity of modern engines. As manufacturers strive to meet stringent emissions regulations and performance targets, engine designs have become more sophisticated, requiring more advanced analysis tools. Cloud-based solutions offer the computational power and scalability needed to handle these complex simulations, making them particularly appealing to automotive companies of all sizes.

Collaboration and data sharing capabilities provided by cloud-based platforms are also driving market demand. With global teams working on engine development projects, the ability to access and share data in real-time across different locations has become crucial. Cloud-based solutions facilitate seamless collaboration, enabling engineers to work together more effectively and make data-driven decisions faster.

The COVID-19 pandemic has further accelerated the adoption of cloud-based tools in engine development. With remote work becoming more prevalent, the ability to access powerful analysis tools from anywhere has become essential. This shift is expected to have a lasting impact on the industry, with many companies likely to continue leveraging cloud-based solutions even as in-person work resumes.

As the automotive industry continues to evolve towards electrification, the demand for cloud-based analysis tools is expected to extend beyond traditional internal combustion engines. Electric powertrain development, battery optimization, and thermal management are all areas where cloud-based solutions can provide significant value, further expanding the market potential for these technologies.

Current State and Challenges in LS Engine Cloud Analysis

Cloud-based analysis for LS engine development optimization has made significant strides in recent years, revolutionizing the way engineers approach engine design and performance enhancement. The current state of this technology is characterized by a robust integration of cloud computing resources with advanced simulation software, enabling more comprehensive and efficient analysis of engine parameters.

One of the primary advantages of cloud-based analysis is the ability to perform complex simulations and calculations at a scale previously unattainable with traditional on-premises systems. This has led to a dramatic reduction in the time required for engine development cycles, allowing manufacturers to iterate designs more rapidly and bring optimized engines to market faster.

However, despite these advancements, several challenges persist in the field of LS engine cloud analysis. Data security remains a significant concern, as proprietary engine designs and performance data must be transmitted and stored in cloud environments. Ensuring the confidentiality and integrity of this sensitive information requires sophisticated encryption and access control measures, which can sometimes introduce latency and complexity to the analysis process.

Another challenge lies in the standardization of cloud-based tools and platforms across the industry. Different manufacturers and research institutions often use varied software suites and analysis methodologies, making it difficult to establish a unified approach to cloud-based LS engine optimization. This lack of standardization can hinder collaboration and slow down the overall pace of innovation in the field.

The scalability of cloud resources, while generally advantageous, also presents challenges in terms of cost management and resource allocation. As simulations become more complex and data-intensive, there is a risk of escalating cloud computing costs, which must be carefully balanced against the benefits of enhanced analysis capabilities.

Furthermore, the integration of legacy systems and data with modern cloud-based platforms remains a significant hurdle for many organizations. Many established engine manufacturers have decades of historical data and analysis tools that are not easily compatible with cloud environments, necessitating complex migration processes and potential loss of valuable historical insights.

Lastly, the rapid pace of technological advancement in cloud computing and data analysis tools creates a constant need for upskilling and training of engineering teams. Keeping personnel up-to-date with the latest cloud-based analysis techniques and software platforms is an ongoing challenge that requires significant investment in education and professional development.

One of the primary advantages of cloud-based analysis is the ability to perform complex simulations and calculations at a scale previously unattainable with traditional on-premises systems. This has led to a dramatic reduction in the time required for engine development cycles, allowing manufacturers to iterate designs more rapidly and bring optimized engines to market faster.

However, despite these advancements, several challenges persist in the field of LS engine cloud analysis. Data security remains a significant concern, as proprietary engine designs and performance data must be transmitted and stored in cloud environments. Ensuring the confidentiality and integrity of this sensitive information requires sophisticated encryption and access control measures, which can sometimes introduce latency and complexity to the analysis process.

Another challenge lies in the standardization of cloud-based tools and platforms across the industry. Different manufacturers and research institutions often use varied software suites and analysis methodologies, making it difficult to establish a unified approach to cloud-based LS engine optimization. This lack of standardization can hinder collaboration and slow down the overall pace of innovation in the field.

The scalability of cloud resources, while generally advantageous, also presents challenges in terms of cost management and resource allocation. As simulations become more complex and data-intensive, there is a risk of escalating cloud computing costs, which must be carefully balanced against the benefits of enhanced analysis capabilities.

Furthermore, the integration of legacy systems and data with modern cloud-based platforms remains a significant hurdle for many organizations. Many established engine manufacturers have decades of historical data and analysis tools that are not easily compatible with cloud environments, necessitating complex migration processes and potential loss of valuable historical insights.

Lastly, the rapid pace of technological advancement in cloud computing and data analysis tools creates a constant need for upskilling and training of engineering teams. Keeping personnel up-to-date with the latest cloud-based analysis techniques and software platforms is an ongoing challenge that requires significant investment in education and professional development.

Existing Cloud Solutions for LS Engine Optimization

01 Engine Control and Optimization

This category focuses on improving LS engine performance through advanced control systems and optimization techniques. It includes methods for fine-tuning engine parameters, implementing adaptive control algorithms, and utilizing real-time data analysis to enhance efficiency and power output. These approaches aim to maximize engine performance while maintaining reliability and fuel efficiency.- Engine Control and Optimization: This category focuses on improving LS engine performance through advanced control systems and optimization techniques. It includes methods for enhancing fuel efficiency, power output, and overall engine management. The optimization process may involve adjusting parameters such as fuel injection timing, valve timing, and ignition timing based on various operating conditions.

- Combustion Analysis and Improvement: This area involves analyzing and enhancing the combustion process in LS engines. It includes techniques for monitoring and optimizing air-fuel mixture, improving flame propagation, and reducing emissions. Advanced sensors and data analysis methods may be used to achieve more efficient and cleaner combustion.

- Thermal Management and Efficiency: This category addresses thermal management strategies to improve LS engine efficiency and longevity. It includes innovative cooling systems, heat recovery methods, and materials that can withstand high temperatures. The goal is to maintain optimal operating temperatures while maximizing energy utilization.

- Engine Design and Component Optimization: This area focuses on optimizing the physical design and components of LS engines. It includes improvements in piston design, cylinder head geometry, intake and exhaust systems, and the use of lightweight materials. The aim is to enhance power-to-weight ratio, reduce friction, and improve overall engine performance.

- Data-Driven Development and Simulation: This category involves the use of advanced data analytics, machine learning, and simulation techniques in LS engine development. It includes creating digital twins, predictive modeling, and virtual testing environments to accelerate the development process and optimize engine performance before physical prototyping.

02 Combustion Process Enhancement

Innovations in this area target the improvement of the combustion process within LS engines. This includes optimizing fuel injection timing and patterns, enhancing air-fuel mixture formation, and developing advanced ignition systems. The goal is to achieve more complete combustion, reduce emissions, and increase overall engine efficiency.Expand Specific Solutions03 Thermal Management and Efficiency

This category encompasses techniques for better thermal management in LS engines. It includes innovative cooling system designs, heat recovery methods, and materials that improve heat dissipation. These advancements aim to maintain optimal operating temperatures, reduce thermal stress on engine components, and potentially convert waste heat into usable energy, thereby increasing overall engine efficiency.Expand Specific Solutions04 Materials and Manufacturing Techniques

Advancements in materials science and manufacturing processes play a crucial role in LS engine development. This includes the use of lightweight, high-strength materials for engine components, advanced coating technologies to reduce friction and wear, and innovative manufacturing techniques such as 3D printing for complex parts. These improvements contribute to increased durability, reduced weight, and enhanced performance of LS engines.Expand Specific Solutions05 Data-Driven Development and Simulation

This category focuses on leveraging big data analytics, machine learning, and advanced simulation techniques in LS engine development. It includes the use of digital twins, predictive modeling, and AI-driven optimization algorithms to accelerate the design and testing processes. These methods enable more efficient prototyping, reduce development costs, and allow for rapid iteration in engine design and optimization.Expand Specific Solutions

Key Players in LS Engine Cloud Analysis Industry

The cloud-based analysis for LS engine development optimization is in a growth phase, with increasing market size and technological advancements. The competitive landscape is characterized by a mix of established tech giants and specialized automotive engineering firms. Companies like IBM, SAP, and Fujitsu are leveraging their cloud computing expertise to offer sophisticated analysis tools. Automotive-focused players such as GM Global Technology Operations and China Automotive Engineering Research Institute are integrating cloud solutions into their development processes. The technology's maturity is advancing rapidly, with Rockwell Automation, Ericsson, and Qualcomm contributing to its evolution through IoT and connectivity innovations. As the market expands, collaboration between tech and automotive sectors is likely to intensify, driving further advancements in cloud-based engine optimization.

International Business Machines Corp.

Technical Solution: IBM's cloud-based analysis for LS engine development optimization centers around its IBM Cloud platform and Watson AI capabilities. The company employs IBM Cloud Pak for Data to integrate and analyze large volumes of engine performance data from various sources[7]. IBM's solution leverages Watson Machine Learning to develop predictive models for engine optimization, considering factors such as fuel efficiency, emissions, and durability. The platform utilizes IBM SPSS for advanced statistical analysis of engine test results, enabling data-driven decision-making in the development process[8]. Additionally, IBM's quantum computing initiatives are exploring potential applications in complex engine simulations, aiming to solve optimization problems beyond the capabilities of classical computers[9].

Strengths: Advanced AI and analytics capabilities, potential for quantum computing applications, and robust data integration tools. Weaknesses: Complexity of implementation and potential high costs for full-scale deployment.

GM Global Technology Operations LLC

Technical Solution: GM's cloud-based analysis for LS (Large-Scale) engine development optimization leverages advanced simulation and data analytics techniques. They utilize high-performance computing (HPC) resources in the cloud to run complex engine simulations, enabling faster iteration and optimization of engine designs. GM's approach integrates machine learning algorithms to analyze vast amounts of simulation data, identifying optimal engine parameters for performance, efficiency, and emissions[1]. The company also employs digital twin technology, creating virtual representations of physical engines to predict behavior and performance under various conditions[2]. This cloud-based system allows for real-time collaboration among global engineering teams, streamlining the development process and reducing time-to-market for new engine designs[3].

Strengths: Accelerated development cycles, improved global collaboration, and enhanced predictive capabilities. Weaknesses: High initial investment in cloud infrastructure and potential data security concerns.

Core Innovations in Cloud-Based Engine Analysis

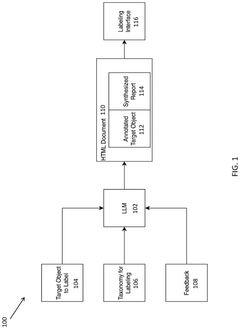

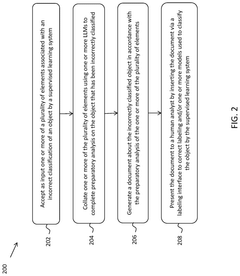

System and method for increasing efficiency in model correction in supervised systems

PatentPendingUS20240354554A1

Innovation

- A system utilizing a large language model (LLM) engine to analyze incorrect classifications, generate preparatory work, and provide suggestions for human analysts, reducing the need for initial investigation and saving time by collating elements like target objects, feedback, and labeling rubrics to correct misclassifications.

Data Security and Privacy in Cloud-Based Engine Development

Cloud-based analysis for LS engine development optimization introduces significant data security and privacy concerns. As sensitive engine design and performance data are transmitted and stored in cloud environments, robust security measures become paramount. Encryption of data both in transit and at rest is essential to protect intellectual property and maintain competitive advantage.

Access control mechanisms must be implemented to ensure that only authorized personnel can view or modify engine development data. This includes multi-factor authentication, role-based access control, and detailed audit logs to track all data interactions. Regular security audits and penetration testing should be conducted to identify and address potential vulnerabilities in the cloud infrastructure.

Data residency and sovereignty issues must be carefully considered, as engine development data may be subject to various national and international regulations. Organizations must ensure compliance with data protection laws such as GDPR, CCPA, and industry-specific regulations. This may require selecting cloud providers with data centers in specific geographic locations or implementing data localization strategies.

Privacy-preserving techniques, such as differential privacy and homomorphic encryption, can be employed to enable collaborative analysis of engine performance data without compromising individual data points. These methods allow for aggregate insights while maintaining the confidentiality of specific engine designs or test results.

Secure data sharing protocols are crucial for collaboration between different teams or organizations involved in LS engine development. Implementing secure APIs, virtual private networks (VPNs), and encrypted communication channels can facilitate safe data exchange while minimizing the risk of unauthorized access or data breaches.

Disaster recovery and business continuity plans must be established to ensure data availability and integrity in case of system failures or cyber attacks. This includes regular data backups, redundant storage systems, and failover mechanisms to maintain continuous access to critical engine development data.

As cloud-based analysis often involves machine learning and AI algorithms, special attention must be given to the security of these models. Protecting against adversarial attacks, model inversion, and data poisoning is crucial to maintain the integrity of engine optimization processes and prevent malicious manipulation of development outcomes.

Access control mechanisms must be implemented to ensure that only authorized personnel can view or modify engine development data. This includes multi-factor authentication, role-based access control, and detailed audit logs to track all data interactions. Regular security audits and penetration testing should be conducted to identify and address potential vulnerabilities in the cloud infrastructure.

Data residency and sovereignty issues must be carefully considered, as engine development data may be subject to various national and international regulations. Organizations must ensure compliance with data protection laws such as GDPR, CCPA, and industry-specific regulations. This may require selecting cloud providers with data centers in specific geographic locations or implementing data localization strategies.

Privacy-preserving techniques, such as differential privacy and homomorphic encryption, can be employed to enable collaborative analysis of engine performance data without compromising individual data points. These methods allow for aggregate insights while maintaining the confidentiality of specific engine designs or test results.

Secure data sharing protocols are crucial for collaboration between different teams or organizations involved in LS engine development. Implementing secure APIs, virtual private networks (VPNs), and encrypted communication channels can facilitate safe data exchange while minimizing the risk of unauthorized access or data breaches.

Disaster recovery and business continuity plans must be established to ensure data availability and integrity in case of system failures or cyber attacks. This includes regular data backups, redundant storage systems, and failover mechanisms to maintain continuous access to critical engine development data.

As cloud-based analysis often involves machine learning and AI algorithms, special attention must be given to the security of these models. Protecting against adversarial attacks, model inversion, and data poisoning is crucial to maintain the integrity of engine optimization processes and prevent malicious manipulation of development outcomes.

Environmental Impact of Cloud-Optimized LS Engines

The environmental impact of cloud-optimized LS engines represents a significant consideration in the development and implementation of this technology. By leveraging cloud-based analysis for LS engine development optimization, manufacturers can potentially reduce the overall environmental footprint of these engines throughout their lifecycle.

One of the primary environmental benefits of cloud-optimized LS engines is the potential for improved fuel efficiency. Through advanced simulation and analysis techniques enabled by cloud computing, engineers can fine-tune engine parameters to maximize performance while minimizing fuel consumption. This optimization can lead to reduced greenhouse gas emissions and lower overall carbon footprint for vehicles equipped with these engines.

Cloud-based optimization also allows for more efficient material usage in engine production. By simulating various design configurations and material choices, manufacturers can identify opportunities to reduce waste and utilize more environmentally friendly materials without compromising engine performance. This approach can contribute to a more sustainable manufacturing process and reduce the environmental impact associated with raw material extraction and processing.

The use of cloud computing in engine development can also lead to more accurate predictions of engine wear and maintenance requirements. This predictive capability enables manufacturers to design engines with longer lifespans and reduced maintenance needs, potentially decreasing the frequency of part replacements and associated waste generation.

Furthermore, cloud-optimized LS engines may contribute to the development of more efficient hybrid and electric vehicle powertrains. By optimizing the integration of LS engines with electric motors and battery systems, manufacturers can create more environmentally friendly hybrid vehicles that balance performance with reduced emissions.

However, it is important to consider the environmental impact of the cloud infrastructure itself. The energy consumption of data centers and the associated carbon emissions must be factored into the overall environmental assessment of cloud-optimized LS engines. As cloud providers continue to transition to renewable energy sources and improve data center efficiency, the net environmental benefit of this approach is likely to increase.

In conclusion, while the environmental impact of cloud-optimized LS engines is multifaceted, the potential for improved efficiency, reduced emissions, and more sustainable manufacturing processes suggests a positive overall effect on the environment. As technology continues to advance, further research and development in this area may unlock additional environmental benefits and contribute to the automotive industry's sustainability goals.

One of the primary environmental benefits of cloud-optimized LS engines is the potential for improved fuel efficiency. Through advanced simulation and analysis techniques enabled by cloud computing, engineers can fine-tune engine parameters to maximize performance while minimizing fuel consumption. This optimization can lead to reduced greenhouse gas emissions and lower overall carbon footprint for vehicles equipped with these engines.

Cloud-based optimization also allows for more efficient material usage in engine production. By simulating various design configurations and material choices, manufacturers can identify opportunities to reduce waste and utilize more environmentally friendly materials without compromising engine performance. This approach can contribute to a more sustainable manufacturing process and reduce the environmental impact associated with raw material extraction and processing.

The use of cloud computing in engine development can also lead to more accurate predictions of engine wear and maintenance requirements. This predictive capability enables manufacturers to design engines with longer lifespans and reduced maintenance needs, potentially decreasing the frequency of part replacements and associated waste generation.

Furthermore, cloud-optimized LS engines may contribute to the development of more efficient hybrid and electric vehicle powertrains. By optimizing the integration of LS engines with electric motors and battery systems, manufacturers can create more environmentally friendly hybrid vehicles that balance performance with reduced emissions.

However, it is important to consider the environmental impact of the cloud infrastructure itself. The energy consumption of data centers and the associated carbon emissions must be factored into the overall environmental assessment of cloud-optimized LS engines. As cloud providers continue to transition to renewable energy sources and improve data center efficiency, the net environmental benefit of this approach is likely to increase.

In conclusion, while the environmental impact of cloud-optimized LS engines is multifaceted, the potential for improved efficiency, reduced emissions, and more sustainable manufacturing processes suggests a positive overall effect on the environment. As technology continues to advance, further research and development in this area may unlock additional environmental benefits and contribute to the automotive industry's sustainability goals.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!