How Computational Chemistries Optimize LS Engine Fuel Compositions

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Computational Chemistry in LS Engine Fuel Optimization

Computational chemistry has emerged as a powerful tool in optimizing fuel compositions for LS (Luxury Sport) engines, revolutionizing the approach to enhancing engine performance and efficiency. This field combines principles of quantum mechanics, molecular dynamics, and statistical mechanics to simulate and predict the behavior of chemical systems at the molecular level. In the context of LS engine fuel optimization, computational chemistry enables researchers to model complex fuel mixtures and their interactions with engine components, providing invaluable insights that were previously unattainable through traditional experimental methods alone.

The application of computational chemistry in LS engine fuel optimization has evolved significantly over the past few decades. Initially, simple molecular modeling techniques were used to study individual fuel components. As computational power increased, more sophisticated methods such as density functional theory (DFT) and molecular dynamics simulations became feasible for larger systems. Today, advanced machine learning algorithms and artificial intelligence are being integrated with computational chemistry techniques, allowing for rapid screening of thousands of potential fuel compositions and their predicted performance in LS engines.

The primary goal of using computational chemistry in this field is to develop fuel compositions that maximize engine performance while minimizing environmental impact. This involves optimizing parameters such as octane rating, combustion efficiency, and emissions reduction. Computational methods allow researchers to explore a vast chemical space of potential fuel additives and blends, predicting their properties and behavior under various engine conditions without the need for extensive physical testing.

One of the key advantages of computational chemistry in LS engine fuel optimization is its ability to provide atomic-level insights into the combustion process. Researchers can simulate the breaking and forming of chemical bonds during combustion, analyze the formation of intermediate species, and study the kinetics of reactions occurring within the engine cylinder. This level of detail helps in understanding the fundamental mechanisms behind fuel performance and guides the design of more efficient and cleaner-burning fuel compositions.

Furthermore, computational chemistry enables the prediction of macroscopic fuel properties based on molecular-level simulations. Properties such as viscosity, volatility, and energy density can be estimated for novel fuel blends before they are synthesized, significantly accelerating the development process. This predictive capability is particularly valuable in the automotive industry, where the demand for high-performance, environmentally friendly fuels for LS engines continues to grow.

The application of computational chemistry in LS engine fuel optimization has evolved significantly over the past few decades. Initially, simple molecular modeling techniques were used to study individual fuel components. As computational power increased, more sophisticated methods such as density functional theory (DFT) and molecular dynamics simulations became feasible for larger systems. Today, advanced machine learning algorithms and artificial intelligence are being integrated with computational chemistry techniques, allowing for rapid screening of thousands of potential fuel compositions and their predicted performance in LS engines.

The primary goal of using computational chemistry in this field is to develop fuel compositions that maximize engine performance while minimizing environmental impact. This involves optimizing parameters such as octane rating, combustion efficiency, and emissions reduction. Computational methods allow researchers to explore a vast chemical space of potential fuel additives and blends, predicting their properties and behavior under various engine conditions without the need for extensive physical testing.

One of the key advantages of computational chemistry in LS engine fuel optimization is its ability to provide atomic-level insights into the combustion process. Researchers can simulate the breaking and forming of chemical bonds during combustion, analyze the formation of intermediate species, and study the kinetics of reactions occurring within the engine cylinder. This level of detail helps in understanding the fundamental mechanisms behind fuel performance and guides the design of more efficient and cleaner-burning fuel compositions.

Furthermore, computational chemistry enables the prediction of macroscopic fuel properties based on molecular-level simulations. Properties such as viscosity, volatility, and energy density can be estimated for novel fuel blends before they are synthesized, significantly accelerating the development process. This predictive capability is particularly valuable in the automotive industry, where the demand for high-performance, environmentally friendly fuels for LS engines continues to grow.

Market Demand for Advanced LS Engine Fuels

The market demand for advanced LS (Low-Speed) engine fuels has been steadily increasing in recent years, driven by a combination of environmental regulations, economic factors, and technological advancements. As global efforts to reduce carbon emissions intensify, there is a growing need for cleaner and more efficient fuel compositions that can optimize the performance of LS engines while minimizing their environmental impact.

One of the primary drivers of this demand is the stringent emission standards imposed by governments worldwide. These regulations have forced engine manufacturers and fuel producers to seek innovative solutions that can meet these requirements without compromising engine performance. Advanced LS engine fuels, optimized through computational chemistry techniques, offer a promising avenue to achieve this balance.

The marine industry, in particular, has shown significant interest in advanced LS engine fuels. With the International Maritime Organization (IMO) implementing stricter sulfur content limits for marine fuels, ship operators are actively seeking alternatives that can comply with these regulations while maintaining operational efficiency. This has created a substantial market opportunity for fuel compositions tailored specifically for LS marine engines.

In the power generation sector, there is a growing demand for advanced fuels that can enhance the efficiency and reliability of stationary LS engines. As many countries transition towards more distributed power generation systems, the need for high-performance, low-emission fuels for these engines has increased. This trend is particularly evident in developing economies where LS engines play a crucial role in providing reliable power supply.

The agricultural sector represents another significant market for advanced LS engine fuels. As modern farming equipment becomes more sophisticated, there is a rising demand for fuel compositions that can optimize the performance of tractors, harvesters, and other agricultural machinery equipped with LS engines. Farmers are increasingly looking for fuels that can provide better fuel economy, reduced emissions, and improved engine longevity.

From an economic perspective, the volatility in crude oil prices has also contributed to the demand for advanced LS engine fuels. Fuel consumers across various industries are seeking ways to reduce their operational costs, and optimized fuel compositions offer a potential solution by improving fuel efficiency and reducing maintenance requirements.

The market for advanced LS engine fuels is not limited to traditional petroleum-based products. There is a growing interest in alternative and renewable fuel sources that can be optimized for LS engines. This includes biofuels, synthetic fuels, and other novel fuel compositions that can offer improved performance characteristics while aligning with sustainability goals.

One of the primary drivers of this demand is the stringent emission standards imposed by governments worldwide. These regulations have forced engine manufacturers and fuel producers to seek innovative solutions that can meet these requirements without compromising engine performance. Advanced LS engine fuels, optimized through computational chemistry techniques, offer a promising avenue to achieve this balance.

The marine industry, in particular, has shown significant interest in advanced LS engine fuels. With the International Maritime Organization (IMO) implementing stricter sulfur content limits for marine fuels, ship operators are actively seeking alternatives that can comply with these regulations while maintaining operational efficiency. This has created a substantial market opportunity for fuel compositions tailored specifically for LS marine engines.

In the power generation sector, there is a growing demand for advanced fuels that can enhance the efficiency and reliability of stationary LS engines. As many countries transition towards more distributed power generation systems, the need for high-performance, low-emission fuels for these engines has increased. This trend is particularly evident in developing economies where LS engines play a crucial role in providing reliable power supply.

The agricultural sector represents another significant market for advanced LS engine fuels. As modern farming equipment becomes more sophisticated, there is a rising demand for fuel compositions that can optimize the performance of tractors, harvesters, and other agricultural machinery equipped with LS engines. Farmers are increasingly looking for fuels that can provide better fuel economy, reduced emissions, and improved engine longevity.

From an economic perspective, the volatility in crude oil prices has also contributed to the demand for advanced LS engine fuels. Fuel consumers across various industries are seeking ways to reduce their operational costs, and optimized fuel compositions offer a potential solution by improving fuel efficiency and reducing maintenance requirements.

The market for advanced LS engine fuels is not limited to traditional petroleum-based products. There is a growing interest in alternative and renewable fuel sources that can be optimized for LS engines. This includes biofuels, synthetic fuels, and other novel fuel compositions that can offer improved performance characteristics while aligning with sustainability goals.

Current State of Computational Fuel Chemistry

Computational fuel chemistry has made significant strides in recent years, revolutionizing the optimization of LS engine fuel compositions. The current state of this field is characterized by advanced modeling techniques, high-performance computing capabilities, and sophisticated algorithms that enable researchers to predict and analyze fuel properties and combustion behaviors with unprecedented accuracy.

One of the key advancements in computational fuel chemistry is the development of detailed chemical kinetic models. These models can simulate complex reaction networks involving hundreds or even thousands of species and reactions. They provide invaluable insights into the combustion process, allowing researchers to understand how different fuel components interact and influence engine performance.

Quantum chemistry methods have also become increasingly important in the field. Ab initio calculations and density functional theory (DFT) are now routinely used to investigate the electronic structure and reactivity of fuel molecules. These techniques enable researchers to predict thermodynamic properties, reaction rates, and transition states with high accuracy, contributing to the development of more efficient and cleaner-burning fuels.

Machine learning and artificial intelligence have emerged as powerful tools in computational fuel chemistry. These techniques can rapidly screen vast numbers of potential fuel compositions, identifying promising candidates for experimental testing. They also help in the development of surrogate fuel models, which simplify complex fuel mixtures while maintaining key combustion characteristics.

Molecular dynamics simulations have become more sophisticated, allowing researchers to study the behavior of fuel molecules at the atomic level. These simulations provide insights into fuel spray dynamics, evaporation processes, and fuel-air mixing, all of which are critical factors in LS engine performance.

Computational fluid dynamics (CFD) coupled with chemical kinetics models has enabled researchers to simulate entire engine cycles, including fuel injection, combustion, and emissions formation. These integrated models provide a holistic view of engine performance and help identify opportunities for optimization.

The current state of computational fuel chemistry also benefits from improved experimental validation techniques. Advanced diagnostics tools, such as laser-induced fluorescence and high-speed imaging, allow researchers to compare computational predictions with real-world observations, refining and validating their models.

As computational power continues to increase, researchers are able to perform more complex simulations and explore larger parameter spaces. This has led to the development of multi-scale modeling approaches that bridge the gap between molecular-level interactions and macroscopic engine performance.

One of the key advancements in computational fuel chemistry is the development of detailed chemical kinetic models. These models can simulate complex reaction networks involving hundreds or even thousands of species and reactions. They provide invaluable insights into the combustion process, allowing researchers to understand how different fuel components interact and influence engine performance.

Quantum chemistry methods have also become increasingly important in the field. Ab initio calculations and density functional theory (DFT) are now routinely used to investigate the electronic structure and reactivity of fuel molecules. These techniques enable researchers to predict thermodynamic properties, reaction rates, and transition states with high accuracy, contributing to the development of more efficient and cleaner-burning fuels.

Machine learning and artificial intelligence have emerged as powerful tools in computational fuel chemistry. These techniques can rapidly screen vast numbers of potential fuel compositions, identifying promising candidates for experimental testing. They also help in the development of surrogate fuel models, which simplify complex fuel mixtures while maintaining key combustion characteristics.

Molecular dynamics simulations have become more sophisticated, allowing researchers to study the behavior of fuel molecules at the atomic level. These simulations provide insights into fuel spray dynamics, evaporation processes, and fuel-air mixing, all of which are critical factors in LS engine performance.

Computational fluid dynamics (CFD) coupled with chemical kinetics models has enabled researchers to simulate entire engine cycles, including fuel injection, combustion, and emissions formation. These integrated models provide a holistic view of engine performance and help identify opportunities for optimization.

The current state of computational fuel chemistry also benefits from improved experimental validation techniques. Advanced diagnostics tools, such as laser-induced fluorescence and high-speed imaging, allow researchers to compare computational predictions with real-world observations, refining and validating their models.

As computational power continues to increase, researchers are able to perform more complex simulations and explore larger parameter spaces. This has led to the development of multi-scale modeling approaches that bridge the gap between molecular-level interactions and macroscopic engine performance.

Existing Computational Methods for Fuel Composition

01 Computational methods for fuel composition optimization

Advanced computational techniques are employed to optimize fuel compositions, enhancing performance and efficiency. These methods involve complex algorithms and simulations to predict and analyze the behavior of various fuel mixtures under different conditions, enabling the development of improved fuel formulations.- Computational methods for fuel composition analysis: Advanced computational techniques are employed to analyze and optimize fuel compositions. These methods involve complex algorithms and simulations to predict fuel properties, performance, and emissions. By utilizing computational chemistry, researchers can efficiently explore various fuel formulations and their potential impacts on engine performance and environmental factors.

- Fuel additives and composition optimization: Computational chemistry is used to design and evaluate fuel additives and optimize overall fuel compositions. This approach allows for the systematic screening of potential additives and their interactions with base fuels. The goal is to enhance fuel properties such as combustion efficiency, stability, and emissions reduction through carefully tailored compositions.

- Molecular modeling of fuel components: Molecular modeling techniques are applied to study the behavior and interactions of fuel components at the atomic and molecular levels. This approach provides insights into the fundamental properties of fuels and helps predict how different molecular structures affect overall fuel performance. Such modeling can guide the development of novel fuel formulations with improved characteristics.

- Machine learning applications in fuel research: Machine learning algorithms are increasingly used in computational chemistry for fuel composition research. These techniques can analyze large datasets of fuel properties and performance metrics to identify patterns and make predictions. Machine learning models can accelerate the discovery of new fuel formulations and optimize existing ones for specific applications.

- Environmental impact assessment of fuel compositions: Computational methods are employed to assess the environmental impact of various fuel compositions. This includes modeling emissions, analyzing lifecycle carbon footprints, and predicting the formation of pollutants during combustion. Such assessments help in developing cleaner fuel formulations and meeting increasingly stringent environmental regulations.

02 Biofuel compositions and computational analysis

Computational chemistry is utilized to design and analyze biofuel compositions, focusing on renewable and sustainable fuel sources. This approach helps in understanding the molecular interactions and properties of biofuels, leading to the development of more efficient and environmentally friendly fuel alternatives.Expand Specific Solutions03 Fuel additive optimization using computational methods

Computational techniques are applied to optimize fuel additives, enhancing combustion efficiency and reducing emissions. These methods involve molecular modeling and simulations to predict the effects of various additives on fuel performance, allowing for the development of tailored additive packages.Expand Specific Solutions04 Computational analysis of fuel combustion processes

Advanced computational models are used to simulate and analyze fuel combustion processes, providing insights into reaction kinetics and thermodynamics. This approach enables the optimization of fuel compositions for improved combustion efficiency and reduced emissions in various applications.Expand Specific Solutions05 Machine learning applications in fuel composition design

Machine learning algorithms are employed to analyze large datasets of fuel compositions and their properties, enabling the prediction and design of novel fuel formulations. This approach accelerates the development of advanced fuels by identifying optimal compositions based on desired performance characteristics.Expand Specific Solutions

Key Players in Computational Fuel Research

The computational chemistry optimization of LS engine fuel compositions is in a mature stage of development, with a significant market size driven by the automotive industry's focus on efficiency and emissions reduction. The technology's maturity is evident from the involvement of major players like ExxonMobil Technology & Engineering Co., GM Global Technology Operations LLC, and Ford Global Technologies LLC, who have extensive research capabilities and industry experience. The competitive landscape is diverse, including oil companies, automotive manufacturers, and specialized chemical firms such as Afton Chemical Corp. and Infineum International Ltd., indicating a well-established ecosystem. As environmental regulations tighten, this field is likely to see continued innovation and market growth, with companies investing in advanced computational methods to further optimize fuel formulations for improved engine performance and reduced environmental impact.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil employs advanced computational chemistry techniques to optimize LS engine fuel compositions. Their approach involves molecular modeling and quantum mechanical calculations to predict fuel properties and performance. They utilize machine learning algorithms to analyze vast datasets of fuel compositions and engine performance metrics, enabling the identification of optimal fuel formulations. ExxonMobil's computational methods include molecular dynamics simulations to study fuel-engine interactions at the atomic level, providing insights into combustion processes and emissions formation[1][3]. Their research also incorporates high-throughput screening of potential fuel additives, allowing for rapid evaluation of thousands of compounds to enhance fuel efficiency and reduce emissions in LS engines[2].

Strengths: Extensive computational resources, vast fuel chemistry expertise, and integrated approach combining molecular modeling with machine learning. Weaknesses: High computational costs and potential challenges in validating complex models against real-world engine performance.

Infineum International Ltd.

Technical Solution: Infineum International Ltd. leverages computational chemistry to develop advanced fuel compositions for LS engines. Their approach combines quantum chemical calculations with statistical thermodynamics to predict fuel properties and behavior under various engine conditions. Infineum utilizes molecular dynamics simulations to study the interactions between fuel molecules and engine components, focusing on optimizing fuel-lubricant interactions to enhance engine efficiency[4]. They employ machine learning algorithms to analyze large datasets of fuel formulations and engine performance data, enabling the identification of optimal additive packages for LS engine fuels. Infineum's computational methods also include reactive force field simulations to study combustion kinetics and emissions formation, allowing for the development of cleaner-burning fuel compositions[5].

Strengths: Specialized focus on fuel and lubricant additives, strong integration of computational methods with experimental validation. Weaknesses: Potential limitations in addressing broader engine design considerations beyond fuel chemistry.

Core Innovations in Fuel Chemistry Modeling

Fuel compositions

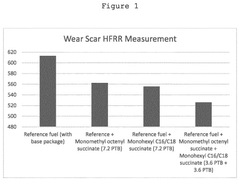

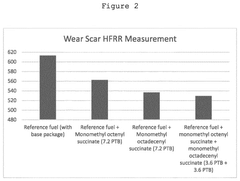

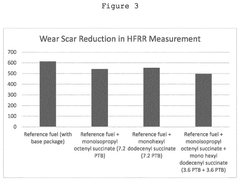

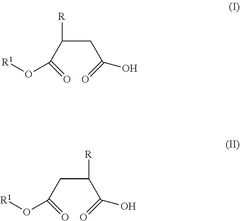

PatentPendingUS20240352364A1

Innovation

- A liquid fuel composition comprising a base fuel and a blend of two monoalkyl alkenyl succinates, where the first and second monoalkyl alkenyl succinates have specific formulas or isomeric mixtures, providing a synergistic reduction in engine wear by forming a protective chemical wall on metal surfaces.

Fuel compositions

PatentActiveUS10995291B2

Innovation

- A fuel composition and additive package comprising sorbitan oleate, polyoxyethylene alcohol, and an amine, combined with submicron or nano-emulsification techniques, which reduces emissions by catalytic reactions during combustion and enhances fuel stability and lubricity, thereby improving engine performance and reducing maintenance costs.

Environmental Impact of Optimized LS Engine Fuels

The optimization of LS engine fuel compositions through computational chemistry methods has significant environmental implications. These optimized fuels can lead to reduced emissions of harmful pollutants, contributing to improved air quality and reduced environmental impact. By fine-tuning fuel compositions, researchers can enhance combustion efficiency, resulting in lower carbon dioxide emissions per unit of energy produced.

One of the key environmental benefits of optimized LS engine fuels is the potential reduction in particulate matter emissions. Computational chemistry allows for the design of fuel molecules that burn more completely, reducing the formation of soot and other particulates that contribute to air pollution and respiratory health issues. This is particularly important in urban areas where vehicle emissions are a major contributor to poor air quality.

Furthermore, optimized fuels can lead to decreased nitrogen oxide (NOx) emissions. NOx is a major contributor to smog formation and acid rain. By using computational methods to design fuel compositions that burn at lower temperatures or with more controlled combustion processes, the formation of NOx can be significantly reduced, mitigating these environmental concerns.

The environmental impact extends beyond air quality. Optimized fuels can also result in improved fuel economy, reducing overall fuel consumption. This has cascading environmental benefits, including reduced oil extraction and refining activities, which are associated with various environmental risks such as oil spills and habitat destruction.

Additionally, computational chemistry can aid in the development of biofuel blends that are more compatible with LS engines. This can facilitate the transition to renewable fuel sources, reducing dependence on fossil fuels and potentially lowering the overall carbon footprint of transportation.

However, it's important to consider potential trade-offs. While optimized fuels may reduce certain emissions, they could potentially increase others or introduce new environmental challenges. For instance, some additives used to enhance fuel performance may have their own environmental impacts during production or disposal. Comprehensive life cycle assessments are crucial to fully understand the net environmental impact of these optimized fuels.

In conclusion, the environmental impact of optimized LS engine fuels is largely positive, offering potential reductions in various pollutants and improved overall efficiency. However, ongoing research and careful consideration of all environmental aspects are necessary to ensure that the benefits outweigh any potential drawbacks.

One of the key environmental benefits of optimized LS engine fuels is the potential reduction in particulate matter emissions. Computational chemistry allows for the design of fuel molecules that burn more completely, reducing the formation of soot and other particulates that contribute to air pollution and respiratory health issues. This is particularly important in urban areas where vehicle emissions are a major contributor to poor air quality.

Furthermore, optimized fuels can lead to decreased nitrogen oxide (NOx) emissions. NOx is a major contributor to smog formation and acid rain. By using computational methods to design fuel compositions that burn at lower temperatures or with more controlled combustion processes, the formation of NOx can be significantly reduced, mitigating these environmental concerns.

The environmental impact extends beyond air quality. Optimized fuels can also result in improved fuel economy, reducing overall fuel consumption. This has cascading environmental benefits, including reduced oil extraction and refining activities, which are associated with various environmental risks such as oil spills and habitat destruction.

Additionally, computational chemistry can aid in the development of biofuel blends that are more compatible with LS engines. This can facilitate the transition to renewable fuel sources, reducing dependence on fossil fuels and potentially lowering the overall carbon footprint of transportation.

However, it's important to consider potential trade-offs. While optimized fuels may reduce certain emissions, they could potentially increase others or introduce new environmental challenges. For instance, some additives used to enhance fuel performance may have their own environmental impacts during production or disposal. Comprehensive life cycle assessments are crucial to fully understand the net environmental impact of these optimized fuels.

In conclusion, the environmental impact of optimized LS engine fuels is largely positive, offering potential reductions in various pollutants and improved overall efficiency. However, ongoing research and careful consideration of all environmental aspects are necessary to ensure that the benefits outweigh any potential drawbacks.

Economic Implications of Computational Fuel Optimization

The economic implications of computational fuel optimization for LS engines are far-reaching and multifaceted. This advanced approach to fuel composition design has the potential to significantly impact various sectors of the economy, from automotive manufacturing to energy production and distribution.

One of the primary economic benefits lies in the potential for increased fuel efficiency. By optimizing fuel compositions through computational methods, engine performance can be enhanced, leading to reduced fuel consumption. This translates directly into cost savings for consumers and businesses that rely heavily on transportation. Fleet operators, logistics companies, and individual vehicle owners could see substantial reductions in their fuel expenditures over time.

The automotive industry stands to gain considerably from these advancements. Manufacturers that can offer vehicles with superior fuel economy due to optimized fuel compositions may gain a competitive edge in the market. This could drive innovation and investment in research and development, potentially creating new job opportunities in the fields of computational chemistry and automotive engineering.

The energy sector is also likely to experience significant shifts. As fuel compositions become more efficient, the demand patterns for various types of fuel may change. Refineries and fuel producers may need to adapt their processes and product offerings to meet the new specifications determined by computational optimization. This could lead to investments in new refining technologies and potential restructuring within the industry.

Environmental regulations and policies play a crucial role in shaping the economic landscape of fuel optimization. As governments worldwide impose stricter emissions standards, the ability to computationally optimize fuel compositions to reduce emissions becomes increasingly valuable. Companies that can provide solutions that meet or exceed these standards may find new market opportunities and potential government incentives.

The technology sector may see growth in demand for high-performance computing resources and specialized software for fuel optimization simulations. This could spur advancements in computational capabilities and create new niches in the software industry focused on fuel and engine optimization tools.

However, the transition to computationally optimized fuels may also present economic challenges. There could be initial costs associated with adapting existing engines to work optimally with new fuel compositions. Additionally, the infrastructure for fuel distribution may require updates to handle and dispense these specialized fuel blends effectively.

In conclusion, the economic implications of computational fuel optimization for LS engines are likely to be transformative, affecting multiple industries and potentially reshaping aspects of the global economy related to transportation and energy use. While challenges exist, the potential for increased efficiency, reduced emissions, and new technological advancements presents significant opportunities for economic growth and innovation.

One of the primary economic benefits lies in the potential for increased fuel efficiency. By optimizing fuel compositions through computational methods, engine performance can be enhanced, leading to reduced fuel consumption. This translates directly into cost savings for consumers and businesses that rely heavily on transportation. Fleet operators, logistics companies, and individual vehicle owners could see substantial reductions in their fuel expenditures over time.

The automotive industry stands to gain considerably from these advancements. Manufacturers that can offer vehicles with superior fuel economy due to optimized fuel compositions may gain a competitive edge in the market. This could drive innovation and investment in research and development, potentially creating new job opportunities in the fields of computational chemistry and automotive engineering.

The energy sector is also likely to experience significant shifts. As fuel compositions become more efficient, the demand patterns for various types of fuel may change. Refineries and fuel producers may need to adapt their processes and product offerings to meet the new specifications determined by computational optimization. This could lead to investments in new refining technologies and potential restructuring within the industry.

Environmental regulations and policies play a crucial role in shaping the economic landscape of fuel optimization. As governments worldwide impose stricter emissions standards, the ability to computationally optimize fuel compositions to reduce emissions becomes increasingly valuable. Companies that can provide solutions that meet or exceed these standards may find new market opportunities and potential government incentives.

The technology sector may see growth in demand for high-performance computing resources and specialized software for fuel optimization simulations. This could spur advancements in computational capabilities and create new niches in the software industry focused on fuel and engine optimization tools.

However, the transition to computationally optimized fuels may also present economic challenges. There could be initial costs associated with adapting existing engines to work optimally with new fuel compositions. Additionally, the infrastructure for fuel distribution may require updates to handle and dispense these specialized fuel blends effectively.

In conclusion, the economic implications of computational fuel optimization for LS engines are likely to be transformative, affecting multiple industries and potentially reshaping aspects of the global economy related to transportation and energy use. While challenges exist, the potential for increased efficiency, reduced emissions, and new technological advancements presents significant opportunities for economic growth and innovation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!