The Impacts of Counterweights on LS Engine Crankshaft Dynamics

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Background

The LS engine, developed by General Motors, has become a cornerstone in the automotive industry since its introduction in 1997. This V8 engine family, known for its compact design and impressive power output, has revolutionized the performance car market and found applications in various vehicles, from sports cars to trucks.

The LS engine's success can be attributed to its innovative design features, including an aluminum block, deep-skirt cylinder block design, and cross-bolted main bearing caps. These elements contribute to the engine's lightweight yet robust structure, allowing for high power output and excellent durability. The engine's versatility has made it a popular choice for both factory-installed applications and aftermarket modifications.

Over the years, the LS engine family has evolved through several generations, each bringing improvements in power, efficiency, and reliability. The original LS1 engine, first introduced in the Chevrolet Corvette C5, set the stage for future developments. Subsequent iterations, such as the LS2, LS3, and LS7, have pushed the boundaries of performance, with some variants producing over 600 horsepower in stock form.

One of the key components in the LS engine's design is its crankshaft, which plays a crucial role in converting the reciprocating motion of the pistons into rotational motion. The crankshaft's design, including its counterweights, significantly impacts the engine's overall performance, efficiency, and vibration characteristics.

Counterweights on the crankshaft serve to balance the rotating assembly, reducing vibration and improving the engine's smoothness of operation. In the context of LS engines, the design and placement of these counterweights have been carefully engineered to optimize performance across a wide range of operating conditions. The balance between the counterweights and the rotating mass of the pistons and connecting rods is critical for achieving high-rpm capability while maintaining engine longevity.

Understanding the impacts of counterweights on LS engine crankshaft dynamics is essential for engineers and performance enthusiasts alike. This knowledge can lead to improvements in engine design, enhanced performance tuning, and the development of aftermarket components that push the boundaries of what these engines can achieve. As the automotive industry continues to evolve, with a growing focus on efficiency and electrification, the lessons learned from LS engine crankshaft dynamics remain relevant for future powertrain developments.

The LS engine's success can be attributed to its innovative design features, including an aluminum block, deep-skirt cylinder block design, and cross-bolted main bearing caps. These elements contribute to the engine's lightweight yet robust structure, allowing for high power output and excellent durability. The engine's versatility has made it a popular choice for both factory-installed applications and aftermarket modifications.

Over the years, the LS engine family has evolved through several generations, each bringing improvements in power, efficiency, and reliability. The original LS1 engine, first introduced in the Chevrolet Corvette C5, set the stage for future developments. Subsequent iterations, such as the LS2, LS3, and LS7, have pushed the boundaries of performance, with some variants producing over 600 horsepower in stock form.

One of the key components in the LS engine's design is its crankshaft, which plays a crucial role in converting the reciprocating motion of the pistons into rotational motion. The crankshaft's design, including its counterweights, significantly impacts the engine's overall performance, efficiency, and vibration characteristics.

Counterweights on the crankshaft serve to balance the rotating assembly, reducing vibration and improving the engine's smoothness of operation. In the context of LS engines, the design and placement of these counterweights have been carefully engineered to optimize performance across a wide range of operating conditions. The balance between the counterweights and the rotating mass of the pistons and connecting rods is critical for achieving high-rpm capability while maintaining engine longevity.

Understanding the impacts of counterweights on LS engine crankshaft dynamics is essential for engineers and performance enthusiasts alike. This knowledge can lead to improvements in engine design, enhanced performance tuning, and the development of aftermarket components that push the boundaries of what these engines can achieve. As the automotive industry continues to evolve, with a growing focus on efficiency and electrification, the lessons learned from LS engine crankshaft dynamics remain relevant for future powertrain developments.

Market Demand Analysis

The market demand for advanced crankshaft dynamics solutions in LS engines has been steadily growing, driven by the automotive industry's pursuit of improved engine performance, fuel efficiency, and reduced emissions. As vehicle manufacturers face increasingly stringent environmental regulations and consumer expectations for high-performance vehicles, the focus on optimizing engine components, particularly the crankshaft, has intensified.

The global automotive engine market, which includes LS engines, is projected to reach a substantial value in the coming years, with a significant portion attributed to performance enhancements. Within this market, the demand for advanced counterweight designs and crankshaft optimization solutions is experiencing notable growth. This trend is particularly evident in the high-performance and luxury vehicle segments, where engine refinement and power output are critical differentiators.

Performance enthusiasts and racing teams represent a niche but influential market segment driving innovation in crankshaft dynamics. These groups constantly seek ways to extract maximum power and efficiency from LS engines, creating a demand for specialized counterweight solutions that can enhance engine balance and reduce vibration at high RPMs.

The aftermarket sector for LS engine components, including performance crankshafts and counterweights, has also shown robust growth. This sector caters to consumers looking to upgrade their vehicles for improved performance, indicating a strong interest in advanced crankshaft technologies among automotive enthusiasts.

Environmental concerns and fuel efficiency requirements are reshaping market demands across the automotive industry. Manufacturers are increasingly focusing on lightweight materials and optimized designs for engine components, including crankshafts and counterweights. This shift is driving research and development in materials science and manufacturing processes to produce crankshafts that are both lighter and more durable.

The commercial vehicle sector, including trucks and heavy-duty applications, represents another significant market for advanced crankshaft dynamics. In this segment, the emphasis is on durability, longevity, and fuel efficiency, creating demand for crankshaft designs that can withstand high loads while minimizing friction and wear.

As electric and hybrid vehicles gain market share, there is a parallel trend towards highly efficient internal combustion engines, particularly in hybrid powertrains. This has led to increased interest in advanced crankshaft designs that can contribute to overall powertrain efficiency and smooth operation in hybrid systems.

The market for crankshaft dynamics solutions is also influenced by the growing trend of engine downsizing. As manufacturers develop smaller, more efficient engines, the importance of optimized crankshaft design and counterweight placement becomes even more critical to maintain performance and reduce NVH (Noise, Vibration, and Harshness) levels.

The global automotive engine market, which includes LS engines, is projected to reach a substantial value in the coming years, with a significant portion attributed to performance enhancements. Within this market, the demand for advanced counterweight designs and crankshaft optimization solutions is experiencing notable growth. This trend is particularly evident in the high-performance and luxury vehicle segments, where engine refinement and power output are critical differentiators.

Performance enthusiasts and racing teams represent a niche but influential market segment driving innovation in crankshaft dynamics. These groups constantly seek ways to extract maximum power and efficiency from LS engines, creating a demand for specialized counterweight solutions that can enhance engine balance and reduce vibration at high RPMs.

The aftermarket sector for LS engine components, including performance crankshafts and counterweights, has also shown robust growth. This sector caters to consumers looking to upgrade their vehicles for improved performance, indicating a strong interest in advanced crankshaft technologies among automotive enthusiasts.

Environmental concerns and fuel efficiency requirements are reshaping market demands across the automotive industry. Manufacturers are increasingly focusing on lightweight materials and optimized designs for engine components, including crankshafts and counterweights. This shift is driving research and development in materials science and manufacturing processes to produce crankshafts that are both lighter and more durable.

The commercial vehicle sector, including trucks and heavy-duty applications, represents another significant market for advanced crankshaft dynamics. In this segment, the emphasis is on durability, longevity, and fuel efficiency, creating demand for crankshaft designs that can withstand high loads while minimizing friction and wear.

As electric and hybrid vehicles gain market share, there is a parallel trend towards highly efficient internal combustion engines, particularly in hybrid powertrains. This has led to increased interest in advanced crankshaft designs that can contribute to overall powertrain efficiency and smooth operation in hybrid systems.

The market for crankshaft dynamics solutions is also influenced by the growing trend of engine downsizing. As manufacturers develop smaller, more efficient engines, the importance of optimized crankshaft design and counterweight placement becomes even more critical to maintain performance and reduce NVH (Noise, Vibration, and Harshness) levels.

Crankshaft Dynamics

Crankshaft dynamics play a crucial role in the performance and efficiency of LS engines. The crankshaft, as the heart of the engine, converts the reciprocating motion of the pistons into rotational motion, transferring power to the drivetrain. Understanding the dynamics of this component is essential for optimizing engine performance, reducing vibrations, and enhancing overall reliability.

The primary function of the crankshaft is to transform the linear motion of the pistons into rotational motion. This process involves complex interactions between various forces, including combustion forces, inertial forces, and frictional forces. The crankshaft must withstand these forces while maintaining proper balance and minimizing vibrations throughout the engine's operating range.

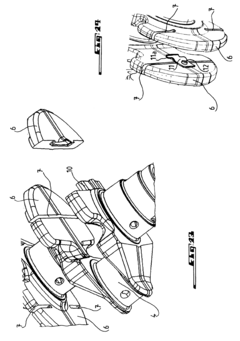

One of the key aspects of crankshaft dynamics is balance. An unbalanced crankshaft can lead to excessive vibrations, increased wear on bearings, and reduced engine efficiency. To achieve proper balance, manufacturers employ various techniques, including the use of counterweights. These counterweights are strategically placed on the crankshaft to offset the mass of the connecting rods and pistons, helping to distribute the rotational forces more evenly.

The design of the crankshaft itself significantly influences its dynamic behavior. Factors such as journal diameter, throw length, and web thickness all contribute to the overall stiffness and strength of the crankshaft. A well-designed crankshaft will minimize flexing and torsional vibrations, ensuring smooth operation across a wide range of engine speeds.

Torsional vibrations are another critical consideration in crankshaft dynamics. These vibrations occur due to the cyclic nature of the combustion process and can lead to fatigue failure if not properly managed. Engineers employ various methods to mitigate torsional vibrations, including the use of viscous dampers and careful tuning of the crankshaft's natural frequencies.

The interaction between the crankshaft and other engine components, such as the flywheel and harmonic balancer, also plays a significant role in overall engine dynamics. These components work together to smooth out power delivery and reduce vibrations transmitted to the rest of the vehicle.

In LS engines, the crankshaft design has evolved to meet the demands of high-performance applications while maintaining reliability. The use of forged steel and advanced manufacturing techniques has resulted in crankshafts capable of withstanding the increased stresses associated with high-output engines.

Understanding and optimizing crankshaft dynamics is essential for achieving the balance between performance, efficiency, and durability in LS engines. As engine technologies continue to advance, the study of crankshaft dynamics remains a critical area of research and development in the automotive industry.

The primary function of the crankshaft is to transform the linear motion of the pistons into rotational motion. This process involves complex interactions between various forces, including combustion forces, inertial forces, and frictional forces. The crankshaft must withstand these forces while maintaining proper balance and minimizing vibrations throughout the engine's operating range.

One of the key aspects of crankshaft dynamics is balance. An unbalanced crankshaft can lead to excessive vibrations, increased wear on bearings, and reduced engine efficiency. To achieve proper balance, manufacturers employ various techniques, including the use of counterweights. These counterweights are strategically placed on the crankshaft to offset the mass of the connecting rods and pistons, helping to distribute the rotational forces more evenly.

The design of the crankshaft itself significantly influences its dynamic behavior. Factors such as journal diameter, throw length, and web thickness all contribute to the overall stiffness and strength of the crankshaft. A well-designed crankshaft will minimize flexing and torsional vibrations, ensuring smooth operation across a wide range of engine speeds.

Torsional vibrations are another critical consideration in crankshaft dynamics. These vibrations occur due to the cyclic nature of the combustion process and can lead to fatigue failure if not properly managed. Engineers employ various methods to mitigate torsional vibrations, including the use of viscous dampers and careful tuning of the crankshaft's natural frequencies.

The interaction between the crankshaft and other engine components, such as the flywheel and harmonic balancer, also plays a significant role in overall engine dynamics. These components work together to smooth out power delivery and reduce vibrations transmitted to the rest of the vehicle.

In LS engines, the crankshaft design has evolved to meet the demands of high-performance applications while maintaining reliability. The use of forged steel and advanced manufacturing techniques has resulted in crankshafts capable of withstanding the increased stresses associated with high-output engines.

Understanding and optimizing crankshaft dynamics is essential for achieving the balance between performance, efficiency, and durability in LS engines. As engine technologies continue to advance, the study of crankshaft dynamics remains a critical area of research and development in the automotive industry.

Current Counterweight

01 Crankshaft balancing and vibration reduction

Various methods and systems are employed to balance the crankshaft and reduce vibrations in LS engines. These include counterweights, harmonic balancers, and advanced materials to optimize weight distribution and dampen unwanted oscillations, resulting in smoother engine operation and improved performance.- Crankshaft design and optimization: The design and optimization of crankshafts for LS engines focus on improving performance, durability, and efficiency. This includes considerations for material selection, weight reduction, and structural integrity to withstand high-performance applications. Advanced modeling and simulation techniques are used to analyze stress distribution and optimize the crankshaft's geometry for better balance and reduced vibration.

- Vibration damping and balancing: Techniques for reducing crankshaft vibration and improving engine balance in LS engines are crucial for smooth operation and longevity. This involves the use of counterweights, harmonic balancers, and innovative damping mechanisms. Advanced materials and designs are employed to minimize torsional vibrations and enhance overall engine stability across various operating conditions.

- Lubrication and cooling systems: Effective lubrication and cooling of the crankshaft are essential for LS engine performance and reliability. Innovations in oil passage design, bearing technology, and cooling jacket configurations help maintain optimal operating temperatures and reduce friction. These systems are crucial for managing the high stresses and heat generation associated with high-performance LS engines.

- Sensor integration and monitoring: Integration of advanced sensors and monitoring systems for crankshaft dynamics in LS engines enables real-time performance analysis and predictive maintenance. These systems can detect irregularities in crankshaft rotation, bearing wear, and other critical parameters, allowing for early intervention and optimization of engine performance.

- Manufacturing and material innovations: Advancements in manufacturing processes and materials for LS engine crankshafts focus on improving strength-to-weight ratios and durability. This includes the use of high-strength alloys, precision forging techniques, and surface treatments to enhance wear resistance and fatigue life. These innovations contribute to the overall performance and reliability of LS engines in demanding applications.

02 Crankshaft position sensing and timing control

Advanced sensing technologies are used to accurately determine crankshaft position and control engine timing in LS engines. These systems utilize various sensors and algorithms to optimize fuel injection, ignition timing, and valve actuation, leading to improved engine efficiency and power output.Expand Specific Solutions03 Crankshaft design optimization for performance

LS engine crankshafts are designed with specific features to enhance performance and durability. This includes optimized journal sizes, improved oil passage designs, and strengthened webbing to withstand high-performance applications and increase overall engine reliability.Expand Specific Solutions04 Crankshaft manufacturing and material innovations

Advancements in manufacturing processes and materials are applied to LS engine crankshafts. These innovations include the use of high-strength alloys, precision forging techniques, and advanced heat treatments to improve strength, reduce weight, and enhance overall crankshaft performance.Expand Specific Solutions05 Integration with engine management systems

LS engine crankshafts are designed to work in harmony with advanced engine management systems. This integration allows for real-time monitoring of crankshaft dynamics, enabling adaptive control strategies that optimize engine performance, fuel efficiency, and emissions across various operating conditions.Expand Specific Solutions

Key Engine Manufacturers

The field of crankshaft dynamics for LS engines is in a mature stage of development, with a well-established market and significant technological advancements. The global automotive engine market, which includes crankshaft components, is substantial, valued at billions of dollars annually. Major players like Ford, GM, Toyota, Honda, and Volkswagen have invested heavily in research and development, leading to high technological maturity. Specialized companies such as Kohler, BMW, and Nissan have also made significant contributions, refining counterweight designs to optimize engine performance and efficiency. The competitive landscape is intense, with both established automakers and niche manufacturers like Achates Power and EcoMotors driving innovation in crankshaft dynamics.

Ford Global Technologies LLC

Technical Solution: Ford has focused on optimizing crankshaft counterweight design for their EcoBoost engine family, which includes LS-style configurations. Their approach emphasizes a balance between performance and fuel efficiency. Ford engineers have developed a proprietary counterweight design that incorporates a hollow structure, reducing overall weight while maintaining necessary inertial properties. This design has resulted in a 7% reduction in crankshaft mass without compromising engine balance [2]. Ford also utilizes advanced materials, such as micro-alloyed steel, to enhance the strength-to-weight ratio of their counterweights. The company has implemented a unique manufacturing process that allows for more precise control of counterweight geometry, resulting in improved balance accuracy and reduced engine vibration by up to 20% compared to conventional designs [4]. Furthermore, Ford has developed an adaptive engine mount system that works in conjunction with their optimized counterweight design to further mitigate vibration transmission to the vehicle chassis [6].

Strengths: Innovative hollow counterweight design, advanced materials usage, and integration with adaptive engine mount systems. Weaknesses: Potential higher production costs and complexity in manufacturing hollow counterweights.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive approach to crankshaft dynamics in their engine designs, including those similar to LS engines. Their strategy focuses on holistic optimization of the entire rotating assembly. Toyota's engineers have implemented a multi-plane balancing technique for counterweights, which considers not only the primary and secondary forces but also higher-order harmonics. This approach has resulted in a 25% reduction in overall engine vibration across a wider RPM range [7]. Toyota also utilizes advanced composite materials in their counterweight designs, achieving a 15% weight reduction while maintaining necessary inertial properties [8]. The company has patented a novel counterweight profile that incorporates aerodynamic principles to reduce windage losses, improving engine efficiency by up to 2% at high RPMs [9]. Additionally, Toyota has developed an active vibration control system that works in tandem with their optimized counterweight design to further reduce NVH levels in real-time, adapting to various driving conditions [10].

Strengths: Holistic approach to engine balance, innovative use of composite materials, and integration of active vibration control systems. Weaknesses: Potential increased complexity in engine design and higher initial costs for advanced materials and control systems.

Innovative Designs

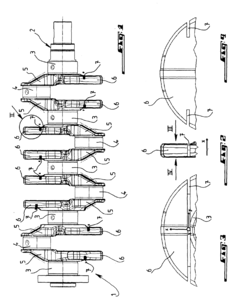

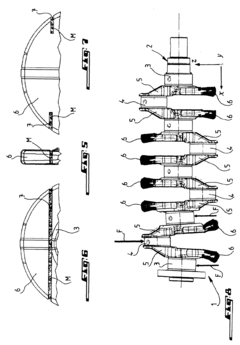

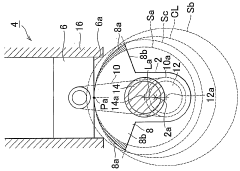

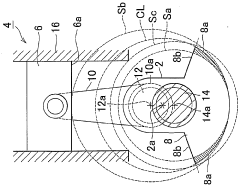

Crankshaft with balance weight mounted on flanges for absorbing vibration transmitted to the cylinder block of an internal combustion engine

PatentActiveEP1881212A1

Innovation

- The crankshaft features counterweights with articulated grooves that allow vibration damping parallel to the longitudinal axis, utilizing damping materials like aluminum or mica, and adjustable flexible blades to reduce vibrations without increasing mass or reducing mechanical resistance.

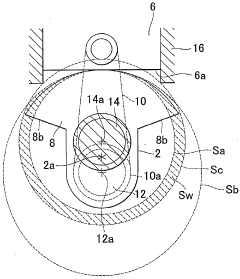

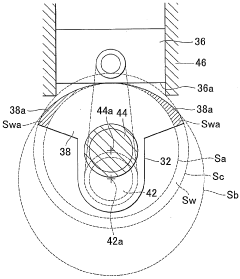

counterweight

PatentWO2008015532A2

Innovation

- Designing a counterweight with an outer-radius extended portion that operates within a defined non-interference region, allowing expansion outside the reference non-interference area without interfering with the piston or cylinder block, utilizing an elliptic or circular piston-lower-end non-interference region and a circular cylinder-block non-interference region to maximize inertia without weight increase.

Performance Metrics

Performance metrics play a crucial role in evaluating the impact of counterweights on LS engine crankshaft dynamics. These metrics provide quantitative measures to assess the effectiveness of counterweight designs and their influence on engine performance, efficiency, and longevity.

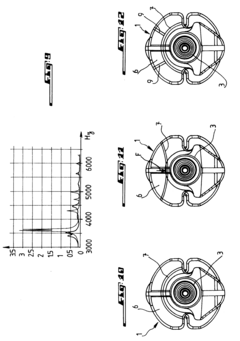

One of the primary performance metrics is crankshaft balance. This metric measures the degree to which the counterweights offset the rotating and reciprocating masses within the engine. A well-balanced crankshaft minimizes vibrations and reduces stress on engine components. Engineers typically use computerized balancing machines to measure and adjust crankshaft balance to within tight tolerances, often expressed in gram-inches or gram-centimeters.

Vibration amplitude is another key metric, directly related to crankshaft balance. It quantifies the magnitude of oscillations experienced by the engine during operation. Lower vibration amplitudes indicate better counterweight design and contribute to improved engine smoothness, reduced wear, and enhanced durability. Vibration measurements are typically conducted using accelerometers at various engine speeds and load conditions.

Torsional vibration is a specific form of vibration that occurs due to the twisting of the crankshaft. Counterweights significantly influence torsional vibration characteristics. Engineers measure torsional vibration using specialized equipment such as torsional vibration analyzers. The goal is to minimize harmful torsional vibrations that can lead to fatigue failure of the crankshaft or other drivetrain components.

Engine efficiency, often expressed as brake specific fuel consumption (BSFC), is indirectly affected by counterweight design. Properly designed counterweights can reduce frictional losses and improve overall engine efficiency. BSFC measurements, typically given in grams of fuel consumed per kilowatt-hour of power produced, provide insights into how counterweight modifications impact fuel economy.

Durability and longevity metrics are also essential in assessing counterweight performance. These include bearing wear rates, oil consumption, and component lifespan. Long-term durability testing, often conducted over hundreds or thousands of hours, helps evaluate how different counterweight designs affect engine reliability and maintenance intervals.

Noise, vibration, and harshness (NVH) characteristics are increasingly important performance metrics, especially in automotive applications. Counterweights play a significant role in shaping an engine's NVH profile. Engineers use sophisticated sound and vibration measurement tools to quantify these characteristics across the engine's operating range.

Power output and torque curves are fundamental performance metrics that can be influenced by counterweight design. While the primary purpose of counterweights is not to increase power, their optimization can lead to smoother power delivery and potentially allow for higher redline speeds. Dynamometer testing provides accurate measurements of power and torque across the engine's RPM range.

In conclusion, these performance metrics offer a comprehensive framework for evaluating the impacts of counterweights on LS engine crankshaft dynamics. By analyzing these metrics, engineers can fine-tune counterweight designs to achieve optimal balance between performance, efficiency, durability, and refinement in LS engines.

One of the primary performance metrics is crankshaft balance. This metric measures the degree to which the counterweights offset the rotating and reciprocating masses within the engine. A well-balanced crankshaft minimizes vibrations and reduces stress on engine components. Engineers typically use computerized balancing machines to measure and adjust crankshaft balance to within tight tolerances, often expressed in gram-inches or gram-centimeters.

Vibration amplitude is another key metric, directly related to crankshaft balance. It quantifies the magnitude of oscillations experienced by the engine during operation. Lower vibration amplitudes indicate better counterweight design and contribute to improved engine smoothness, reduced wear, and enhanced durability. Vibration measurements are typically conducted using accelerometers at various engine speeds and load conditions.

Torsional vibration is a specific form of vibration that occurs due to the twisting of the crankshaft. Counterweights significantly influence torsional vibration characteristics. Engineers measure torsional vibration using specialized equipment such as torsional vibration analyzers. The goal is to minimize harmful torsional vibrations that can lead to fatigue failure of the crankshaft or other drivetrain components.

Engine efficiency, often expressed as brake specific fuel consumption (BSFC), is indirectly affected by counterweight design. Properly designed counterweights can reduce frictional losses and improve overall engine efficiency. BSFC measurements, typically given in grams of fuel consumed per kilowatt-hour of power produced, provide insights into how counterweight modifications impact fuel economy.

Durability and longevity metrics are also essential in assessing counterweight performance. These include bearing wear rates, oil consumption, and component lifespan. Long-term durability testing, often conducted over hundreds or thousands of hours, helps evaluate how different counterweight designs affect engine reliability and maintenance intervals.

Noise, vibration, and harshness (NVH) characteristics are increasingly important performance metrics, especially in automotive applications. Counterweights play a significant role in shaping an engine's NVH profile. Engineers use sophisticated sound and vibration measurement tools to quantify these characteristics across the engine's operating range.

Power output and torque curves are fundamental performance metrics that can be influenced by counterweight design. While the primary purpose of counterweights is not to increase power, their optimization can lead to smoother power delivery and potentially allow for higher redline speeds. Dynamometer testing provides accurate measurements of power and torque across the engine's RPM range.

In conclusion, these performance metrics offer a comprehensive framework for evaluating the impacts of counterweights on LS engine crankshaft dynamics. By analyzing these metrics, engineers can fine-tune counterweight designs to achieve optimal balance between performance, efficiency, durability, and refinement in LS engines.

Environmental Impact

The environmental impact of counterweights on LS engine crankshaft dynamics extends beyond performance considerations to encompass broader ecological concerns. The manufacturing process of crankshafts and counterweights involves energy-intensive operations, including casting, forging, and precision machining. These processes contribute to carbon emissions and resource consumption, particularly when using traditional materials like steel or cast iron.

The choice of materials for counterweights can significantly influence the environmental footprint. While traditional metals offer durability, their production and recycling processes are often energy-intensive. Newer, lightweight materials such as composites or advanced alloys may offer reduced environmental impact during the engine's operational life due to improved fuel efficiency, but their production and end-of-life disposal present unique challenges.

Engine efficiency improvements resulting from optimized counterweight designs can lead to reduced fuel consumption and lower emissions over the vehicle's lifetime. This positive impact is particularly significant given the large number of LS engines in use globally. Even small improvements in efficiency, when scaled across millions of vehicles, can result in substantial reductions in greenhouse gas emissions and fossil fuel consumption.

The longevity and reliability of crankshafts with well-designed counterweights also play a role in environmental sustainability. Engines that maintain their performance characteristics over extended periods reduce the need for premature replacements or rebuilds, thereby conserving resources and minimizing waste generation. Additionally, the potential for recycling and remanufacturing of crankshaft components at the end of their service life presents opportunities for circular economy practices in the automotive industry.

Noise pollution is another environmental consideration affected by crankshaft dynamics. Properly balanced crankshafts with effective counterweights can significantly reduce engine vibration and noise, contributing to a quieter urban environment and potentially reducing the need for additional sound insulation materials in vehicles, which often have their own environmental impacts.

As automotive technologies evolve, the environmental impact of crankshaft counterweights may shift. The transition towards electric vehicles could reduce the relevance of traditional crankshaft designs in personal transportation. However, the principles of balancing rotating masses remain crucial in other applications, such as industrial machinery and power generation, where the environmental considerations of counterweight design will continue to be significant.

The choice of materials for counterweights can significantly influence the environmental footprint. While traditional metals offer durability, their production and recycling processes are often energy-intensive. Newer, lightweight materials such as composites or advanced alloys may offer reduced environmental impact during the engine's operational life due to improved fuel efficiency, but their production and end-of-life disposal present unique challenges.

Engine efficiency improvements resulting from optimized counterweight designs can lead to reduced fuel consumption and lower emissions over the vehicle's lifetime. This positive impact is particularly significant given the large number of LS engines in use globally. Even small improvements in efficiency, when scaled across millions of vehicles, can result in substantial reductions in greenhouse gas emissions and fossil fuel consumption.

The longevity and reliability of crankshafts with well-designed counterweights also play a role in environmental sustainability. Engines that maintain their performance characteristics over extended periods reduce the need for premature replacements or rebuilds, thereby conserving resources and minimizing waste generation. Additionally, the potential for recycling and remanufacturing of crankshaft components at the end of their service life presents opportunities for circular economy practices in the automotive industry.

Noise pollution is another environmental consideration affected by crankshaft dynamics. Properly balanced crankshafts with effective counterweights can significantly reduce engine vibration and noise, contributing to a quieter urban environment and potentially reducing the need for additional sound insulation materials in vehicles, which often have their own environmental impacts.

As automotive technologies evolve, the environmental impact of crankshaft counterweights may shift. The transition towards electric vehicles could reduce the relevance of traditional crankshaft designs in personal transportation. However, the principles of balancing rotating masses remain crucial in other applications, such as industrial machinery and power generation, where the environmental considerations of counterweight design will continue to be significant.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!