Additive Manufacturing Techniques for LS Engine Spare Parts

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AM for LS Engine Parts: Background and Objectives

Additive Manufacturing (AM) has emerged as a transformative technology in the automotive industry, particularly in the production of spare parts for LS (Luxury Sport) engines. This research aims to explore the application of AM techniques in manufacturing high-quality, cost-effective spare parts for LS engines, addressing the challenges of traditional manufacturing methods and meeting the evolving demands of the automotive sector.

The development of AM technologies has progressed significantly over the past three decades, evolving from rapid prototyping to a viable manufacturing process for end-use parts. In the context of LS engine spare parts, AM offers the potential to overcome limitations associated with conventional manufacturing, such as long lead times, high tooling costs, and inventory management issues. The primary objective of this research is to investigate and evaluate the feasibility of implementing AM techniques for producing LS engine spare parts, with a focus on enhancing performance, reducing production costs, and improving supply chain efficiency.

The automotive industry has witnessed a growing interest in AM technologies due to their ability to produce complex geometries, customize parts, and facilitate on-demand manufacturing. For LS engines, known for their high-performance characteristics and precision engineering, AM presents an opportunity to optimize component design, reduce weight, and potentially enhance engine efficiency. This research seeks to identify the most suitable AM processes for LS engine spare parts, considering factors such as material properties, surface finish, dimensional accuracy, and production scalability.

As the automotive market continues to evolve, with increasing emphasis on sustainability and personalization, AM technologies align well with these trends. The ability to produce spare parts on-demand can significantly reduce inventory costs and minimize waste, contributing to more sustainable manufacturing practices. Additionally, AM's capacity for rapid iteration and customization can support the development of performance-enhancing components for LS engines, catering to the demands of enthusiasts and specialized markets.

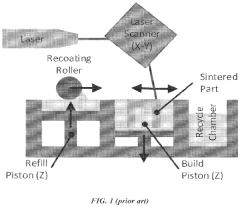

This research will explore the current state of AM technologies applicable to LS engine spare parts, including but not limited to selective laser sintering (SLS), direct metal laser sintering (DMLS), and fused deposition modeling (FDM). By examining these technologies' capabilities and limitations, we aim to identify the most promising approaches for manufacturing high-quality LS engine components. The study will also consider the broader implications of adopting AM in the automotive spare parts industry, including potential shifts in supply chain dynamics, intellectual property considerations, and quality assurance processes.

The development of AM technologies has progressed significantly over the past three decades, evolving from rapid prototyping to a viable manufacturing process for end-use parts. In the context of LS engine spare parts, AM offers the potential to overcome limitations associated with conventional manufacturing, such as long lead times, high tooling costs, and inventory management issues. The primary objective of this research is to investigate and evaluate the feasibility of implementing AM techniques for producing LS engine spare parts, with a focus on enhancing performance, reducing production costs, and improving supply chain efficiency.

The automotive industry has witnessed a growing interest in AM technologies due to their ability to produce complex geometries, customize parts, and facilitate on-demand manufacturing. For LS engines, known for their high-performance characteristics and precision engineering, AM presents an opportunity to optimize component design, reduce weight, and potentially enhance engine efficiency. This research seeks to identify the most suitable AM processes for LS engine spare parts, considering factors such as material properties, surface finish, dimensional accuracy, and production scalability.

As the automotive market continues to evolve, with increasing emphasis on sustainability and personalization, AM technologies align well with these trends. The ability to produce spare parts on-demand can significantly reduce inventory costs and minimize waste, contributing to more sustainable manufacturing practices. Additionally, AM's capacity for rapid iteration and customization can support the development of performance-enhancing components for LS engines, catering to the demands of enthusiasts and specialized markets.

This research will explore the current state of AM technologies applicable to LS engine spare parts, including but not limited to selective laser sintering (SLS), direct metal laser sintering (DMLS), and fused deposition modeling (FDM). By examining these technologies' capabilities and limitations, we aim to identify the most promising approaches for manufacturing high-quality LS engine components. The study will also consider the broader implications of adopting AM in the automotive spare parts industry, including potential shifts in supply chain dynamics, intellectual property considerations, and quality assurance processes.

Market Analysis for AM LS Engine Spare Parts

The market for additive manufacturing (AM) in the production of LS engine spare parts is experiencing significant growth, driven by the increasing demand for customized and on-demand parts in the automotive industry. This market segment is particularly attractive due to the aging fleet of LS-powered vehicles and the need for replacement parts that may no longer be in production through traditional manufacturing methods.

The global automotive spare parts market is projected to reach a substantial value in the coming years, with a considerable portion attributed to engine components. Within this broader market, the demand for LS engine spare parts manufactured using AM techniques is expected to grow at a faster rate than traditional manufacturing methods. This growth is fueled by the advantages AM offers, such as reduced lead times, lower inventory costs, and the ability to produce complex geometries that can enhance performance.

Key market drivers include the rising adoption of 3D printing technologies in the automotive sector, the need for lightweight and fuel-efficient components, and the increasing focus on reducing vehicle downtime. The aftermarket segment, in particular, shows promising potential for AM LS engine spare parts, as enthusiasts and repair shops seek cost-effective solutions for maintaining and upgrading older vehicles.

Regional analysis indicates that North America currently holds the largest market share for AM LS engine spare parts, owing to the high concentration of LS-powered vehicles in the region and the strong presence of automotive aftermarket suppliers. However, emerging markets in Asia-Pacific and Europe are expected to witness rapid growth in the coming years, driven by the expansion of the automotive industry and increasing adoption of AM technologies.

The market landscape is characterized by a mix of established automotive parts manufacturers expanding into AM and specialized 3D printing service providers focusing on automotive applications. This competitive environment is fostering innovation and driving down costs, making AM solutions increasingly accessible to a broader range of customers.

Challenges in the market include ensuring consistent quality and material properties of AM-produced parts, addressing intellectual property concerns, and overcoming the reluctance of some customers to adopt parts manufactured using non-traditional methods. However, ongoing advancements in AM technologies, materials science, and quality control processes are gradually mitigating these concerns.

Looking ahead, the market for AM LS engine spare parts is poised for continued growth, with opportunities for expansion into new applications and materials. The integration of digital inventory systems and on-demand manufacturing models is expected to further revolutionize the spare parts supply chain, offering significant advantages in terms of cost reduction and improved service levels for vehicle owners and repair facilities.

The global automotive spare parts market is projected to reach a substantial value in the coming years, with a considerable portion attributed to engine components. Within this broader market, the demand for LS engine spare parts manufactured using AM techniques is expected to grow at a faster rate than traditional manufacturing methods. This growth is fueled by the advantages AM offers, such as reduced lead times, lower inventory costs, and the ability to produce complex geometries that can enhance performance.

Key market drivers include the rising adoption of 3D printing technologies in the automotive sector, the need for lightweight and fuel-efficient components, and the increasing focus on reducing vehicle downtime. The aftermarket segment, in particular, shows promising potential for AM LS engine spare parts, as enthusiasts and repair shops seek cost-effective solutions for maintaining and upgrading older vehicles.

Regional analysis indicates that North America currently holds the largest market share for AM LS engine spare parts, owing to the high concentration of LS-powered vehicles in the region and the strong presence of automotive aftermarket suppliers. However, emerging markets in Asia-Pacific and Europe are expected to witness rapid growth in the coming years, driven by the expansion of the automotive industry and increasing adoption of AM technologies.

The market landscape is characterized by a mix of established automotive parts manufacturers expanding into AM and specialized 3D printing service providers focusing on automotive applications. This competitive environment is fostering innovation and driving down costs, making AM solutions increasingly accessible to a broader range of customers.

Challenges in the market include ensuring consistent quality and material properties of AM-produced parts, addressing intellectual property concerns, and overcoming the reluctance of some customers to adopt parts manufactured using non-traditional methods. However, ongoing advancements in AM technologies, materials science, and quality control processes are gradually mitigating these concerns.

Looking ahead, the market for AM LS engine spare parts is poised for continued growth, with opportunities for expansion into new applications and materials. The integration of digital inventory systems and on-demand manufacturing models is expected to further revolutionize the spare parts supply chain, offering significant advantages in terms of cost reduction and improved service levels for vehicle owners and repair facilities.

Current AM Challenges in LS Engine Part Production

Additive Manufacturing (AM) techniques for LS engine spare parts production face several significant challenges that hinder widespread adoption and optimal performance. One of the primary obstacles is achieving the required dimensional accuracy and surface finish for critical engine components. LS engines often demand tight tolerances and smooth surfaces to ensure proper functionality and longevity. Current AM processes struggle to consistently meet these stringent requirements without extensive post-processing, which can increase production time and costs.

Material selection and qualification pose another major challenge. LS engine parts must withstand high temperatures, pressures, and mechanical stresses. While AM offers a wide range of materials, including metals and advanced alloys, ensuring these materials possess the necessary properties and perform reliably under extreme conditions remains a complex task. Extensive testing and certification processes are required to validate AM-produced parts for use in LS engines, which can be time-consuming and expensive.

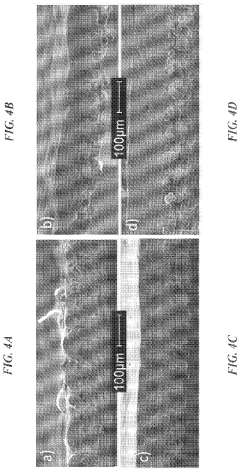

The issue of part density and internal defects is also a significant concern. AM processes, particularly those using metal powders, can sometimes result in parts with internal porosity or microscopic defects. These imperfections can compromise the structural integrity and performance of engine components, potentially leading to premature failure. Addressing this challenge requires advanced process control, optimized printing parameters, and sophisticated quality assurance methods.

Scalability and production speed present additional hurdles for AM in LS engine part manufacturing. While AM excels in producing complex geometries and customized parts, it often falls short in terms of production volume and speed compared to traditional manufacturing methods. This limitation can be particularly problematic for high-demand spare parts or when rapid production is required to minimize engine downtime.

Cost-effectiveness remains a significant barrier to widespread adoption of AM for LS engine spare parts. The initial investment in AM equipment, materials, and skilled personnel can be substantial. Additionally, the per-part cost for AM production may still exceed that of traditional manufacturing methods for certain components, especially in high-volume scenarios. Balancing the benefits of AM, such as reduced lead times and inventory costs, against these higher production costs is a complex challenge for engine manufacturers and spare parts suppliers.

Lastly, the development of design methodologies specifically tailored for AM in the context of LS engine parts is an ongoing challenge. While AM offers new design freedoms, fully leveraging these capabilities while adhering to engine performance and safety requirements demands a paradigm shift in design thinking. Engineers must learn to optimize part designs for AM processes while ensuring they meet or exceed the performance of traditionally manufactured components.

Material selection and qualification pose another major challenge. LS engine parts must withstand high temperatures, pressures, and mechanical stresses. While AM offers a wide range of materials, including metals and advanced alloys, ensuring these materials possess the necessary properties and perform reliably under extreme conditions remains a complex task. Extensive testing and certification processes are required to validate AM-produced parts for use in LS engines, which can be time-consuming and expensive.

The issue of part density and internal defects is also a significant concern. AM processes, particularly those using metal powders, can sometimes result in parts with internal porosity or microscopic defects. These imperfections can compromise the structural integrity and performance of engine components, potentially leading to premature failure. Addressing this challenge requires advanced process control, optimized printing parameters, and sophisticated quality assurance methods.

Scalability and production speed present additional hurdles for AM in LS engine part manufacturing. While AM excels in producing complex geometries and customized parts, it often falls short in terms of production volume and speed compared to traditional manufacturing methods. This limitation can be particularly problematic for high-demand spare parts or when rapid production is required to minimize engine downtime.

Cost-effectiveness remains a significant barrier to widespread adoption of AM for LS engine spare parts. The initial investment in AM equipment, materials, and skilled personnel can be substantial. Additionally, the per-part cost for AM production may still exceed that of traditional manufacturing methods for certain components, especially in high-volume scenarios. Balancing the benefits of AM, such as reduced lead times and inventory costs, against these higher production costs is a complex challenge for engine manufacturers and spare parts suppliers.

Lastly, the development of design methodologies specifically tailored for AM in the context of LS engine parts is an ongoing challenge. While AM offers new design freedoms, fully leveraging these capabilities while adhering to engine performance and safety requirements demands a paradigm shift in design thinking. Engineers must learn to optimize part designs for AM processes while ensuring they meet or exceed the performance of traditionally manufactured components.

Existing AM Solutions for LS Engine Components

01 3D printing techniques for complex structures

Additive manufacturing techniques are used to create complex three-dimensional structures layer by layer. These methods allow for the production of intricate geometries that would be difficult or impossible to achieve with traditional manufacturing processes. The techniques can involve various materials, including metals, polymers, and ceramics, and can be applied in industries such as aerospace, automotive, and medical devices.- 3D printing techniques for complex structures: Additive manufacturing techniques are used to create complex 3D structures layer by layer. These methods allow for the production of intricate designs that would be difficult or impossible to achieve with traditional manufacturing processes. The techniques can involve various materials, including metals, polymers, and composites, and can be applied to a wide range of industries such as aerospace, automotive, and medical devices.

- Material extrusion and deposition methods: This category of additive manufacturing techniques involves the extrusion or deposition of materials to build objects. Methods such as fused deposition modeling (FDM) and direct ink writing are included. These techniques are known for their versatility in material selection and ability to create functional parts with good mechanical properties. They are widely used in prototyping and small-scale production.

- Powder bed fusion technologies: Powder bed fusion is a group of additive manufacturing processes that use thermal energy to selectively fuse regions of a powder bed. Techniques such as selective laser sintering (SLS) and electron beam melting (EBM) fall into this category. These methods are capable of producing high-density parts with excellent mechanical properties and are particularly useful for metal additive manufacturing.

- Vat photopolymerization processes: This category includes additive manufacturing techniques that use light-activated polymerization to create objects from a vat of liquid photopolymer resin. Stereolithography (SLA) and digital light processing (DLP) are examples of such processes. These methods are known for their high resolution and smooth surface finish, making them suitable for applications requiring fine details or aesthetically pleasing parts.

- Hybrid and multi-material additive manufacturing: These advanced additive manufacturing techniques combine different materials or manufacturing processes to create parts with enhanced properties or functionality. They may involve the use of multiple materials in a single print or the integration of additive manufacturing with traditional manufacturing methods. Such hybrid approaches allow for the creation of parts with optimized mechanical properties, embedded electronics, or other advanced features.

02 Material extrusion and deposition methods

This category of additive manufacturing techniques involves the extrusion or deposition of materials to build objects. Methods such as fused deposition modeling (FDM) and direct ink writing are included. These techniques are widely used for rapid prototyping and small-scale production due to their versatility and relatively low cost. They can work with a variety of thermoplastics and composite materials.Expand Specific Solutions03 Powder bed fusion technologies

Powder bed fusion is an additive manufacturing technique that uses thermal energy to selectively fuse regions of a powder bed. This category includes methods such as selective laser sintering (SLS) and electron beam melting (EBM). These technologies are particularly useful for producing metal parts with high precision and complex geometries, making them valuable in aerospace and medical applications.Expand Specific Solutions04 Vat photopolymerization processes

This category encompasses additive manufacturing techniques that use light-activated polymerization to create objects from liquid resins. Stereolithography (SLA) and digital light processing (DLP) are examples of vat photopolymerization processes. These methods are known for their high resolution and smooth surface finish, making them ideal for applications in jewelry, dentistry, and prototyping of detailed parts.Expand Specific Solutions05 Hybrid and multi-material additive manufacturing

This emerging area of additive manufacturing combines different techniques or materials within a single build process. Hybrid systems may integrate additive and subtractive manufacturing methods, while multi-material printing allows for the creation of objects with varying material properties. These advanced techniques enable the production of parts with enhanced functionality, such as embedded electronics or gradient material properties.Expand Specific Solutions

Key Players in AM for Automotive Spare Parts

The additive manufacturing techniques for LS engine spare parts market is in a growth phase, driven by increasing demand for customized and lightweight components in the automotive industry. The global market size for this technology is expanding, with projections indicating significant growth in the coming years. Technologically, the field is advancing rapidly, with companies like Siemens Energy, Renishaw, and EOS GmbH leading innovation. These firms are developing more efficient and cost-effective 3D printing solutions specifically tailored for engine components. However, the technology's maturity varies across different applications, with some areas still in early stages of development and others approaching mainstream adoption.

Siemens AG

Technical Solution: Siemens AG has developed advanced additive manufacturing techniques for LS engine spare parts, focusing on selective laser melting (SLM) and direct metal laser sintering (DMLS). Their approach integrates digital twin technology with AM processes, allowing for real-time monitoring and optimization of part production[1]. Siemens has also implemented a comprehensive end-to-end digital workflow, from design to production, which includes topology optimization and generative design algorithms to create lightweight yet robust engine components[2]. The company has successfully produced complex geometries for turbine blades and combustion system components, achieving up to 30% weight reduction and improved cooling efficiency[3].

Strengths: Integrated digital workflow, advanced simulation capabilities, and proven track record in producing complex engine components. Weaknesses: High initial investment costs and potential limitations in material selection for certain engine parts.

Safran Aircraft Engines SAS

Technical Solution: Safran Aircraft Engines SAS has developed a comprehensive additive manufacturing strategy for LS engine spare parts, focusing on critical components such as fuel injectors and turbine blades. Their approach utilizes selective laser melting (SLM) and electron beam melting (EBM) technologies, combined with advanced powder characterization and process monitoring systems[13]. Safran has implemented a digital thread throughout their AM workflow, from design optimization to post-processing and quality control, ensuring traceability and repeatability[14]. The company has successfully produced complex geometries with internal cooling channels, achieving weight reductions of up to 25% and improved fuel efficiency in engine components[15].

Strengths: Extensive experience in aerospace-grade AM applications, advanced process monitoring capabilities, and proven weight reduction achievements. Weaknesses: Potential challenges in scaling up production for larger engine components and meeting stringent aerospace certification requirements.

Innovative AM Techniques for LS Engine Parts

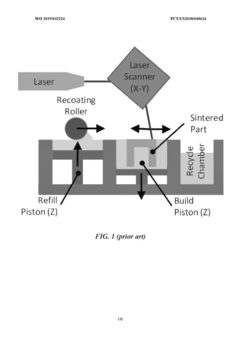

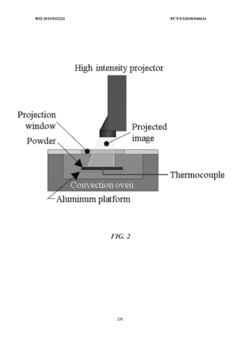

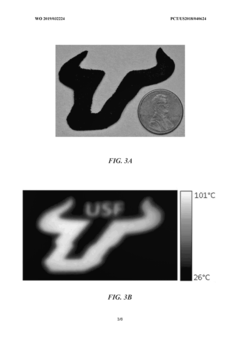

Large area sintering test platform and associated method of use

PatentWO2019032224A1

Innovation

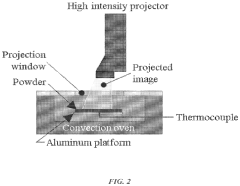

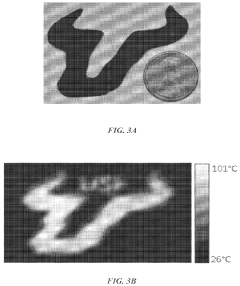

- A large area sintering system utilizing a high-intensity projector to sinter polymer powders in a controlled environment, allowing for simultaneous sintering of entire layers with adjustable exposure times and intensities, and closed-loop temperature control to optimize the sintering process.

Large area sintering test platform and associated method of use

PatentActiveUS20230250028A1

Innovation

- A system utilizing a high-intensity projector to sinter polymer powders in large areas simultaneously, with closed-loop temperature control and synchronized powder deposition, allowing for extended exposure times and reduced thermal losses, thereby improving material density and consistency.

Material Considerations for AM LS Engine Components

The selection of appropriate materials for additive manufacturing (AM) of LS engine components is crucial for ensuring the performance, durability, and reliability of the final parts. The primary materials used in AM for LS engine components include various metals, alloys, and composites, each with specific properties suited for different engine parts and operating conditions.

High-strength aluminum alloys, such as AlSi10Mg and AlSi7Mg, are commonly used for AM of LS engine components due to their excellent strength-to-weight ratio, good thermal conductivity, and corrosion resistance. These alloys are particularly suitable for parts like pistons, cylinder heads, and engine blocks, where weight reduction and heat dissipation are critical factors.

Nickel-based superalloys, including Inconel 718 and Hastelloy X, are preferred for high-temperature applications within the LS engine. These materials exhibit exceptional strength, creep resistance, and oxidation resistance at elevated temperatures, making them ideal for components such as turbocharger housings, exhaust manifolds, and valves.

Titanium alloys, particularly Ti6Al4V, are gaining popularity in AM for LS engine components due to their high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. These alloys are suitable for manufacturing lightweight, high-performance parts such as connecting rods, valves, and rocker arms.

Stainless steels, including 316L and 17-4 PH, are utilized for AM of LS engine components that require good corrosion resistance and moderate strength. These materials are often used for parts like fuel injectors, sensor housings, and brackets.

When considering materials for AM LS engine components, it is essential to evaluate factors such as mechanical properties, thermal characteristics, corrosion resistance, and fatigue behavior. The selected material must withstand the harsh operating conditions within the engine, including high temperatures, cyclic loading, and exposure to various fluids and gases.

Furthermore, the compatibility of the chosen material with the specific AM process is crucial. Different AM techniques, such as selective laser melting (SLM), electron beam melting (EBM), or directed energy deposition (DED), may have varying requirements for material properties and processing parameters. The material's powder characteristics, including particle size distribution, flowability, and packing density, must be optimized for the selected AM process to ensure consistent part quality and reproducibility.

High-strength aluminum alloys, such as AlSi10Mg and AlSi7Mg, are commonly used for AM of LS engine components due to their excellent strength-to-weight ratio, good thermal conductivity, and corrosion resistance. These alloys are particularly suitable for parts like pistons, cylinder heads, and engine blocks, where weight reduction and heat dissipation are critical factors.

Nickel-based superalloys, including Inconel 718 and Hastelloy X, are preferred for high-temperature applications within the LS engine. These materials exhibit exceptional strength, creep resistance, and oxidation resistance at elevated temperatures, making them ideal for components such as turbocharger housings, exhaust manifolds, and valves.

Titanium alloys, particularly Ti6Al4V, are gaining popularity in AM for LS engine components due to their high strength-to-weight ratio, excellent corrosion resistance, and biocompatibility. These alloys are suitable for manufacturing lightweight, high-performance parts such as connecting rods, valves, and rocker arms.

Stainless steels, including 316L and 17-4 PH, are utilized for AM of LS engine components that require good corrosion resistance and moderate strength. These materials are often used for parts like fuel injectors, sensor housings, and brackets.

When considering materials for AM LS engine components, it is essential to evaluate factors such as mechanical properties, thermal characteristics, corrosion resistance, and fatigue behavior. The selected material must withstand the harsh operating conditions within the engine, including high temperatures, cyclic loading, and exposure to various fluids and gases.

Furthermore, the compatibility of the chosen material with the specific AM process is crucial. Different AM techniques, such as selective laser melting (SLM), electron beam melting (EBM), or directed energy deposition (DED), may have varying requirements for material properties and processing parameters. The material's powder characteristics, including particle size distribution, flowability, and packing density, must be optimized for the selected AM process to ensure consistent part quality and reproducibility.

Quality Control and Certification in AM Automotive Parts

Quality control and certification are critical aspects of additive manufacturing (AM) for automotive parts, especially in the context of LS engine spare parts production. The automotive industry demands high standards of reliability, safety, and performance, which necessitates rigorous quality assurance processes for AM-produced components.

In the realm of quality control for AM automotive parts, several key factors are considered. Material consistency is paramount, as variations in raw material properties can significantly impact the final product's performance. Advanced spectroscopic and microscopic techniques are employed to analyze powder characteristics, ensuring batch-to-batch consistency. Process monitoring is another crucial element, with in-situ sensors and real-time data analytics used to detect anomalies during the build process. Post-processing quality checks, including dimensional accuracy measurements and non-destructive testing methods like CT scanning, are routinely performed to verify part integrity.

Certification of AM automotive parts involves a multi-faceted approach. Industry standards such as those developed by ASTM International and SAE provide guidelines for material properties, process parameters, and testing methodologies specific to AM. These standards are continually evolving to keep pace with technological advancements. Automotive manufacturers often develop their own internal certification processes, which may include extensive durability testing, environmental exposure tests, and performance simulations.

The certification process for LS engine spare parts produced via AM typically involves a series of steps. Initially, the design is validated through computer simulations and virtual testing. Prototype parts are then manufactured and subjected to rigorous physical testing, including fatigue tests, thermal cycling, and chemical resistance evaluations. Once the part design and manufacturing process are validated, a production qualification run is conducted to ensure repeatability and consistency in large-scale manufacturing.

Traceability is a key component of quality control and certification for AM automotive parts. Each part is assigned a unique identifier, allowing for complete tracking from raw material to final installation. This traceability system enables rapid identification and resolution of any quality issues that may arise during the part's lifecycle.

As AM technologies continue to advance, new challenges and opportunities in quality control and certification emerge. Machine learning algorithms are being developed to predict and prevent defects based on historical data and real-time process information. Additionally, blockchain technology is being explored as a means to enhance traceability and ensure the authenticity of AM-produced spare parts in the automotive supply chain.

In the realm of quality control for AM automotive parts, several key factors are considered. Material consistency is paramount, as variations in raw material properties can significantly impact the final product's performance. Advanced spectroscopic and microscopic techniques are employed to analyze powder characteristics, ensuring batch-to-batch consistency. Process monitoring is another crucial element, with in-situ sensors and real-time data analytics used to detect anomalies during the build process. Post-processing quality checks, including dimensional accuracy measurements and non-destructive testing methods like CT scanning, are routinely performed to verify part integrity.

Certification of AM automotive parts involves a multi-faceted approach. Industry standards such as those developed by ASTM International and SAE provide guidelines for material properties, process parameters, and testing methodologies specific to AM. These standards are continually evolving to keep pace with technological advancements. Automotive manufacturers often develop their own internal certification processes, which may include extensive durability testing, environmental exposure tests, and performance simulations.

The certification process for LS engine spare parts produced via AM typically involves a series of steps. Initially, the design is validated through computer simulations and virtual testing. Prototype parts are then manufactured and subjected to rigorous physical testing, including fatigue tests, thermal cycling, and chemical resistance evaluations. Once the part design and manufacturing process are validated, a production qualification run is conducted to ensure repeatability and consistency in large-scale manufacturing.

Traceability is a key component of quality control and certification for AM automotive parts. Each part is assigned a unique identifier, allowing for complete tracking from raw material to final installation. This traceability system enables rapid identification and resolution of any quality issues that may arise during the part's lifecycle.

As AM technologies continue to advance, new challenges and opportunities in quality control and certification emerge. Machine learning algorithms are being developed to predict and prevent defects based on historical data and real-time process information. Additionally, blockchain technology is being explored as a means to enhance traceability and ensure the authenticity of AM-produced spare parts in the automotive supply chain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!