Catalytic Converter Innovations for LS Engine Emission Control

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Emissions Background and Objectives

The LS engine, introduced by General Motors in 1997, has become a cornerstone of modern automotive engineering. Known for its compact design, lightweight construction, and impressive power output, the LS engine series has found widespread use in various vehicles, from sports cars to trucks. However, with increasing global focus on environmental protection and stringent emission regulations, the need for effective emission control in LS engines has become paramount.

Historically, emission control for internal combustion engines has been a significant challenge. The primary pollutants produced by LS engines include carbon monoxide (CO), nitrogen oxides (NOx), and unburned hydrocarbons (HC). These emissions contribute to air pollution, smog formation, and potential health hazards. As environmental awareness grew and regulations tightened, particularly with the introduction of Euro 6 and Tier 3 standards, the automotive industry faced mounting pressure to develop more efficient emission control technologies.

The catalytic converter has emerged as a crucial component in addressing these emission challenges. First introduced in the 1970s, catalytic converters have undergone continuous refinement to meet increasingly stringent emission standards. For LS engines, which are known for their high performance, the development of advanced catalytic converter technologies is particularly critical to balance power output with environmental responsibility.

The primary objective of catalytic converter innovations for LS engine emission control is to achieve a significant reduction in harmful emissions while maintaining or improving engine performance. This involves developing catalysts that can operate efficiently under the high-temperature, high-flow conditions typical of LS engines. Additionally, there is a focus on creating more durable and cost-effective solutions that can withstand the rigors of long-term use in various driving conditions.

Another key goal is to improve the cold-start performance of catalytic converters. LS engines, like all internal combustion engines, produce the highest levels of emissions during the first few minutes of operation when the catalytic converter has not yet reached its optimal operating temperature. Innovations in this area aim to reduce the time it takes for the converter to become fully effective, thereby significantly cutting overall emissions.

Furthermore, researchers and engineers are exploring ways to integrate advanced materials and nanotechnology into catalytic converter design. This includes the development of new substrate materials, improved catalyst formulations, and novel coating techniques to enhance the converter's efficiency and longevity. The ultimate aim is to create a new generation of catalytic converters that can meet or exceed future emission standards while being compatible with the high-performance characteristics of LS engines.

Historically, emission control for internal combustion engines has been a significant challenge. The primary pollutants produced by LS engines include carbon monoxide (CO), nitrogen oxides (NOx), and unburned hydrocarbons (HC). These emissions contribute to air pollution, smog formation, and potential health hazards. As environmental awareness grew and regulations tightened, particularly with the introduction of Euro 6 and Tier 3 standards, the automotive industry faced mounting pressure to develop more efficient emission control technologies.

The catalytic converter has emerged as a crucial component in addressing these emission challenges. First introduced in the 1970s, catalytic converters have undergone continuous refinement to meet increasingly stringent emission standards. For LS engines, which are known for their high performance, the development of advanced catalytic converter technologies is particularly critical to balance power output with environmental responsibility.

The primary objective of catalytic converter innovations for LS engine emission control is to achieve a significant reduction in harmful emissions while maintaining or improving engine performance. This involves developing catalysts that can operate efficiently under the high-temperature, high-flow conditions typical of LS engines. Additionally, there is a focus on creating more durable and cost-effective solutions that can withstand the rigors of long-term use in various driving conditions.

Another key goal is to improve the cold-start performance of catalytic converters. LS engines, like all internal combustion engines, produce the highest levels of emissions during the first few minutes of operation when the catalytic converter has not yet reached its optimal operating temperature. Innovations in this area aim to reduce the time it takes for the converter to become fully effective, thereby significantly cutting overall emissions.

Furthermore, researchers and engineers are exploring ways to integrate advanced materials and nanotechnology into catalytic converter design. This includes the development of new substrate materials, improved catalyst formulations, and novel coating techniques to enhance the converter's efficiency and longevity. The ultimate aim is to create a new generation of catalytic converters that can meet or exceed future emission standards while being compatible with the high-performance characteristics of LS engines.

Market Demand for Advanced Catalytic Converters

The market demand for advanced catalytic converters in LS engine emission control systems has been steadily increasing due to stricter environmental regulations and growing consumer awareness of vehicle emissions. This trend is particularly evident in developed automotive markets such as North America, Europe, and parts of Asia.

Stringent emission standards, such as Euro 6 in Europe and Tier 3 in the United States, have significantly driven the need for more efficient catalytic converters. These regulations aim to reduce harmful pollutants like nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM) from vehicle exhaust. As a result, automotive manufacturers are actively seeking innovative catalytic converter solutions to meet these standards while maintaining engine performance.

The global market for catalytic converters is experiencing robust growth, with a particular focus on advanced technologies for high-performance engines like the LS series. Market research indicates that the automotive catalytic converter market is expected to expand at a compound annual growth rate (CAGR) of over 8% in the coming years. This growth is largely attributed to the increasing production of vehicles equipped with gasoline engines, including those using LS engine platforms.

In the context of LS engines, which are known for their high performance and efficiency, there is a specific demand for catalytic converters that can handle increased exhaust temperatures and flow rates without compromising emission control. This has led to a surge in research and development activities focused on materials and designs that can withstand these challenging conditions while effectively reducing emissions.

The aftermarket segment for LS engine catalytic converters is also showing significant potential. Performance enthusiasts and custom vehicle builders are increasingly seeking advanced catalytic converter options that comply with emission standards without sacrificing engine output. This niche market is driving innovation in lightweight, high-flow catalytic converter designs that can be easily integrated into modified LS engine systems.

Furthermore, the push towards electrification in the automotive industry has not diminished the demand for advanced catalytic converters in LS engines. Instead, it has created a parallel market for hybrid vehicles that combine internal combustion engines with electric powertrains. These hybrid systems often utilize high-performance engines like the LS series and require specialized catalytic converters to manage emissions during combustion engine operation.

The market demand is also influenced by the increasing focus on sustainable manufacturing practices. Consumers and regulators are showing interest in catalytic converters that not only reduce emissions but are also produced using environmentally friendly processes and materials. This has opened up new avenues for innovation in catalyst formulations and recycling technologies.

Stringent emission standards, such as Euro 6 in Europe and Tier 3 in the United States, have significantly driven the need for more efficient catalytic converters. These regulations aim to reduce harmful pollutants like nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM) from vehicle exhaust. As a result, automotive manufacturers are actively seeking innovative catalytic converter solutions to meet these standards while maintaining engine performance.

The global market for catalytic converters is experiencing robust growth, with a particular focus on advanced technologies for high-performance engines like the LS series. Market research indicates that the automotive catalytic converter market is expected to expand at a compound annual growth rate (CAGR) of over 8% in the coming years. This growth is largely attributed to the increasing production of vehicles equipped with gasoline engines, including those using LS engine platforms.

In the context of LS engines, which are known for their high performance and efficiency, there is a specific demand for catalytic converters that can handle increased exhaust temperatures and flow rates without compromising emission control. This has led to a surge in research and development activities focused on materials and designs that can withstand these challenging conditions while effectively reducing emissions.

The aftermarket segment for LS engine catalytic converters is also showing significant potential. Performance enthusiasts and custom vehicle builders are increasingly seeking advanced catalytic converter options that comply with emission standards without sacrificing engine output. This niche market is driving innovation in lightweight, high-flow catalytic converter designs that can be easily integrated into modified LS engine systems.

Furthermore, the push towards electrification in the automotive industry has not diminished the demand for advanced catalytic converters in LS engines. Instead, it has created a parallel market for hybrid vehicles that combine internal combustion engines with electric powertrains. These hybrid systems often utilize high-performance engines like the LS series and require specialized catalytic converters to manage emissions during combustion engine operation.

The market demand is also influenced by the increasing focus on sustainable manufacturing practices. Consumers and regulators are showing interest in catalytic converters that not only reduce emissions but are also produced using environmentally friendly processes and materials. This has opened up new avenues for innovation in catalyst formulations and recycling technologies.

Current Catalytic Converter Technology Challenges

Catalytic converters for LS engines face several significant challenges in meeting increasingly stringent emission control standards. One of the primary issues is the need for improved low-temperature catalytic activity. Current catalysts often struggle to effectively reduce emissions during cold starts and short trips, when the engine and exhaust system have not reached optimal operating temperatures.

Another challenge lies in the durability and longevity of catalytic converters. The harsh operating conditions within the exhaust system, including high temperatures and exposure to various chemical compounds, can lead to catalyst degradation over time. This degradation results in reduced efficiency and increased emissions, particularly as vehicles age.

The cost of precious metals used in catalytic converters, such as platinum, palladium, and rhodium, presents an ongoing challenge for manufacturers. These materials are essential for effective emission control but are also expensive and subject to price fluctuations. Finding ways to reduce the amount of precious metals used while maintaining or improving catalytic performance is a key focus area for research and development.

Space constraints within modern vehicle designs pose another significant challenge. As engines become more compact and efficient, there is less room available for large catalytic converter systems. This necessitates the development of more compact and efficient catalyst designs that can deliver the required performance within limited space.

The complexity of exhaust gas composition from LS engines also presents challenges for catalytic converter technology. These engines produce a wide range of pollutants, including carbon monoxide, nitrogen oxides, and unburned hydrocarbons. Developing catalysts that can effectively treat all these pollutants simultaneously under varying operating conditions remains a significant technical hurdle.

Furthermore, the increasing use of alternative fuels and engine technologies, such as hybrid systems, creates new challenges for catalytic converter design. These systems often have different exhaust gas compositions and temperature profiles, requiring adaptable catalyst formulations and designs.

Lastly, the need for improved diagnostic and monitoring systems for catalytic converters is becoming increasingly important. Current on-board diagnostic systems may not always accurately detect catalyst degradation or malfunction, leading to potential increases in emissions without timely intervention. Developing more sophisticated and reliable monitoring technologies is crucial for ensuring long-term emission control effectiveness in LS engines.

Another challenge lies in the durability and longevity of catalytic converters. The harsh operating conditions within the exhaust system, including high temperatures and exposure to various chemical compounds, can lead to catalyst degradation over time. This degradation results in reduced efficiency and increased emissions, particularly as vehicles age.

The cost of precious metals used in catalytic converters, such as platinum, palladium, and rhodium, presents an ongoing challenge for manufacturers. These materials are essential for effective emission control but are also expensive and subject to price fluctuations. Finding ways to reduce the amount of precious metals used while maintaining or improving catalytic performance is a key focus area for research and development.

Space constraints within modern vehicle designs pose another significant challenge. As engines become more compact and efficient, there is less room available for large catalytic converter systems. This necessitates the development of more compact and efficient catalyst designs that can deliver the required performance within limited space.

The complexity of exhaust gas composition from LS engines also presents challenges for catalytic converter technology. These engines produce a wide range of pollutants, including carbon monoxide, nitrogen oxides, and unburned hydrocarbons. Developing catalysts that can effectively treat all these pollutants simultaneously under varying operating conditions remains a significant technical hurdle.

Furthermore, the increasing use of alternative fuels and engine technologies, such as hybrid systems, creates new challenges for catalytic converter design. These systems often have different exhaust gas compositions and temperature profiles, requiring adaptable catalyst formulations and designs.

Lastly, the need for improved diagnostic and monitoring systems for catalytic converters is becoming increasingly important. Current on-board diagnostic systems may not always accurately detect catalyst degradation or malfunction, leading to potential increases in emissions without timely intervention. Developing more sophisticated and reliable monitoring technologies is crucial for ensuring long-term emission control effectiveness in LS engines.

Existing Catalytic Solutions for LS Engines

01 Catalytic converter design and structure

Innovations in catalytic converter design focus on improving the structure to enhance emission control efficiency. This includes optimizing the shape, size, and internal configuration of the converter to maximize contact between exhaust gases and catalytic materials. Advanced designs may incorporate multiple stages or chambers to target different pollutants more effectively.- Catalytic converter design and structure: Innovations in catalytic converter design focus on improving the structure to enhance emission control efficiency. This includes optimizing the shape, size, and internal configuration of the converter to maximize contact between exhaust gases and catalytic materials. Advanced designs may incorporate multiple stages or chambers to target different pollutants more effectively.

- Novel catalytic materials and coatings: Development of new catalytic materials and coatings aims to improve the conversion efficiency of harmful emissions. These may include advanced precious metal formulations, rare earth elements, or novel composite materials. Coatings are designed to increase the active surface area and durability of the catalyst, enhancing its performance and longevity.

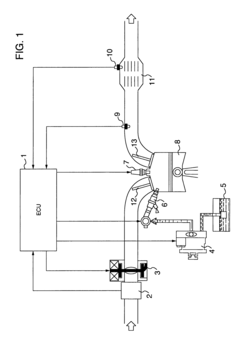

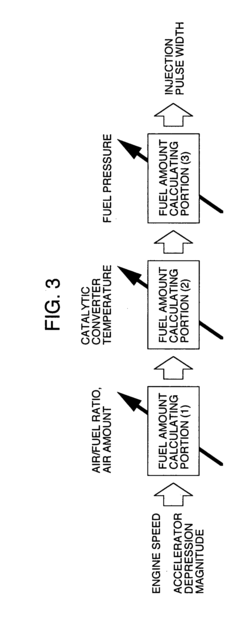

- Sensor integration and control systems: Integration of sensors and advanced control systems in catalytic converters allows for real-time monitoring and adjustment of emission control processes. These systems can detect the composition of exhaust gases, temperature, and other parameters to optimize the converter's performance under varying operating conditions.

- Regeneration and self-cleaning mechanisms: Incorporation of regeneration and self-cleaning mechanisms in catalytic converters helps maintain their efficiency over time. These systems may include thermal management techniques, periodic purging processes, or the use of additives to prevent catalyst poisoning and extend the operational life of the converter.

- Integration with other emission control technologies: Catalytic converters are increasingly integrated with other emission control technologies to create comprehensive exhaust treatment systems. This may involve combining catalytic converters with particulate filters, selective catalytic reduction (SCR) systems, or exhaust gas recirculation (EGR) to address a wider range of pollutants and meet stricter emission standards.

02 Novel catalytic materials and coatings

Development of new catalytic materials and coatings aims to improve the performance and durability of catalytic converters. These may include advanced precious metal formulations, rare earth elements, or nanostructured materials that offer higher catalytic activity, better resistance to thermal degradation, and improved conversion efficiency for various pollutants.Expand Specific Solutions03 Sensor integration and control systems

Integration of sensors and advanced control systems in catalytic converters enables real-time monitoring of emissions and adjustment of engine parameters. This approach allows for more precise control of the catalytic process, optimizing performance under various operating conditions and ensuring compliance with stringent emission standards.Expand Specific Solutions04 Regeneration and self-cleaning mechanisms

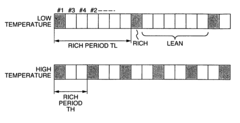

Incorporation of regeneration and self-cleaning mechanisms in catalytic converters helps maintain their efficiency over time. These systems may use thermal management, periodic rich/lean cycling, or other techniques to remove accumulated contaminants and restore catalytic activity, extending the converter's lifespan and maintaining its emission control performance.Expand Specific Solutions05 Integration with other emission control technologies

Combining catalytic converters with other emission control technologies, such as particulate filters, selective catalytic reduction (SCR) systems, or exhaust gas recirculation (EGR), creates more comprehensive emission control solutions. These integrated systems can address a wider range of pollutants and achieve higher overall emission reduction rates across various engine types and operating conditions.Expand Specific Solutions

Key Players in Automotive Catalytic Converter Industry

The catalytic converter innovation landscape for LS engine emission control is in a mature stage, with a well-established market dominated by major automotive manufacturers and specialized component suppliers. The global market size for catalytic converters is substantial, driven by stringent emission regulations worldwide. Technologically, the field is advanced, with companies like GM Global Technology Operations, Ford Global Technologies, and Umicore SA leading in research and development. These firms, along with others such as Volkswagen AG and Honda Motor Co., are continuously improving catalyst efficiency, durability, and cost-effectiveness. Emerging players like Advanced Technology Emission Solutions are introducing novel technologies, indicating ongoing innovation in this mature market.

GM Global Technology Operations LLC

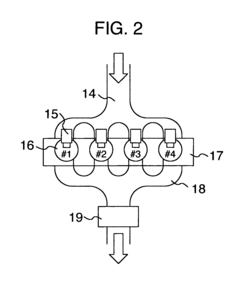

Technical Solution: GM has developed an innovative three-way catalytic converter system specifically designed for LS engines. This system incorporates advanced precious metal catalysts and a high cell density substrate to maximize surface area for reactions. The converter utilizes a close-coupled design, positioning it near the exhaust manifold to quickly reach optimal operating temperature[1]. GM's system also features an oxygen storage component to maintain the ideal air-fuel ratio for efficient catalysis. Additionally, they've implemented a dual-bed converter configuration, with the first bed optimized for quick light-off and the second for sustained performance[3].

Strengths: Rapid light-off time, high conversion efficiency, and durability. Weaknesses: Potentially higher cost due to precious metal content and complex design.

Ford Global Technologies LLC

Technical Solution: Ford has developed a novel catalytic converter system for LS engines focusing on cold-start emissions reduction. Their approach uses an electrically heated catalyst (EHC) technology, which rapidly heats the catalyst to its light-off temperature within seconds of engine start[2]. The system incorporates a thin, metallic substrate coated with advanced low-PGM (Platinum Group Metals) formulations to reduce costs while maintaining performance. Ford's design also features a dual-layer washcoat technology, with the bottom layer optimized for oxygen storage and the top layer for pollutant conversion[4]. To further enhance efficiency, they've implemented an advanced engine control module that adjusts air-fuel ratios and ignition timing to optimize catalyst performance during various driving conditions[5].

Strengths: Excellent cold-start emissions control, reduced PGM loading, and adaptive performance. Weaknesses: Increased complexity and potential reliability issues with the electrical heating system.

Core Innovations in Catalytic Materials

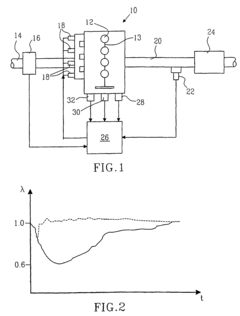

Emission control device for cylinder fuel injection engine

PatentInactiveUS6957529B2

Innovation

- An exhaust control system that measures the catalytic converter temperature and adjusts the air/fuel ratio, fuel injection timing, and auxiliary injection to maintain a rich mixture during low temperatures, and utilizes reaction heat to elevate the catalytic converter temperature, while inhibiting ignition at high temperatures to optimize purification and activation.

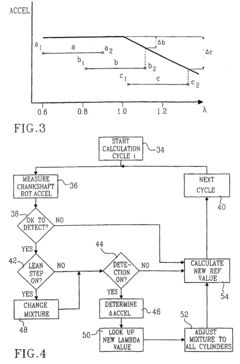

Method of reduction of cold-start emissions from internal combustion engines

PatentInactiveEP1108131B1

Innovation

- A method that measures rotational acceleration of the crankshaft in multiple cylinders with different air/fuel mixtures to compare and adjust the lambda value, allowing for quicker adoption of a leaner mixture, reducing HC emissions and fuel consumption, and is insensitive to variations due to wear or external factors.

Environmental Regulations Impact on Converter Development

Environmental regulations have played a pivotal role in shaping the development of catalytic converters for LS engines. The increasingly stringent emission standards set by regulatory bodies worldwide have driven continuous innovation in converter technology. In the United States, the Environmental Protection Agency (EPA) has progressively tightened emission limits for vehicles, compelling manufacturers to enhance the efficiency of their catalytic converters.

The introduction of Tier 3 emission standards in 2017 marked a significant milestone, requiring substantial reductions in nitrogen oxides (NOx), particulate matter (PM), and non-methane organic gases (NMOG). These regulations have necessitated the development of advanced converter designs capable of meeting these more stringent requirements while maintaining engine performance.

European regulations, particularly the Euro 6 standards, have also influenced converter development for LS engines. These standards have set even lower limits for pollutants, especially NOx emissions from diesel engines. This has led to the adoption of selective catalytic reduction (SCR) systems and diesel particulate filters (DPF) in many LS engine applications.

The impact of these regulations extends beyond the technical aspects of converter design. Manufacturers have been compelled to invest heavily in research and development to create more efficient and durable catalytic converters. This has resulted in the exploration of novel materials, such as advanced precious metal catalysts and washcoat formulations, to enhance converter performance and longevity.

Moreover, the regulatory landscape has fostered collaboration between engine manufacturers and converter suppliers. This partnership approach has become crucial in developing integrated emission control systems that optimize the interaction between the engine, exhaust system, and catalytic converter.

The push for cleaner emissions has also led to the development of on-board diagnostics (OBD) systems specifically designed to monitor converter performance. These systems ensure that vehicles maintain their emission control effectiveness throughout their lifecycle, aligning with regulatory requirements for long-term emission compliance.

As global concerns about air quality and climate change continue to grow, it is anticipated that emission regulations will become even more stringent in the future. This ongoing regulatory pressure is likely to drive further innovations in catalytic converter technology for LS engines, potentially leading to breakthroughs in materials science, nanotechnology, and system integration approaches.

The introduction of Tier 3 emission standards in 2017 marked a significant milestone, requiring substantial reductions in nitrogen oxides (NOx), particulate matter (PM), and non-methane organic gases (NMOG). These regulations have necessitated the development of advanced converter designs capable of meeting these more stringent requirements while maintaining engine performance.

European regulations, particularly the Euro 6 standards, have also influenced converter development for LS engines. These standards have set even lower limits for pollutants, especially NOx emissions from diesel engines. This has led to the adoption of selective catalytic reduction (SCR) systems and diesel particulate filters (DPF) in many LS engine applications.

The impact of these regulations extends beyond the technical aspects of converter design. Manufacturers have been compelled to invest heavily in research and development to create more efficient and durable catalytic converters. This has resulted in the exploration of novel materials, such as advanced precious metal catalysts and washcoat formulations, to enhance converter performance and longevity.

Moreover, the regulatory landscape has fostered collaboration between engine manufacturers and converter suppliers. This partnership approach has become crucial in developing integrated emission control systems that optimize the interaction between the engine, exhaust system, and catalytic converter.

The push for cleaner emissions has also led to the development of on-board diagnostics (OBD) systems specifically designed to monitor converter performance. These systems ensure that vehicles maintain their emission control effectiveness throughout their lifecycle, aligning with regulatory requirements for long-term emission compliance.

As global concerns about air quality and climate change continue to grow, it is anticipated that emission regulations will become even more stringent in the future. This ongoing regulatory pressure is likely to drive further innovations in catalytic converter technology for LS engines, potentially leading to breakthroughs in materials science, nanotechnology, and system integration approaches.

Cost-Benefit Analysis of Advanced Catalytic Technologies

The cost-benefit analysis of advanced catalytic technologies for LS engine emission control reveals a complex interplay between environmental benefits and economic considerations. Advanced catalytic converters, while more expensive upfront, offer significant long-term advantages in terms of emission reduction and fuel efficiency.

Initial investment in these technologies can be substantial, with costs ranging from $500 to $2000 per unit, depending on the specific technology and materials used. However, the benefits of improved emission control are considerable. Advanced catalytic converters can reduce harmful emissions by up to 90% compared to standard models, significantly contributing to air quality improvement and public health.

From a fuel efficiency perspective, these technologies can lead to savings of 2-5% in fuel consumption. Over the lifetime of a vehicle, this can translate to substantial cost savings for consumers, potentially offsetting the initial higher cost of the advanced catalytic converter.

Maintenance costs for advanced catalytic technologies are generally lower due to their increased durability and longevity. Many of these systems are designed to last the entire lifetime of the vehicle, reducing replacement costs and associated labor expenses.

Environmental regulations play a crucial role in the cost-benefit equation. As emission standards become more stringent, the adoption of advanced catalytic technologies becomes increasingly necessary. Failure to comply with these standards can result in hefty fines for manufacturers, making the investment in advanced technologies a prudent long-term strategy.

The scalability of production for these advanced technologies is another important factor. As production volumes increase, economies of scale are likely to drive down costs, making advanced catalytic converters more accessible and cost-effective for a broader range of vehicles and consumers.

In terms of performance, advanced catalytic technologies often contribute to improved engine efficiency and power output. This can enhance the overall driving experience and vehicle marketability, potentially increasing sales and market share for manufacturers who adopt these technologies early.

While the upfront costs of implementing advanced catalytic technologies are significant, the long-term benefits in terms of emission reduction, fuel efficiency, regulatory compliance, and potential market advantages present a compelling case for their adoption. As the automotive industry continues to prioritize sustainability and environmental responsibility, the cost-benefit ratio of these technologies is likely to improve further, making them an increasingly attractive option for manufacturers and consumers alike.

Initial investment in these technologies can be substantial, with costs ranging from $500 to $2000 per unit, depending on the specific technology and materials used. However, the benefits of improved emission control are considerable. Advanced catalytic converters can reduce harmful emissions by up to 90% compared to standard models, significantly contributing to air quality improvement and public health.

From a fuel efficiency perspective, these technologies can lead to savings of 2-5% in fuel consumption. Over the lifetime of a vehicle, this can translate to substantial cost savings for consumers, potentially offsetting the initial higher cost of the advanced catalytic converter.

Maintenance costs for advanced catalytic technologies are generally lower due to their increased durability and longevity. Many of these systems are designed to last the entire lifetime of the vehicle, reducing replacement costs and associated labor expenses.

Environmental regulations play a crucial role in the cost-benefit equation. As emission standards become more stringent, the adoption of advanced catalytic technologies becomes increasingly necessary. Failure to comply with these standards can result in hefty fines for manufacturers, making the investment in advanced technologies a prudent long-term strategy.

The scalability of production for these advanced technologies is another important factor. As production volumes increase, economies of scale are likely to drive down costs, making advanced catalytic converters more accessible and cost-effective for a broader range of vehicles and consumers.

In terms of performance, advanced catalytic technologies often contribute to improved engine efficiency and power output. This can enhance the overall driving experience and vehicle marketability, potentially increasing sales and market share for manufacturers who adopt these technologies early.

While the upfront costs of implementing advanced catalytic technologies are significant, the long-term benefits in terms of emission reduction, fuel efficiency, regulatory compliance, and potential market advantages present a compelling case for their adoption. As the automotive industry continues to prioritize sustainability and environmental responsibility, the cost-benefit ratio of these technologies is likely to improve further, making them an increasingly attractive option for manufacturers and consumers alike.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!